Self-lubricating ultrasonic sound guide pad and preparation method thereof

A self-lubricating, ultrasonic technology, applied in the direction of echo/ultrasonic imaging agents, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve the problem of decreased lubricating performance of ultrasonic pads, inconvenient inspection process, Problems such as difficulty in moving the probe can be achieved to improve accuracy, avoid coupling agent loss, and avoid medical waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

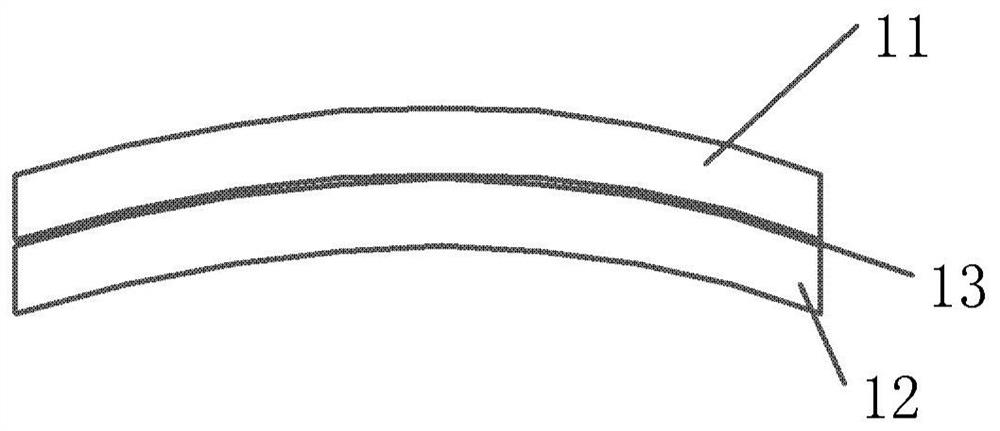

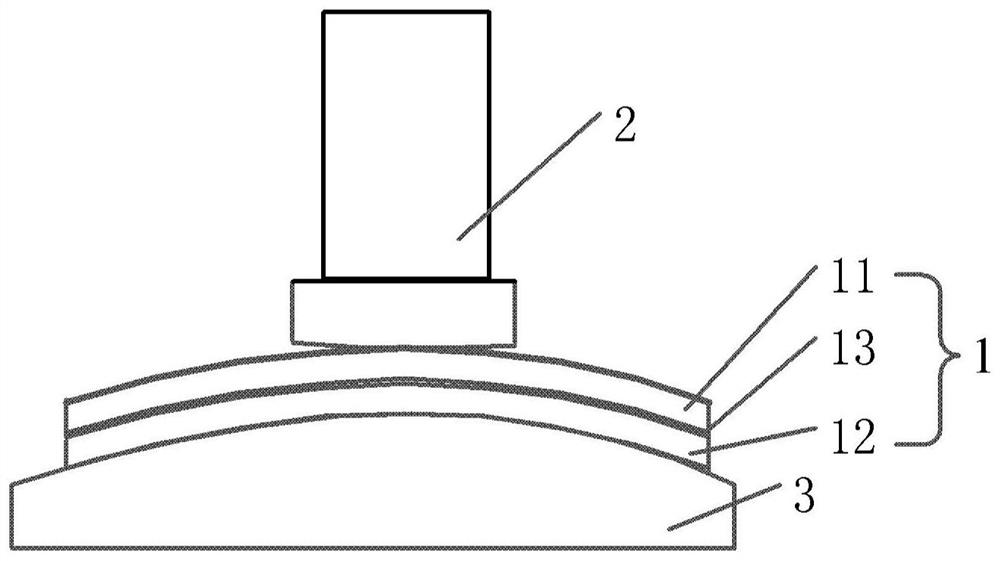

[0022] The invention provides a method for preparing a self-lubricating ultrasonic sound-conducting pad, comprising:

[0023] applying an adhesive to the first surface of the adhesive hydrogel layer;

[0024] applying an adhesive to the second surface of the slippery hydrogel layer;

[0025] bonding the first surface of the viscous hydrogel layer coated with an adhesive to the second surface of the slippery hydrogel layer coated with an adhesive to obtain a self-lubricating ultrasonic sound-conducting pad;

[0026] Wherein, the adhesive includes an adhesive and a dispersion, and the adhesive includes any one or more of polyurethane, isooctyl acrylate, methyl cyanoacrylate, octyl cyanoacrylate or ethyl cyanoacrylate. In combination, the dispersion includes alkenyl organics.

[0027] In some embodiments of the present invention, the mass ratio of the adhesive in the adhesive to the dispersion is (1 to 2.5): (3.5 to 5), for example, it can be 1:3.5, 1.5:3.5, 2:3.5 , 2.5:3.5, 1...

Embodiment 1

[0078] The preparation method of the self-lubricating ultrasonic sound-conducting pad in this embodiment may comprise the following steps:

[0079] (1) Preparation of viscous hydrogel layer:

[0080] Step S11: Add 20g of monomer to 100mL of deionized water and stir until completely dissolved, then add 12mL of viscosity modifier, 1mL of initiator, 7.6mL of crosslinking agent, and 82μL of catalyst in sequence, and stir well to obtain a viscous hydrogel prepolymer solution.

[0081] The monomer can include acrylamide; the viscosity modifier can include glycerin; the crosslinking agent can include N,N-methylenebisacrylamide solution, N,N-methylenebisacrylamide solution in N,N-methylene The mass percentage of bisacrylamide can be 0.2wt%; Initiator can comprise ammonium persulfate solution, and the volume concentration of ammonium persulfate in the ammonium persulfate solution can be 1mol / L; Catalyst can comprise tetramethylethylenediamine, and the tetramethylethylenediamine Methy...

Embodiment 2

[0099] The difference between the preparation method of the self-lubricating ultrasonic sound-conducting pad in this example and the preparation method in Example 1 lies in the preparation of the slippery hydrogel layer.

[0100] In this embodiment, the preparation of the slippery hydrogel layer may include the following steps:

[0101] Step S51: Add 5 g of the first material into deionized water, heat and stir at 150° C. until completely dissolved to obtain a first hydrogel solution. The first material may include agar.

[0102] Step S52: adding 1 g of the second material to the first hydrogel solution, heating and stirring at 150° C. until completely dissolved, to obtain a third hydrogel solution. The second material may include sodium alginate.

[0103] Step S53: adding 1 g of the toughening material to the third hydrogel solution, heating and stirring at 150° C. to obtain a second slippery hydrogel prepolymer solution. Toughening materials can include lignin.

[0104]S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com