Foundation pit support breast beam wire saw cutting method

A cutting method and foundation pit support technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems that diamond wire saws cannot be cut and concrete blocks are difficult to lift, and achieve less labor waste, easy operation, and reduced The effect of cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

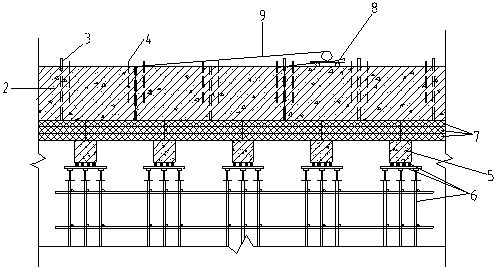

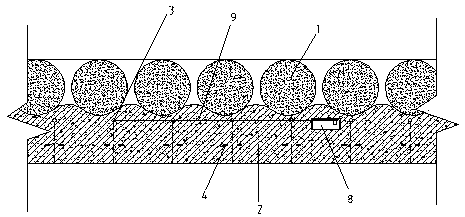

[0021] Such as Figure 1-2 Shown: a wire saw cutting method for foundation pit support waist beam, it includes the following steps:

[0022] Step 1: Plant reinforcement on the cast-in-place pile according to the design requirements, chisel the contact surface between the cast-in-place pile 1 and the waist beam 2, and start binding the waist beam reinforcement;

[0023] Step 2: After the reinforcement of the waist beam is bound, plan the cutting scheme of the waist beam 2 wire saw, and draw the cutting block diagram;

[0024] Step 3: Pre-embed D50 PVC casing 3 at a distance of 100mm from the cast-in-place pile on the dividing line on the block diagram. The casing is more than 100mm higher than both sides, and the finished product should be protected to avoid casing blockage;

[0025] Step 4: According to the block diagram, pre-embed round steel hooks 4 with a diameter of 20mm at a distance of 100mm from the edge on both sides of each concrete block to be cut;

[0026] Step 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com