Anti-rust device for PC steel strand

A steel strand and shell technology, applied in the field of steel strand, can solve the problems of insufficient anti-rust treatment, inapplicability, and inability to form a protective film on the steel strand, and achieve the effects of saving resources, improving efficiency, and ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

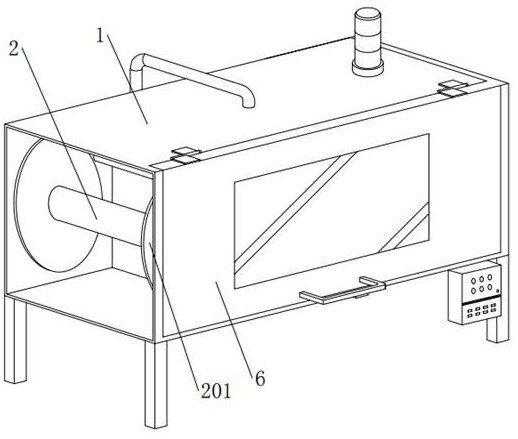

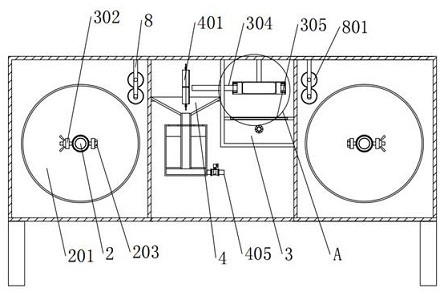

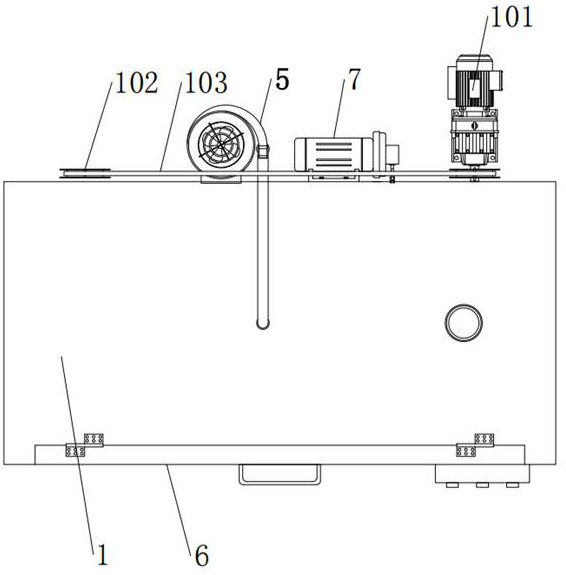

[0040] A PC steel strand antirust device, including a casing 1, the casing 1 is a cuboid box structure, the left and right sides of the casing 1 are designed to be open, and the two sides of the casing 1 are rotatably connected with two winding rollers 2, two winding rollers 2 installed at the same level, the back of the housing 1 is fixed with a servo motor 101, the output end of the servo motor 101 is fixedly connected with the winding roller 2 on the right side, and the back of the two winding rollers 2 are fixed with pulleys 102 , the two pulleys 102 rotate synchronously through the belt 103, an oil tank 3 is arranged between the two winding rollers 2, the oil tank 3 is fixed on the inner right side of the shell 1, and anti-rust oil is injected into the oil tank 3, the top of the shell 1 A three-color warning light is installed on the right side;

[0041] The antirust device for PC steel strands also includes a cleaning tank 4, which is fixed on the left side of the shell ...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the front of the winding roller 2 is nested with a side plate 201, and the front of the side plate 201 is fixed with two symmetrically arranged fixed blocks 202, and the inside of the fixed block 202 is embedded with a positioning Rod 203, positioning rod 203 is threadedly connected with fixed block 202;

[0045] The outer surface of the winding roller 2 is provided with a through hole with the same diameter as the positioning rod 203;

[0046] Before derusting, prepare the coiled steel strands, rotate the positioning rod 203, so that the positioning rod 203 is separated from the winding roller 2 and the fixed block 202, so that the side plate 201 can be slid to the disengaged state along the winding roller 2, and then the The winding roller 2 is fully exposed, and then the coiled steel strand is placed on the winding roller 2;

[0047] An annular air knife 401 is installed in the middle of the cleaning ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com