Dust removal device and method of efficient cleaning filter

A technology for cleaning filters and dust removal devices, applied in filter regeneration, chemical instruments and methods, filtration separation, etc., which can solve problems such as large water consumption, increased material costs, and damage to filter bags, so as to save water and prolong use Cycle, the effect of preventing dust from flying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

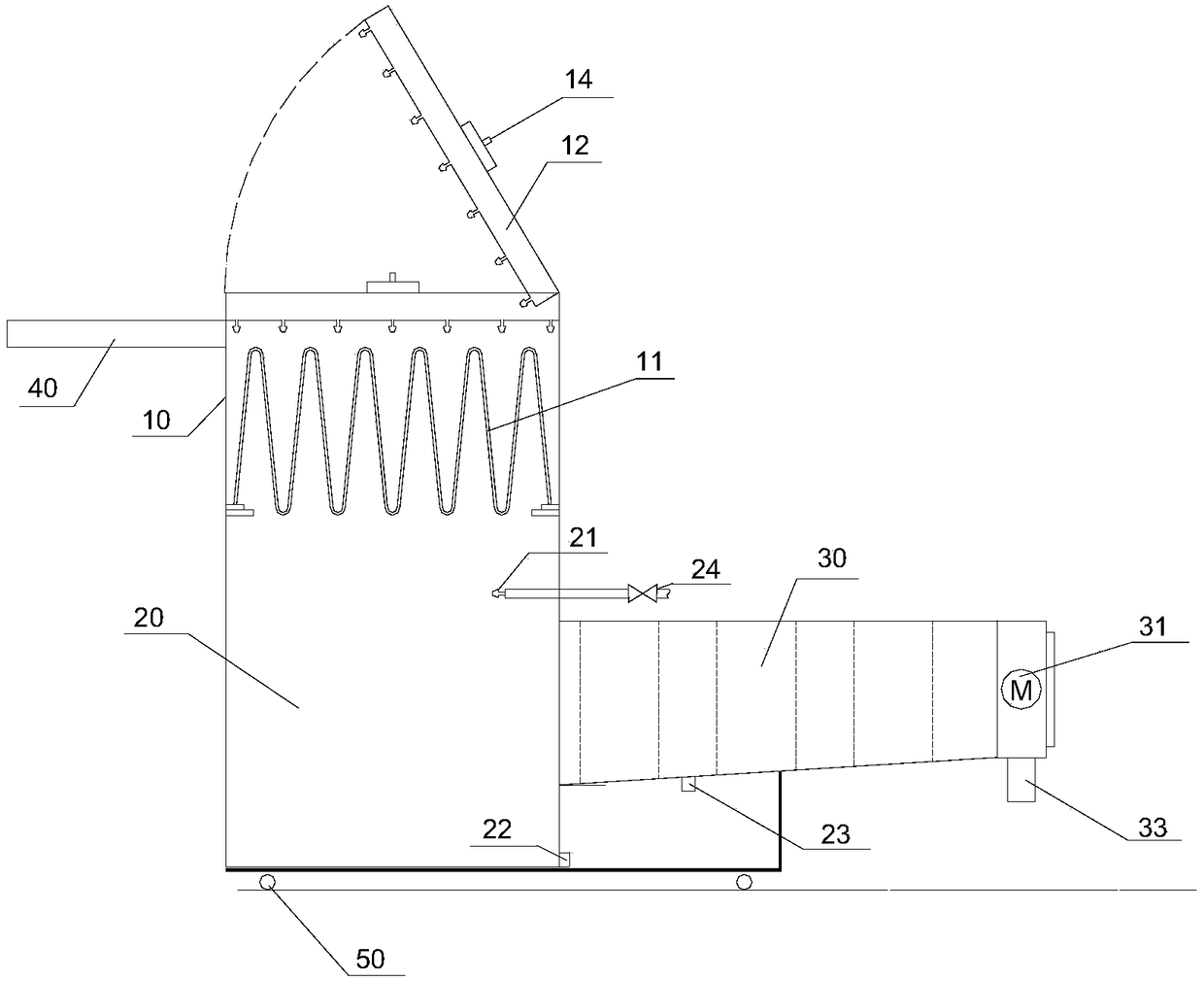

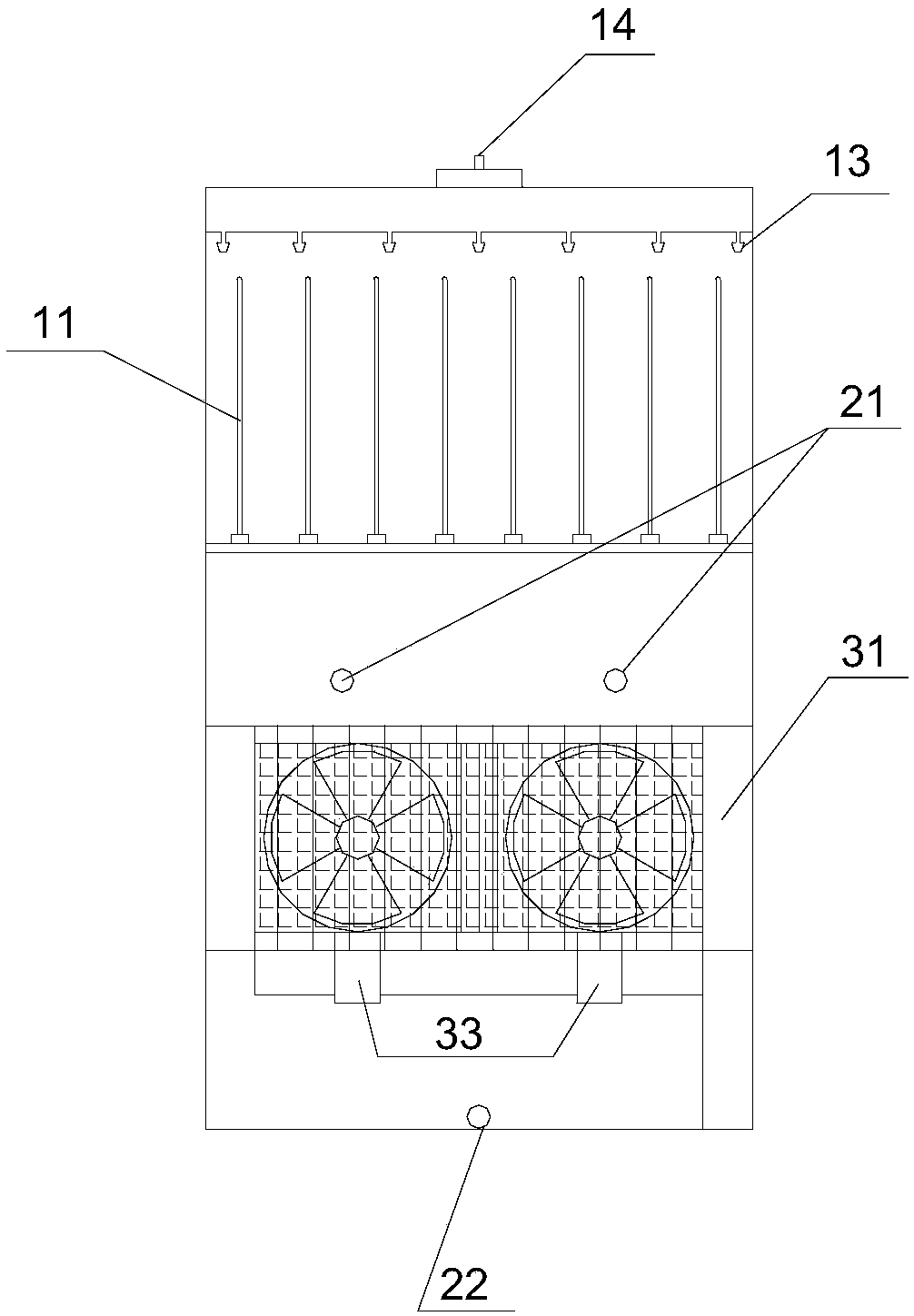

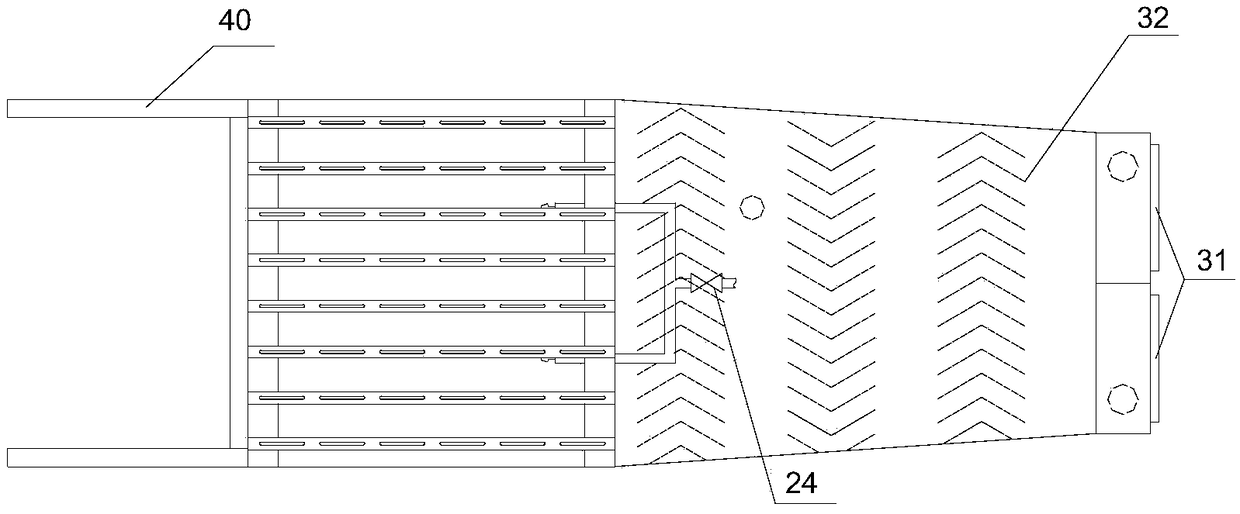

[0046] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0047] Such as Figure 1 to Figure 7 As shown, the dust removal device of the high-efficiency cleaning filter of the present invention is used for the maintenance of air-conditioning equipment of the central air conditioner and the centralized air supply system, and is mainly used for the filter device of the air conditioning system of the central air conditioner and the centralized air supply system, and the interior is supported by a metal mesh basket Filter bag, the filter bag intercepts dust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com