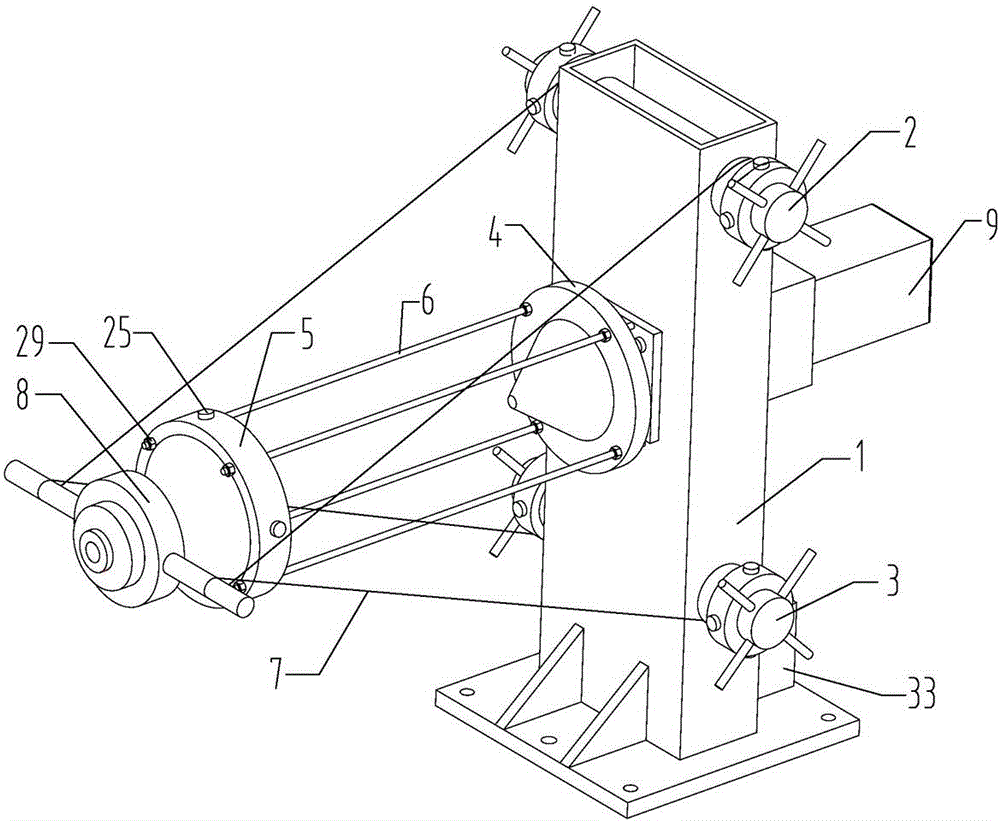

Derusting and lining pouring integrated machine for interior of centrifugal pipe

A centrifugal, all-in-one technology, used in grinding frames, surface-polishing machine tools, and devices for coating liquids on surfaces, etc. The effect of small space occupation, small dust pollution and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

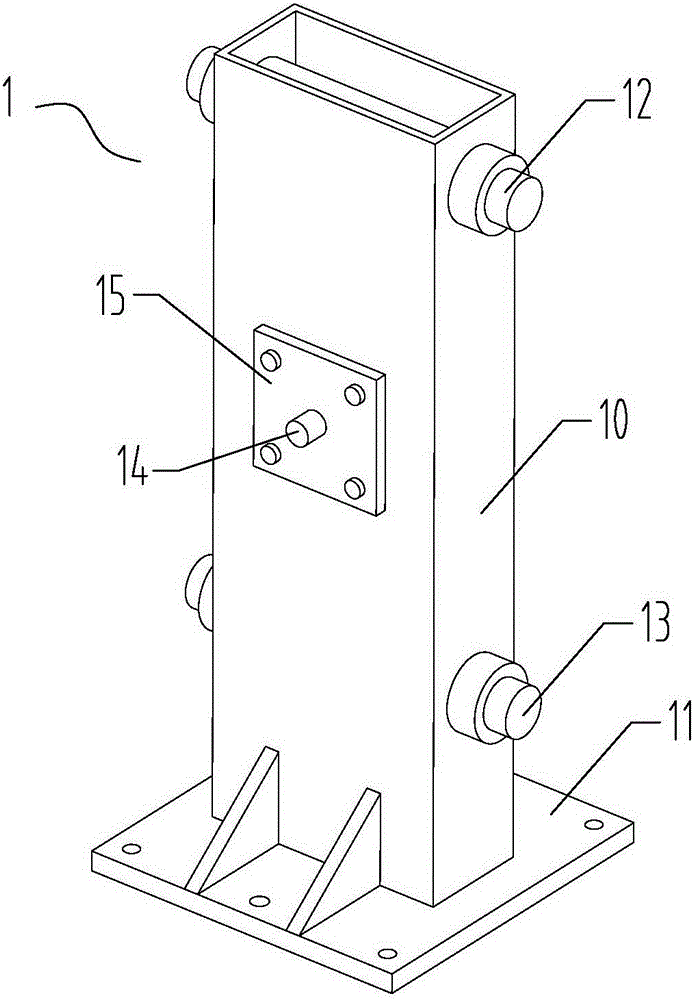

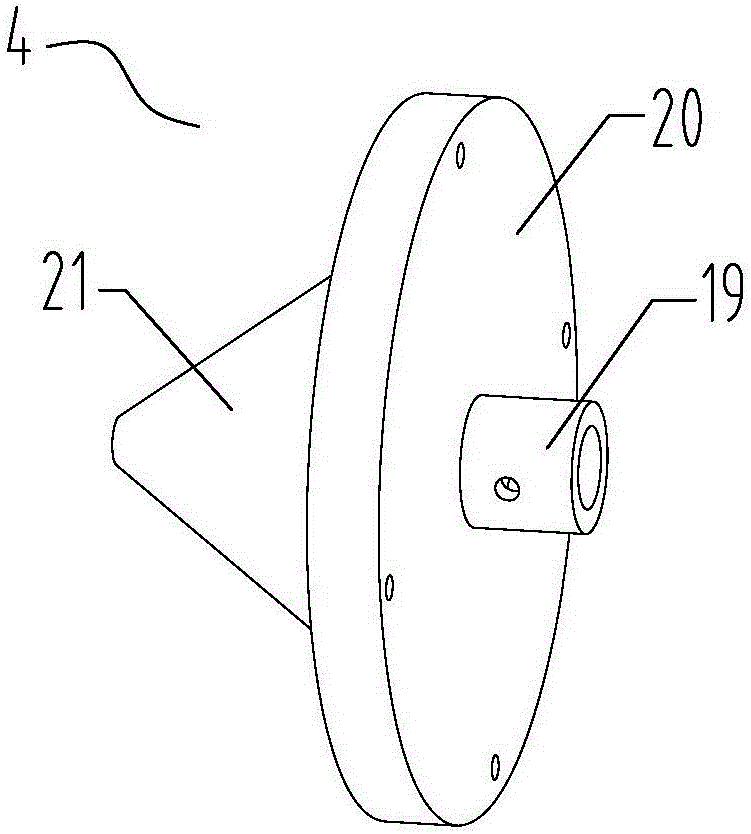

Embodiment 1

[0024] Embodiment one: the height of frame 1 of the present invention is 800mm, and the power of speed-regulating motor 9 is 250W, and the diameter of the transmission shaft inserting counterbore of the cylinder section 19 of fixed end centering and positioning cone 4 is 40mm, and the diameter of fixed end is 40mm. The cone point angle of the inner cone surface of the centering and positioning cone 4 and the cone point angle of the cantilever end to the cone section 21 of the centering and pressing cone 5 are both 90 degrees, and the outer cone of the fixed end centering and positioning cone 4 and The maximum diameter of the cross-section of the inner cone surface of the cantilever end to the middle pressure buckle cone 5 is 256mm, the diameter of the tension rod 6 is 10mm, and the two ends are M8 threads. Connect the power cord of the all-in-one machine for derusting, pouring and lining inside the tube to the control box 33 of the speed-regulating motor, fix the centering and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com