Irrigation-fed filter

A filter, water conservancy technology, applied in the direction of filtration separation, filtration loop, chemical instruments and methods, etc., can solve the problems of poor filtration effect, affecting the speed and quality of filtration, and unfavorable use by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

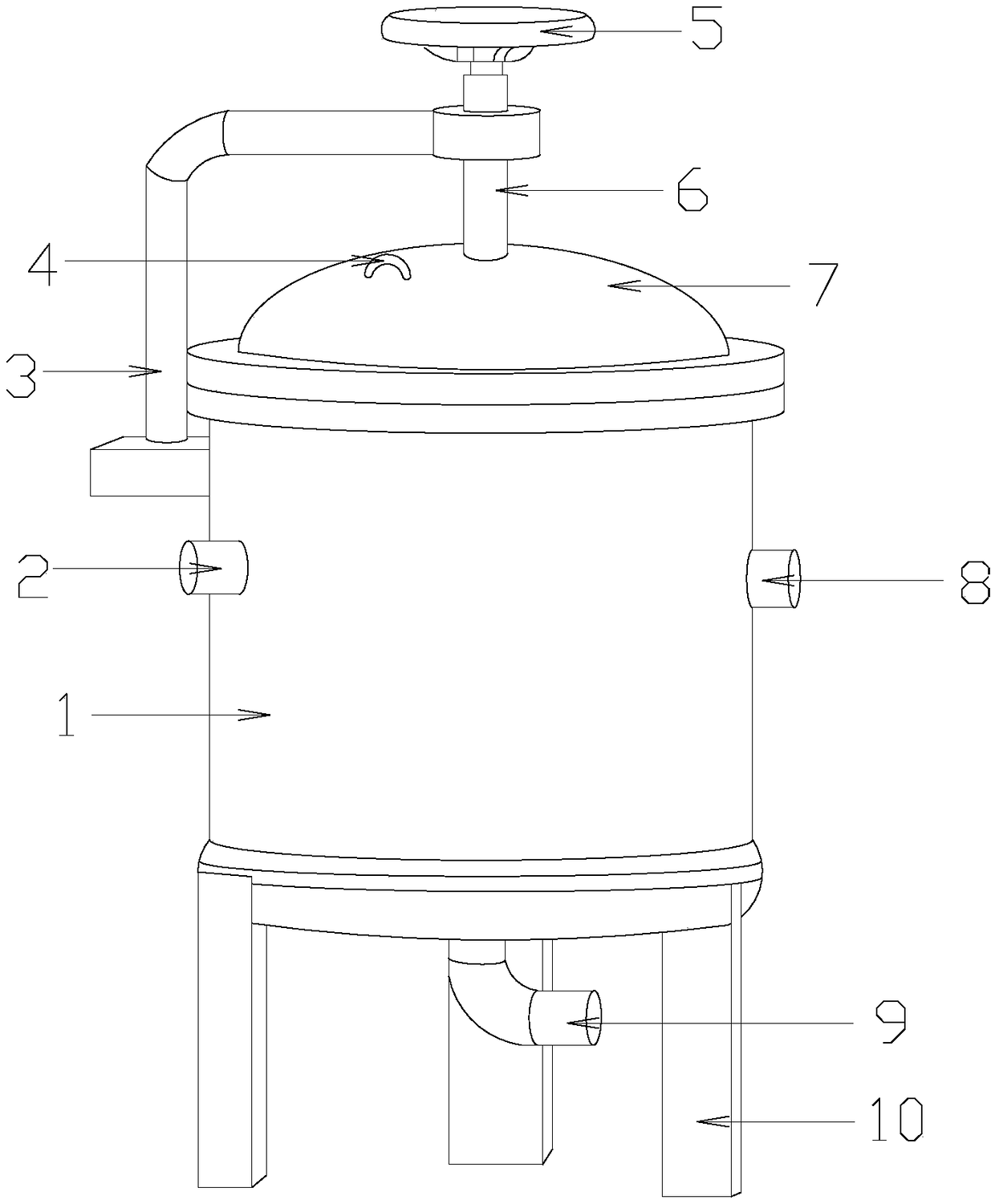

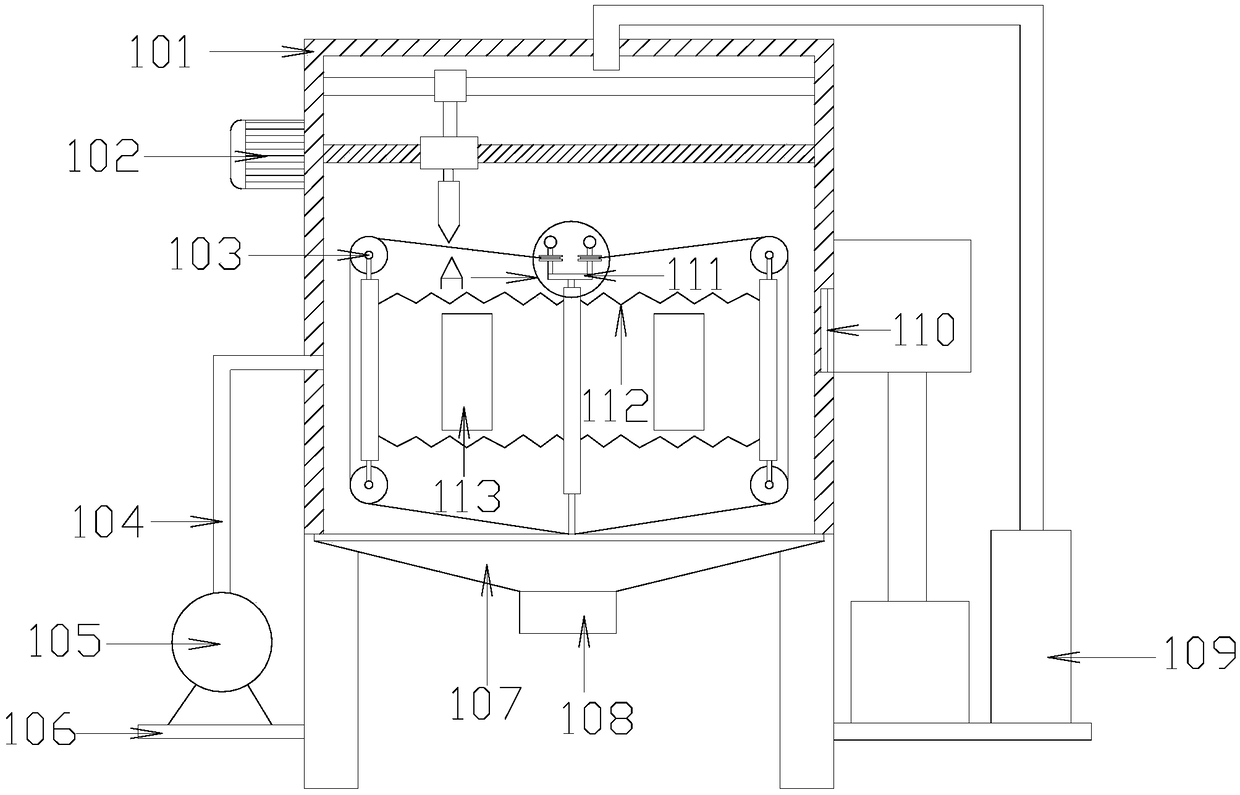

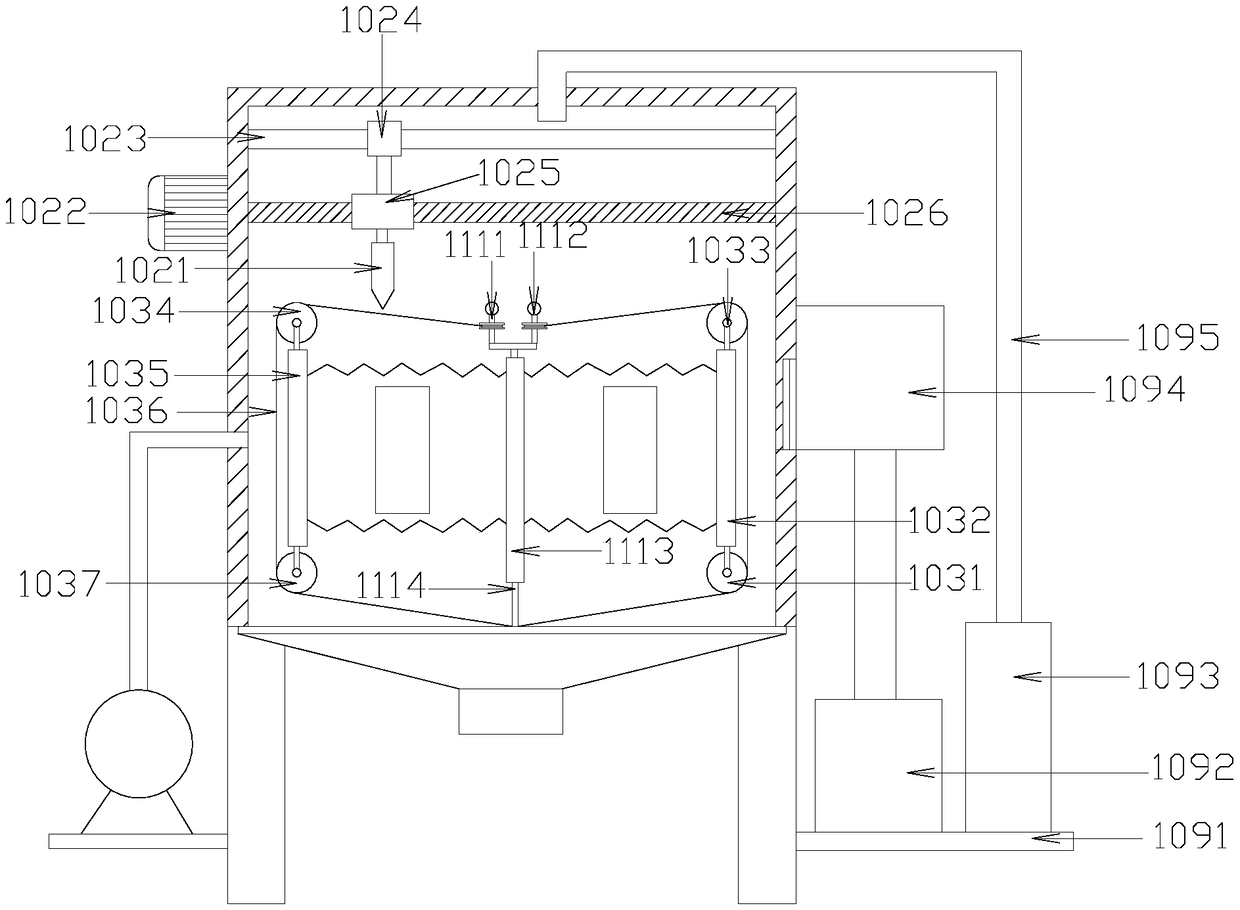

[0022] Such as Figure 1-Figure 5As shown, the present invention provides a water conservancy irrigation filter, the structure of which includes an automatic high-efficiency filter mechanism 1, an air intake channel 2, a rotating arm 3, a handle 4, a hand wheel 5, a lifting rod 6, a cover 7, an air outlet channel 8, Sewage channel 9, support frame 10, described support frame 10 is provided with more than two and is welded on the bottom surface of automatic high-efficiency filter mechanism 1 respectively, and the upper end of described sewage channel 9 is fixedly welded on the bottom end of automatic high-efficiency filter mechanism 1 and both inside The air inlet channel 2 and the air outlet channel 8 are in the same size, and the air inlet channel 2 and the air outlet channel 8 are respectively welded to the left and right ends of the automatic high-efficiency filter mechanism 1 and they are connected inside. The bottom of the cover 7 is fixedly welded to the top of the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com