Purification method for ceramic production

A purification method and ceramic technology, which is applied in the field of ceramic processing, can solve the problems of increasing the time of ceramic purification, reducing the quality of reprocessing, and reducing the internal filtering effect, so as to improve processing quality, prolong service life, and reduce processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

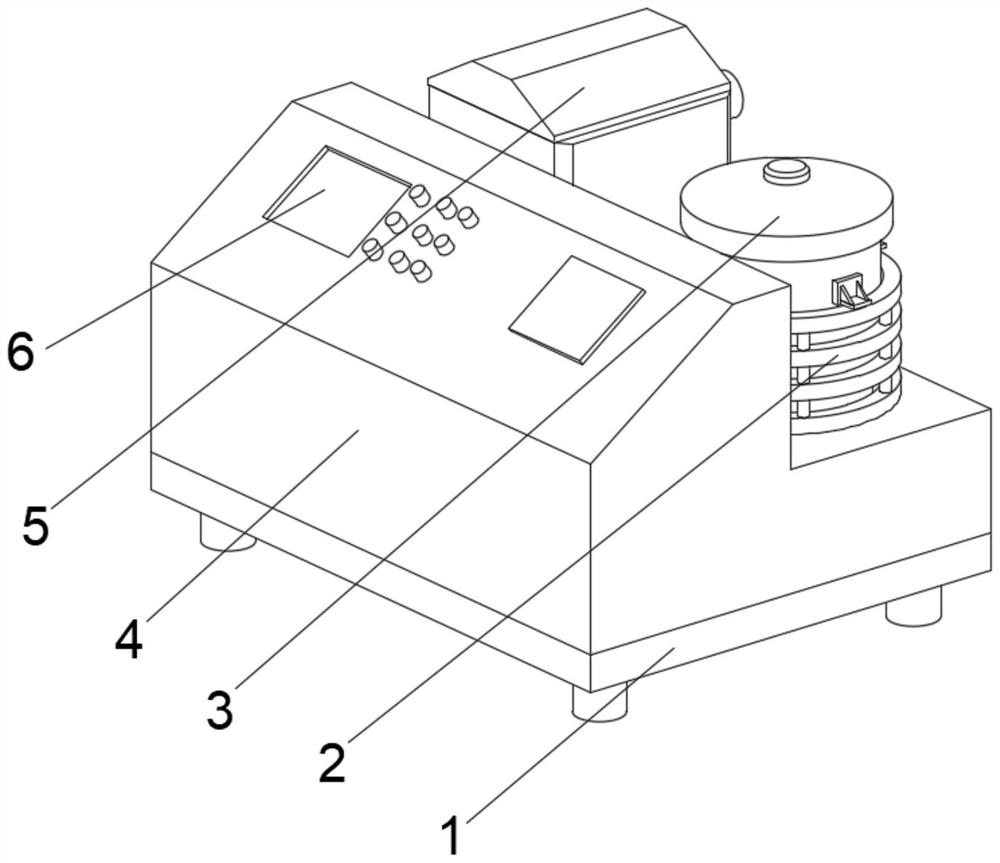

[0040] see Figure 1-6 , the present invention provides a technical solution: a purification method for ceramic production, comprising a fixed bottom plate 1, a main body 4 is fixedly connected to the top of the fixed bottom plate 1, a control panel 6 is fixedly connected to the left side of the top of the main body 4, and the main body 4 is away from A sintering device 3 is arranged on the right side of the position where the bottom plate 1 is fixed. The bottom of the sintering device 3 runs through the main body 4 and extends to the inside of the main body 4. The middle parts of the outer walls of both sides of the sintering device 3 are fixedly connected with the connecting frame 2. The main body 4 is far away from the fixed A purification device 5 is fixedly connected to the left side of the bottom plate 1 .

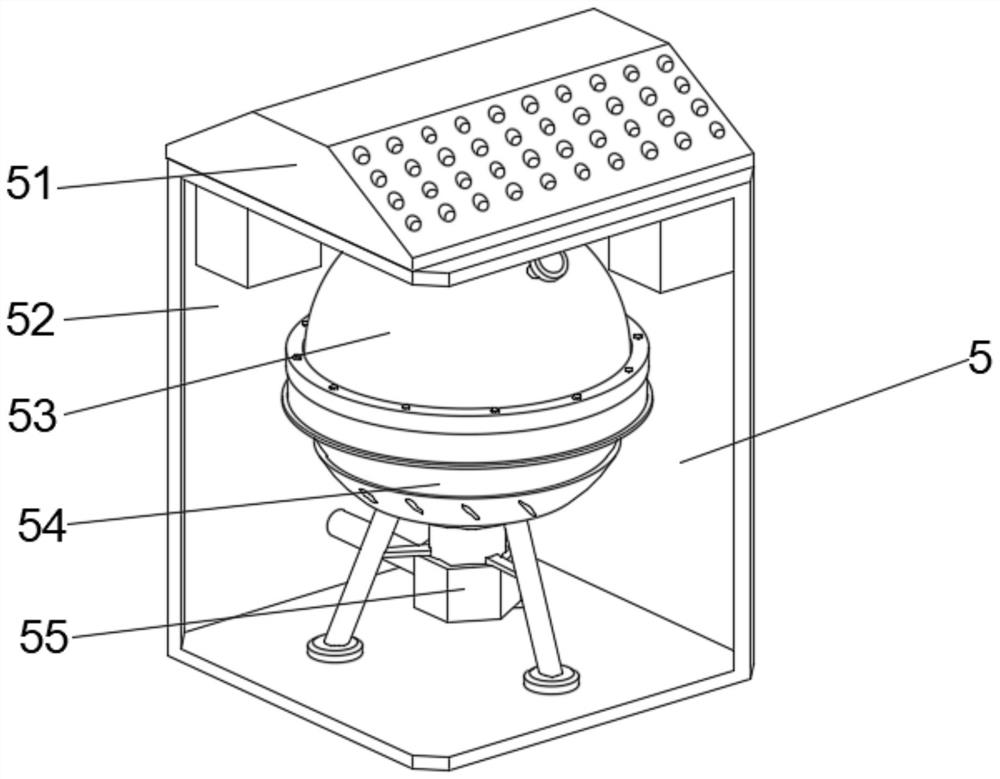

[0041] Wherein, the purifying device 5 comprises a sealed box 52, the top of the sealed box 52 is fixedly connected with a transmission member 51, and the inner cavi...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a purification method for ceramic production, step 1: install and electrify the equipment, and connect the sintering device 3 and the purification device 5 with pipelines, and connect the The sintering vessel 3 is heated by electricity;

[0048] Step 2: Purify the bulk raw material after high temperature treatment, and connect the transmission member 51 with the sealing box 52 through the connection between the pipeline and the filter mechanism 53, so that the further processed raw material is transported through the conveying frame 55 connected with the adsorption mechanism 54, realizing Sufficient collection of powdered raw materials;

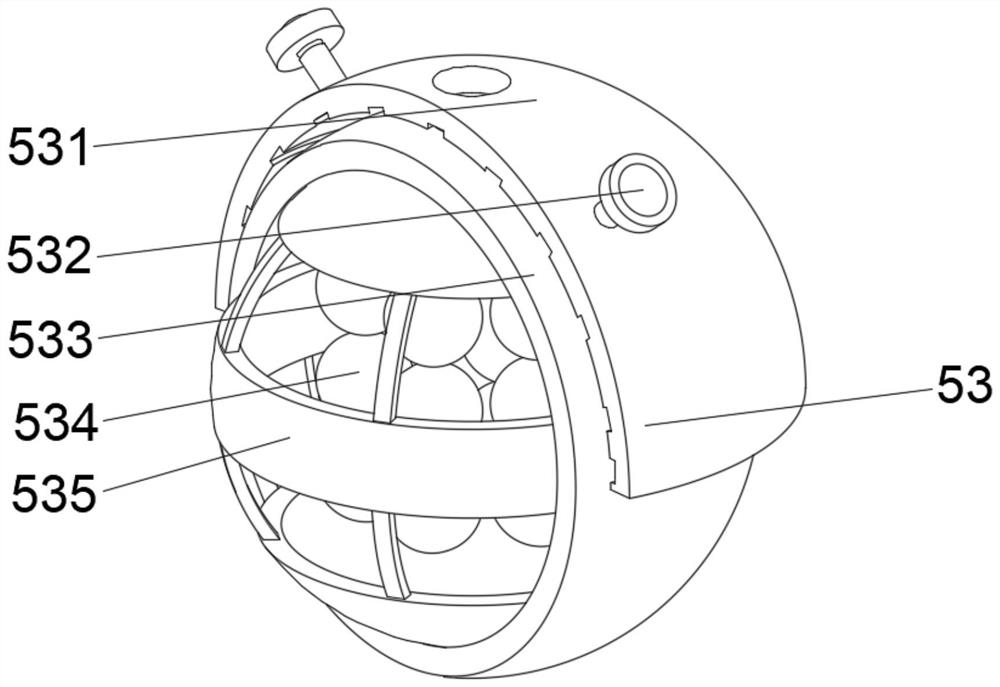

[0049] Step 3: The heating shell 531 and the screening body 533 are closely attached to transmit the temperature generated by the electric heating. The grinding track formed by the grinding ball 534 and the positioning guide frame 535 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com