Graded screening device for sand and gravel on construction site

A technology for grading screening and construction sites, applied in the fields of sieving, solid separation, separation methods, etc., can solve the problems of reducing screening efficiency, not easy to remove it, and lung harm, etc., to improve screening efficiency, reduce labor intensity, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

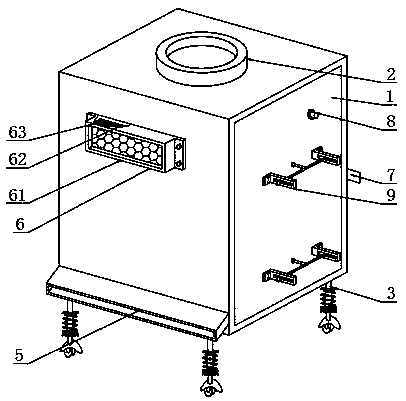

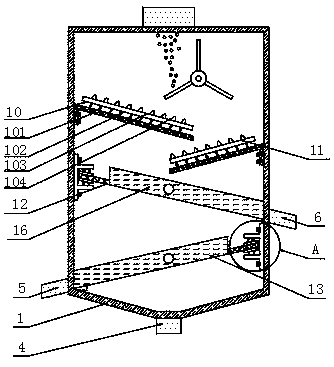

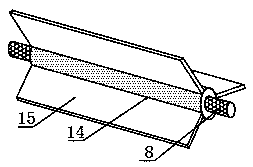

[0022] see Figure 1~6 , in an embodiment of the present invention, a gravel grading and screening device on a construction site, comprising a screening box 1, a feed port 2, a support leg 3, a No. 1 discharge port 4, a No. 2 discharge port 5, an adsorption mechanism 6, Air outlet 61, Class I dust filter 62, Class II dust filter 63, No. III outlet 7, rotating rod 8, pulling mechanism 9, support rod 91, handle rod 92, fixed frame 93, chute 94, telescopic sleeve Pipe 95, return spring 96, first evacuation mechanism 10, fixed plate 101, spring 102, movable plate 103, protrusion 104, second evacuation mechanism 11, first screen 12, second screen 13, sleeve 14, Movable leaf 15, baffle plate 16, fixed block 17, buffer spring 18 and buffer plate 19, the upper surface of screening box 1 is provided with feed inlet 2, and the middle of the lower surface of screening box 1 is provided with No. 1 discharge opening 4, and The four corners of the lower surface of the screening box 1 are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com