Novel rapid building block core filling device

A filling device and fast technology, applied in ceramic molding machines, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of lower production efficiency of composite thermal insulation blocks, unqualified block performance indicators, and increased production costs. The effect of continuous automated production, improving the quality of the working environment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

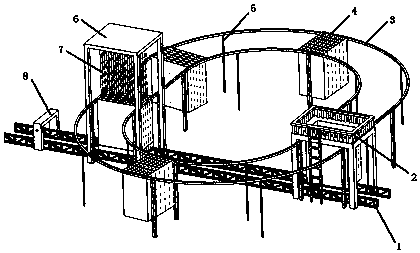

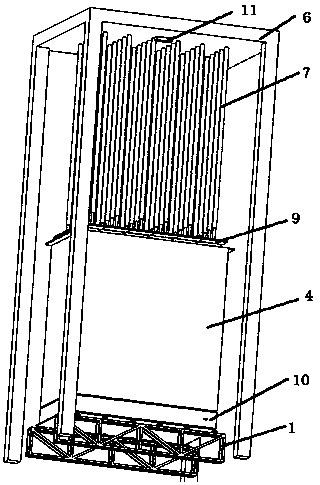

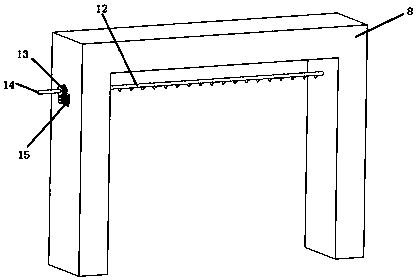

[0015] Refer to the attached figure 1 to attach Figure 5 A new type of fast filling device for block inner core of the present invention will be described in detail below.

[0016] A new type of fast filling device for the inner core of blocks, including a quick filling mechanism for the inner core combined with a hydraulic cylinder 7, an inner core pressing plate 9 and a frame 6, a photoelectric sensor 11 is installed on the upper side, a mold transport device 1 is installed on the lower side, and The core warehouse transport slide rail 3 has a high-pressure air-flow cleaning device 8 equipped with a high-pressure air-flow nozzle 12, a stepping motor 15 and a gear 13, and a manual loading station 2 at the rear.

[0017] The transportation device 1 drives the mold to move forward. When the mold reaches the filling position, the photoelectric sensor 11 is activated, and the hydraulic cylinder starts to work under the control of PLC. After the filling is completed, the transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com