Tunnel construction method with shield methodand new Austrian tunneling method being combined

A technology of tunnel construction and new Austrian method, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of high construction cost, high safety risk and low construction efficiency of new Austrian method by shield tunneling method, and improve the working environment Quality, rapid construction, and the effect of reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A tunnel construction method combining shield tunneling and new Austrian method, the steps are as follows:

[0026] Step S1, tunnel excavation. A non-explosive excavation of one excavation length of the tunnel to be excavated is carried out using a shield machine. According to the self-stability of the surrounding rock, the excavation method is divided into partial excavation and full-face excavation. When the self-stability of the surrounding rock is good, the open shield machine is used in combination with rock and soil excavation equipment to excavate the tunnel face in sections by using the step method. The excavation equipment includes an excavator and a cantilever roadheader. Under the protection of the shield shell of the open shield machine, when the surrounding rock is earthy, the excavator is used to excavate the face of the tunnel in sections; When the rock is rocky surrounding rock, the cantilever roadheader is used to excavate the tunnel fac...

Embodiment 2

[0038] Embodiment 2: The present invention will be further described in detail below by taking a double-track railway tunnel project in a typical loess stratum as an example.

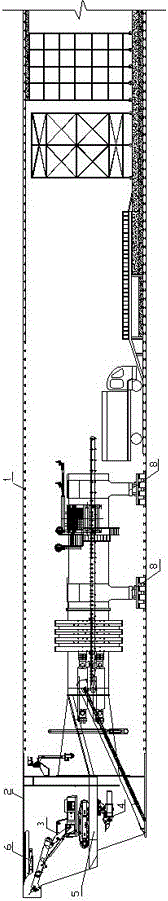

[0039] Such as figure 1As shown, the tunnel is in the loess layer without groundwater. The grade of the surrounding rock is mainly grade IV, and the section is horseshoe-shaped, with a width of 14.5m and a height of 12m (including the inverted arch). The whole ring of the tunnel adopts I22a steel arch frame, and the distance between arch frame 1 is 0.8m. The sprayed concrete is C25 concrete with a thickness of 30cm; the length of the side wall anchor rod is 3.0m, and the length of the lock foot anchor pipe is 4m. Each longitudinal connecting bar is 102cm long, and the circumferential spacing is 1m.

[0040] The steps of adopting this method construction are as follows:

[0041] Step S1, using the open shield machine to excavate the tunnel in sections with an excavation length by using the step metho...

Embodiment 3

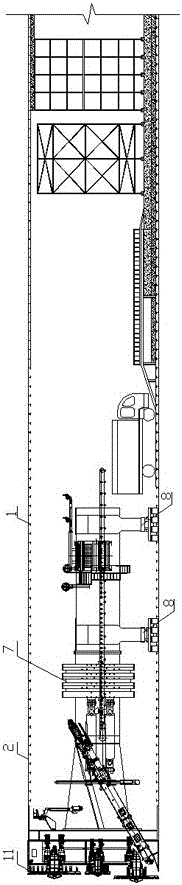

[0050] Embodiment 3: The present invention will be further specifically described below by taking a single-track railway tunnel project in a V-level argillaceous shale stratum with poor self-stability of the surrounding rock as an example.

[0051] Such as figure 2 As shown, the section is horseshoe-shaped, with a width of 9m and a height of 10m (including the inverted arch). For a small amount of groundwater, use a closed shield machine for full-face excavation. The construction steps are as follows:

[0052] In step S1, a full-section excavation of an excavation length is performed on the tunnel with a closed cutter head. On the cutter head 11 of the closed shield machine, there are tools for excavating rock and soil. Through the rotation of the cutter head 11, the rock and soil on the face of the tunnel are cut off, and the cut rock and soil blocks are discharged through the slag discharge system. Each excavation footage is an arch frame.

[0053] In step S2, initial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com