Dust-containing gas conveying pipeline and dust-containing gas conveying method

A technology for conveying pipelines and gas, which is applied in the field of dusty gas transportation and filtration. It can solve the problems of pipeline blockage, secondary dust emission, temperature distribution, etc., and achieve the effects of small scouring force, easy dust removal, and difficulty in pipeline blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

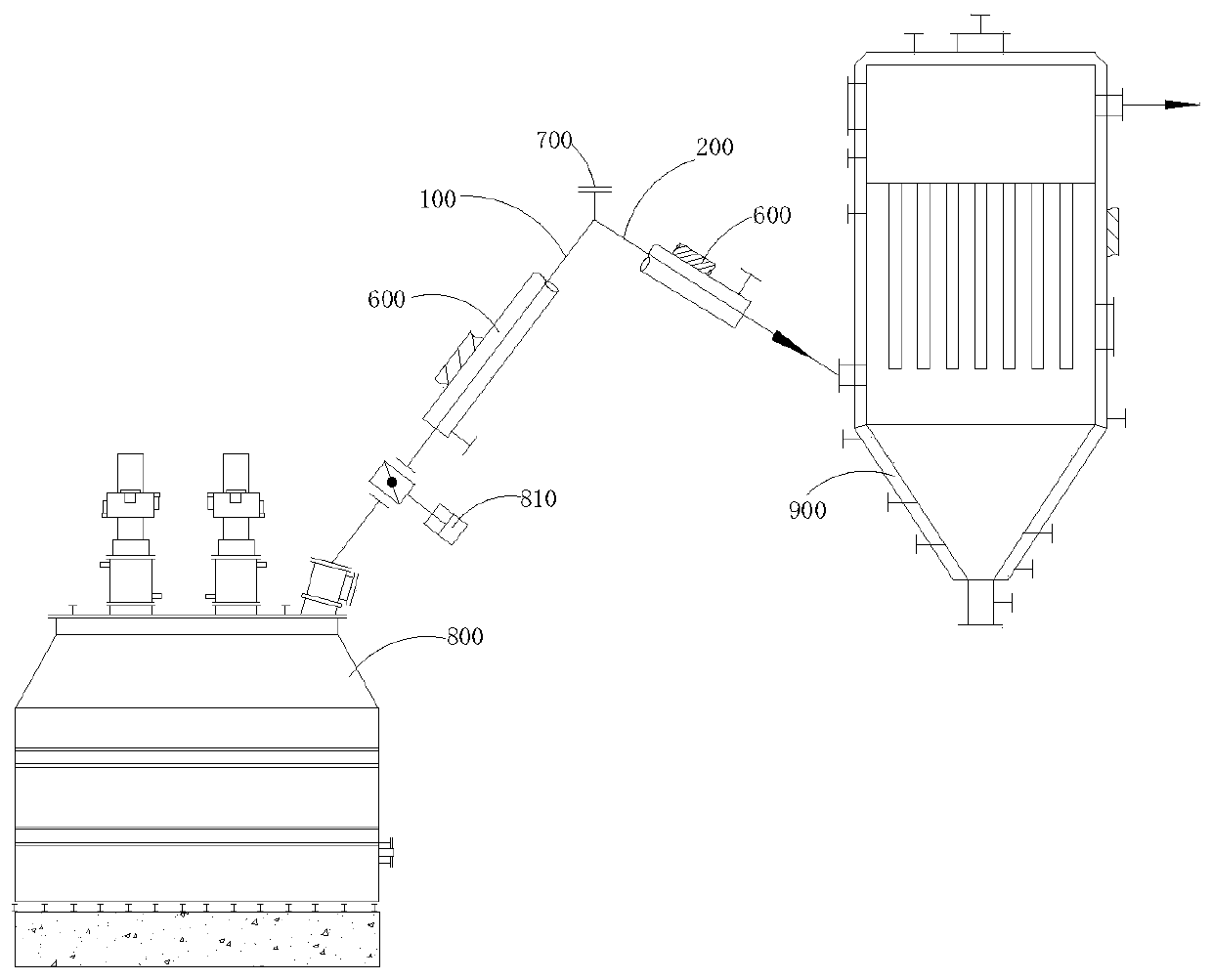

[0044] Such as figure 1 The shown dust-laden gas conveying pipeline connecting the dust-laden gas generating equipment 800 and the dust collector 900, along the conveying direction of the dust-laden gas, the conveying pipeline includes a first ascending pipe 100 and a first descending pipe 200 connected in sequence, so The input end of the first ascending pipe 100 is connected to the gas outlet of the dust-laden gas generating device 800, and the output end of the first descending pipe 200 is connected to the air inlet of the dust collector 900 in the direction toward the lower part of the dust collector 900. , the junction of the first ascending pipe 100 and the first descending pipe 200 forms an obtuse downward angle.

[0045] A soot removal device is provided on the conveying pipeline, and the soot removal device includes a soot removal hole 700 located at the junction of the first riser 100 and the first downcomer 200; the soot removal hole 700 is a fast Open the hand hol...

Embodiment 2

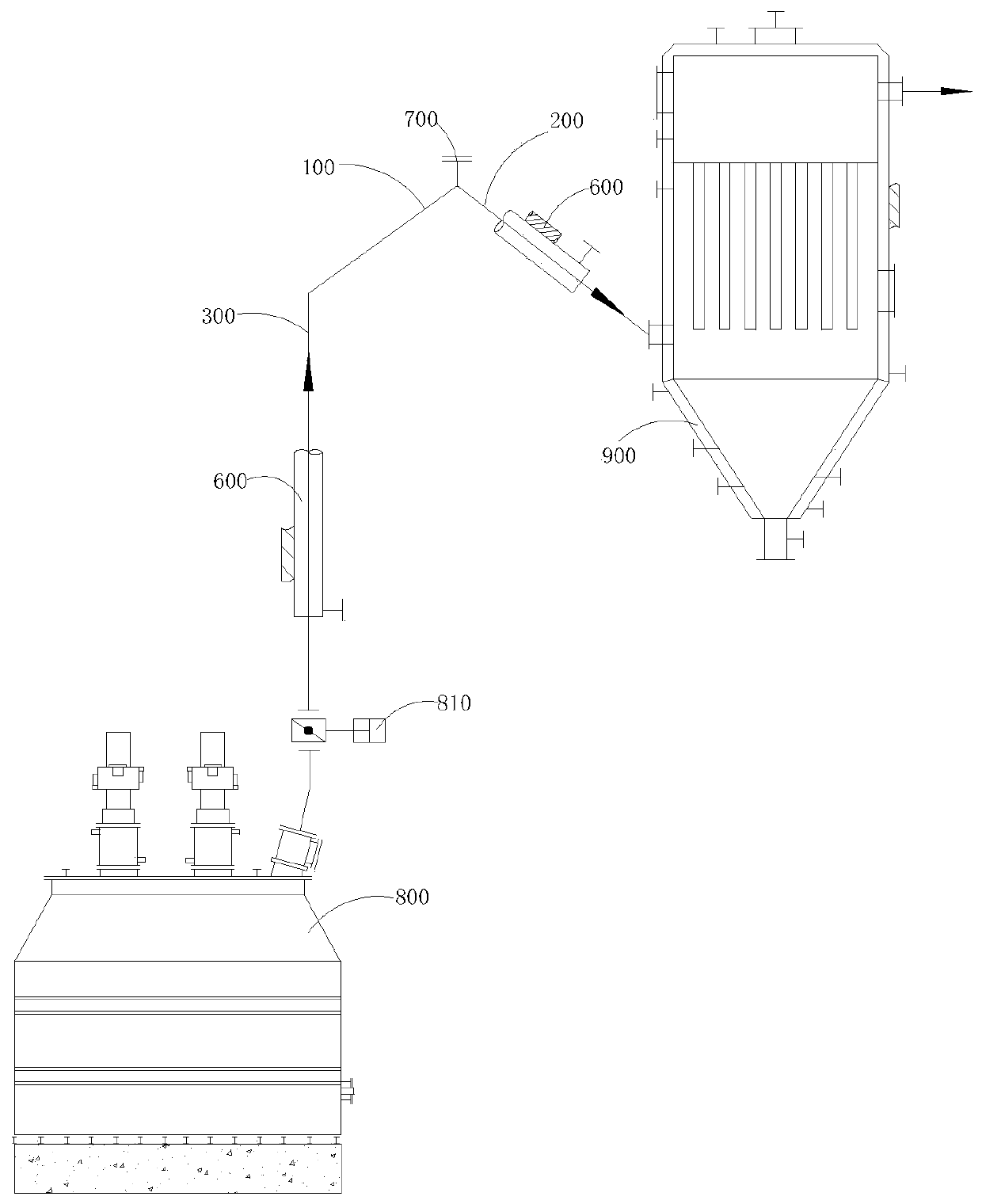

[0050] Compared with Embodiment 1, the difference that the dust-laden gas conveying pipeline of the present embodiment has is: as figure 2As shown, a second riser 300 is provided between the first riser 100 and the gas outlet of the dusty gas generating equipment 800, the second riser 300 is placed vertically, and the first riser 100 and the second riser The included angle between the two ascending pipes 300 is an obtuse angle; at this time, the air intake valve 810 is arranged on the second ascending pipe 300 .

Embodiment 3

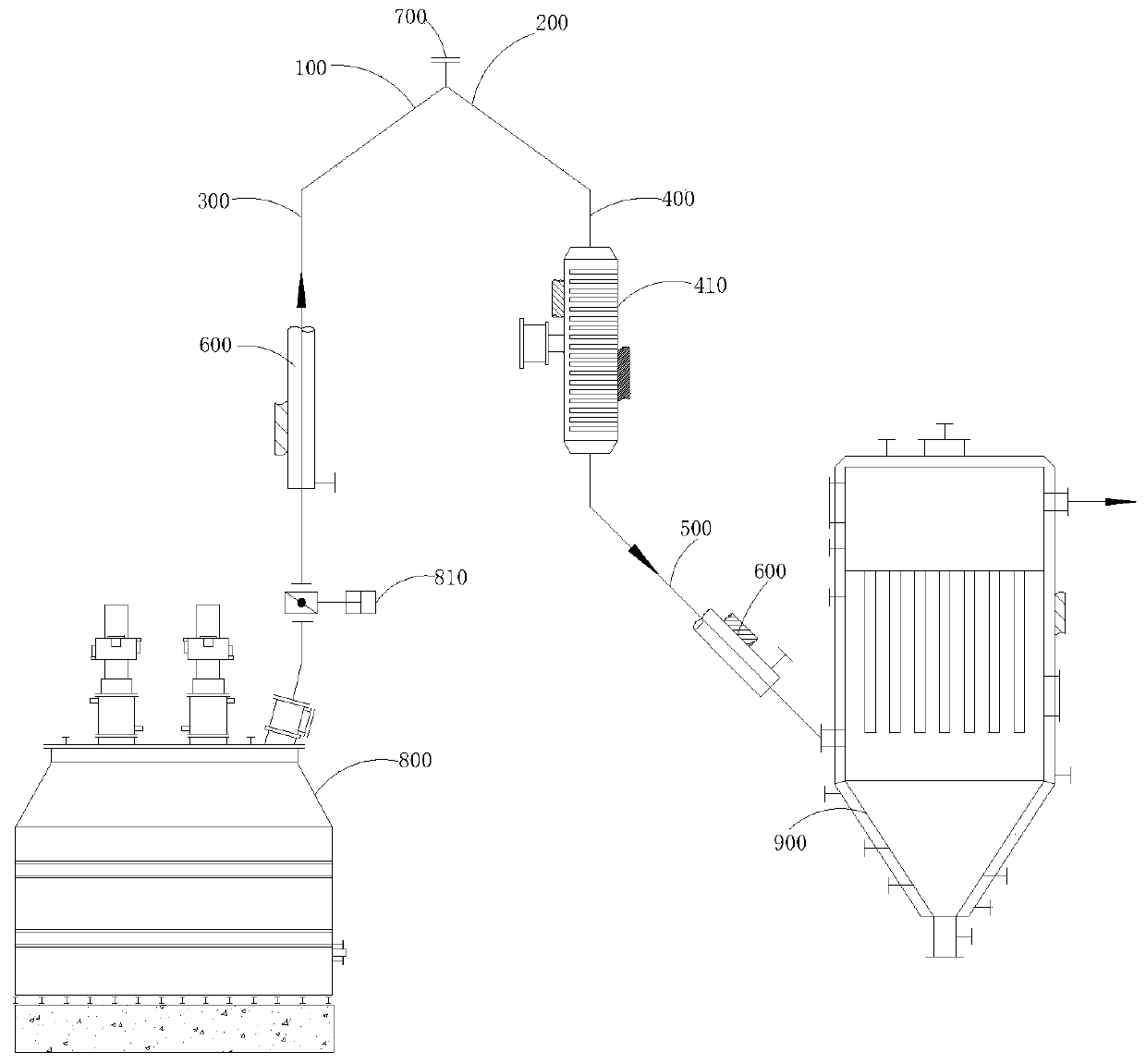

[0052] Compared with embodiment 2, the difference that the dust-laden gas conveying pipeline of the present embodiment has is: as image 3 As shown, a second downcomer is provided between the first downcomer 200 and the air inlet of the dust collector 900, and the second downcomer includes:

[0053] The first pipe body 400, the first pipe body 400 is connected with the first descending pipe 200, and the first pipe body 400 is placed vertically;

[0054] The second pipe body 500 is arranged between the first pipe body 400 and the air inlet of the dust collector 900 .

[0055] The included angle between the first descending pipe 200 and the first pipe body 400 is an obtuse angle;

[0056] The included angle between the first tube body 400 and the second tube body 500 is an obtuse angle.

[0057] A heating device 410 for heating the dust-containing gas is provided on the first pipe body 400 , and the heating tube of the heating device 410 is perpendicular to the conveying direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com