Small polishing rust-removal device special for kitchen hardware

A hardware and small-scale technology, which is applied in the field of small grinding and derusting devices for kitchen hardware, can solve the problems of adjusting grinding wheels, human health damage, etc., and achieves high controllability, simple structure, and the effect of improving the quality of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

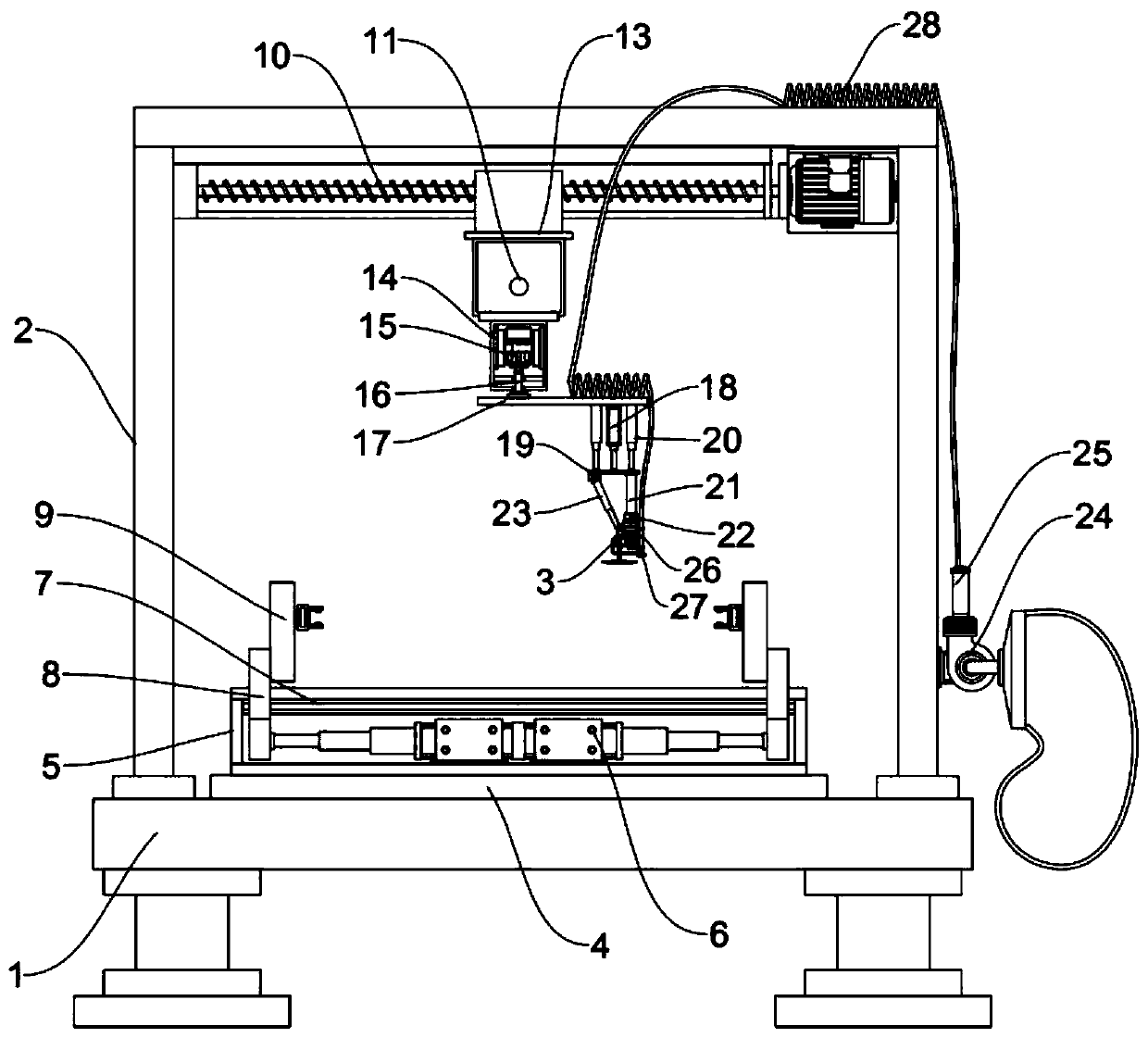

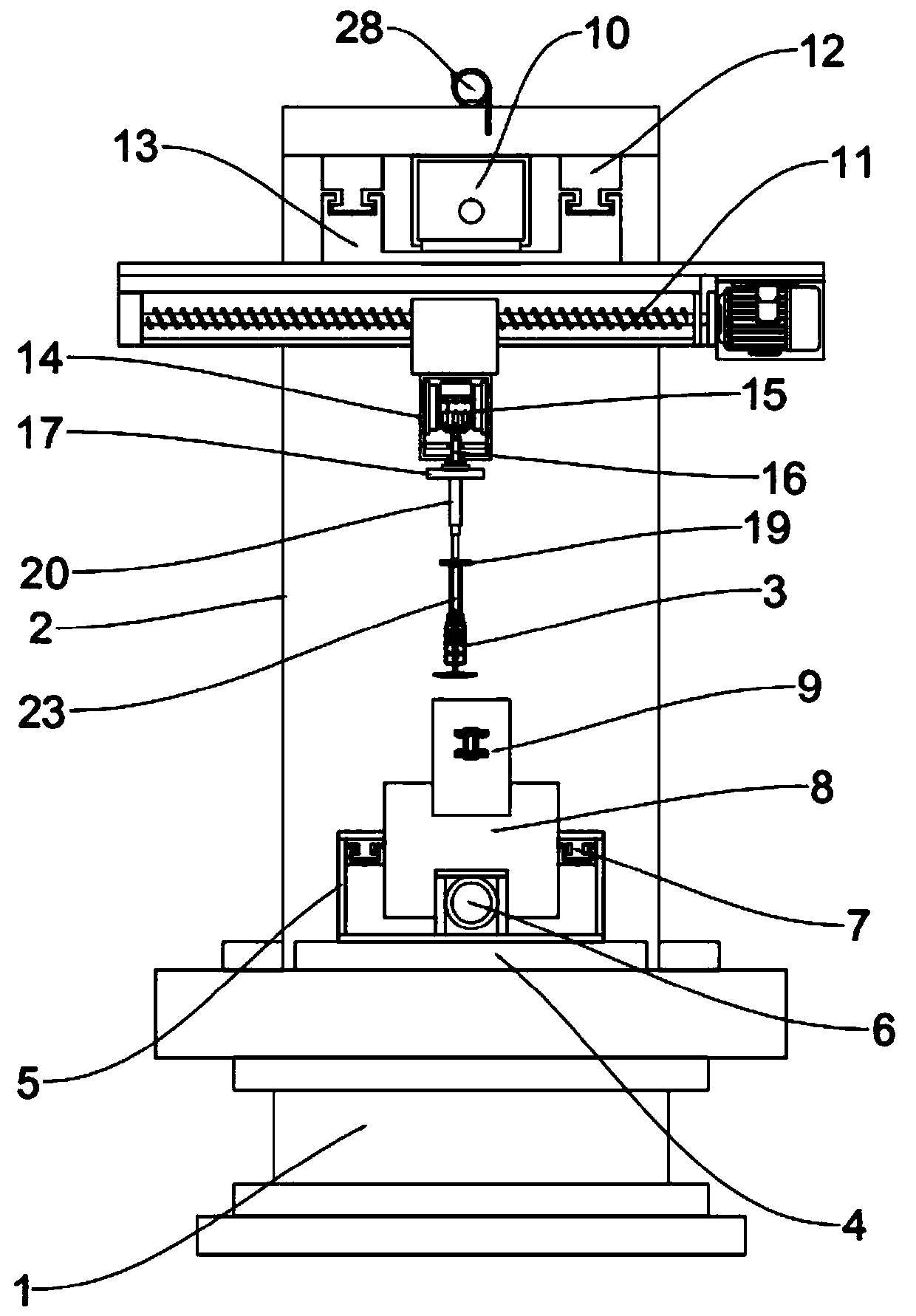

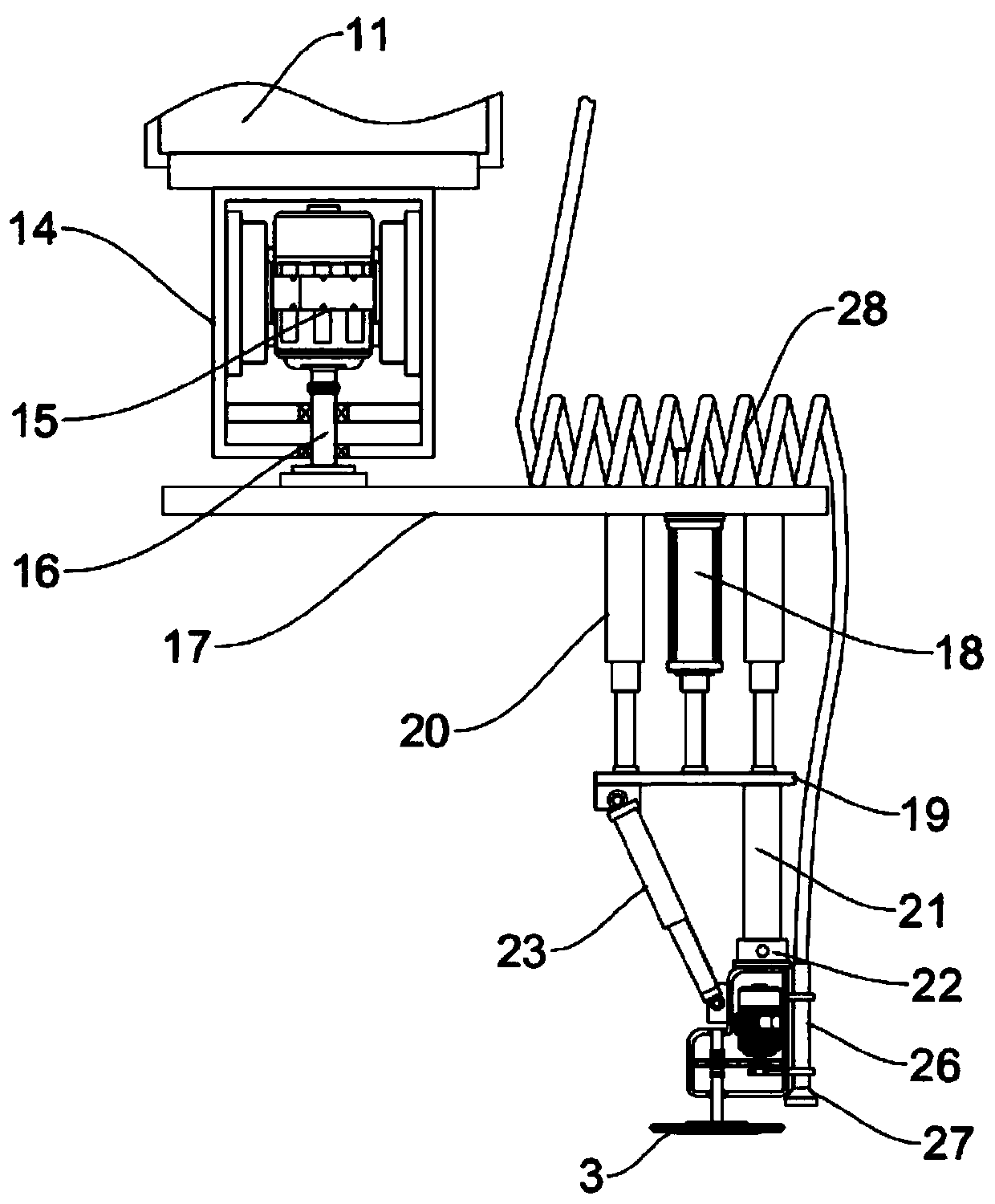

[0037] Embodiment: attached by specification Figure 1-5 It can be seen that this solution includes an operation table 1, a support frame 2 and a grinding head 3, and their positional relationship and connection relationship are as follows, the support frame 2 is installed on the operation table 1, the grinding head 3 is installed on the support frame 2, and the operation The table 1 is provided with a clamping and fixing mechanism, the support frame 2 is provided with an adjustable grinding mechanism, and is connected to the grinding machine head 3, and the operating table 1 is provided with a centrifugal dust removal mechanism, wherein the clamping and fixing mechanism includes: fixed The seat 4 and the clamping and fixing structure have the following positional relationship and connection relationship. The fixing seat 4 is installed on the console 1, and the clamping and fixing structure is installed on the fixing seat 4. The above-mentioned adjustable grinding mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com