Method for preventing label paper from separating from label and paper jamming of thermal printer

A technology of thermal printers and printers, applied in printing devices, printing, etc., can solve problems such as no solution, paper jams, easy to stick to the printer at the edge of the paper inlet 02, and achieve the effect of avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

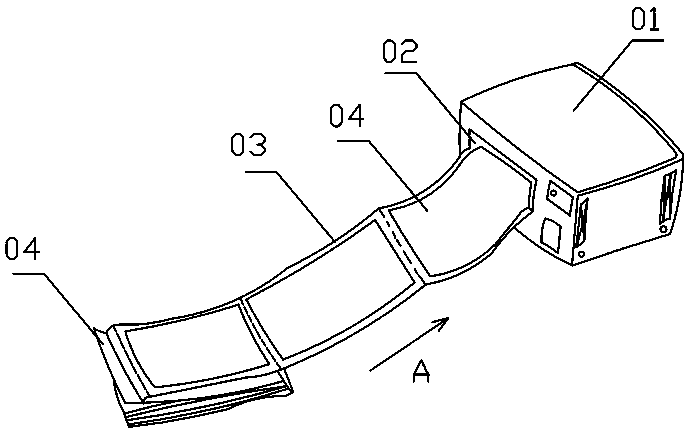

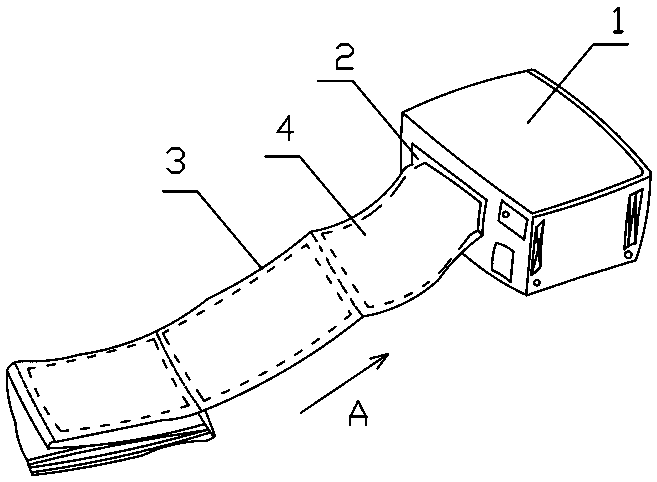

[0018] combined with figure 2 And attached image 3 , a method for preventing degumming and jamming of label paper in thermal printers. When feeding paper, the printer adopts the reverse feeding method of label paper 3 to feed paper, that is, when viewed along the paper feeding direction A, the label paper 3 is on top , the label 4 is on the bottom; in this paper feeding mode, the positions of the printer’s paper feed wheel and print head are exchanged, that is, the printer’s paper feed wheel and print head are set on the side close to the bottom of the printer, and the printing of the print head Orientation is toward the top of the printer.

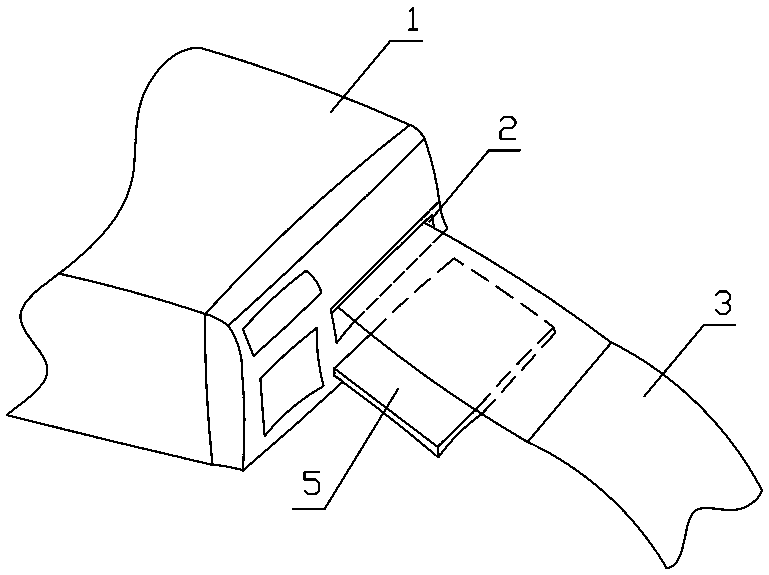

[0019] As preferably, a mirror 5 is also provided at the paper inlet 2 of the printer, and the reflective surface of the mirror 5 is directed upwards to the bottom of the label paper 3 at the paper inlet 2 for reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com