Mining technology for gold ore

A kind of technology and technology of gold mine, which is applied in the field of gold mining technology, can solve the problems of unreachable mining recovery rate, resource waste, economic loss, and small mining quantity, so as to reduce resource waste and economic loss, reduce Effects of noise and dust pollution and improvement of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

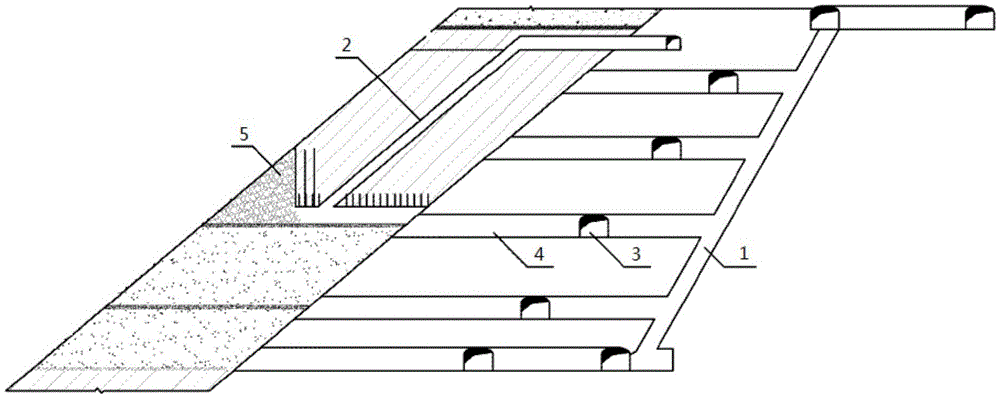

[0022] The invention provides a mining process for gold mines, which includes a stope parameter confirmation step, and determines various parameters of the stope according to the direction of the ore veins in the stope. The length of the stope along the direction is 40-50m, and the width is the width of the ore body. 5m intercolumn, bottom column 5m, top column 4m, stope height is stage height 50m;

[0023] The mining and cutting steps include the arrangement of transportation roadways, mining patios, connecting roads, bottom pulling and funnels according to the above parameters. Specifically, segmental entryways 3 are arranged at the boundary of the footwall parallel to the ore body, and each segmental entryway 3 communicates with the ramp outside the vein through the ramp connection road, and the stope segmental entryway 4 connects the stope and each segmental entryway 3. The ore exiting horizontal roadway outside the vein is connected with the ore exit shaft 1 in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com