Dustproof powdery medicament material packing mechanism

A dust-proof and powder-like technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low packaging accuracy and waste of powder medicine, and achieve the effects of ensuring health, avoiding dust, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

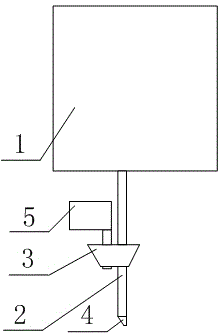

[0021] Anti-dust powder packaging mechanism, such as figure 1 As shown, it includes a powder tank 1, a powder pipe 2, and a powder pipe on-off control mechanism arranged in the powder pipe 2. The bottom end of the powder pipe 2 is provided with a conical seal 3, and the powder The tube 2 runs through the conical seal 3 and is provided with a discharge port 4 at the bottom end thereof. The conical seal 3 is also provided with an air suction device 5 for sucking air in the packaging bottle.

[0022] In this embodiment, the powder pipe 2 and the powder tank 1 are threadedly connected.

Embodiment 2

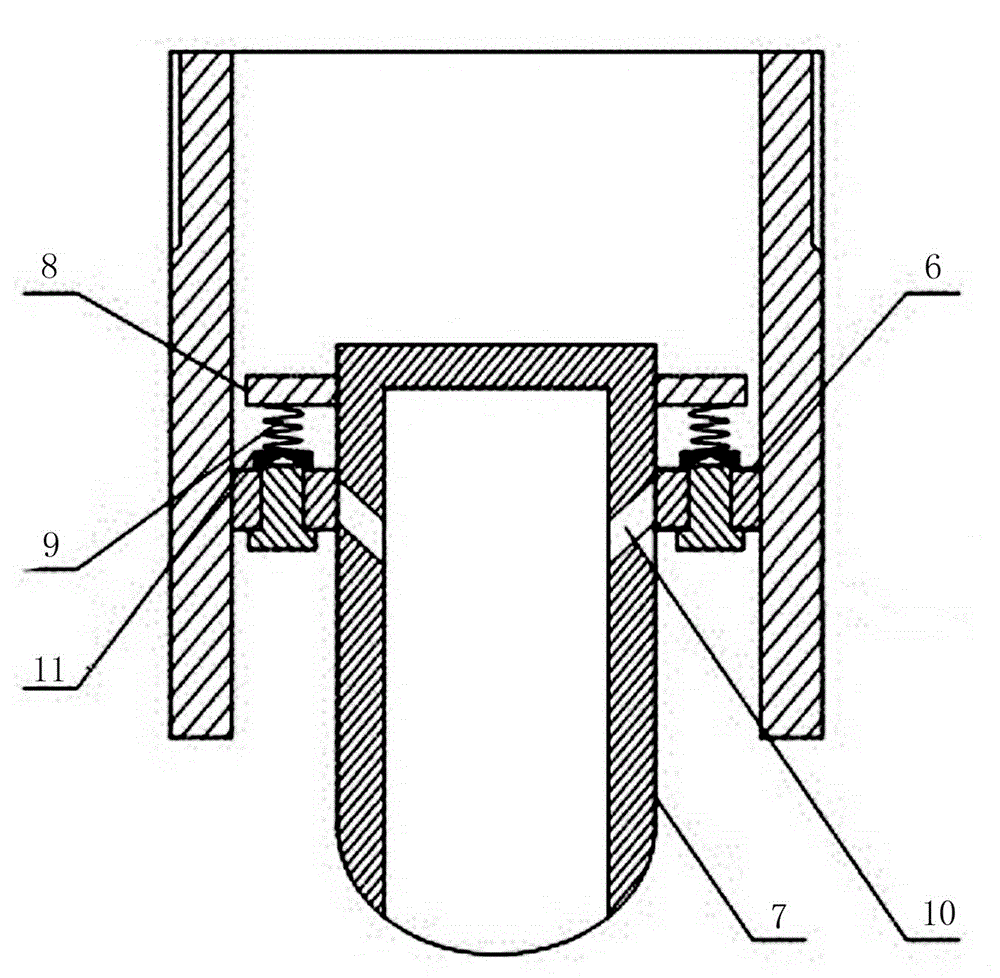

[0024] The difference between this embodiment and Embodiment 1 is: the specific structure of the powder pipe on-off control mechanism is given in this embodiment, as figure 2 As shown, the specific settings are as follows:

[0025] The on-off control mechanism of the powder pipe includes a spring mounting seat 6 whose outer side is fixedly connected with the inner wall of the powder pipe 2. The spring mounting seat 6 is provided with a through hole, and the upper end of the through hole is provided with a gap fit therein. The closed discharge pipe 7 is also provided with a first spring seat 8 on the discharge pipe 7, a spring 9 is arranged between the first spring seat 8 and the spring mounting seat 6, and a discharge spring is also provided on the side wall of the discharge pipe 7. The material hole 10, the lower end of the discharge pipe 7 is an inclined surface.

[0026] In this embodiment, the powder pipe 2 and the powder tank 1 are connected by bolts.

Embodiment 3

[0028] The difference between this embodiment and Embodiment 2 is that: in this embodiment, the structure of the powder pipe on-off control mechanism is further optimized, such as figure 2 As shown, the specific settings are as follows:

[0029] The powder pipe on-off control mechanism also includes a second spring seat 11, the two ends of the spring 9 are fixedly connected with the first spring seat 8 and the second spring seat 11 respectively, and the second spring seat 11 is installed with the spring Become bolt connection between seat 6. The discharge pipe 7 is a circular pipe, and there are more than one discharge holes 10, which are evenly distributed in a ring shape around the discharge pipe 7. The discharge hole 10 is an oblique hole inclined toward the center of the discharge pipe 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com