Laser cutting machine with safety protection device

A safety protection device and laser cutting machine technology, applied in the field of machining, can solve problems affecting the health of operators, reduce production efficiency, and work environment pollution, so as to improve the quality of the work environment, improve operation safety, and reduce dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

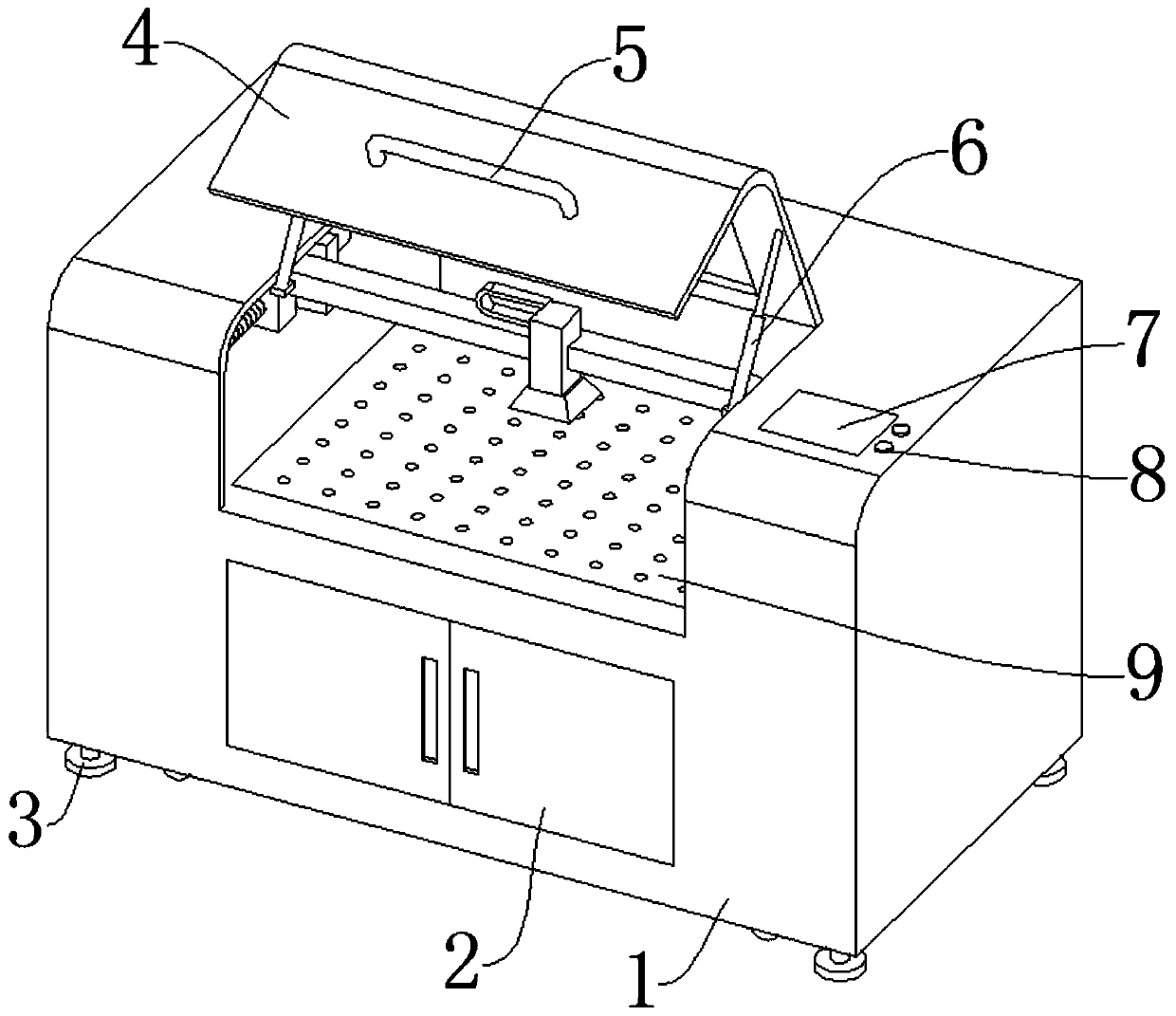

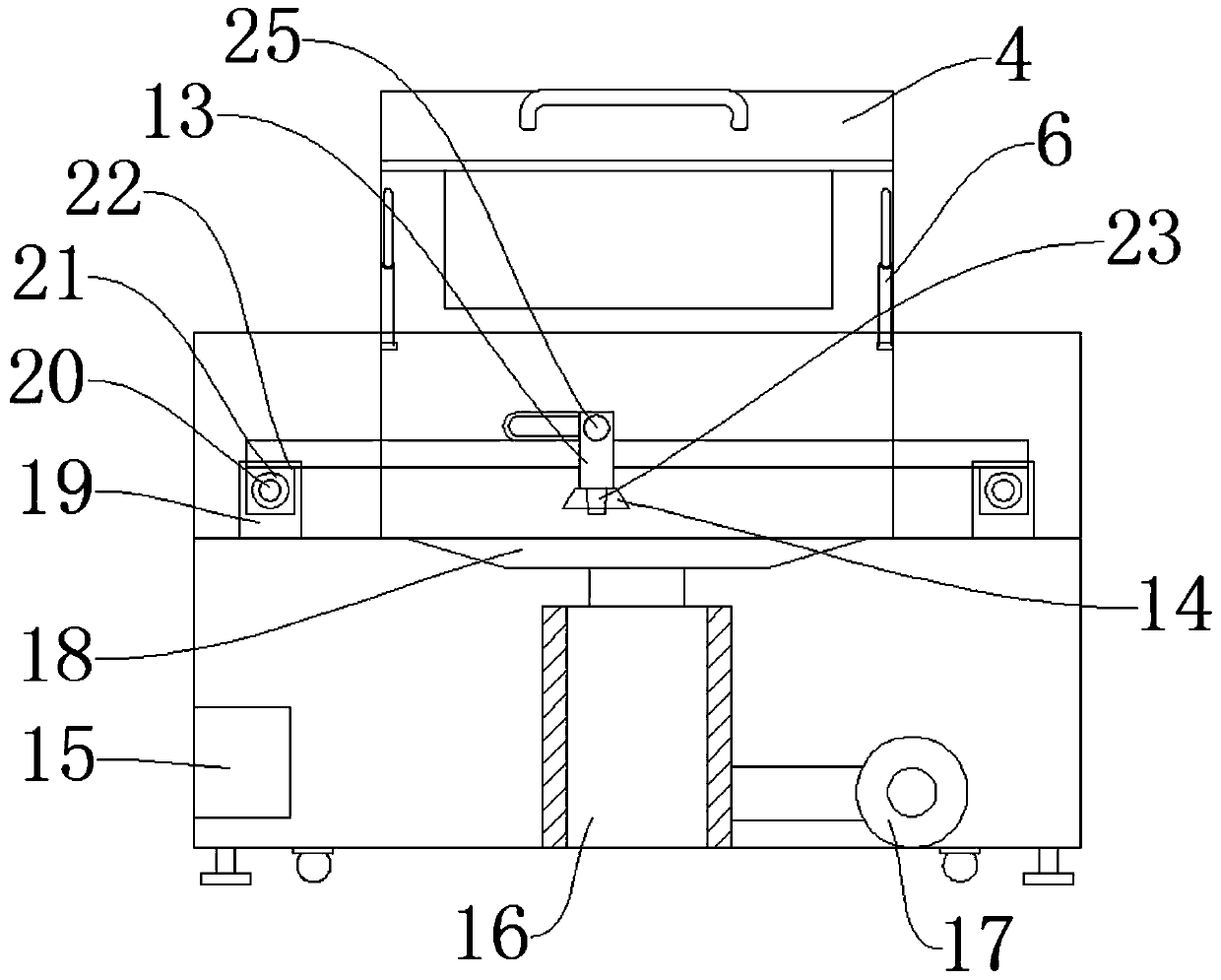

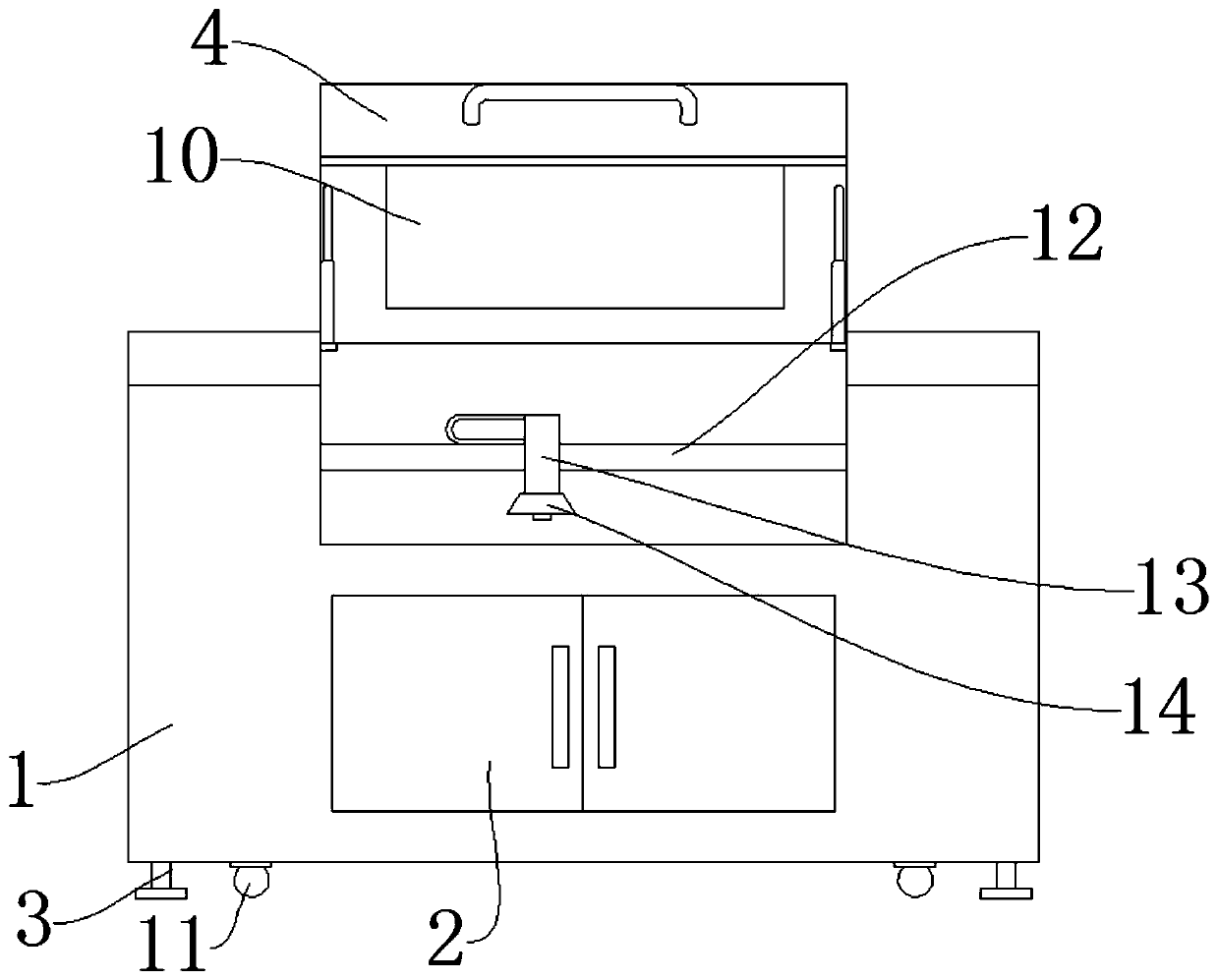

[0035] Such as Figure 1-Figure 5 As shown, a laser cutting machine with a safety protection device includes a box body 1, a safety cover 4, a dust cover 14, and a filter screen 16. The inside of the box body 1 is provided with a filter screen 16 to absorb dust during the cutting process. , the filter screen 16 is cylindrical, and an exhaust fan 17 is arranged on one side of the filter screen 16 to generate power for absorbing dust. The workbench 9 is used to support the placement of cutting workpieces. There are through holes evenly distributed on the workbench 9. The four corners of the lower end of the box body 1 are provided with support seats 3 to support the overall stability of the placement. There are moving wheels 11 between the support seats 3 to facilitate overall movement. A box door 2 is installed on the front side of the box body 1, a safety cover 4 is arranged on the top of the box door 2, a handle 5 is installed on the front side of the safety cover 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com