Clearing method for pulverized coal separating wheel

A cleaning method and separation wheel technology, applied in the direction of descaling devices, dryers, furnaces, etc., can solve the problems of separation wheel jamming, rotary kiln production reduction, rotary kiln material stoppage, etc., to achieve easy cleaning, ensure drying effect, Avoid the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

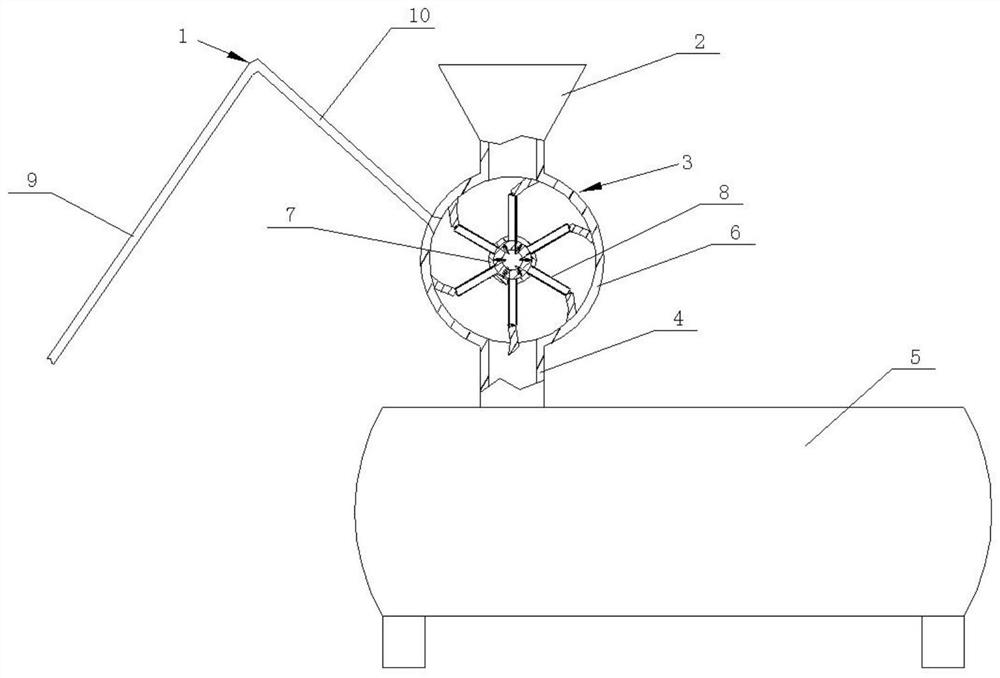

[0019] The method for cleaning the pulverized coal separation wheel is to input the hot air in the rotary kiln into the separation wheel 3 through the bent hot air duct 1, and reduce the accumulation of raw coal in the separation wheel during the rotation of the separation wheel 3.

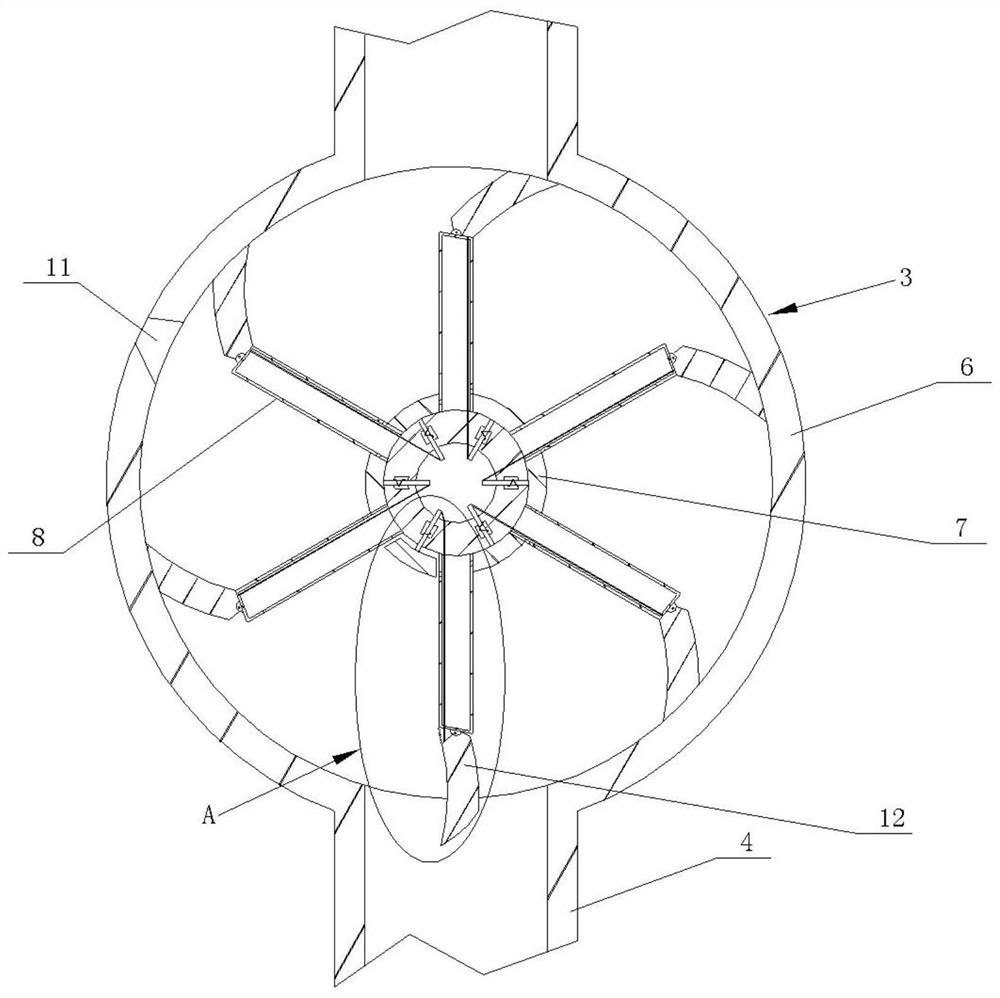

[0020] Specifically, as figure 1 As shown, the coal mill system includes a feeding hopper 2, a separating wheel 3, a grinding chute 4 and a coal mill 5, which are arranged in sequence from top to bottom, as shown in the figure. figure 2 As shown, the separation wheel 3 includes a casing 6, a rotating shaft 7 and a spacer 8 evenly distributed around the rotating shaft 7. The rotating shaft 7 and the outside of the casing 6 are bolted to the output shaft of the motor mounted on the frame by coaxial welding or by means of a method. The flange connection, that is, the rotating shaft 7 and the separating sheet 8 are rotatably arranged in the casing 6, and the casing 6 is connected with the coal mill 5...

Embodiment 2

[0024] On the basis of Embodiment 1, in addition to cleaning the raw coal inside the separation wheel 3 by hot air drying, the separation wheel 3 itself is also convenient for cleaning the pulverized coal.

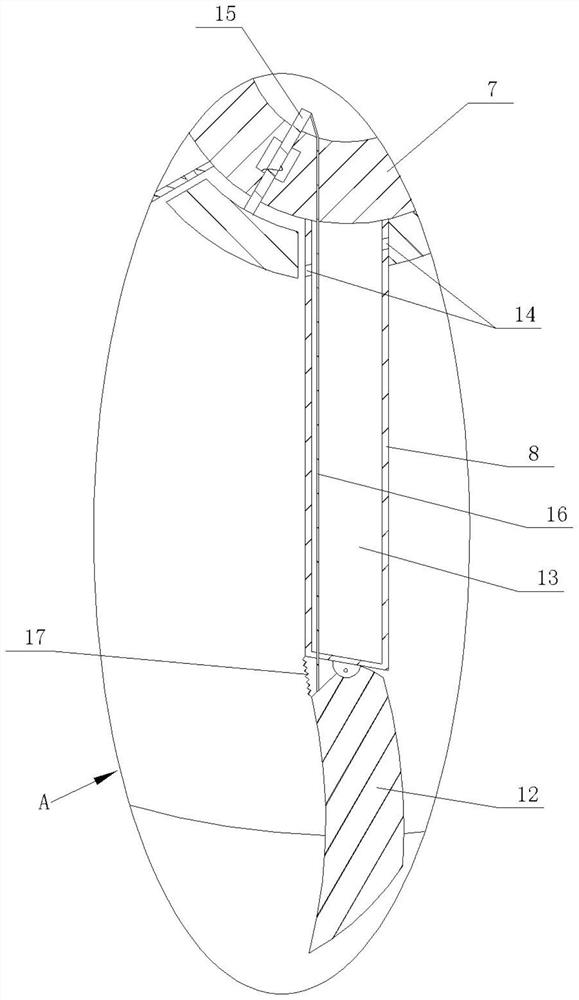

[0025] Specifically, as figure 2 As shown, the rotating shaft 7 of the separation wheel 3 is hollow, as shown in image 3 As shown, a scraper 12 is hinged on the partition 8 of the partition wheel 3 through a pin, a cavity 13 is opened in the partition 8, and a hole 14 is opened on the partition 8 that communicates with the cavity 13; adjacent partitions 8 A cleaning sheet that can block the pores 14 is slid between them. Specifically, the section of the cleaning sheet is fan-shaped, the side wall of the rotating shaft 7 has a through hole in the shape of "middle", and a sliding rod is slidably arranged in the through hole. 15. One end of the sliding rod 15 is fixedly connected with the cleaning sheet, such as welding, and a spring is sleeved on the sliding rod 15; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com