Patents

Literature

45results about How to "Prevent dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant high-heat-resistant polypropylene composite material for transparent electric cooker and preparing method and application of flame retardant high-heat-resistant polypropylene composite material

The invention discloses a flame retardant high-heat-resistant polypropylene composite material for a transparent electric cooker and a preparing method and application of the flame retardant high-heat-resistant polypropylene composite material. The composite material is composed of, by mass, 60-97% of high-crystallized homo-polypropylene, 1-20% of transparent padding master batch, 1.7-10% pf flame retardant master batch, 0.1-5% of scraping-resistant master batch, 0.1-2% of thermal oxidative aging resisting agent and 0.2-3% of addition agent. All the components are evenly mixed and added in a parallel double-screw extruding machine, blending and melt extrusion are carried out, and the composite material is obtained. The composite material is low in cost and excellent in comprehensive physical and mechanical property and can be used in the fields of small household appliances such as electric cookers, pressure cookers, induction cookers and soybean milk machines.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

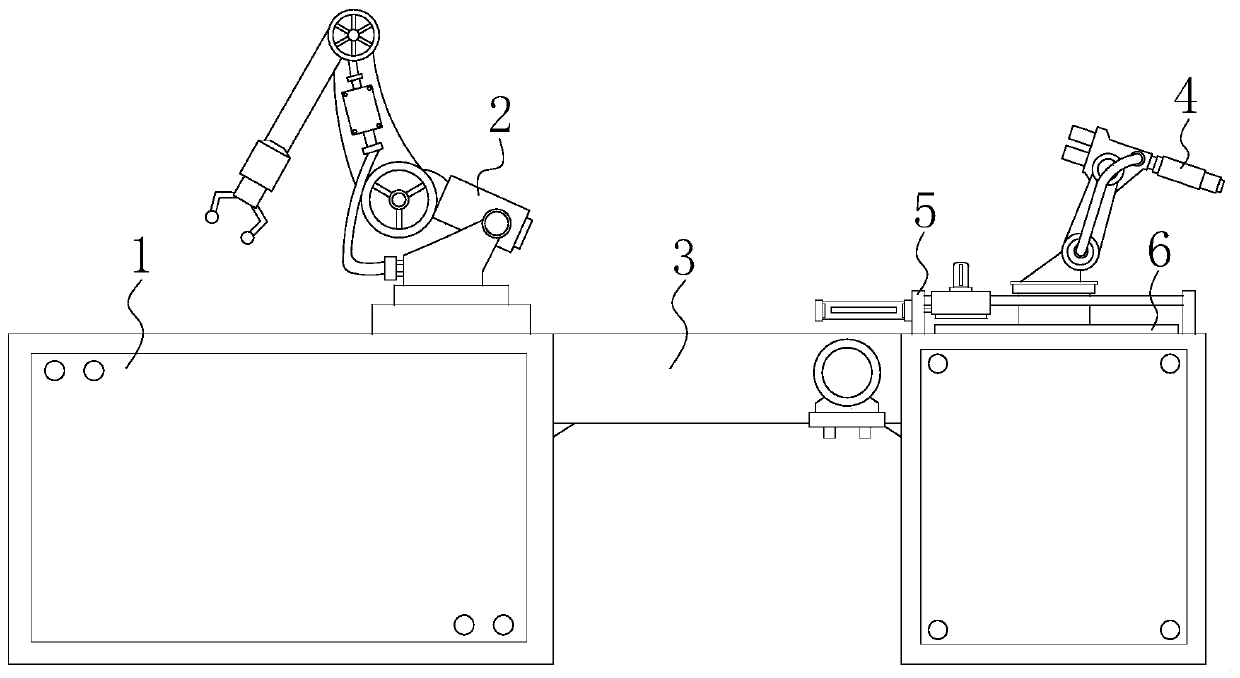

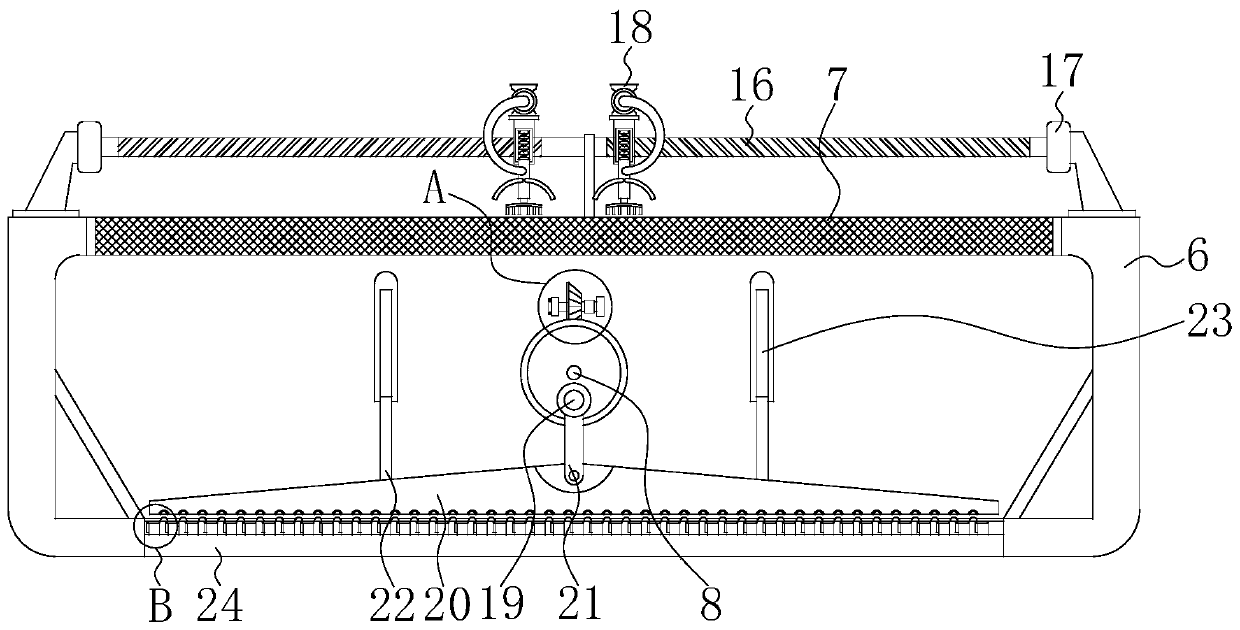

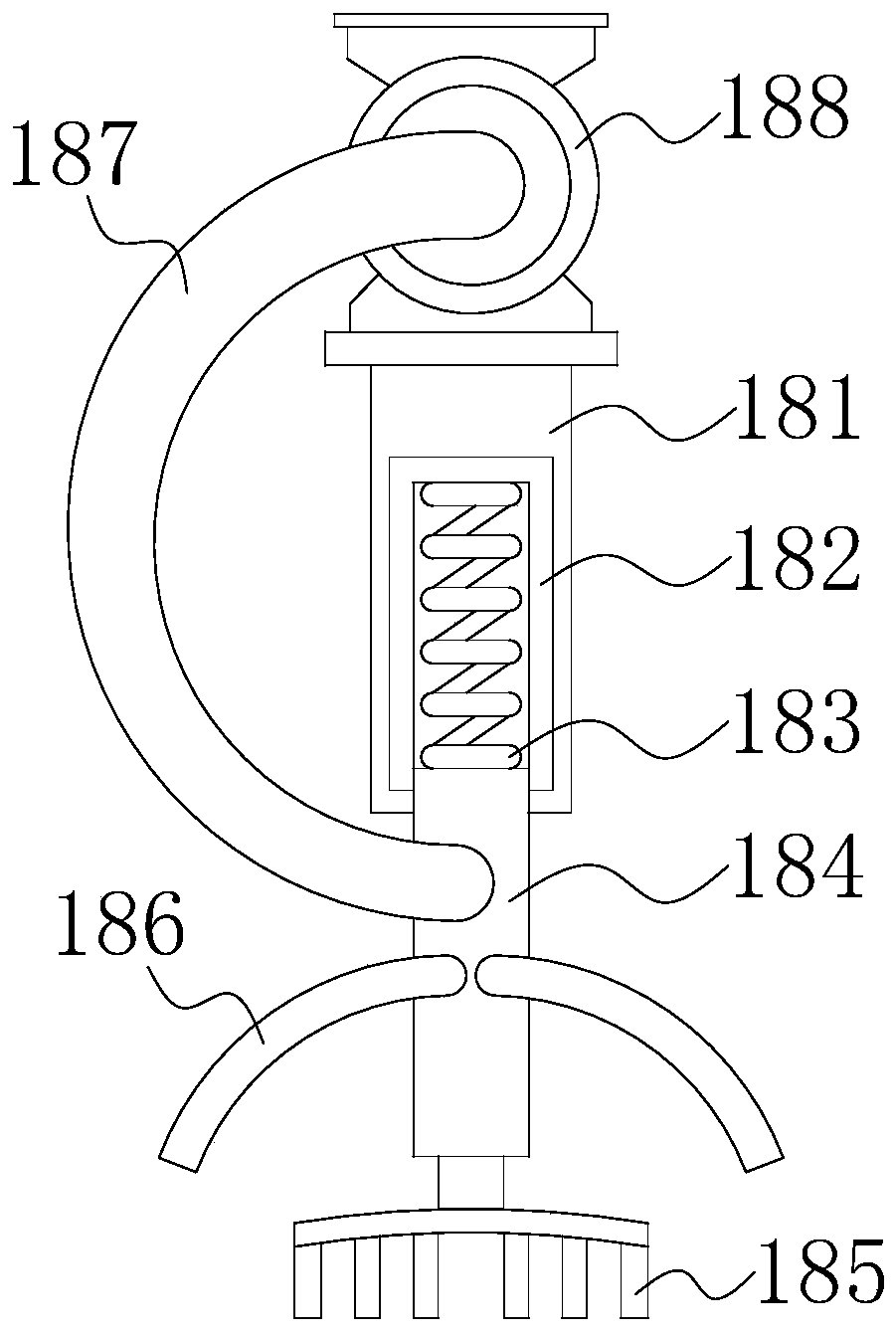

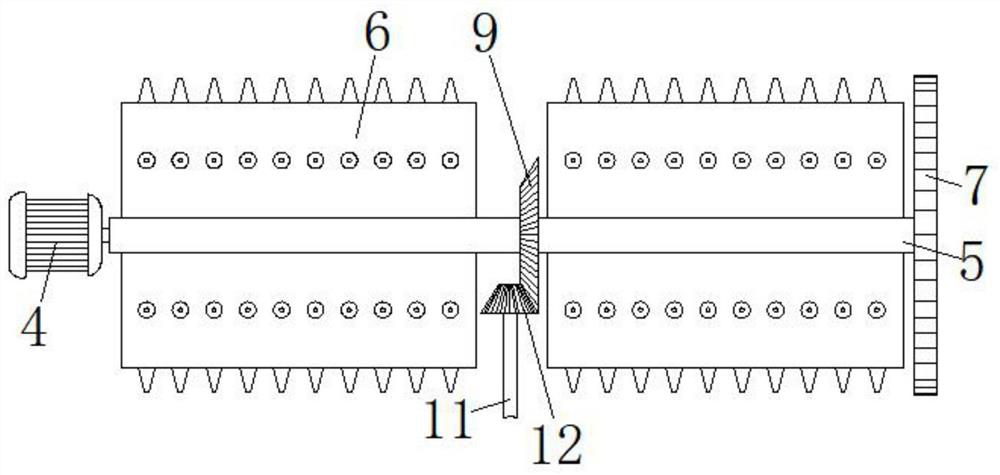

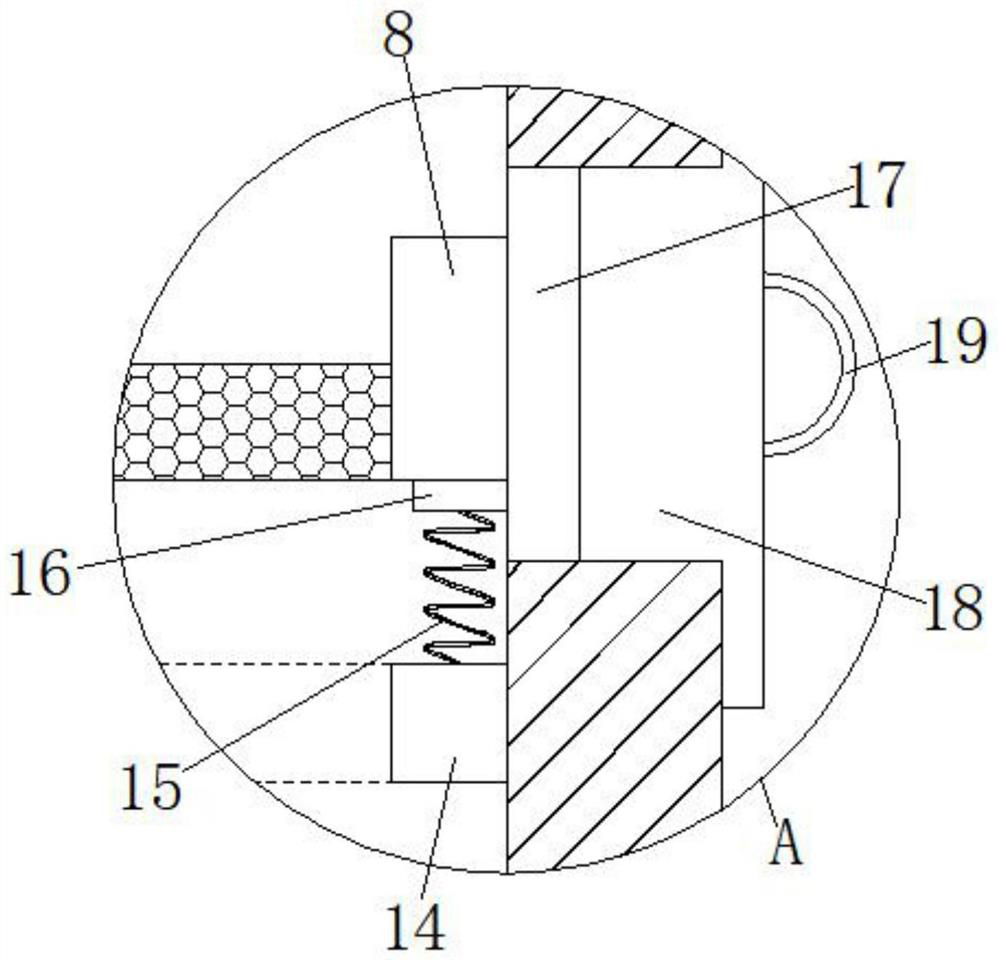

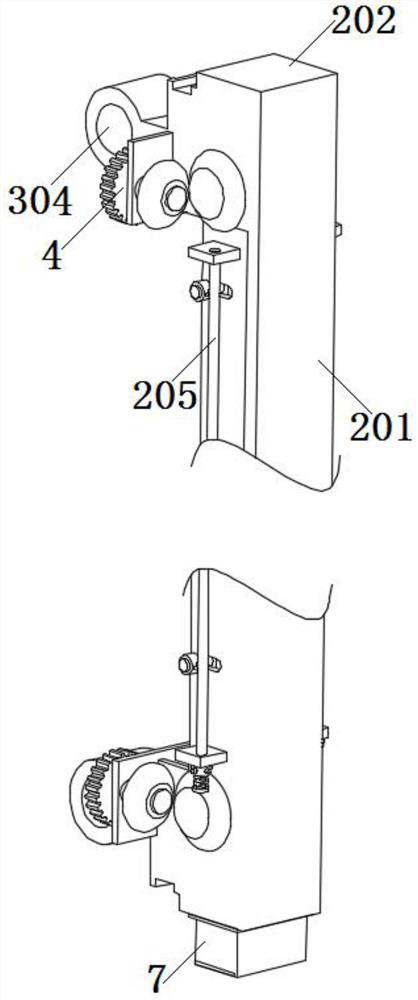

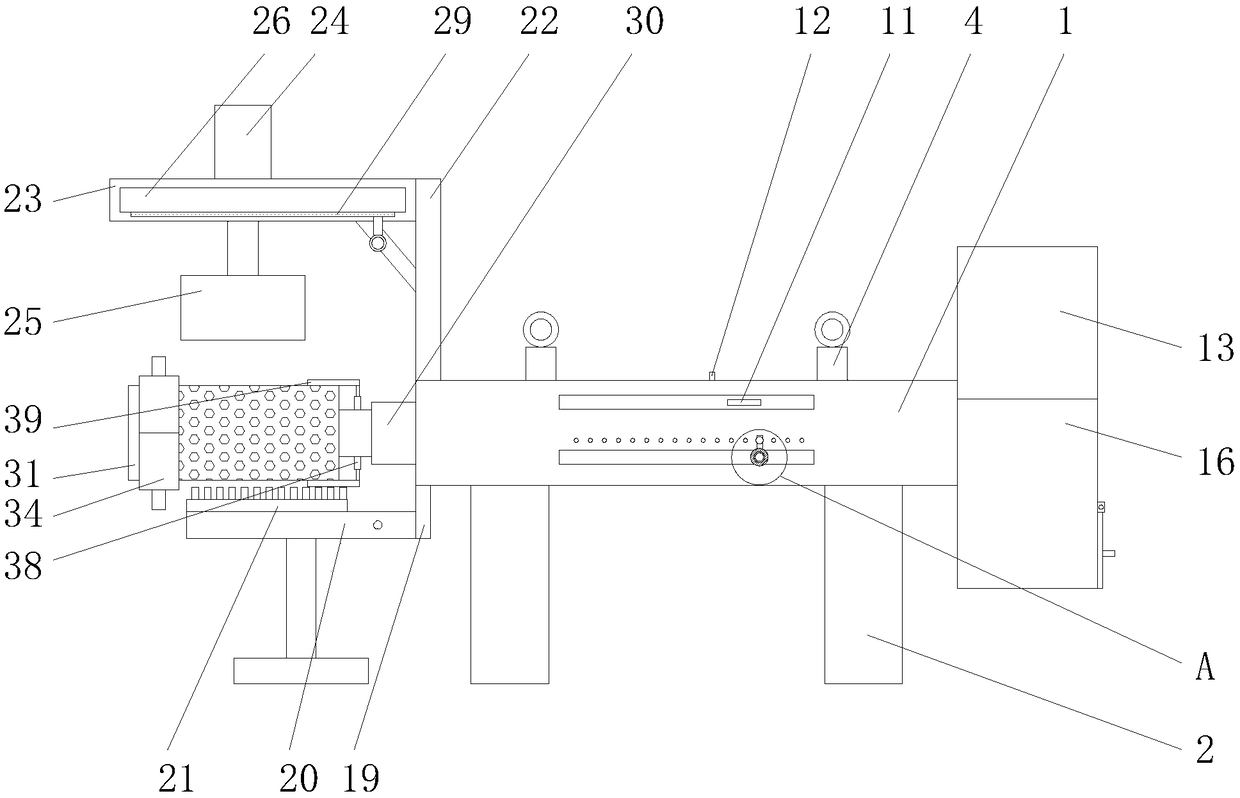

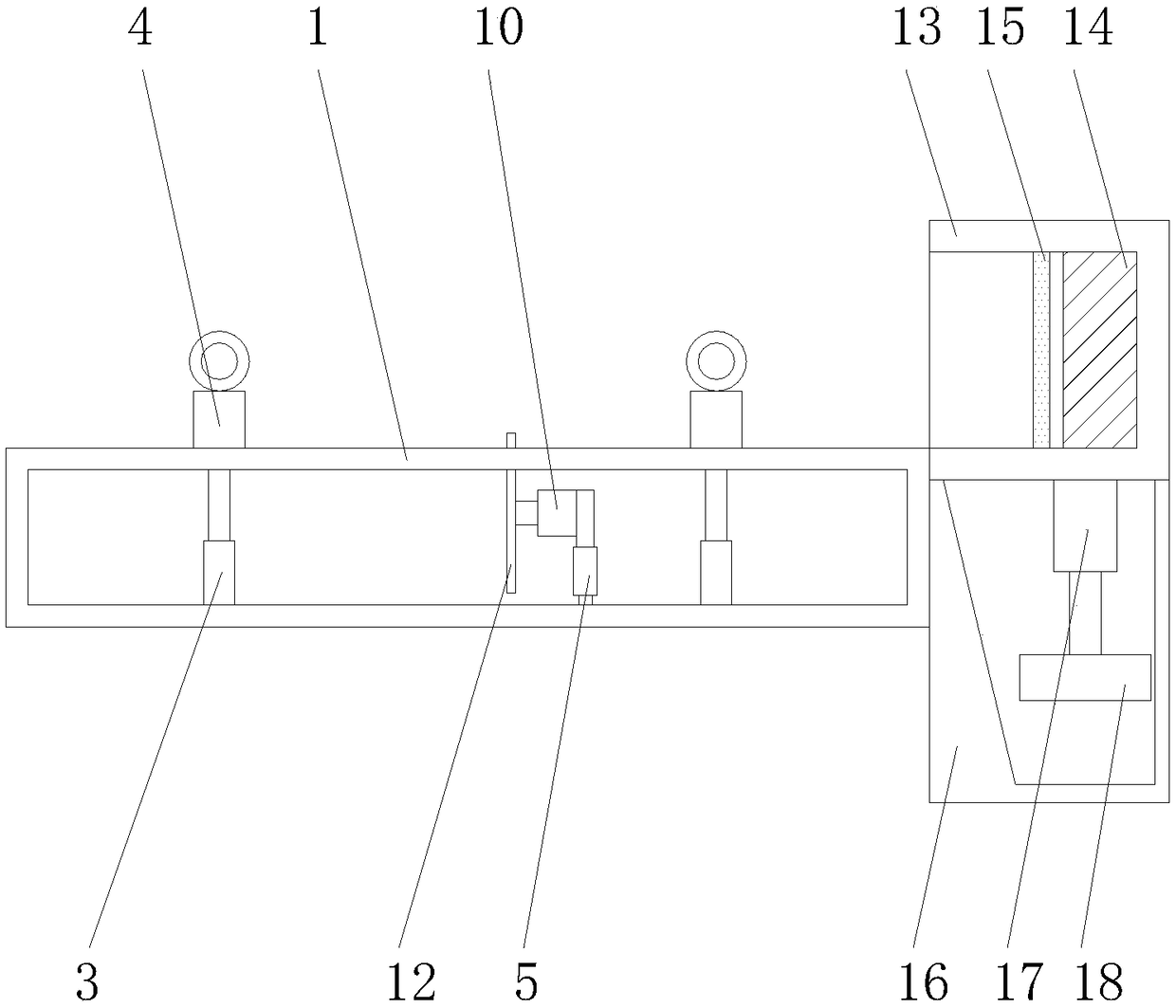

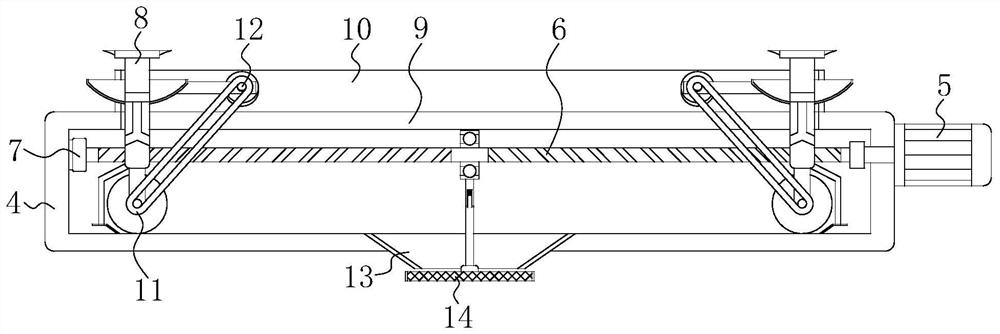

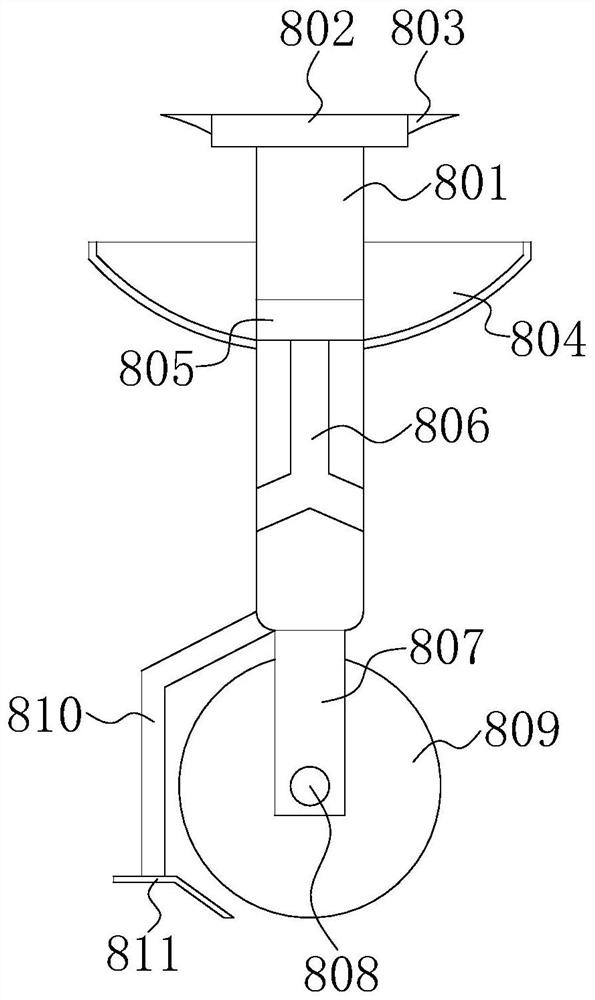

Automatic welding production line and automatic welding method for stand column of door plate

ActiveCN109759758AReduce loosenessPrevent dustWelding/cutting auxillary devicesAuxillary welding devicesProduction lineBristle

The invention discloses an automatic welding production line and an automatic welding method for a stand column of a door plate, and relates to the technical field of door plate stand column production. The automatic welding production line for the stand column of the door plate comprises a loading device, a loading robot, a conveying device, a welding robot platform and a positioning device, wherein the loading robot is fixedly arranged on one side of the top part of the loading device; the conveying device is fixedly arranged on the right side of the loading device; the welding robot platform is fixedly arranged on the right side of the conveying device; and the positioning device is fixedly arranged on the top part of the welding robot platform. According to the automatic welding production line and the automatic welding method for the stand column of the door plate, welding slags attached to the surface of the stand column of the door plate are swept to the surface of a net body through bristles and are discharged into a hollow plate through the net body so as to be collected, and meanwhile, a pressing plate moves up and down in a reciprocating way so as to compact the weldingslags accumulated on the bottom part in the hollow plate, so that the loose degree of the welding slags is reduced, and the occurrence of the phenomenon of dust raise is avoided.

Owner:佛山市慧智智能装备有限公司

Yarn guiding device for warp finishing of fabric spinning

The invention discloses a yarn guiding device for warp finishing of fabric spinning. The yarn guiding device comprises a yarn changing box, a supporting base, a processing table and an electric yarn arranging cylinder; a control panel is fixedly installed on one face of the processing table; a yarn guiding wheel is fixedly installed at the top end of the processing table; and a yarn changing bin is formed in the front face of the yarn changing box. Through the arrangement of a rotating main shaft, a yarn changing wheel, a cone yarn tray, a counterweight plate, a yarn falling opening, a yarn storage box, a yarn inlet hole and a three-tooth push rod, cone yarn can be put into the yarn storage box in advance, then the yarn changing bin is rotated, and the cone yarns on the cone yarn tray are subjected to waste yarn removing and new yarn feeding, so that one worker can replace a plurality of cone yarns at the same time, the worker can conveniently and quickly replace the cone yarns, the cost of human resources is saved, the production efficiency is improved to a certain extent, the cost is indirectly reduced, and the benefits are increased; and meanwhile, the yarn guiding device is easy to operate and learn, and operation and teaching of the worker are facilitated.

Owner:桐乡市恒秋服饰有限公司

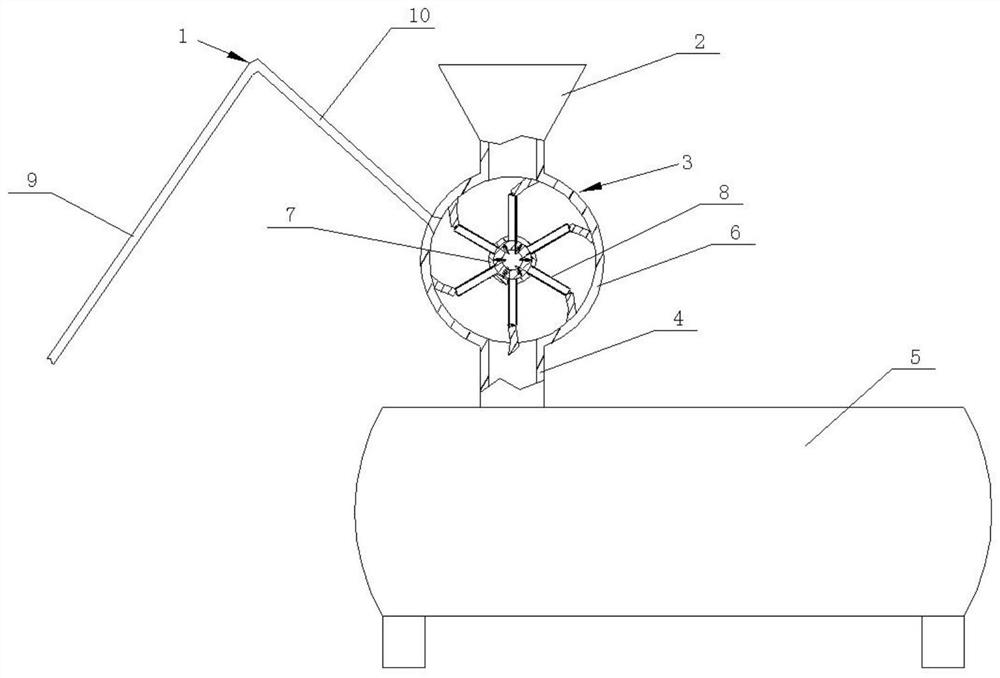

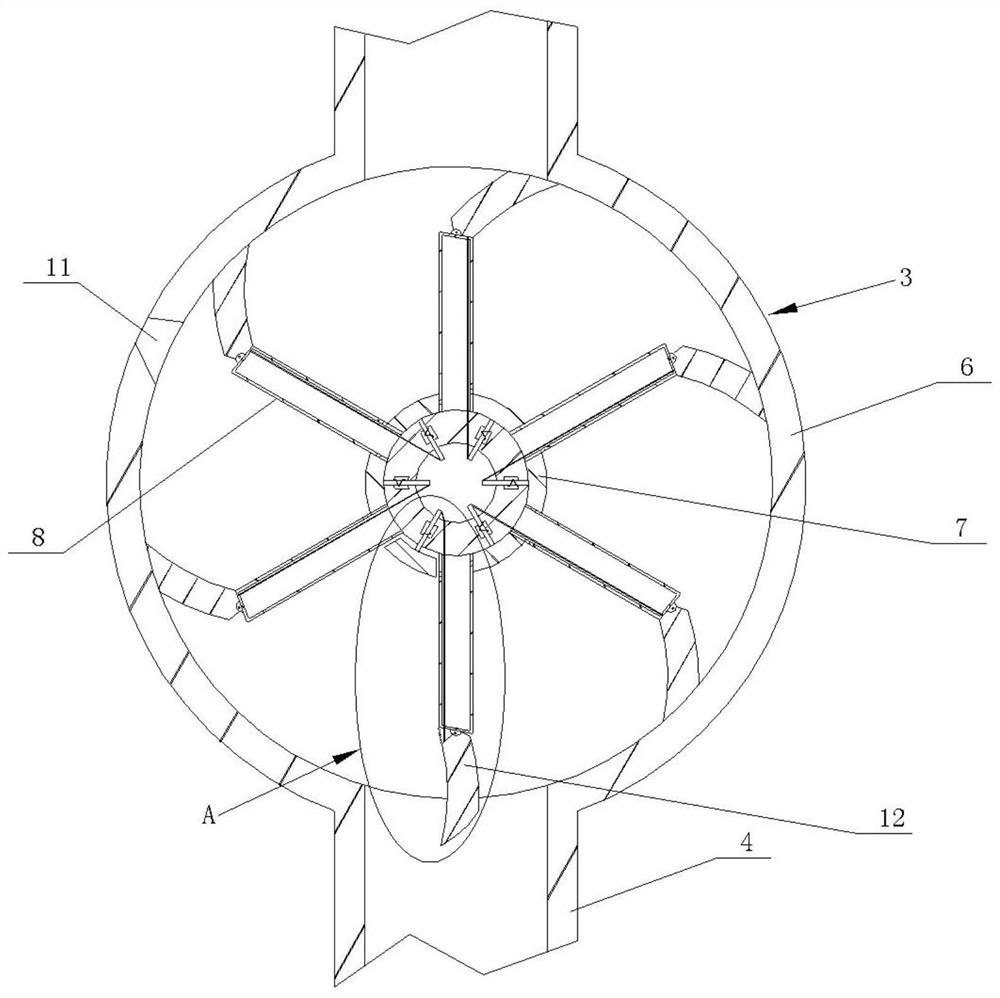

Clearing method for pulverized coal separating wheel

ActiveCN113267059ABlocking does not affectDoes not cause temperatureDrying gas arrangementsIncrustation removal devicesThermodynamicsHot blast

The invention relates to the field of separating wheel clearing, in particular to a clearing method for a pulverized coal separating wheel. The clearing method comprises the following steps: inputting hot air in a rotary kiln into a separating wheel through a bent hot air pipeline, wherein the hot air pipeline comprises an air guide tube which communicates with the rotary kiln and an air inlet tube which communicates with the separating wheel; and the connecting position between the air inlet tube and the separating wheel is a 60-90-degree interval or a 270-300-degree interval of the separating wheel. With the adoption of the technical scheme, accumulation inside the separating wheel of raw coal is favorably reduced.

Owner:冀东水泥重庆合川有限责任公司

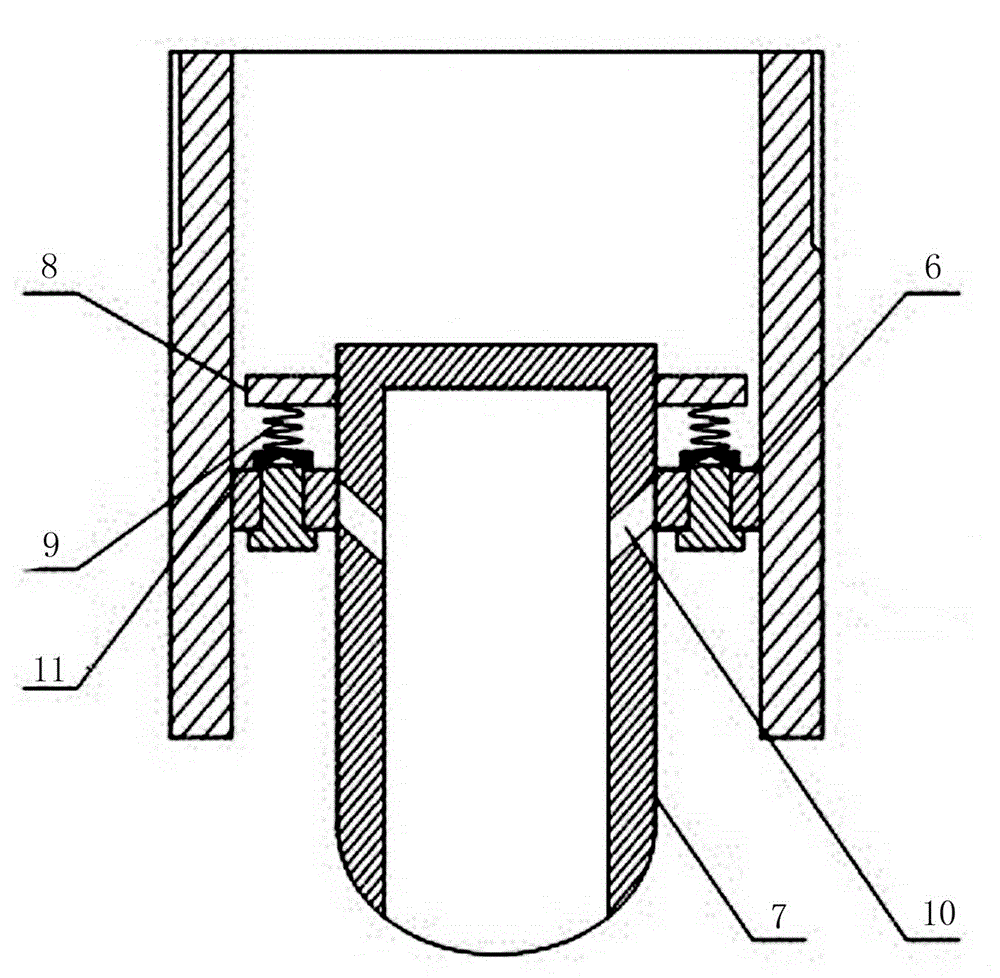

Mine rockfall protective video surveillance light transmission device

ActiveCN104243937APrevent dustShorten the timeOptical transmission adaptationsElectrical cable transmission adaptationEngineeringSmall hole

The invention discloses a mine rockfall protective video surveillance light transmission device which comprises a case with an upper opening which is covered with a cover plate. A plurality of wire through holes are formed in the side wall of the case. An inverted-L-shaped sealing part is arranged on the outer side of each wire through hole, a through hole extending is formed in the sealing part and communicated with the corresponding wire through hole, and a downward joint of the sealing part is of stepped holes, namely a big hole and a small hole; the big hole is close to the downward joint of the sealing part, and a pressure plug is in threaded connection in the big hole; an O-shaped ring is arranged between the pressure plug and the small hole; and the pressure plug is provided with a via hole along an extending direction thereof. The mine rockfall protective video surveillance light transmission device has the advantages that due to the L-shaped sealing parts with the downward joints, dust accumulation at the downward joints is avoided, the O-shaped rings are protected against dust accumulation, and the process of cleaning the O-shaped rings to guarantee sealing performance is omitted during mounting of the O-shaped rings after maintenance to save time; meanwhile, the sealing parts covered with the cover plate are prevented from being smashed by rocks and accordingly are protected.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

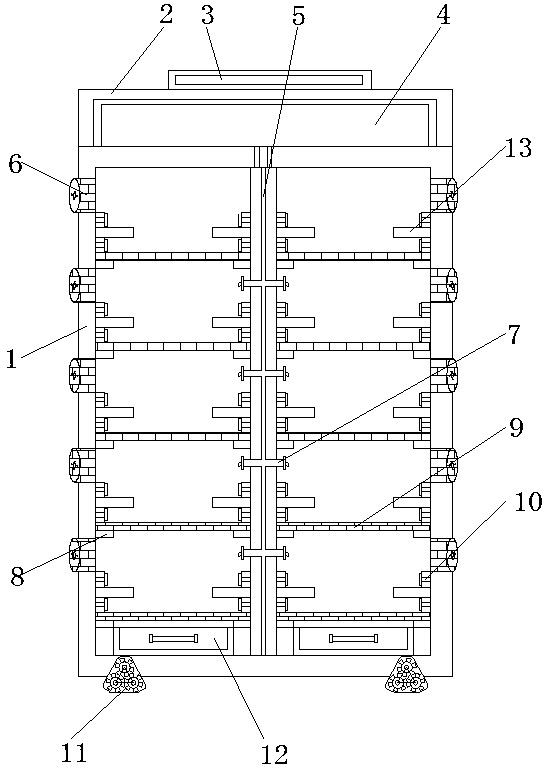

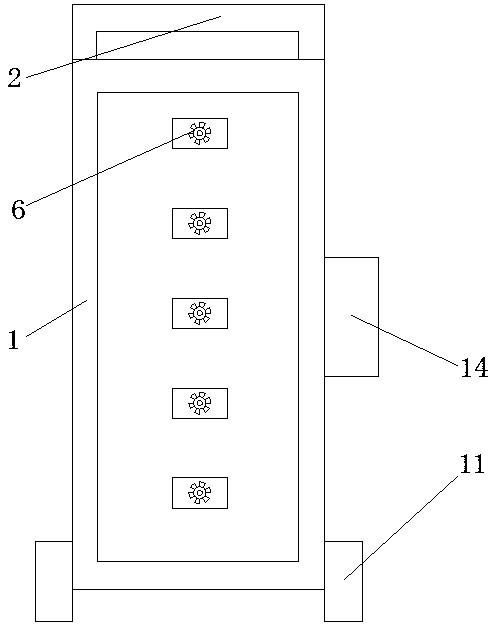

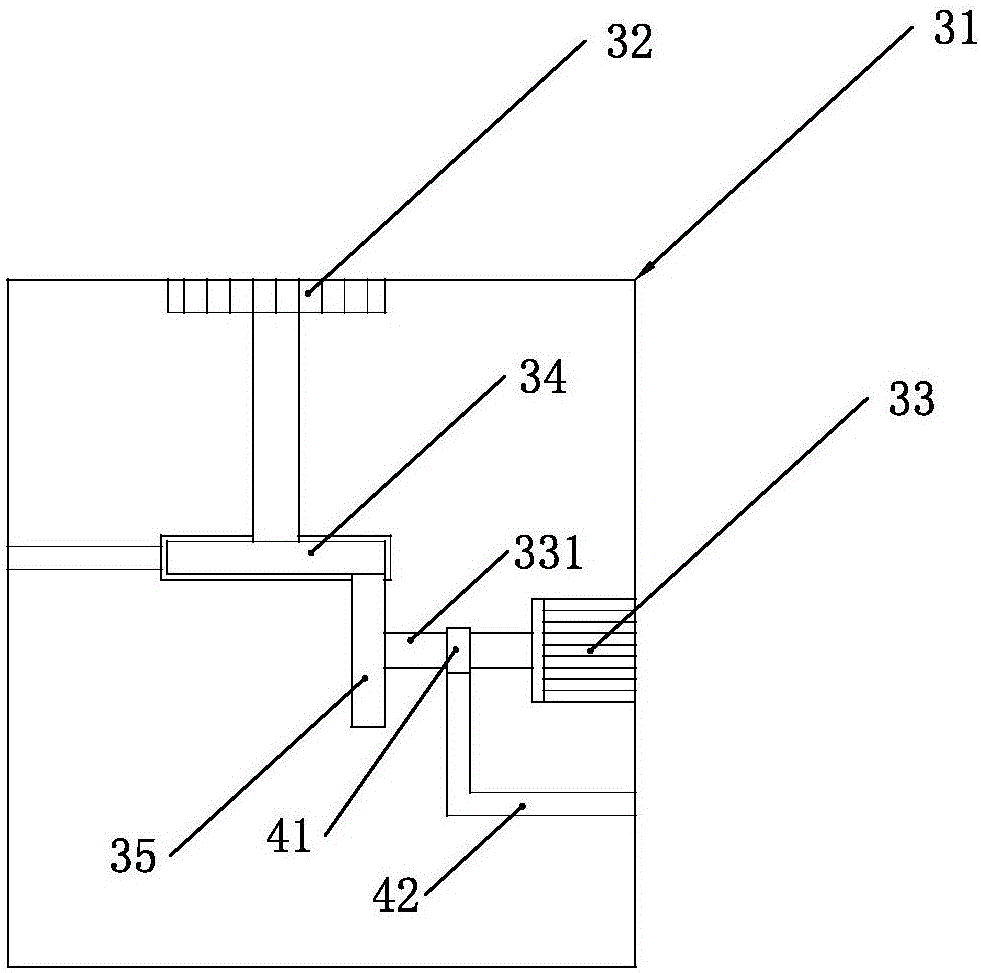

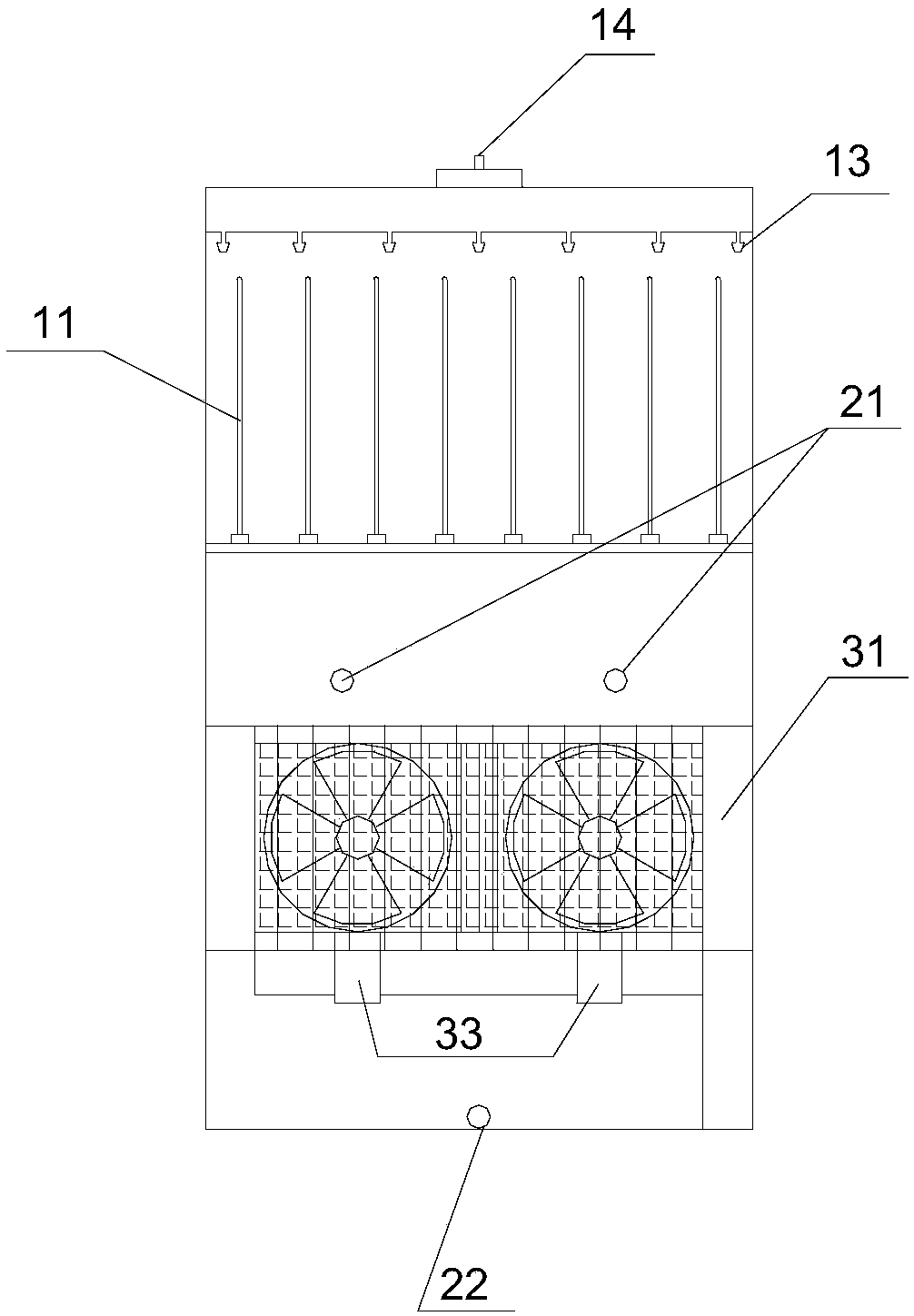

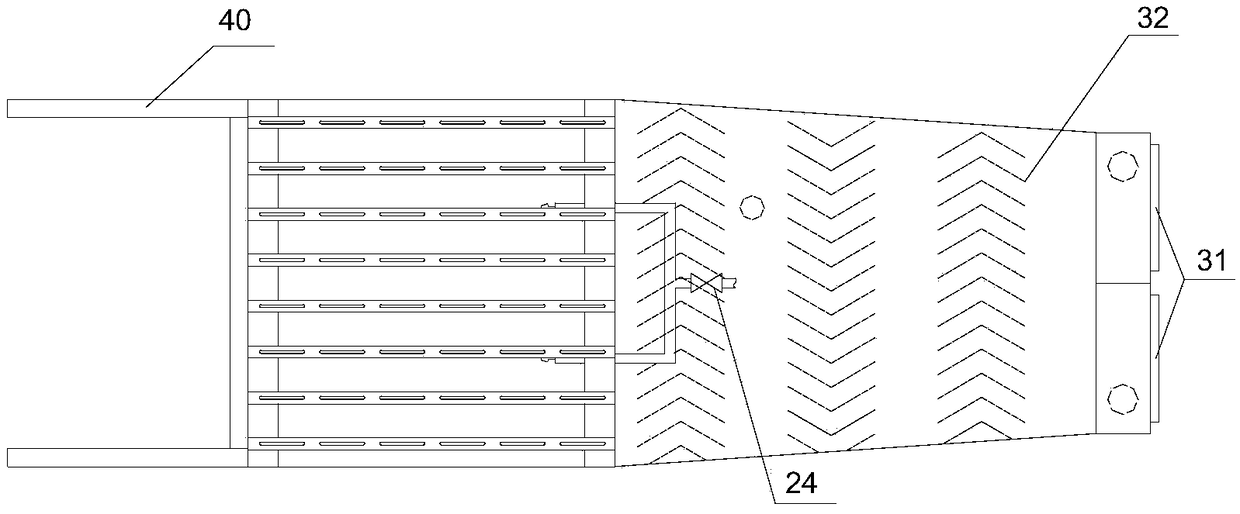

Grouping type machine room cabinet of integrated signal circuit

InactiveCN108718503AReduce air leakagePrevent dustServersCleaning using gasesGroup typeAgricultural engineering

The invention discloses a grouping type machine room cabinet of an integrated signal circuit. The grouping type machine room cabinet comprises a main body, a gas tank, a damp-proof board, a combined wheel and a dust collection box, wherein a jet box is installed on the main body, a cover is placed on the jet box, the gas tank is installed in the jet box, a jet pipe is placed under the gas tank, air nozzles are installed on left and right sides of the jet pipe, block sheets are arranged in the air nozzles, handles are installed on the right sides of the block sheets, a support plate is installed in the main body, bolts are fixed on upper and lower sides of the support plate, cooling fans are arranged on left and right sides of the main body, the damp-proof board is arranged under the support plate, sliding rails are arranged on left and right sides of the damp-proof board, the combined wheel is installed under the main body, and a belt is installed on the outer side of the combined wheel. The grouping type machine room cabinet of the integrated signal circuit provided by the invention is provided with the dismountable damp-proof board that can be quickly replaced, so that the applicability of the machine room cabinet is increased.

Owner:周楚楚

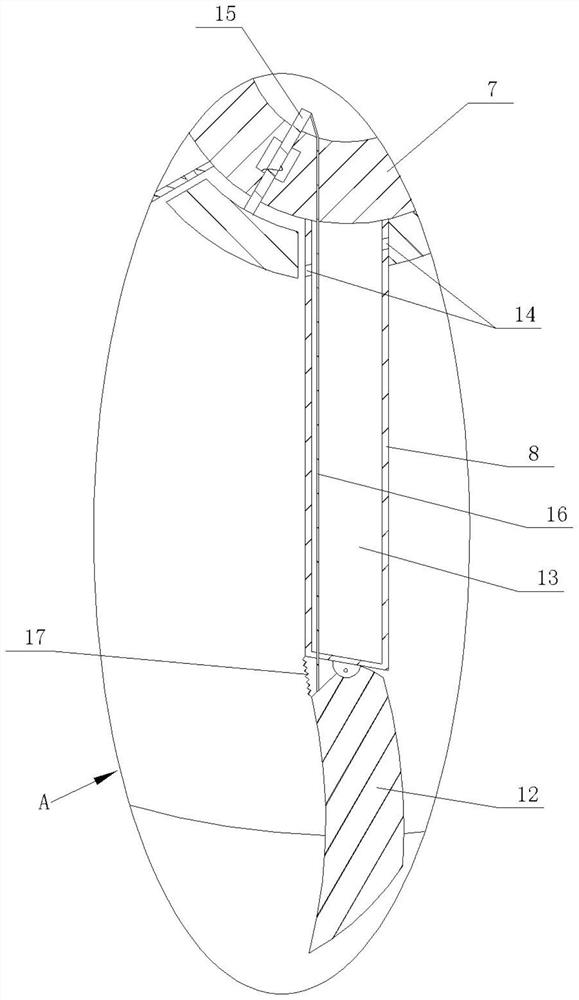

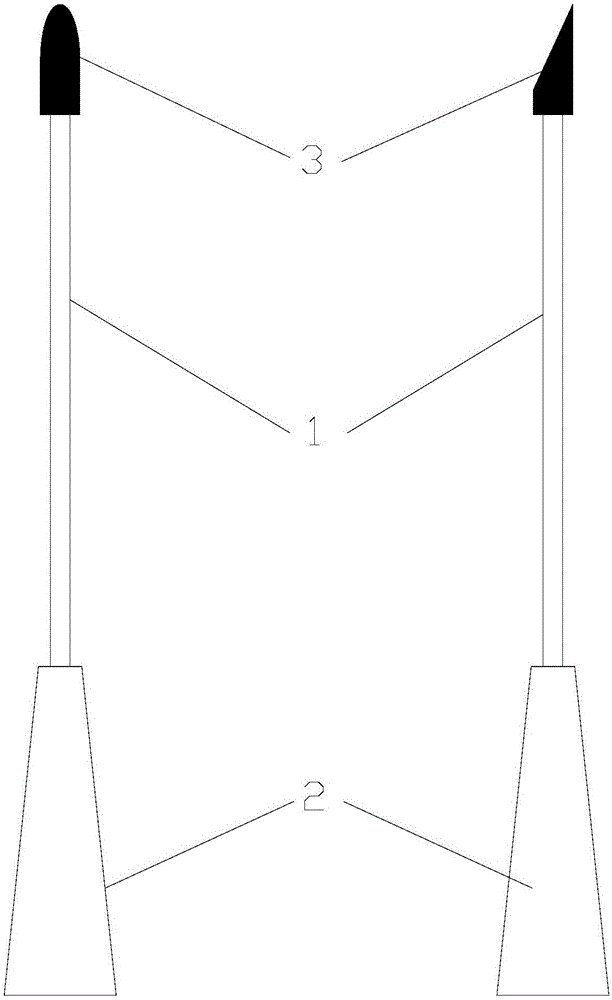

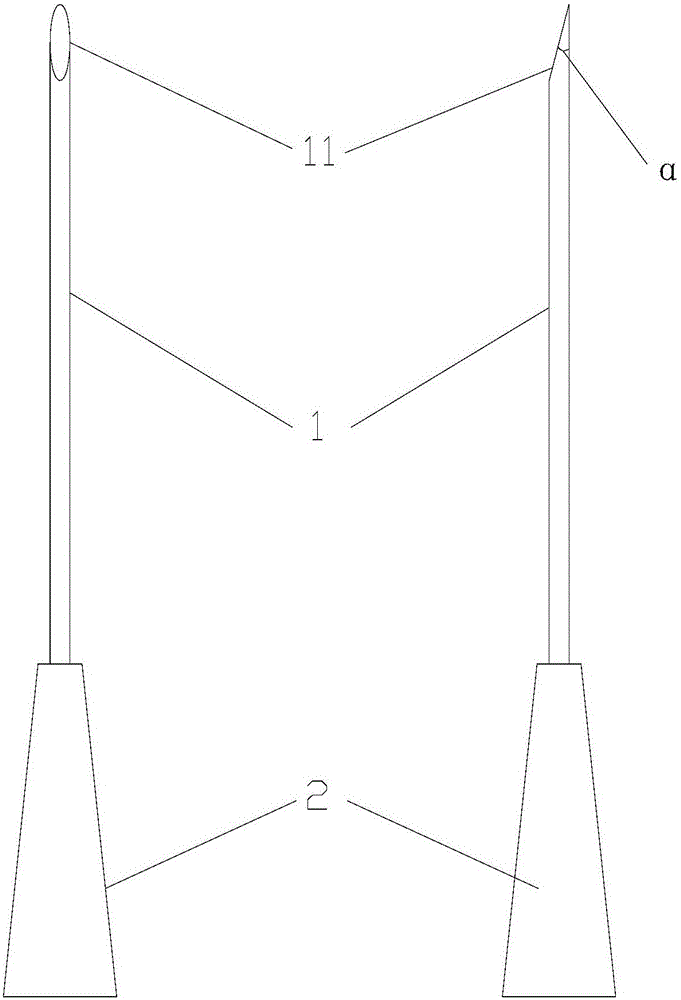

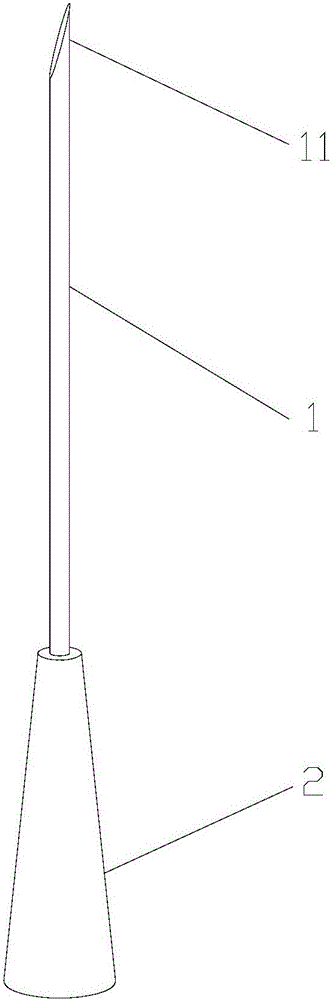

Aseptic cotton bud used for medical apparatus and instruments

The invention relates to an aseptic cotton bud used for medical apparatus and instruments. The aseptic cotton bud is composed of a cotton bud rod, a hand-held handle and a bud head, wherein the head end of the cotton bud rod is pinpoint-shaped, the tail end of the cotton bud rod is connected with the hand-held handle, the length of the cotton bud rod is 5-6 cm, the diameter of the cotton bud rod is 1mm, the length of the head end of the cotton bud rod is 0.5-0.6 mm, the included angle alpha between the inclined surface of the head end of the cotton bud rod and the axis of the cotton bud rod is 30-45 degrees, the diameter of the hand-held handle is greater than that of the cotton bud rod, and the bud head tightly wraps the periphery of the head end of the cotton bud rod. The head end of the aseptic cotton bud is sharp, thus being capable of easily penetrating the structure such as a groove for cleaning dirt and cleaning the blood scab on a threaded hole, the shortened cotton bud rod enables the aseptic cotton bud to have the small possibility of breaking off, the thickened hand-held handle is convenient to hold, and the medical apparatus and instruments, such as the intravenous catheter, needing long-time indwelling can be completely cleaned and disinfected easily, the residue of dust, dirt and bloodstain is avoided, and the occurrence of adverse events such as catheter infection is reduced.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

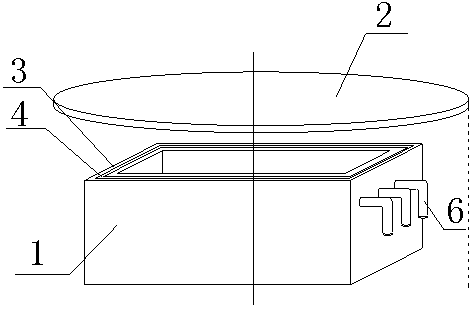

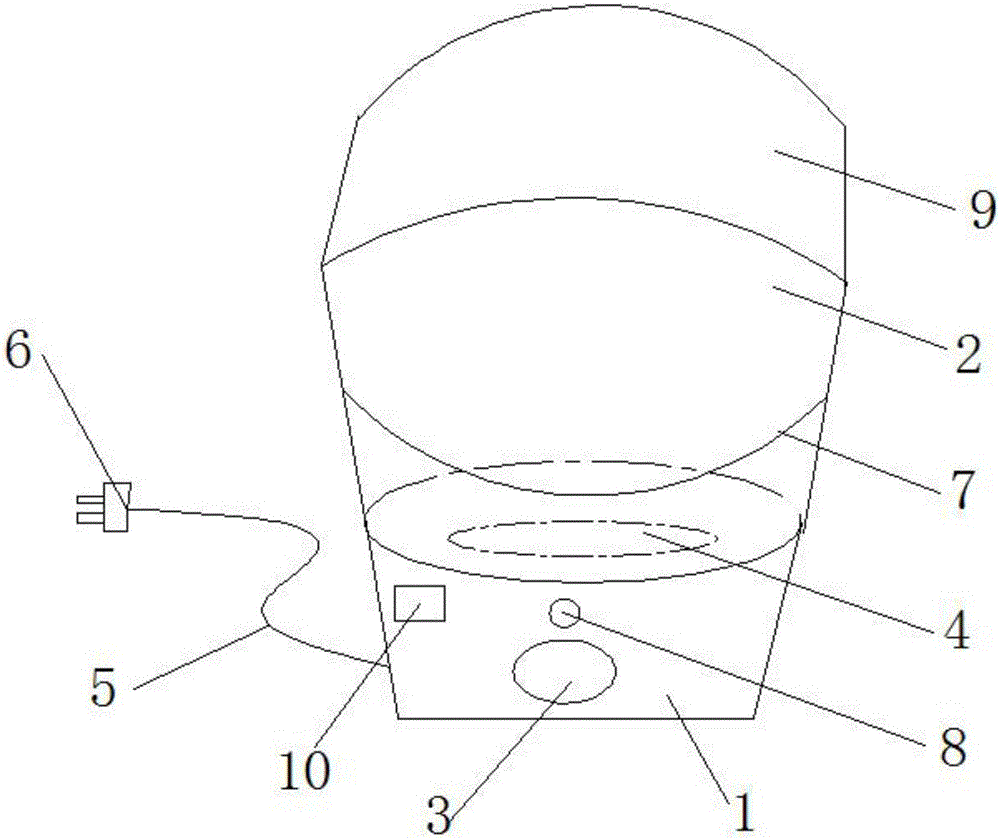

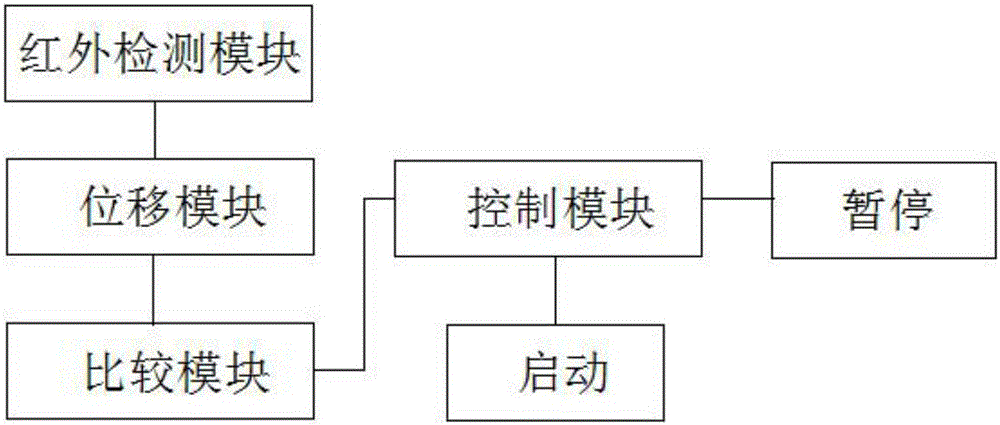

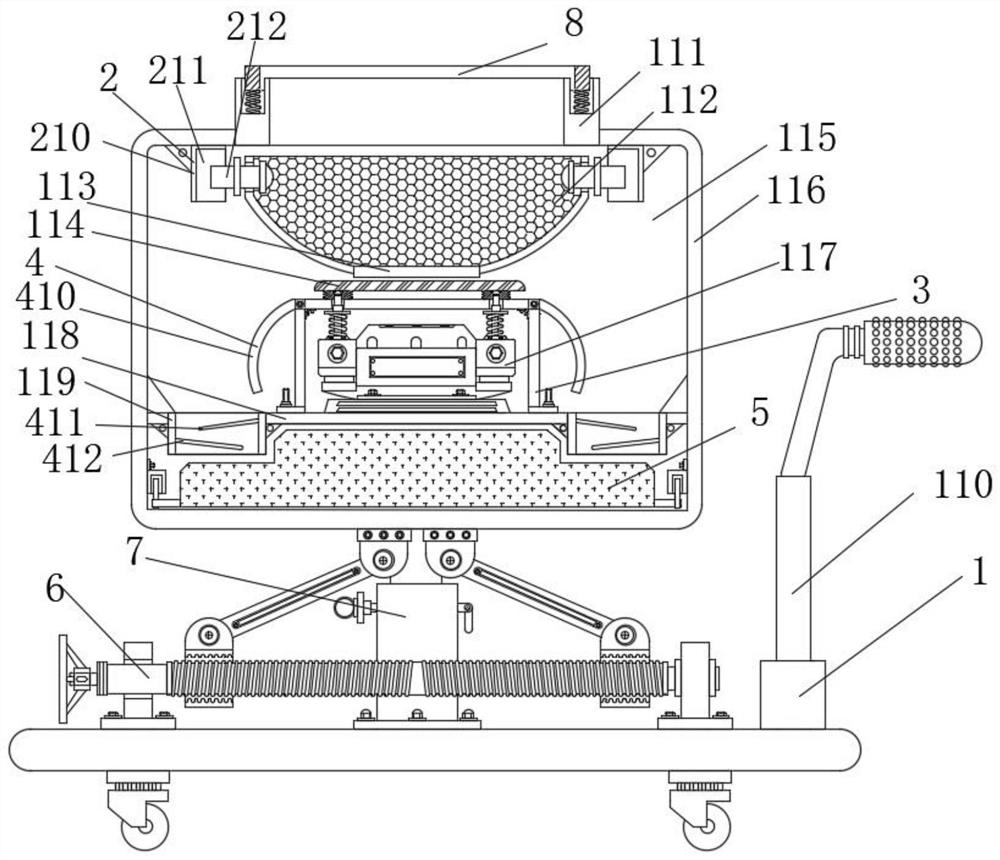

Face steaming device

The invention relates to a face steaming device. A water groove (4) is formed in the center position inside a base (1); a switch (3) and an indicating lamp (8) are arranged on the base; a power supply wire (5) is connected onto the side wall of the base; the other end of the power supply wire is connected with a plug (6); a middle cover (7) is movably connected with the front end of the base; the bottom end shape of a face shielding cover (9) is matched with the top end shape of a face cover (2); the bottom end of the face shielding cover (9) is movably connected with the top end of the face cover (2); the face shielding cover can forwards and backwards turn at the top end of the face cover (2); a control device (10) is arranged on the base; an infrared detection module is electrically connected with the control module after passing through a displacement module and a comparison module. In the face steaming process, the face steaming device can be automatically closed or opened according to the leaving or place taking time of a user; convenience and practicability are realized; the face steaming effect is good; after the face steaming is completed, the face cover can be shielded; the effect of protecting the face cover is achieved; dust can be prevented from falling onto the face cover.

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

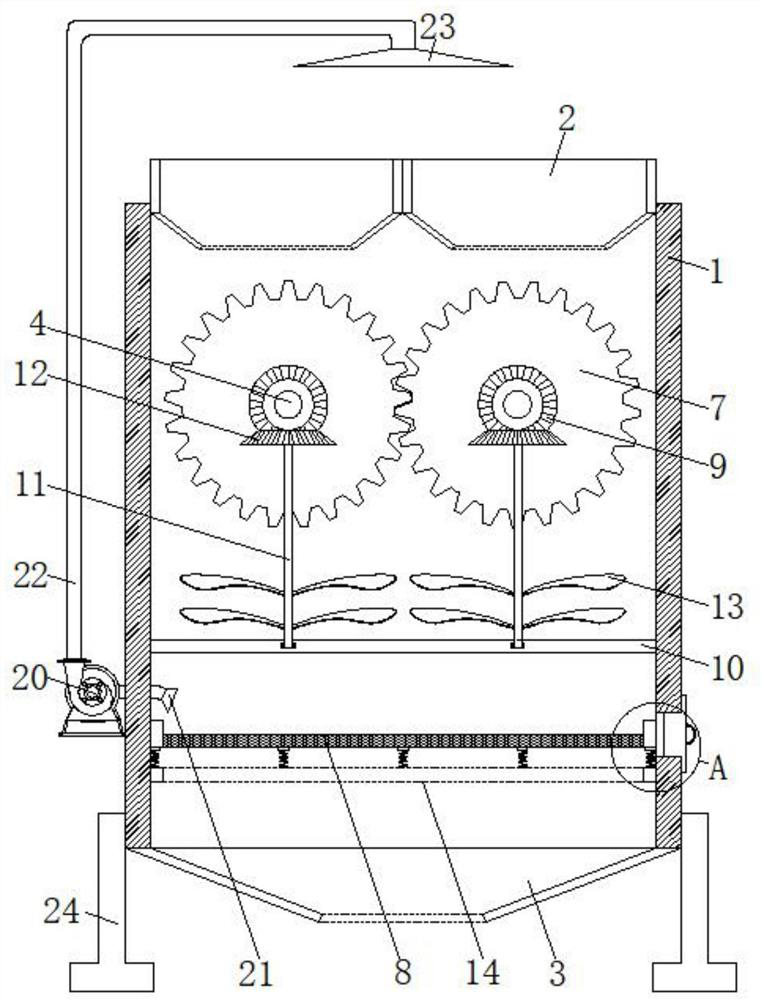

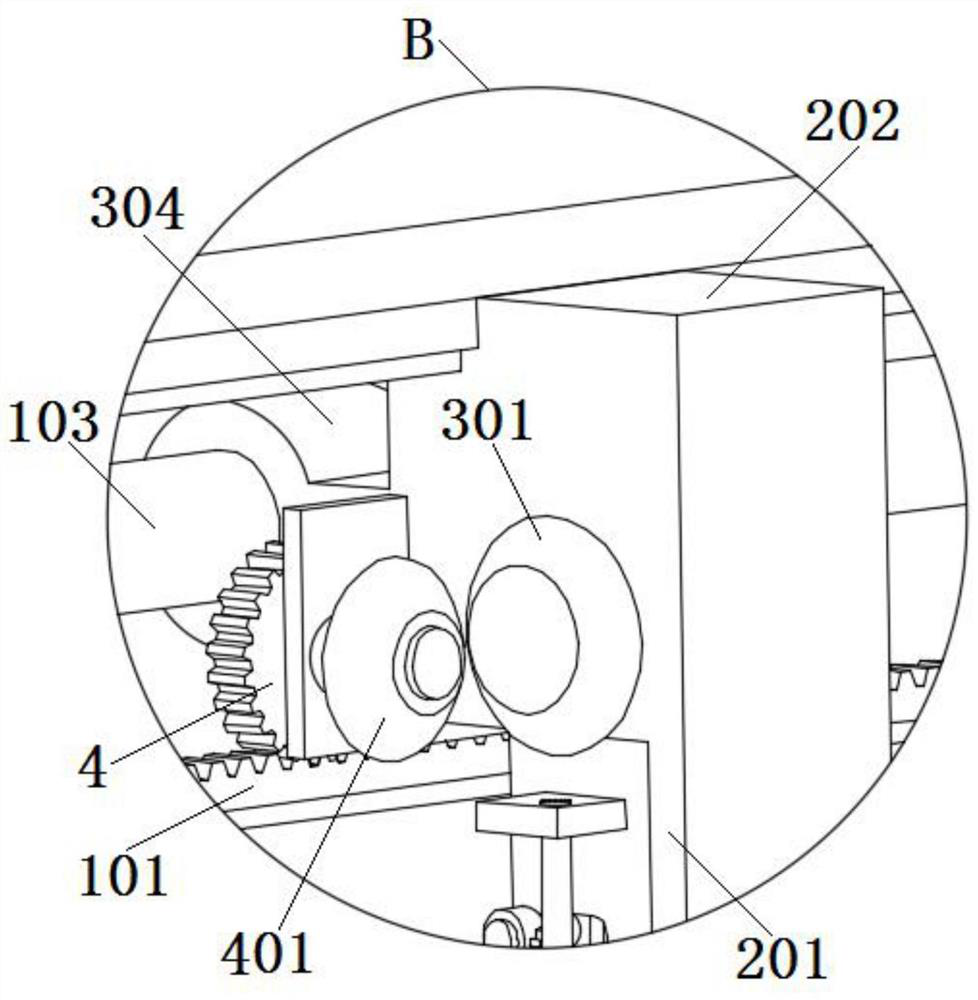

Raw material crushing device for hardware coating production

PendingCN113908920AImprove crushing effectImprove efficiencyDirt cleaningGrain treatmentsElectric machineGear wheel

The invention discloses a raw material crushing device for hardware coating production, which comprises a crushing cylinder; the top and the bottom of the crushing cylinder are connected with two feeding hoppers and a discharging hopper correspondingly; the two feeding hoppers are symmetrically arranged in an abutting mode; two symmetrically-arranged power shafts are rotatably installed on the inner wall of the crushing cylinder; a crushing motor is installed on the front face of the crushing cylinder; and an output end of the crushing motor is fixedly connected with the end of one power shaft. According to the raw material crushing device for the hardware coating production provided by the invention, in the crushing process of a crushing roller, the power shafts of the crushing device drive a first bevel gear to rotate, the first bevel gear drives a second bevel gear to rotate, then a linkage rod drives crushing rotating blades to crush and stir preliminarily crushed raw materials, on one hand, the crushing effect and efficiency of the crushing device are enhanced on the other hand, loss caused by the fact that the crushing rotating blades directly crush the blocky raw materials is avoided, and the crushed raw materials are screened through a screening net hopper so that the needed crushed raw materials can be obtained.

Owner:澳昌(武汉)生态科技有限公司

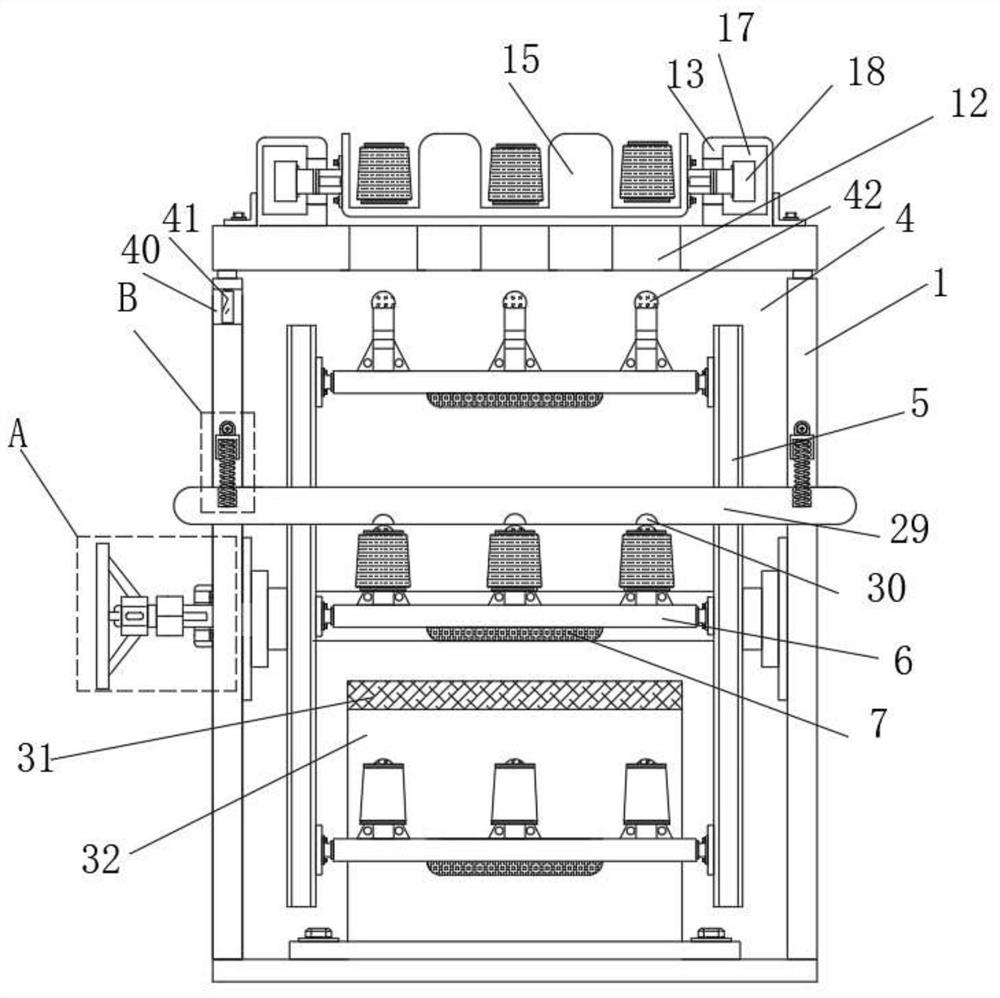

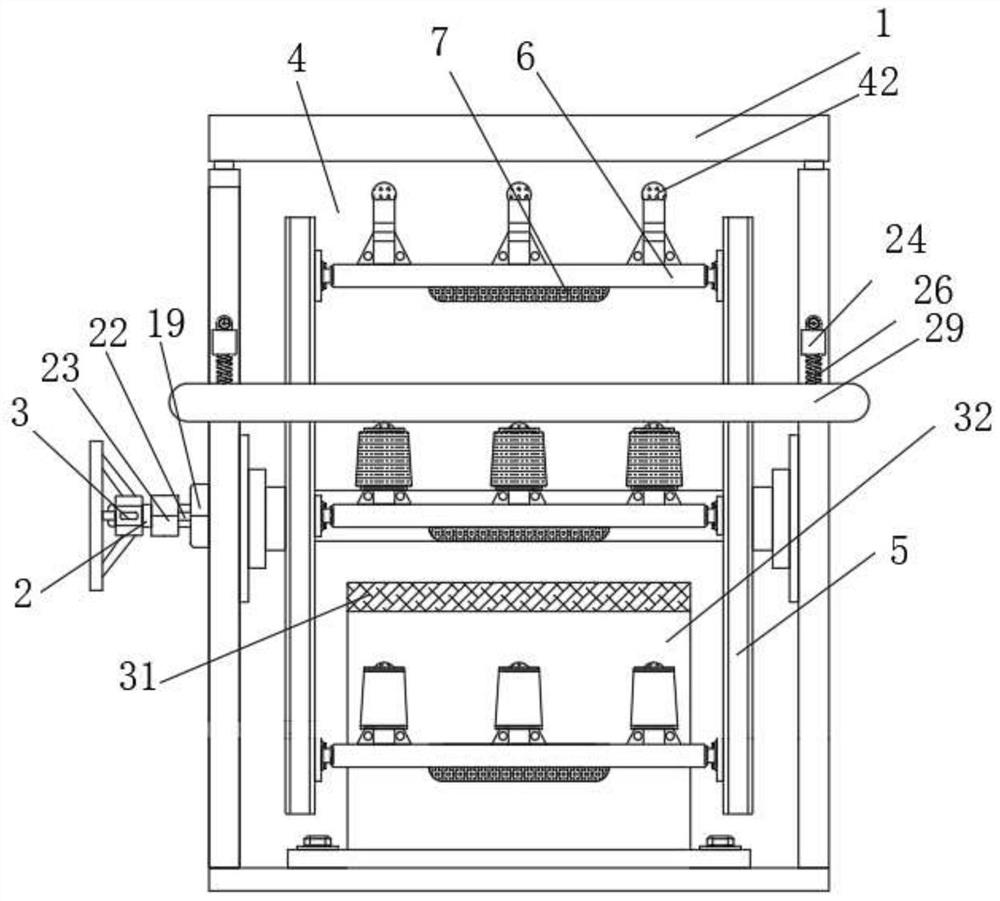

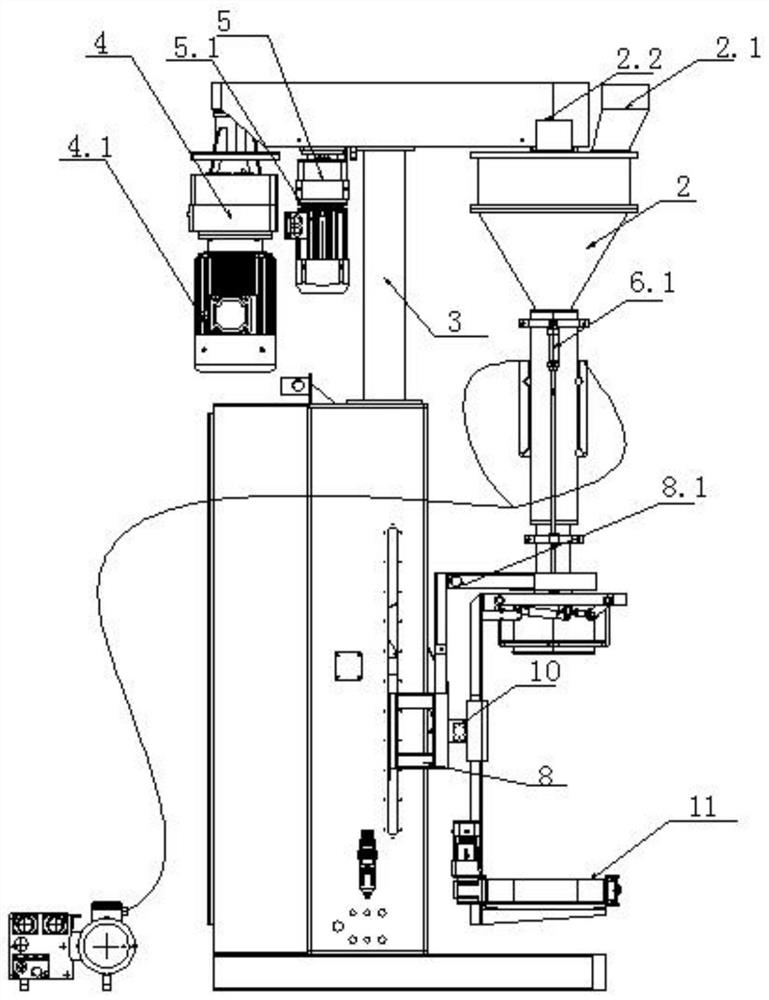

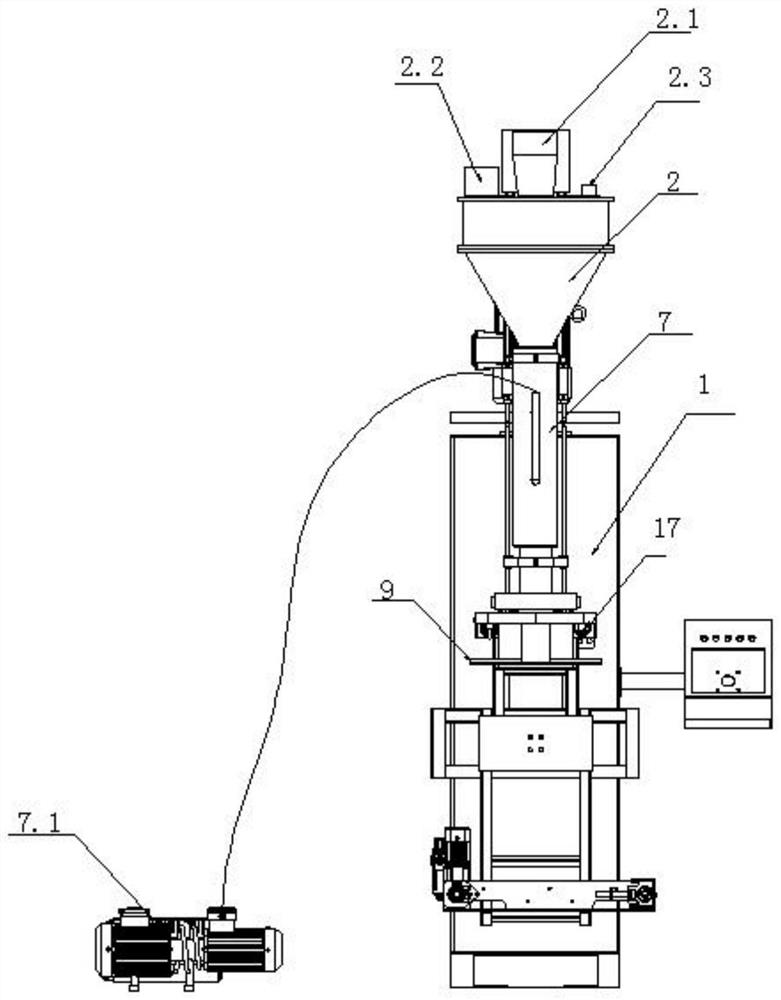

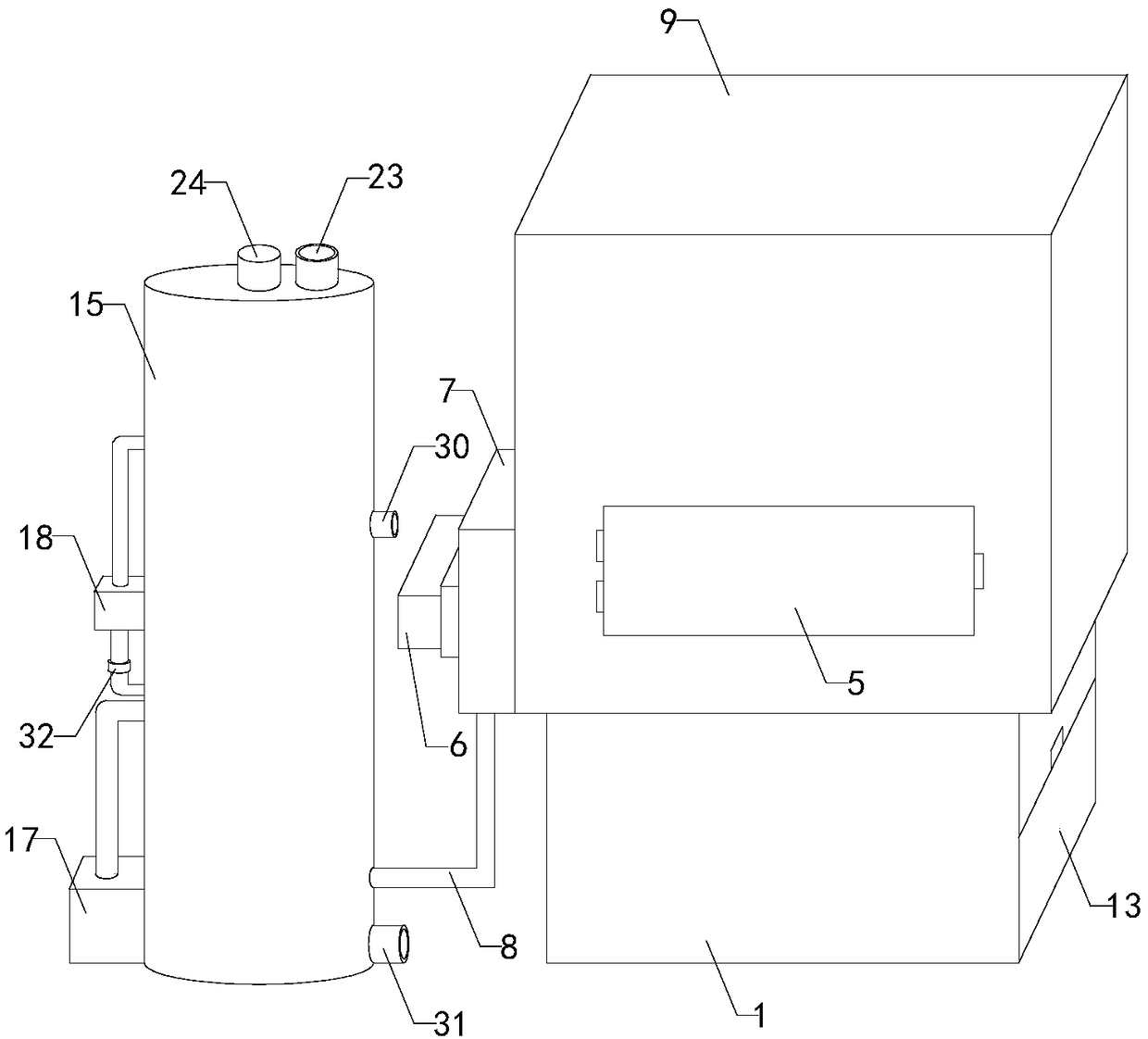

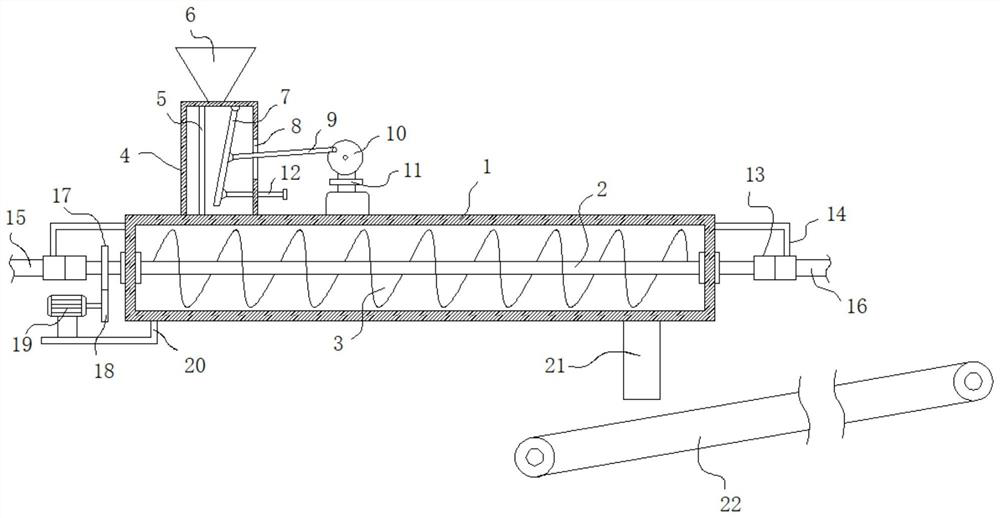

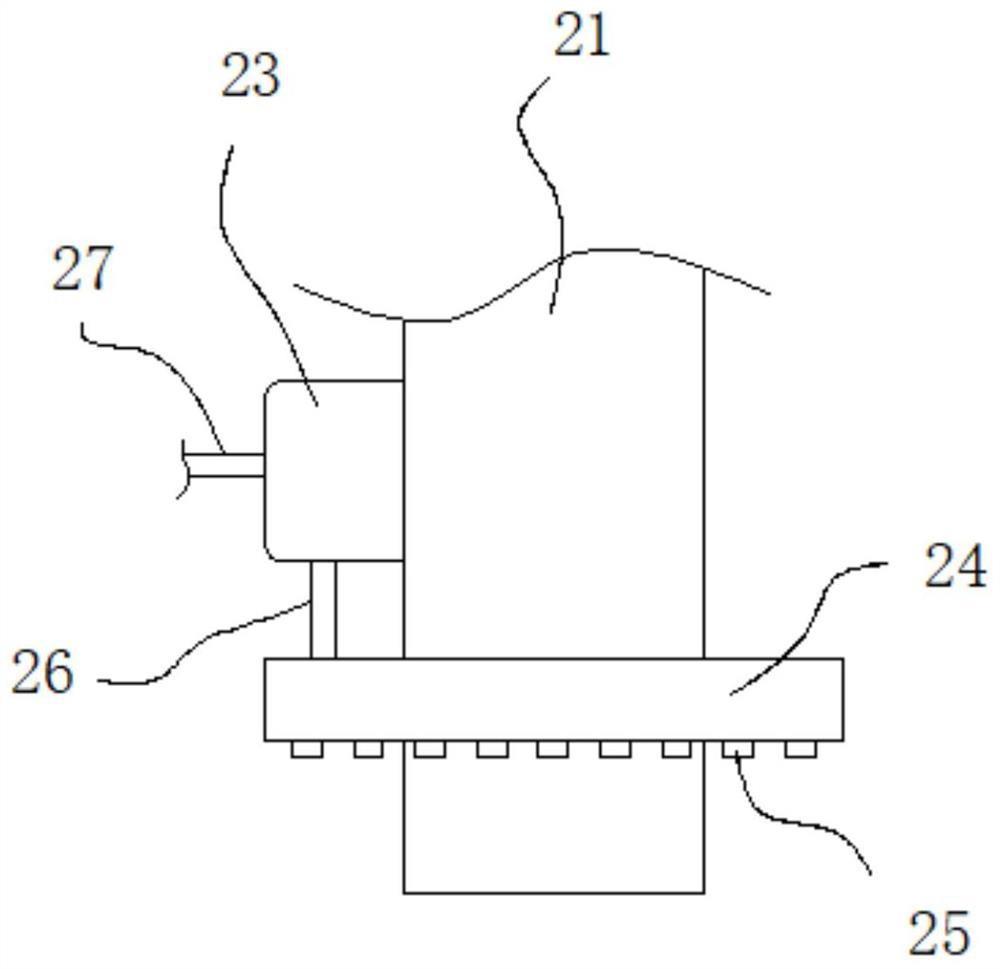

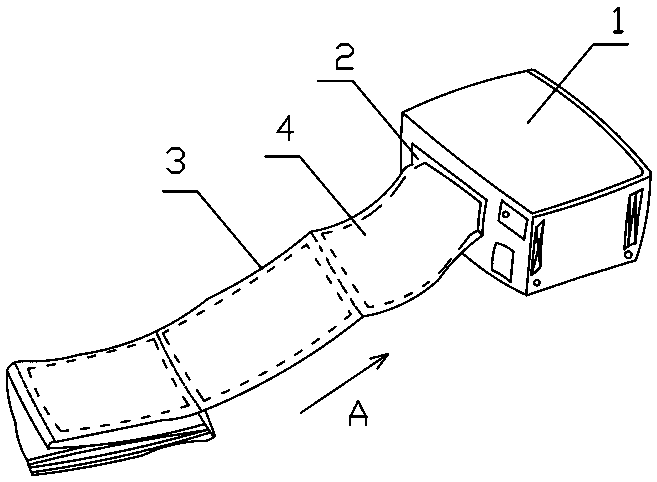

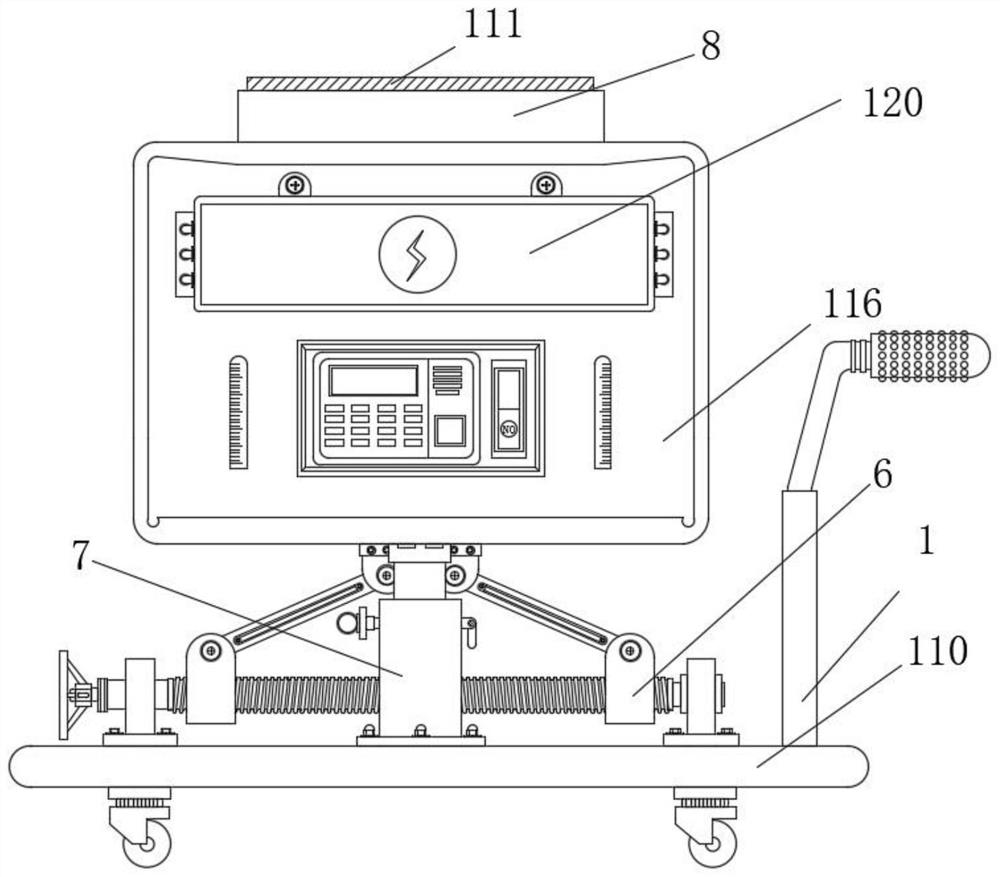

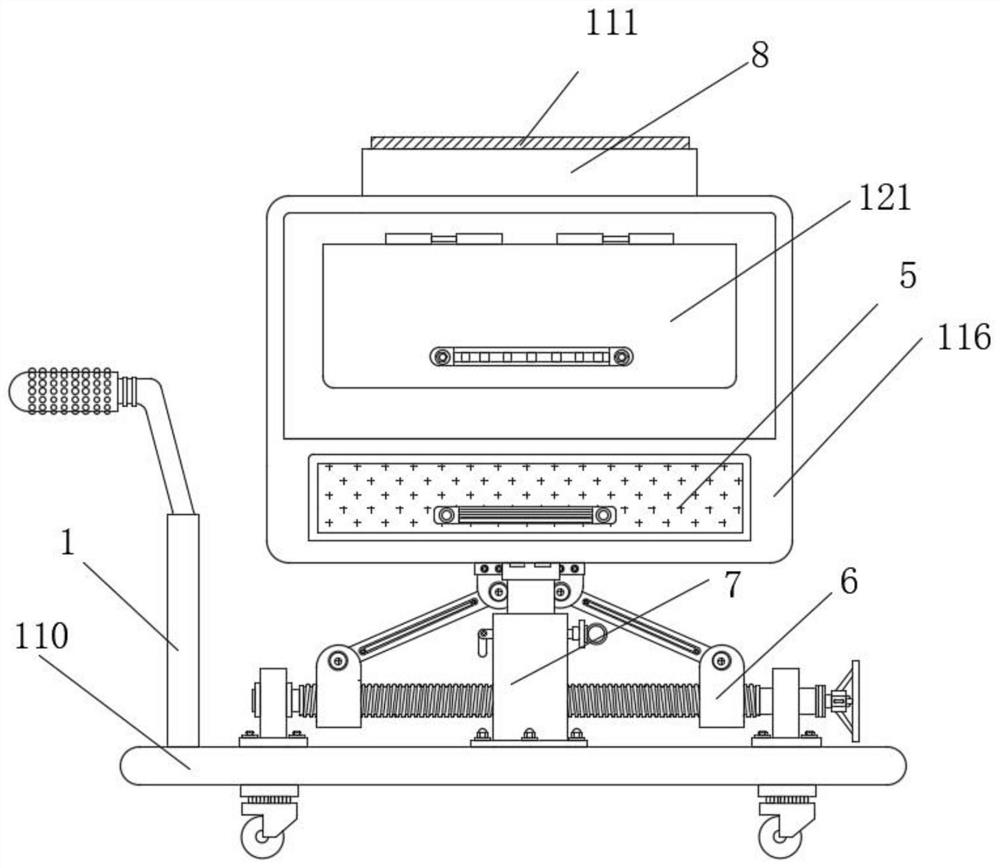

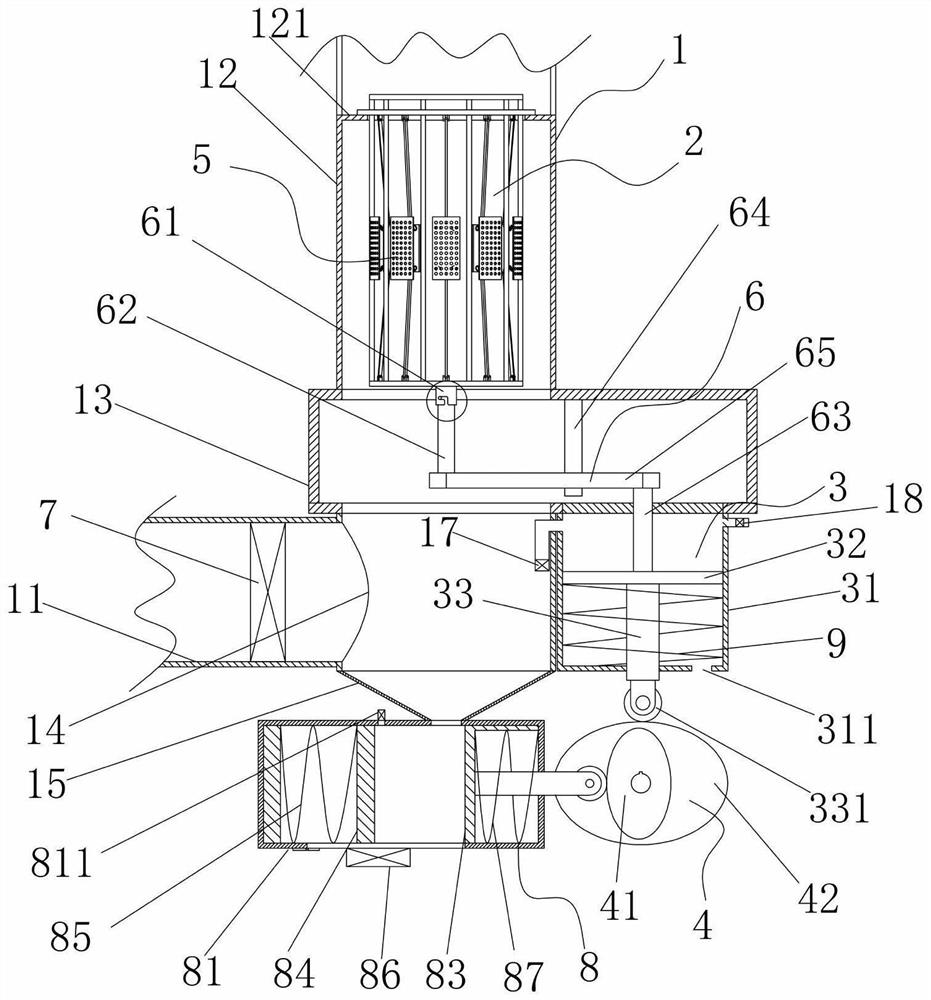

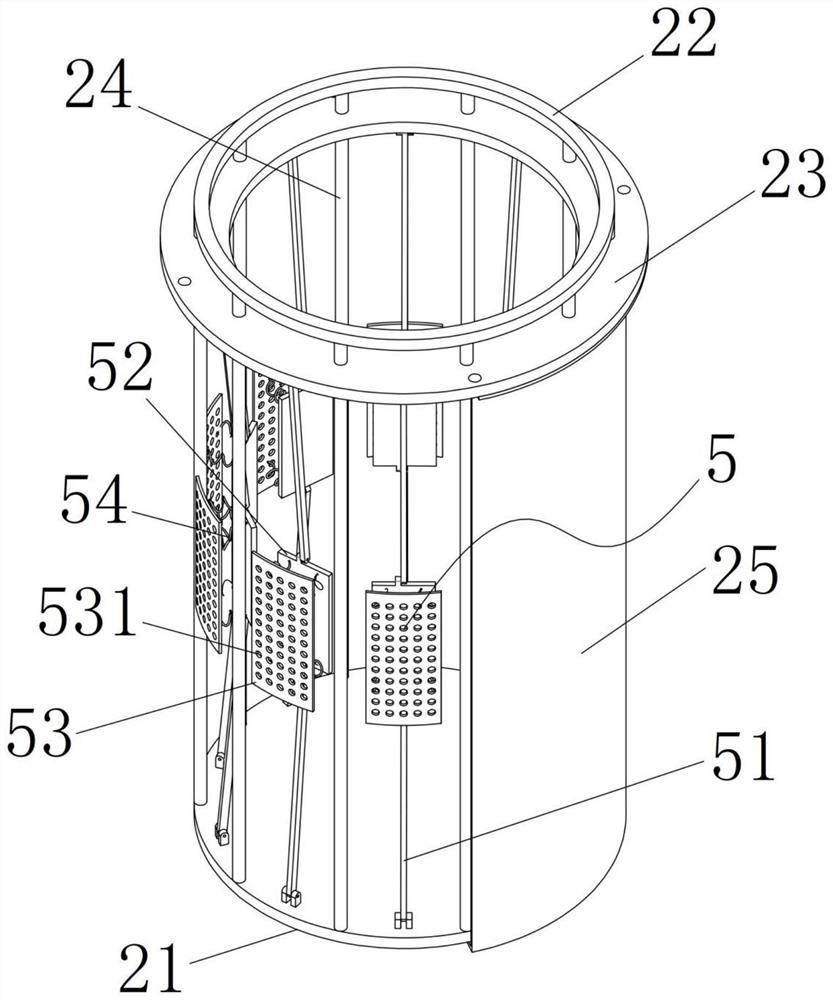

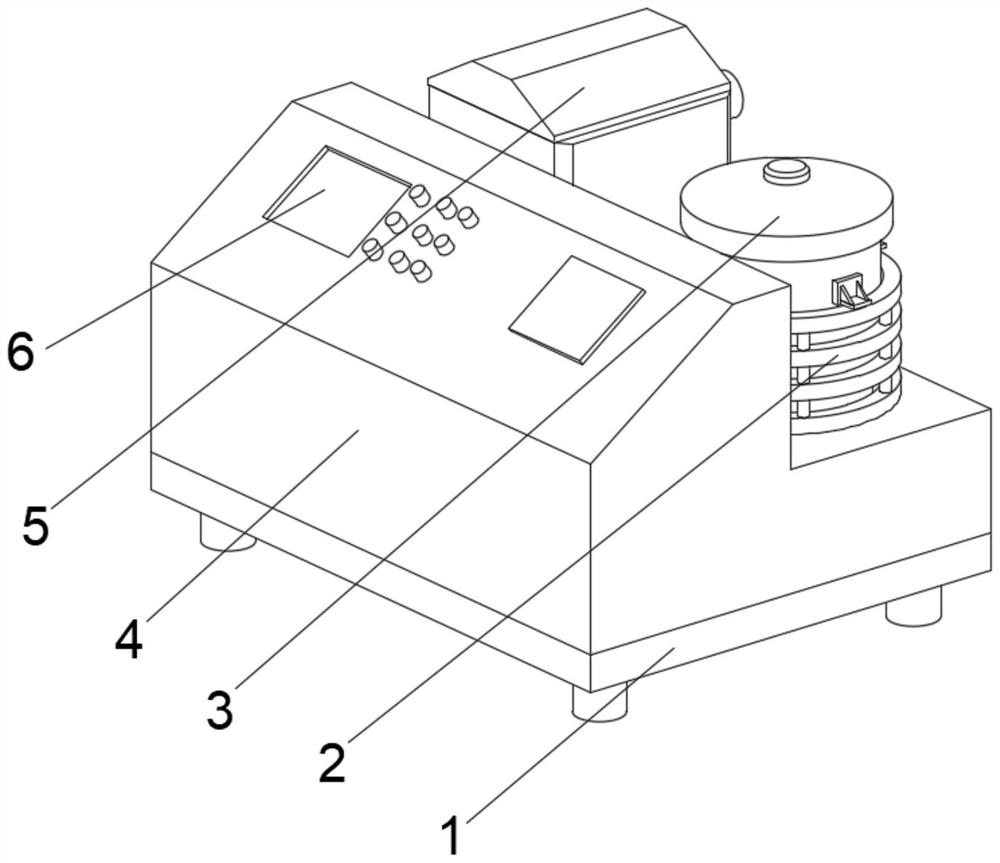

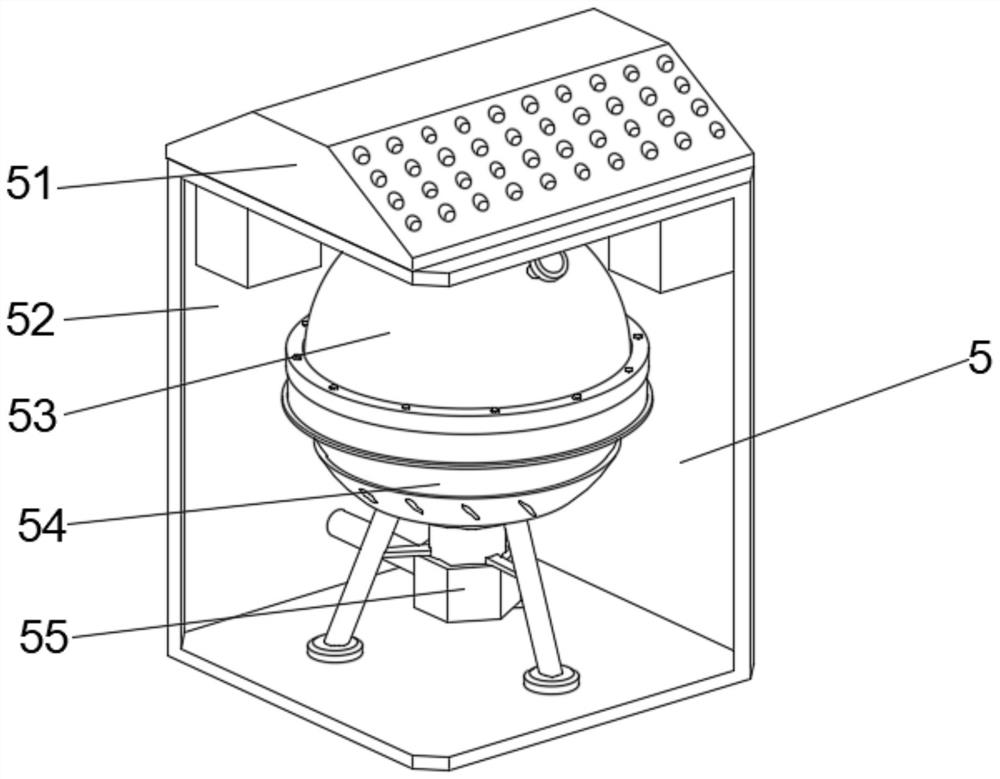

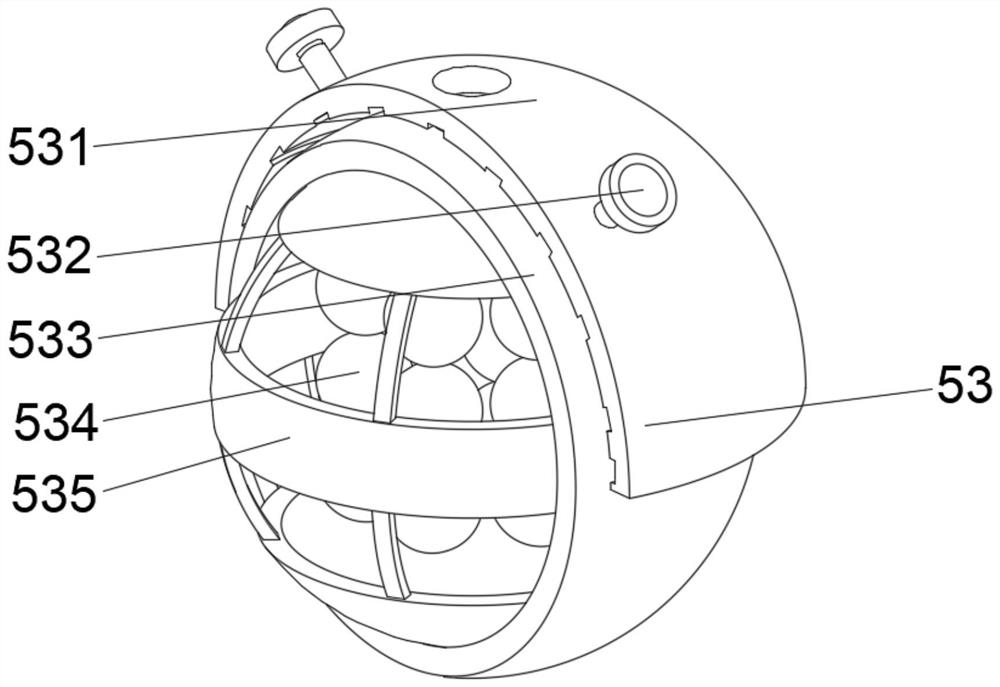

Small automatic degassing packaging machine

PendingCN112141405AMeet quantitativeAvoid dust collectionPackaging under vacuum/special atmosphereSolid materialDust controlProcess engineering

The invention relates to a small automatic degassing packaging machine. The small automatic degassing packaging machine comprises a machine box and a stock bin. A stand column is arranged on the machine box. A feeding mechanism and a stirring mechanism are arranged on the stand column. The stirring mechanism is arranged in the stock bin. A discharging port and a breathing port are formed in the stock bin. A material level device is arranged on the stock bin and used for monitoring the material amount in the stock bin. A discharging mechanism and an air extractor are arranged at the bottom of the stock bin. The air extractor is arranged on the outer ring of the discharging mechanism. The air extractor is connected with a vacuum pump. The small automatic degassing packaging machine is simplein structure, convenient to operate and high in safety coefficient. According to the small automatic degassing packaging machine, due to the arrangement of a dust removal opening, the dust raising situation in the powder packaging process can be effectively prevented, and the dust suction phenomenon of workers is avoided. By the adoption of the design that the air extractor and a weighing moduleoperate at the same time, air can be extracted and compacted while powdery substances are packaged in the packaging process of the packaging bag, and meanwhile quantitative packaging can be achieved.

Owner:无锡满意集成技术有限公司

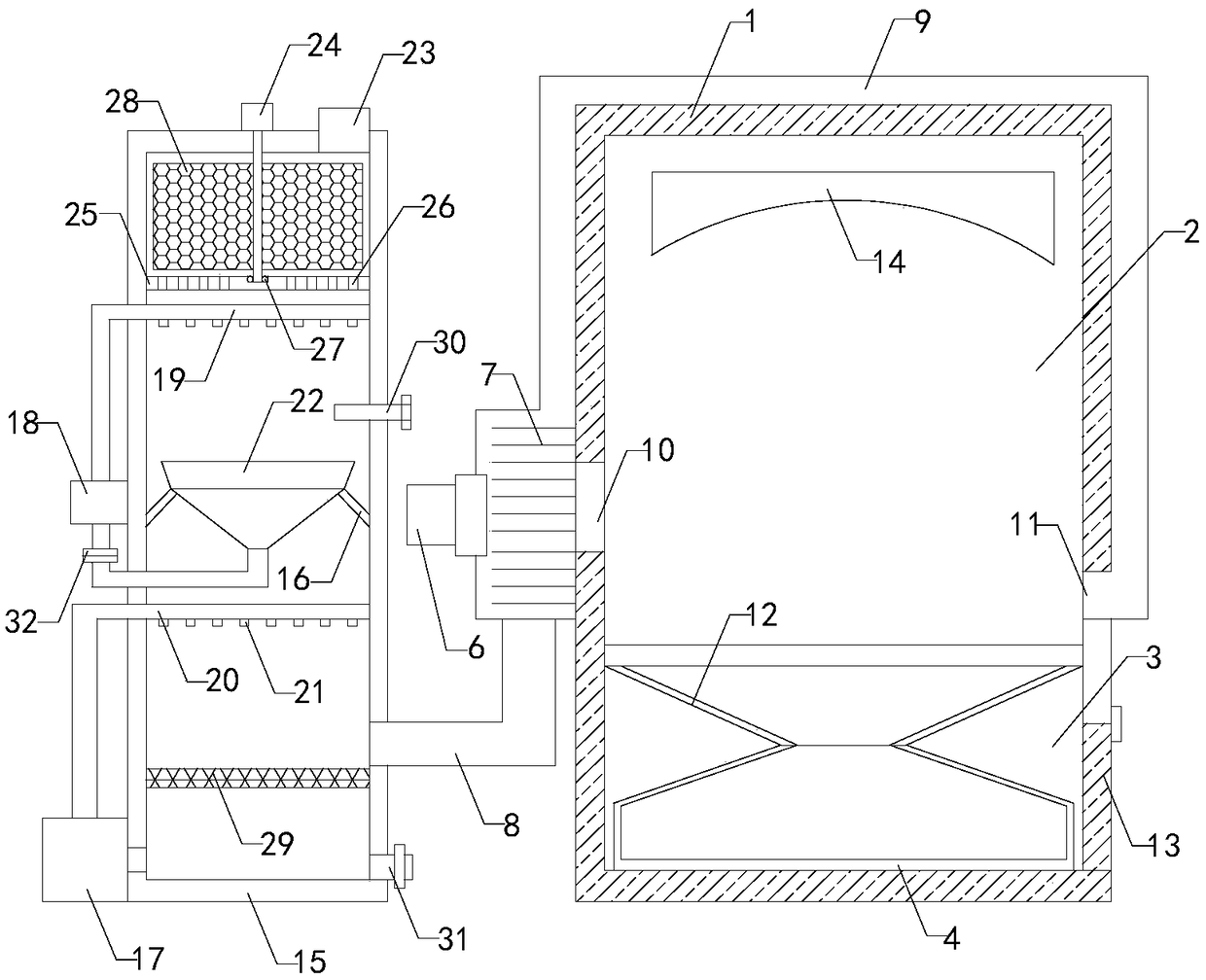

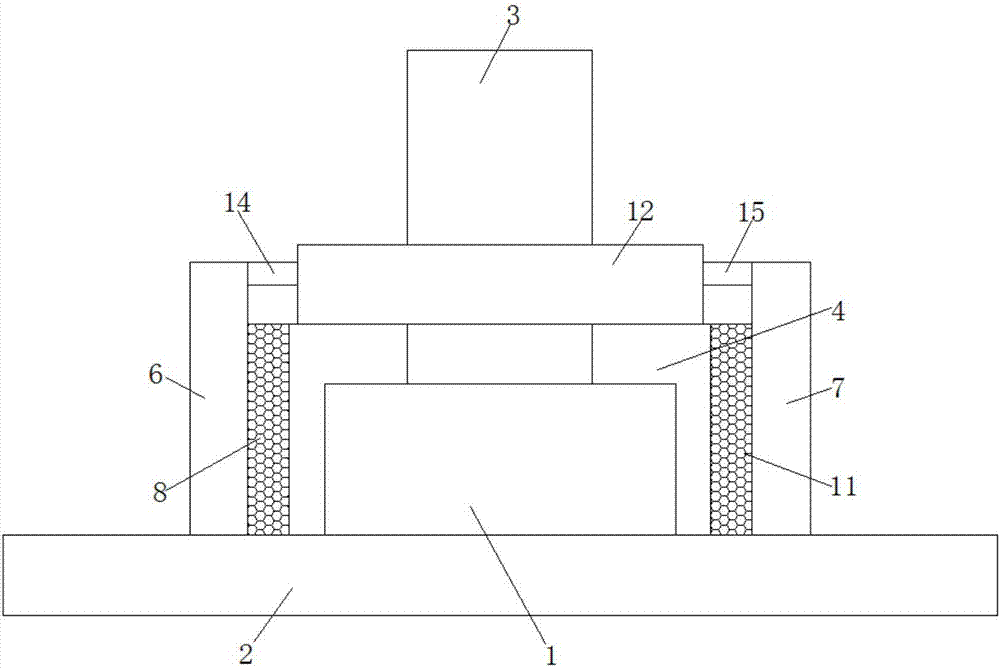

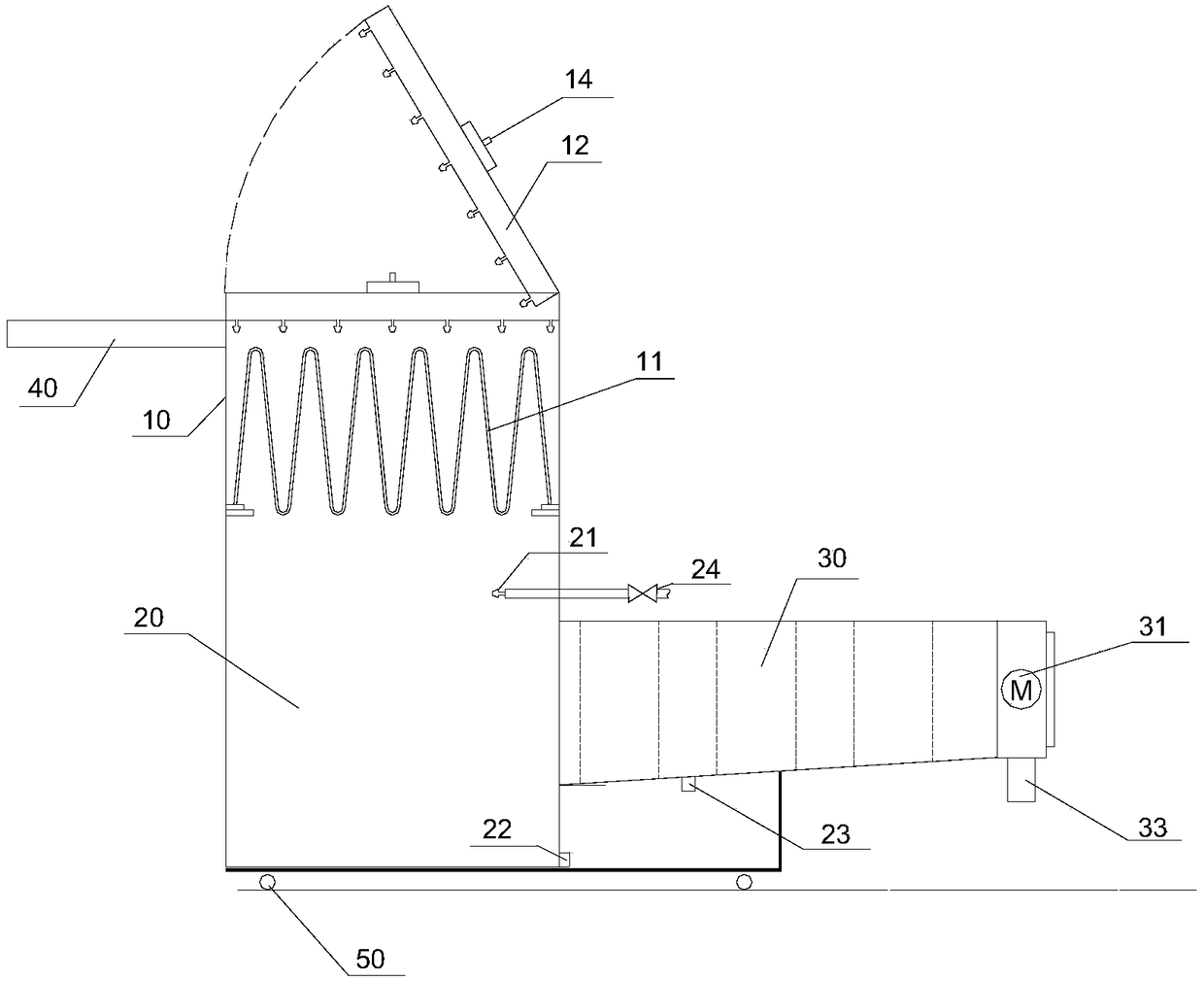

Multifunctional environment-friendly auxiliary heating furnace

InactiveCN108955279AImprove combustion efficiencyReduce pollutionCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to the technical field of heating furnace accessory devices, in particular to a multifunctional environment-friendly auxiliary heating furnace. Part of heat in smoke dust can bereused, and energy is saved; the combustion efficiency of a combustion object is improved, the conversion efficiency of a chemical energy to a heat energy conversion is improved, so that the practicability is improved; meanwhile, the situation that the soot in an ash removal drawer generates dust in a combustion cavity and an ash discharge cavity is prevented, the concentration of pollutants in the smoke dust in a smoke exhaust pipe is reduced, the pollution to the environment is reduced, and the use reliability is improved; the heating furnace comprises a furnace body, the furnace body is internally provided with the combustion cavity positioned at the upper part and the ash discharge cavity positioned at the bottom, and an ash discharge drawer is arranged at the bottom of the ash discharge cavity, and the front end of the furnace body is provided with an adding port communicating with the combustion cavity; and the heating furnace further comprises an air blower, an air preheater, aconnecting vent pipe, a smoke discharging box, an air inlet, an air outlet and an ash falling hopper, a clearing port is formed in the bottom of the right end of the furnace body, the clearing port communicates with the ash discharge cavity, and a baffle is arranged at the clearing port.

Owner:SUZHOU BIAOGAN INTPROP OPERATION CO LTD

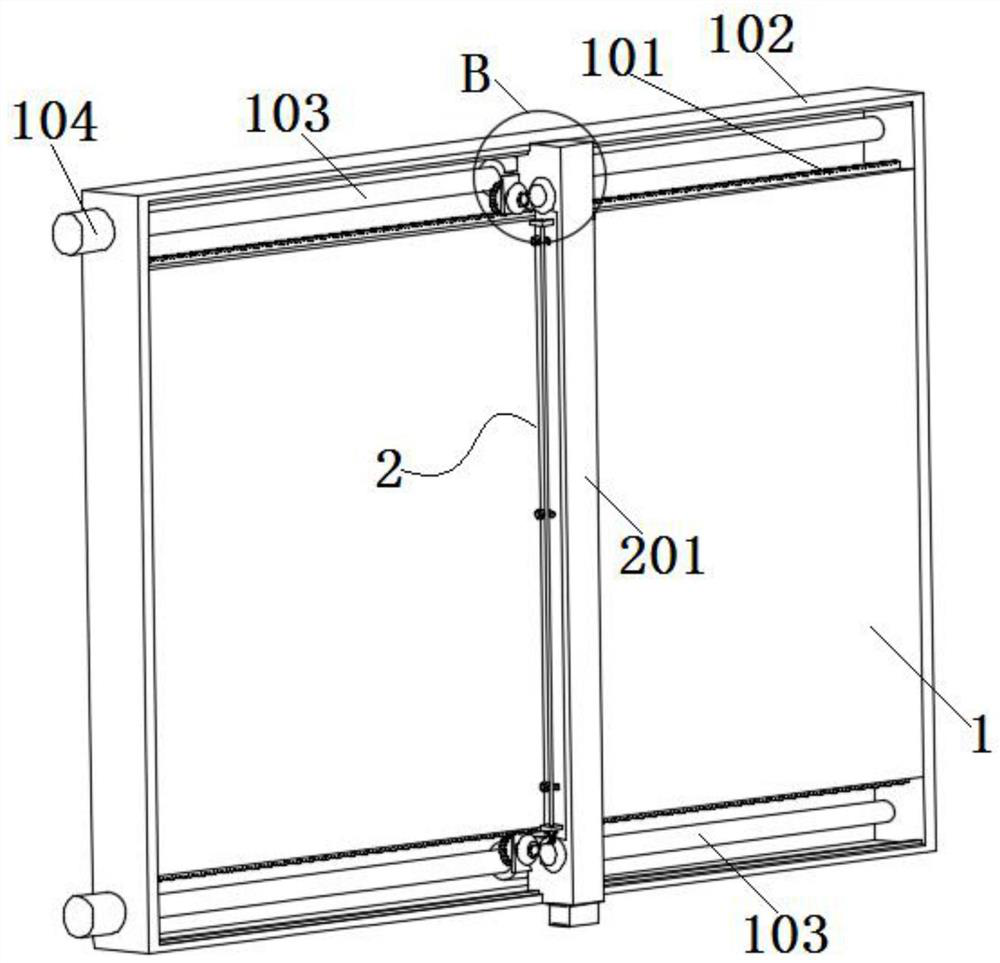

Rapid wiping device for intelligent blackboard and using method

InactiveCN112123981AAutomate cleaningImprove cleaning efficiencyBoard cleaning devicesDrive wheelDrive shaft

Owner:安徽文香信息技术有限公司

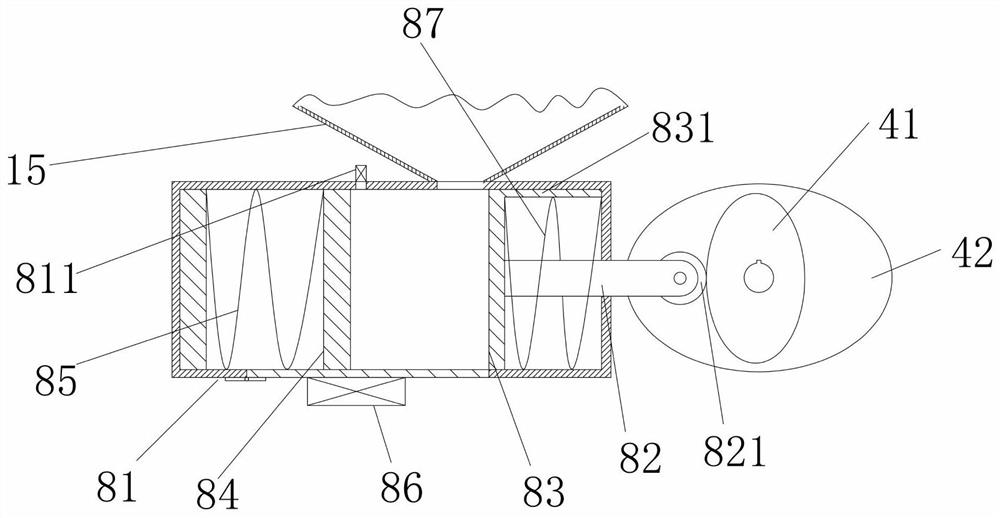

Industrial furnace coal cinder transfer equipment with thorough cooling function

InactiveCN112827541AAvoid High Temperature Pollution SituationsPrevent dustCleaning using liquidsGrain treatmentsThermodynamicsWater flow

The invention belongs to the field of coal cinder treatment, and particularly relates to industrial furnace coal cinder transfer equipment with a thorough cooling function. The industrial furnace coal cinder transfer equipment comprises a conveying pipe, the top of the conveying pipe is communicated with a crushing box, the top of the crushing box is communicated with a feeding hopper, and a first crushing plate is fixedly mounted on the left side of an inner cavity of the crushing box. According to the industrial furnace coal cinder transfer equipment with the thorough cooling function, a first motor drives a second crushing plate to continuously move in a reciprocating mode, and therefore crushing can be carried out on coal cinder through the first crushing plate and the second crushing plate, the fact that large particles exist is avoided, then the coal cinder enters the conveying pipe, conveying is carried out through rotation of a spiral blade, water enters through a water inlet pipe in the conveying process, entering water is discharged through a water discharging pipe, and therefore the flowing water flow can take away the temperature of the coal cinder, the crushed small-particle coal cinder can be thoroughly cooled, and the situation of high-temperature pollution caused by residual high temperature in the interior of the coal cinder is avoided.

Owner:袁萃

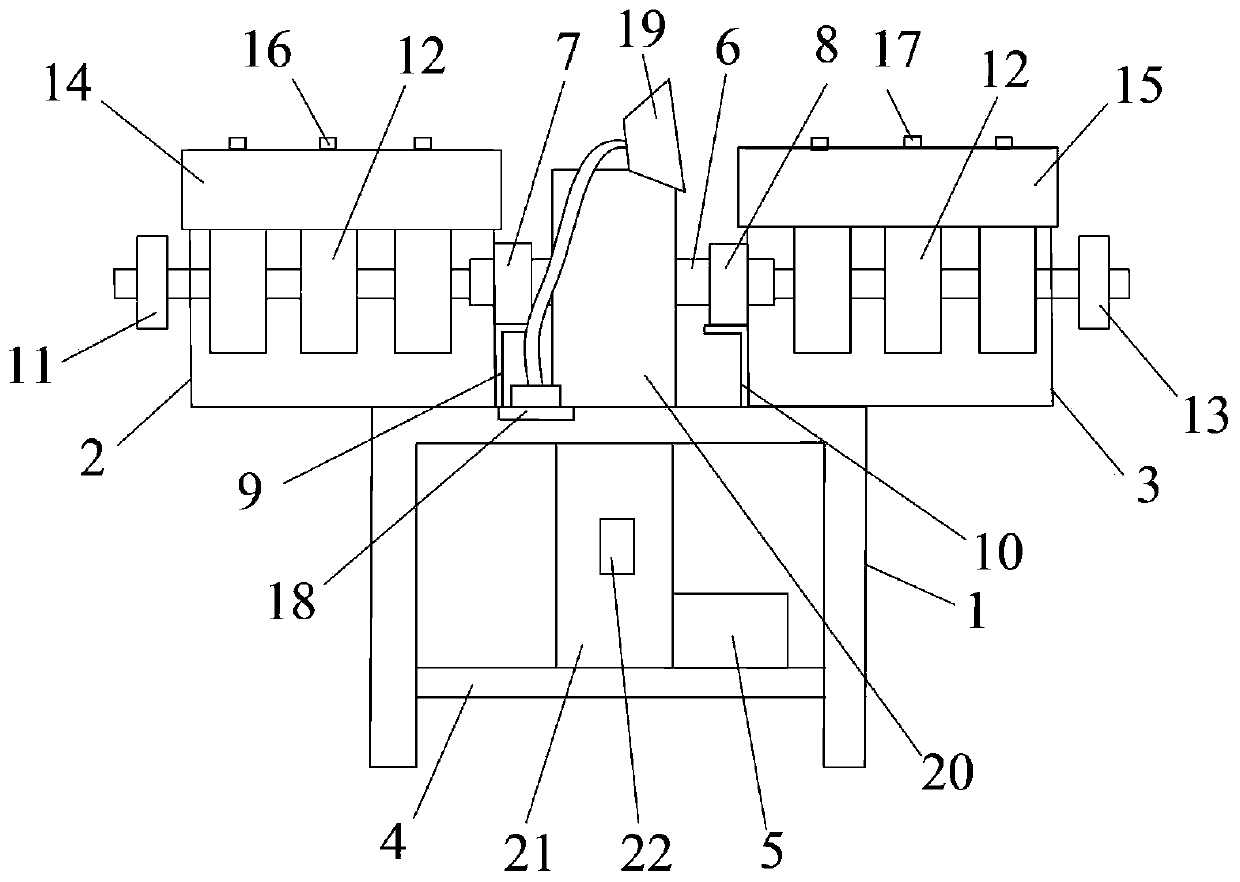

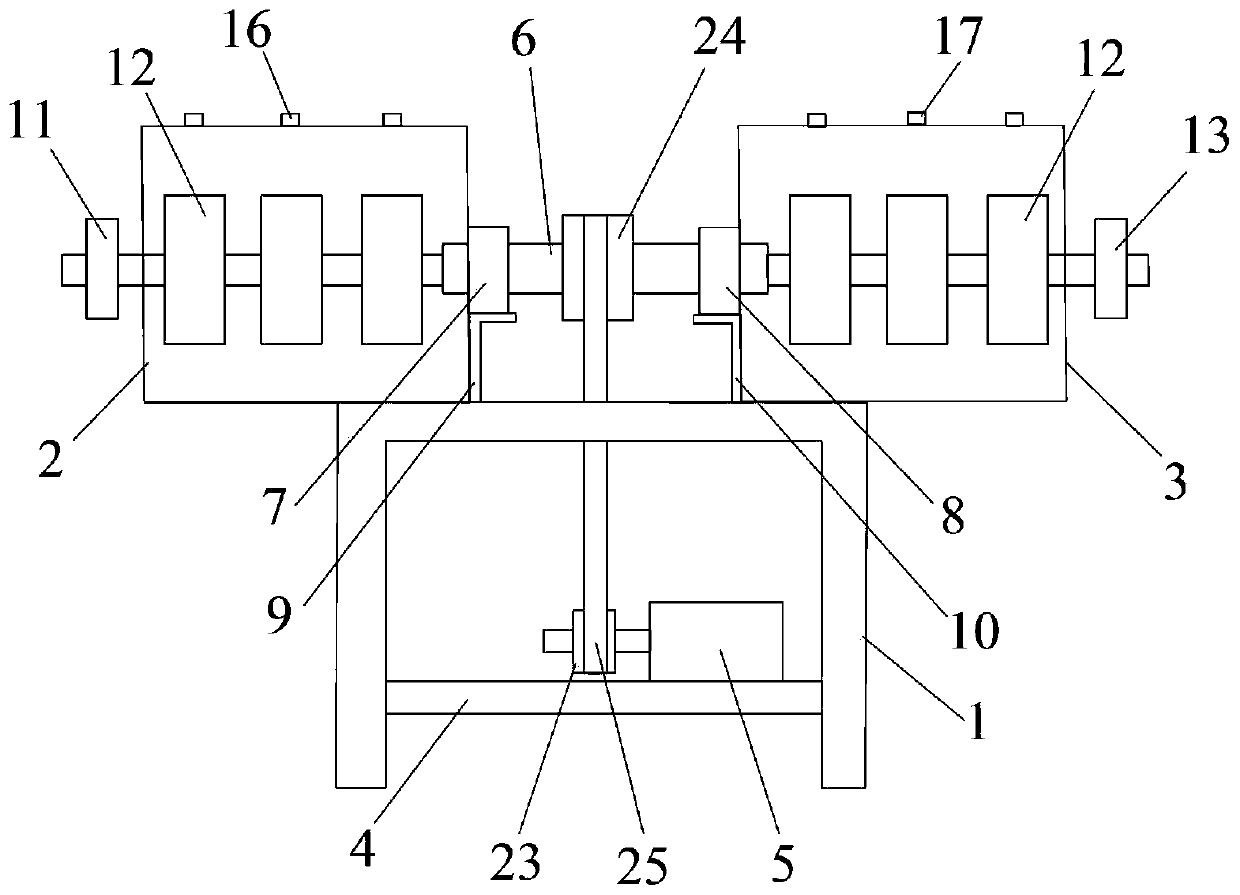

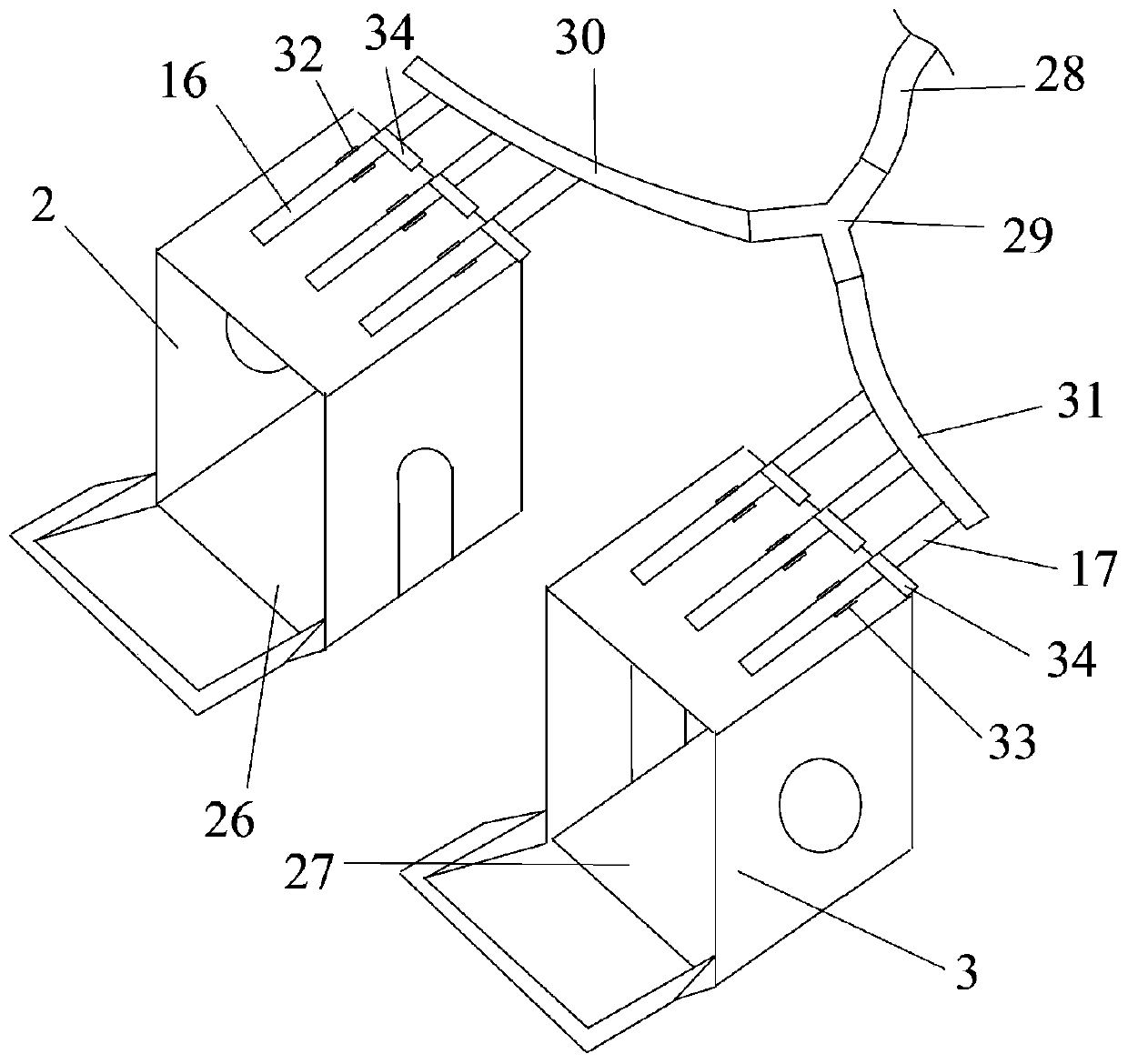

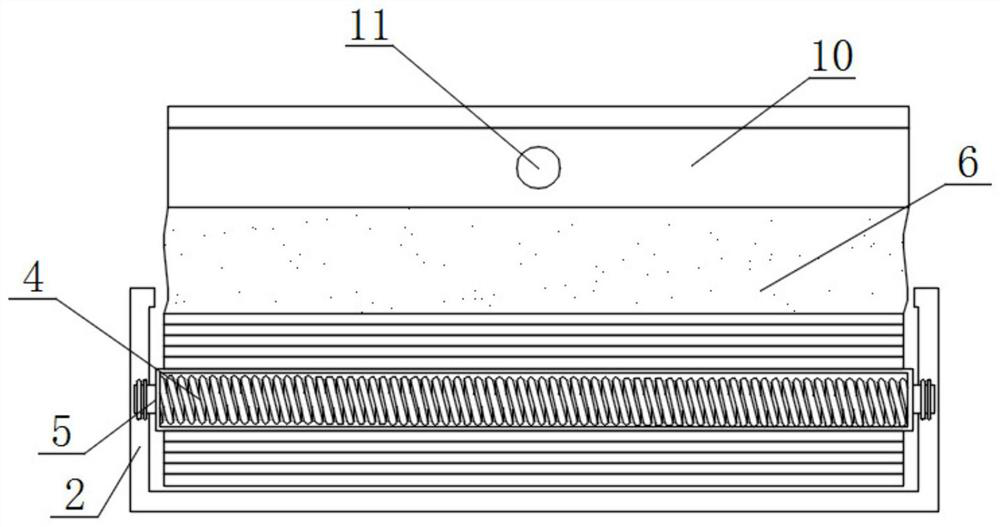

Jade grinding and polishing machine

PendingCN110228005AReduce wearPrevent dustGrinding carriagesPolishing machinesAgricultural engineeringMachining

The invention discloses a jade grinding and polishing machine, and relates to the technical field of jade machining. The two ends of the upper part of a main frame body are symmetrically provided witha left bearing pedestal and a right bearing pedestal, and the outer sides of the left bearing pedestal and the right bearing pedestal are symmetrically provided with a left cover body and a right cover body; the left bearing pedestal is internally provided with a left bearing, and the right bearing pedestal is internally provided with a right bearing; a main shaft is installed in the left bearingand the right bearing, and the two ends of the main shaft penetrate through the left cover body and the right cover body, and extend to outside separately; a plurality of grinding wheels are fixedlyarranged on the main shaft in a sleeved manner, and located in the left cover body or the right cover body; the mesh numbers of the multiple grinding wheels are increased from left to right in sequence, and the upper surfaces of the left cover body and the right cover body are each provided with a plurality of water supply holes; a water feeding component is used for spraying water to the corresponding grinding wheels through the water supply holes, and a flat wheel is fixedly installed at the leftmost end of the main shaft; and a polishing leather wheel is fixedly installed at the rightmost end of the main shaft. The machine is integrated with jade molding, grinding and polishing functions, and miniaturization of processing machinery is achieved; and the wear of the grinding wheels is reduced, and the health of users is benefited.

Owner:高创

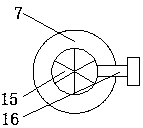

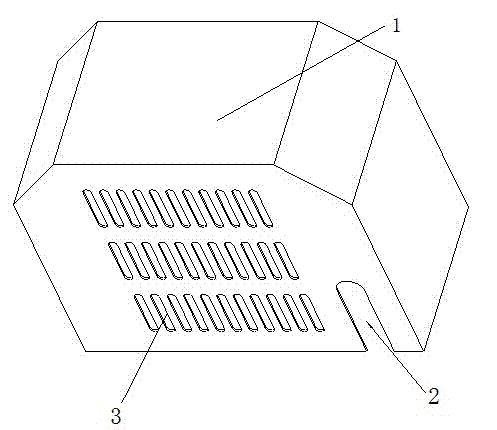

Novel radiator for notebook computer

InactiveCN106108382AAdequate heat dissipationPrevent dustOffice tablesFurniture partsEngineeringBevel gear

A new radiator for notebook computers, comprising a table body, table legs and a cooling device. The table body is provided with a transparent square opening up and down. The cooling device is located below the square opening and is fixed on the table leg. The above-mentioned heat dissipation device includes a shell, blades, and a motor. The shell is not provided with a bottom plate, and a through hole located directly below the square opening is opened on the top plate. A blade is placed in the through hole, and the blade is arranged at the same On the rotating shaft, the first bevel gear is fixed on the side plate of the housing and meshes with the second bevel gear. The second bevel gear is installed on the output shaft of the motor, and the motor is fixed on the other side of the housing. onboard and controlled by a wireless controller. The heat sink is not restricted by the lower space of the notebook, can fully dissipate heat, and can be used for a long time without accumulating a large amount of dust. At the same time, the blades do not protrude from the housing, so the user's legs will not be scratched or injured, or children who will get into the bottom of the table body.

Owner:LUOYANG JIUDING ELECTRONICS TECH

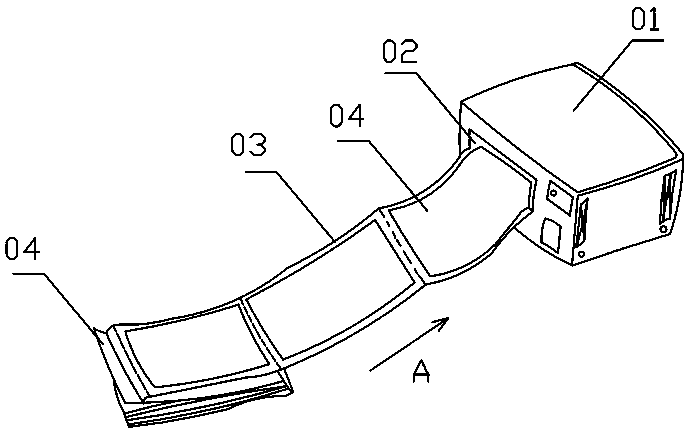

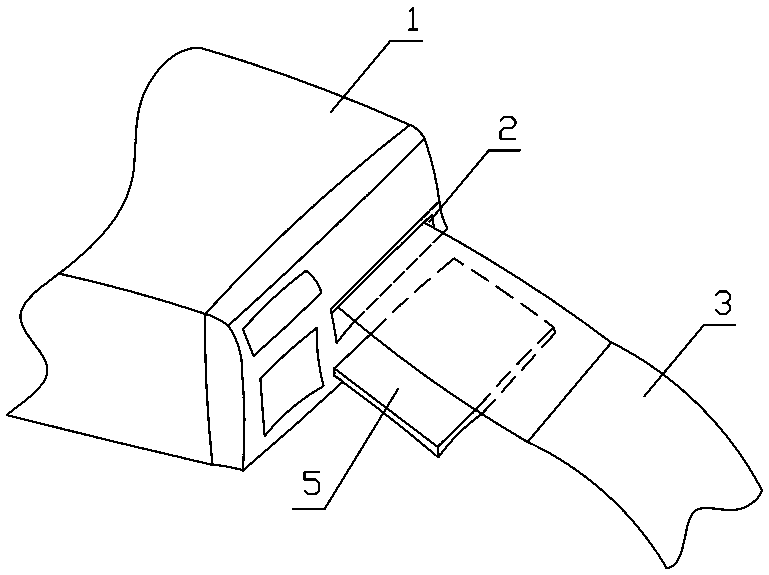

Method for preventing label paper from separating from label and paper jamming of thermal printer

InactiveCN111169176APrevent dustNot easy to degummingOther printing apparatusEngineeringMechanical engineering

The invention discloses a method for effectively preventing label paper from separating from a label and paper jamming of a thermal printer. The method comprises the following steps that when the paper is fed into the printer, a paper feeding mode of reversing the label paper (3) is adopted to feed the paper, namely, the label paper (3) is arranged above and the label (4) is arranged below when aworker views in the paper feeding direction; and under the paper feeding mode, the positions of a paper feeding rotating wheel and a printing head of the printer are changed in a matched mode, namely,the paper feeding rotating wheel and the printing head of the printer are arranged on one side close to the bottom of the printer, and the printing direction of the printing head faces the top of theprinter. A paper inlet (2) of the printer is also provided with a mirror (5), and the reflecting surface of the mirror (5) is upwards aligned to the lower surface of the label paper (3) at the paperinlet (2), and is used for reflecting the information of the label (4) on the label paper (3). The mirror (5) is of a drawer-type structure and is arranged at the bottom of the printer.

Owner:苏少中

X-axis motor cover with screw rod engraving machine

InactiveCN103401340APrevent dustImprove stabilitySupports/enclosures/casingsProduct processingProcessing accuracy

The invention discloses an X-axis motor cover with a screw rod engraving machine. The X-axis motor cover is manufactured from a cold-rolled sheet through welding, and is characterized by comprising a motor cover main body, wherein the motor cover main body is provided with an electric wire discharge outlet, and the motor cover main body is further provided with heat emission holes. The X-axis motor cover disclosed by the invention can be used for effectively protecting a motor from being damaged, playing a role in preventing dust, enabling the motor to be more stable in a processing process, improving the stability of the motor, and ensuring the product processing precision.

Owner:KUNSHAN ETEK METAL IND

Solid waste collecting device for camellia seed deep processing

InactiveCN111849626AGood stabilityProtect the working environmentSievingScreeningElectric machineryAgricultural engineering

The invention relates to the technical field of rapeseed processing. The solid waste collecting device for camellia seed deep processing comprises a base, the recycling machine comprises a recycling machine body, the recycling machine body comprises a movable base, a processing box is arranged at the top end of the movable base, a collecting bin is formed in the processing box, a supporting plateis fixedly installed on the inner wall of the collecting bin, and an oscillating motor is fixedly installed at the top end of the supporting plate. According to the invention, an arc-shaped filter screen, an oscillating motor and a limiting mechanism are arranged; therefore, crushed camellia seeds and camellia shells are driven by the oscillating motor to be separated in the arc-shaped filter screen; meanwhile, crushed rapeseeds are collected and recycled, resources can be utilized more reasonably, meanwhile, a magnet plate and an iron sheet are attracted, a worker can disassemble and clean the arc-shaped filter screen conveniently, meanwhile, a limiting mechanism can prevent the arc-shaped filter screen from shaking around due to vibration, and the stability of the device is better.

Owner:湖南泥头山油茶开发有限公司

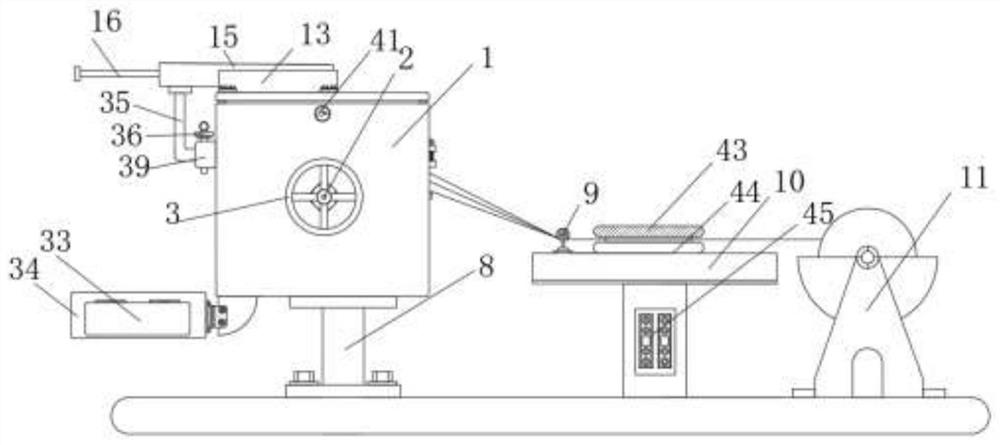

Anti-rust device for PC steel strand

ActiveCN114074054AImprove permeabilityImprove oiling efficiencyLiquid surface applicatorsCleaning using toolsOil pumpFront cover

The invention provides a PC steel strand rust prevention device which comprises a cleaning tank, the cleaning tank is fixed to the left side of the interior of a shell, the front face of the shell is fixedly connected with a front cover through a hinge, and the opening direction of the front cover faces the upper portion of the front face; the design of am oil groove, an inner cylinder and an oil pump is adopted, rust-proof oil is pumped into the inner cylinder through the oil pump, the pressure of the rust-proof oil is increased through the pressure generated when the oil pump works, and in the steel strand transferring process, the rust-proof oil with the pressure can better permeate into an inner core of a steel strand, so that the steel strand is fully lubricated, and the oiling efficiency of the steel strand is effectively improved.

Owner:武汉钢铁江北集团金属制品有限公司

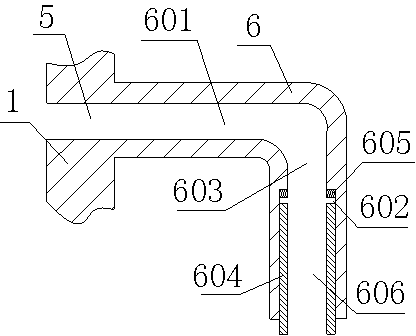

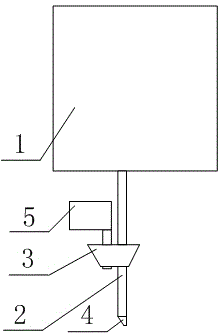

Dustproof powdery medicament material packing mechanism

InactiveCN104908984AAvoid Churn SituationsAvoid contactSolid materialPackaging automatic controlEngineeringBottle

The invention discloses a dustproof powdery medicament material packing mechanism, and mainly solves the problems that the precision of packing is low, and the powdery medicament is wasted. The packing mechanism comprises a powdery material groove (1), a powdery material pipe (2) and a powdery material pipe on-off controlling mechanism arranged in the powdery material pipe (2). The packing mechanism is characterized in that the bottom end of the powdery material pipe (2) is provided with a cone-shaped sealing piece (3), the powdery material pipe (2) penetrates through the cone-shaped sealing piece (3), the bottom end of the powdery material pipe (2) is provided with a material outlet (4), and the cone-shaped sealing piece (3) is further provided with an air sucking device (5) used for sucking air in a packing bottle. The dustproof powdery medicament material packing mechanism has the advantages that the locating precision of the position is high, and the cost is low.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

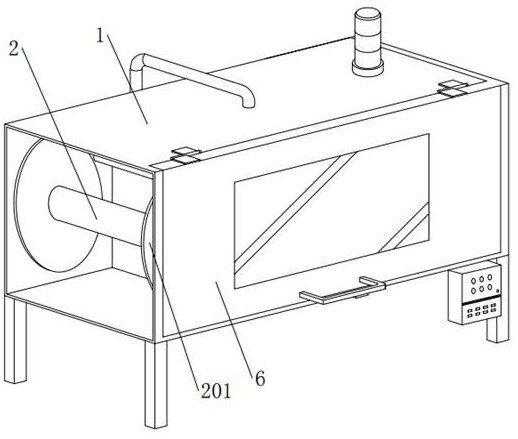

Dust removal and waste recovery device used in garment processing

ActiveCN109112811APrevent dustAvoid wasting resourcesMechanical cleaningPressure cleaningEngineeringWaste recovery

The invention discloses a dust removal and waste recovery device used in garment processing. The device comprises a work bench. The two sides of the bottom of the work bench are fixedly connected to support legs. The top of the work bench is provided with openings equidistantly. The upper portion and the lower portion of the front side of the work bench are provided with punching holes. By using the dust removal and waste recovery device used in the garment processing, through the cooperation usage of the work bench, a first telescopic plate, a moving rod, a connecting ring, a short plate, a bolt, a first motor, a pressing plate, a cutting disk, a shell, a suction fan, a fixed shell, a first hydraulic cylinder, balancing weight, a connecting plate, a fixing plate, a hairbrush, a long plate, a top plate, a second hydraulic cylinder, a sponge ring, a second motor, a leakage cylinder, a fixed block, a spring, a semicircular plate, a short rod and a hair dryer, during garment processing, dust on garments can be effectively cleaned so as to avoid dust on the surface of the garments; and simultaneously, waste materials after the garment processing can be well collected so that resource wastes are avoided.

Owner:HUNAN UNIV OF ARTS & SCI

Connector structure of OTT television box and OTT television box thereof

InactiveCN113949912AFirmly connectedPrevent dustSelective content distributionTelecommunicationsStructural engineering

The invention relates to the technical field of television boxes, in particular to a connector structure of an OTT television box and the OTT television box thereof. The electronic devices are installed in the box body, the connector is connected to the side wall of the box body and used for being connected with a circuit, the installation block is connected to the side wall of the box body in a threaded mode and located on the outer side of the connector, and the protection sleeve is fixedly connected with the installation block and further covers the outer side of the connector to protect the connector. The connecting assembly can seal the opening position of the protection sleeve, so that the connection between the circuit and the connector is more stable, and meanwhile, when the circuit is not used for connection, the protection sleeve seals the connector, so that the effects of preventing dust and isolating water are achieved, the circuit is safer to communicate, the television box is safer to use, and the user experience feeling is better.

Owner:重庆嘉肯科技有限公司

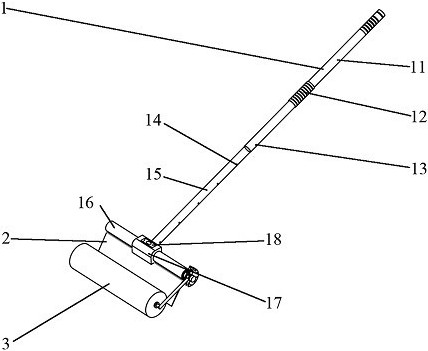

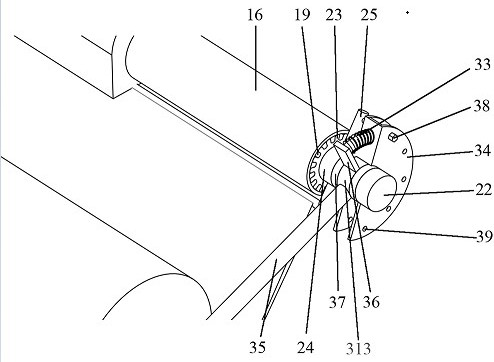

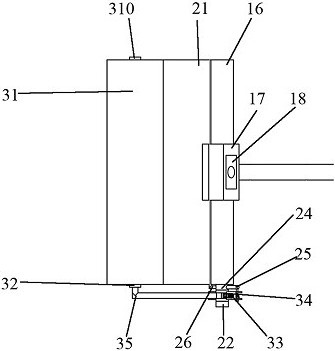

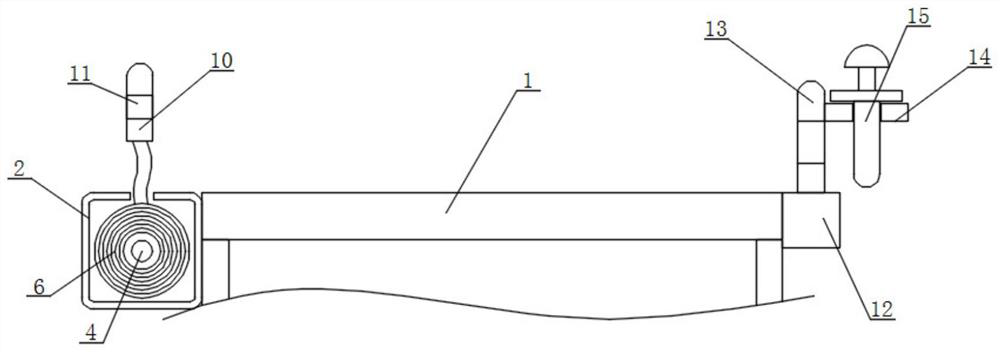

Soil leveling tool applied to model test and using method of soil leveling tool

PendingCN112414822AGuaranteed flatnessPrevent dustPreparing sample for investigationEarth material testingAgricultural engineeringEnvironmental geology

The invention discloses a soil leveling tool applied to a model test and a using method of the soil leveling tool. The soil leveling tool is composed of a telescopic horizontal rod, a gear shaft mud scraping plate and a pressure adjusting type idler wheel. The telescopic horizontal rod is formed by connecting a long-arm handle sleeved with a sponge handle to a T-shaped handle provided with a horizontal ruler through a fastening bolt. The gear shaft mud scraping plate is formed by connecting a gear type fixing buckle with a mud scraping plate through a mud scraping plate connecting shaft connected with a cylindrical connecting shaft; the pressure adjusting type roller is formed in a way that a cylindrical roller which sleeves one end of an L-shaped connecting shaft, and the other end of theL-shaped connecting shaft is connected with a pressure adjusting valve; the gear shaft mud scraping plate is inserted into the gear type buckle structure on the lower portion of the T-shaped handle through the gear type fixing buckle to be connected with the telescopic horizontal rod, and the pressure adjusting type idler wheel is arranged on the cylindrical sliding way in a sleeving mode throughthe L-shaped connecting shaft circular ring and the pressure adjusting valve circular ring to be connected with the gear shaft mud scraping plate. The soil leveling tool is high in adaptability and high in integrity, and the working efficiency can be improved.

Owner:SHANDONG UNIV OF SCI & TECH

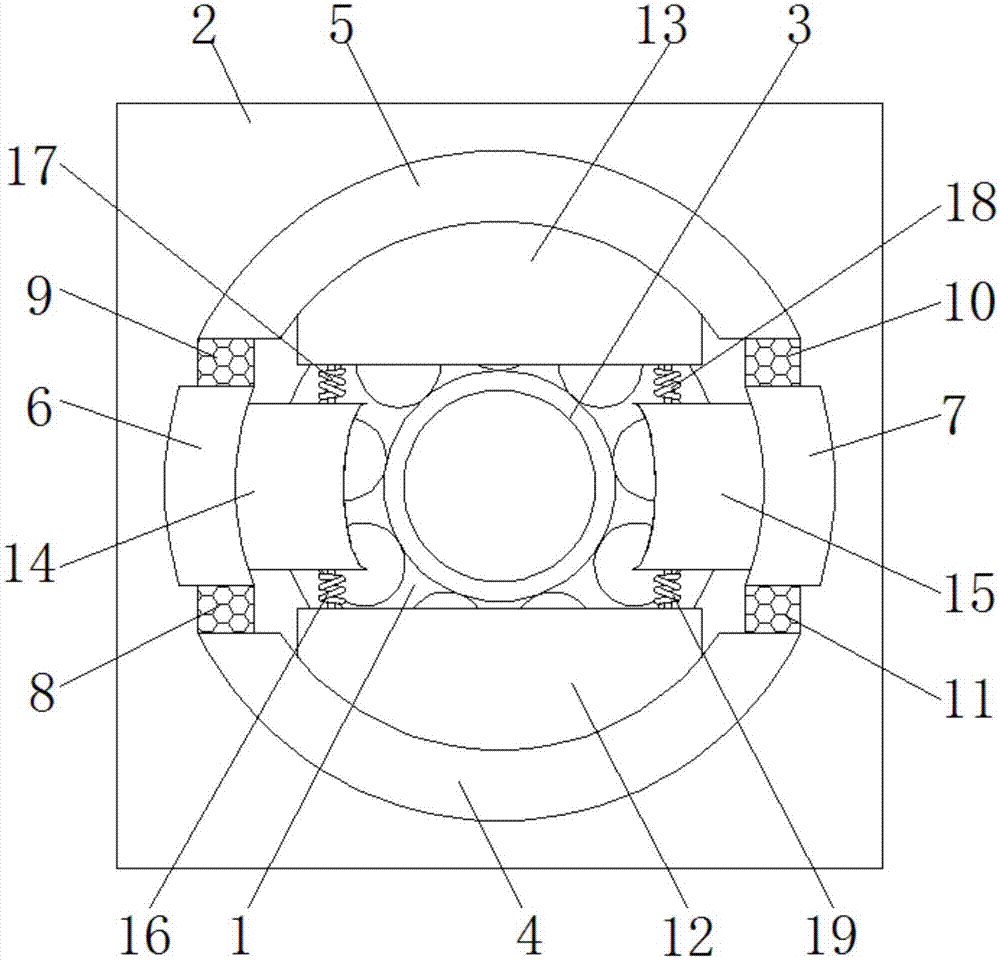

Bearing for electric equipment with long service life

InactiveCN107989908AExtended service lifePrevent dustNon-rotating vibration suppressionBearing unit rigid supportEngineeringElectric equipment

The invention provides a bearing for electric equipment with long service life. The bearing comprises a bearing body, a fixed base and a rotating body; the bottom of the bearing body is fixedly mounted at the top of the fixed base; the rotating body is fixedly mounted on the inner wall of an inner ring of the bearing body; the top of the fixed base is fixedly connected with a front side plate; andthe front side plate is positioned in front of the bearing body. The bearing for the electric equipment with long service life is provided with a front side plate, a back side plate, a left side plate and a right side plate for preventing external dust of the electric equipment from entering the bearing body and attaching on the surfaces of balls to cause increment of friction between the balls;and meanwhile, through matching arrangement of a first dustproof net, a second dustproof net, a third dustproof net and a fourth dustproof net, the dust is prevented from entering the internal of thebearing body, the tension of the front side plate, the back side plate, the left side plate and the right side plate is reduced, and the service life of the bearing body is prolonged.

Owner:淮安龙马羽绒制品有限公司

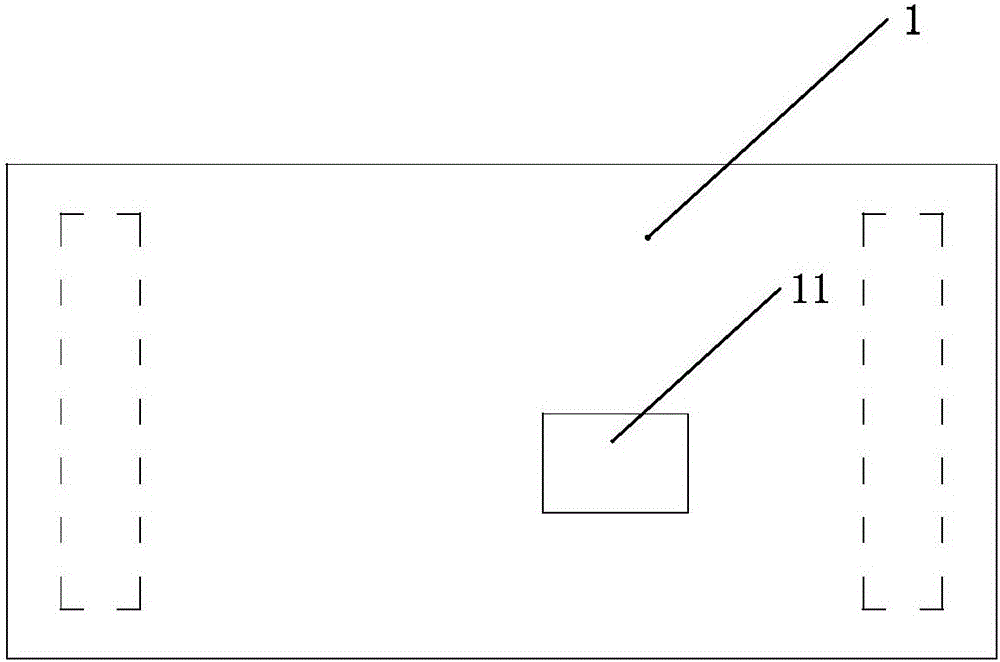

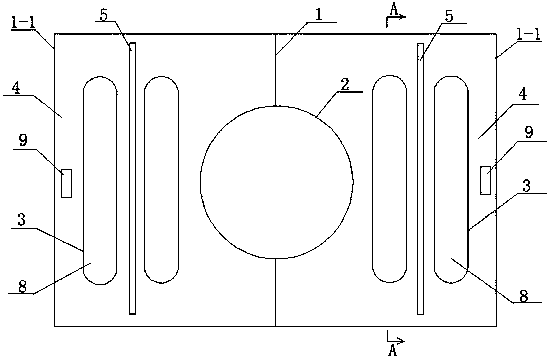

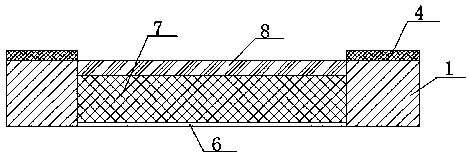

Tree pool cover board with lawn vegetation

InactiveCN109537396AImprove wear resistanceExtended service lifeTemporary pavingsReceptacle cultivationVegetationMetal rubber

The invention discloses a tree pool cover board with lawn vegetation, wherein the tree pool cover board comprises a cover board body (1) which is formed by butt joint of two symmetrical plates (1-1) made of cast nylon. A tree hole (2) is arranged in the center of the cover board body (1), and at least one waist-shaped through hole (3) is formed in the cover board body (1); the upper end face of the cover board body (1) is also provided with a metal rubber protective layer (4), and the metal rubber protective layer (4) is provided with at least one long-strip anti-skid grain (5) in an outward-protruding manner. The bottom end of the waist-shaped through hole (3) is provided with a water permeable net layer (6) which is integrated with the cover board body (1), and the waist-shaped through hole (3) is internally provided with a nutrient soil filling layer (7); the lawn vegetation (8) is arranged on the nutrient soil filling layer (7). The tree pool cover board with the lawn vegetation isadopted, and the structure design is reasonable.

Owner:刘浩荫

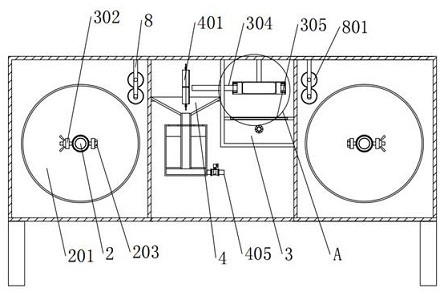

Limestone dust collection and treatment equipment

ActiveCN112604405BImprove cleaning efficiencyAvoid failure situationsDispersed particle filtrationRubber membraneAdhesive

Owner:安徽省恒金矿业有限公司

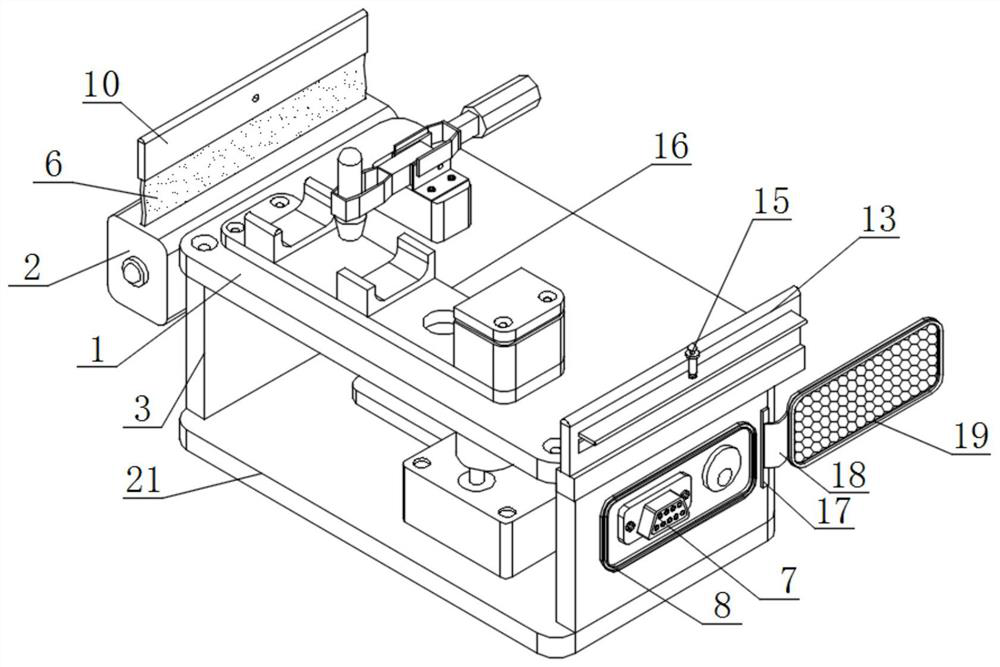

Dustproof tool jig for part production

The invention discloses a dustproof tool jig for part production. The dustproof tool jig comprises a working platform, a take-up box and a fixing panel, the take-up box is arranged at one side of the working platform, the fixing panel is arranged at one side of the bottom of the working platform, a torsion spring is connected to one side of the inner wall of the take-up box, a winding rod is connected to one side of the surface of the torsion spring, one end of the winding rod is connected to the inner wall of the take-up box through a rotating shaft, dustproof cloth is connected to one side of the surface of the winding rod, a plug-in interface is formed at one side of the surface of the fixing panel, and a mounting panel is mounted in the middle of the surface of the fixing panel. An inserting groove is formed at one side of the surface of the mounting panel. According to the jig, through the arrangement of the fixing panel, the plug-in interface, the mounting panel, the inserting groove, a connection block, a movable rope, a sealing cover and a sealing block, the plug-in interface is sealed, dust is prevented from entering the plug-in interface, and the plug-in interface is convenient to use.

Owner:苏州米品精密科技有限公司

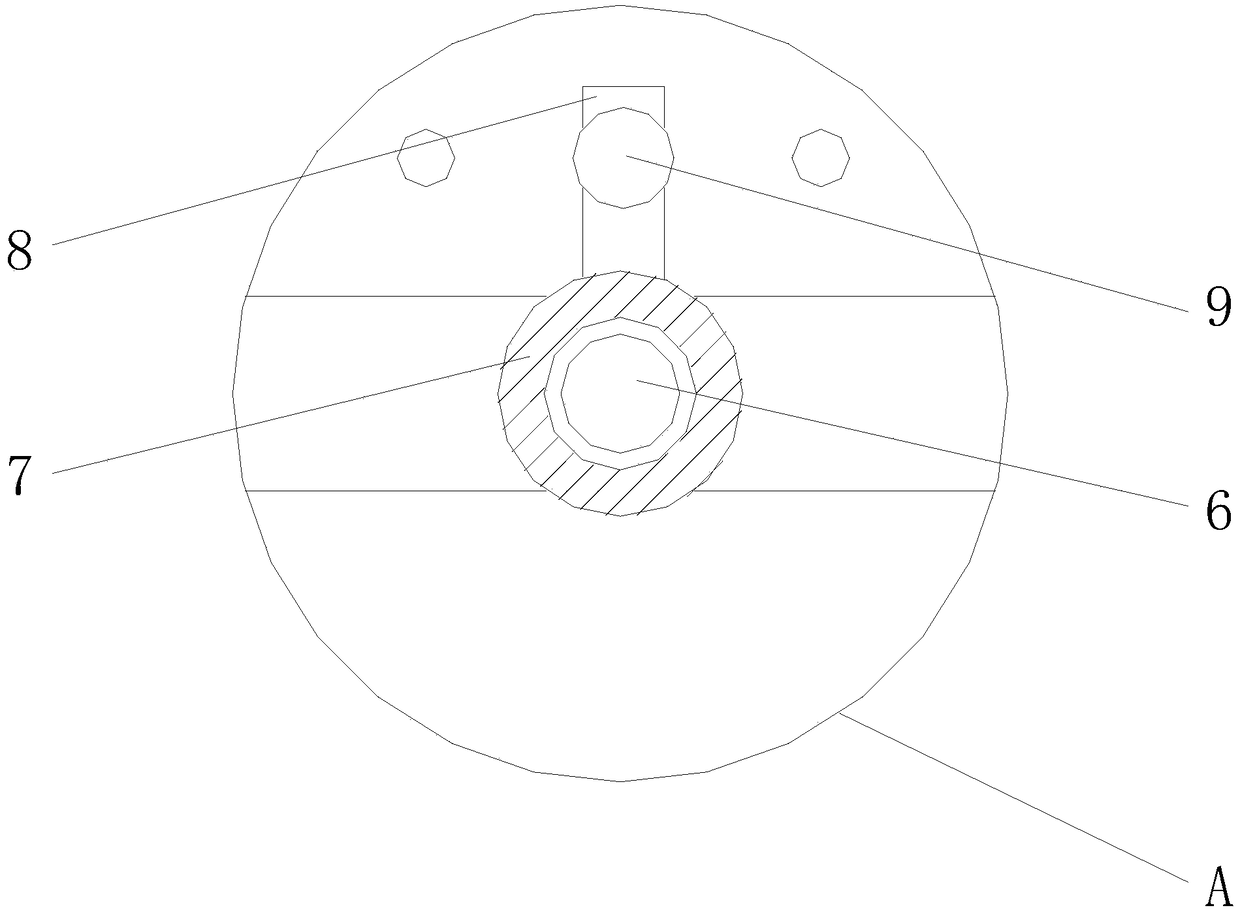

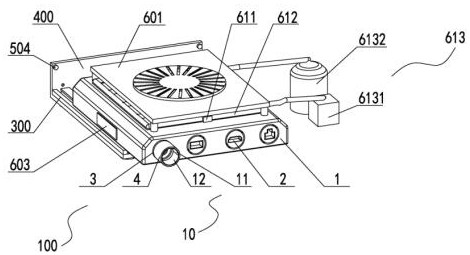

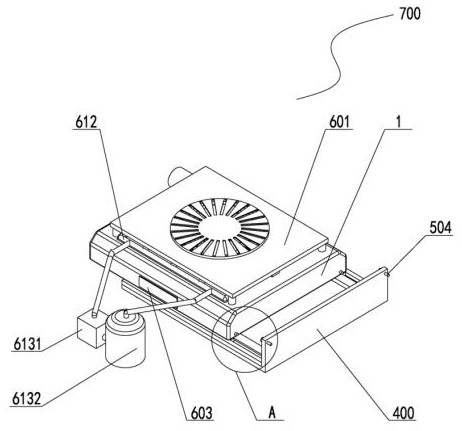

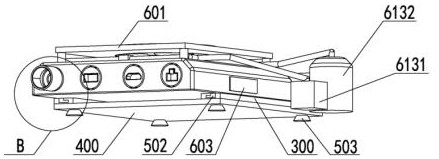

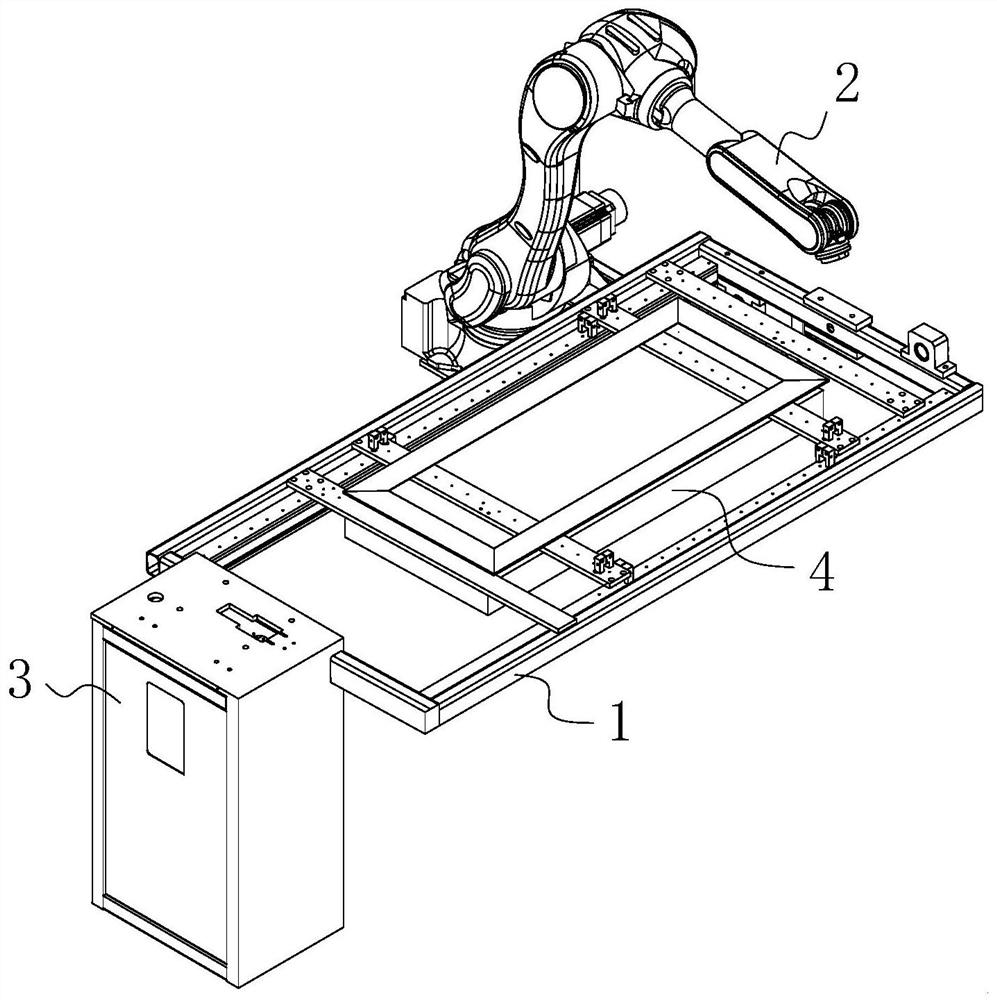

A robot welding tooling device

ActiveCN109746600BDoes not take up limited spaceAvoid Contaminated SituationsWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Electric machine

Owner:广东泰格威机器人科技有限公司

Purification method for ceramic production

InactiveCN114405613ARealize the collectionImprove processing qualityGrain treatmentsPurification methodsProcess engineering

The invention discloses a purification method for ceramic production, which comprises a fixed bottom plate, the top of the fixed bottom plate is fixedly connected with a main body, the left side of the top of the main body is fixedly connected with a control panel, and the right side of the position, far away from the fixed bottom plate, of the main body is provided with a sintering device; and connecting frames are fixedly connected to the middles of the outer walls of the two sides of the sintering device, and a purifying device is fixedly connected to the left side of the position, away from the fixed bottom plate, of the main body. According to the purification method for ceramic production, follow-up processing work is facilitated, the processing time can be shortened, the working process in the device is in a sealed state, and the internal movement range is limited, so that the situation of dust raising during work is avoided, produced powder is fully collected, and the production efficiency is improved. And meanwhile, after high-temperature calcination, the structure of the raw material is destroyed, so that the raw material loses magnetism, full utilization of the raw material is facilitated, and the processing quality of the powder is improved.

Owner:李少航

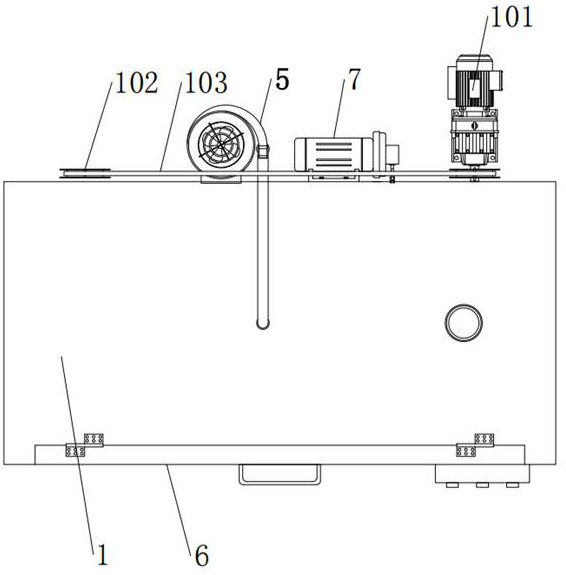

Dust removal device and method of efficient cleaning filter

ActiveCN109364585AExtend the life cyclePrevent dustDispersed particle filtrationFilter regenerationSpray nozzleDust particles

The invention discloses a dust removal device and method of an efficient cleaning filter. The dust removal device comprises a blowing bin and a water spray treatment bin communicated with the blowingbin and located below the blowing bin; a filter bag support for fixing a filter bag of a filter is arranged in the blowing bin, a liftable cover plate is arranged at the top of the blowing bin, and high-pressure blowing nozzles are uniformly arranged on the cover plate; an atomizing nozzle for forming a water spray effect is arranged on the side surface of the water spray treatment bin; the dust removal device also comprises a water retaining bin communicated with the water spray treatment bin and located on one side of the water spray treatment bin. The dust removal device is simple in process principle, simple in processing and production process, small in field limitation and suitable for field operation, soaking of the filter bag is avoided due to adoption of high-pressure blowing, thedamage to a filter material is reduced, the service cycle of the filter is prolonged, and the maintenance cost is saved. Besides, dust particles are blown in a full-sealed state, environmental pollution is avoided, the water resource is greatly saved through water spray, and green and environmental protection roles are played.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL INSTALLATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com