Energy-saving embedded type light inside and outside wall board

An inlaid, energy-saving technology, used in ceramic products, other household appliances, household appliances, etc., can solve the problems of easy collapse of walls, poor safety, unstable products, etc., and achieve the effect of reducing dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

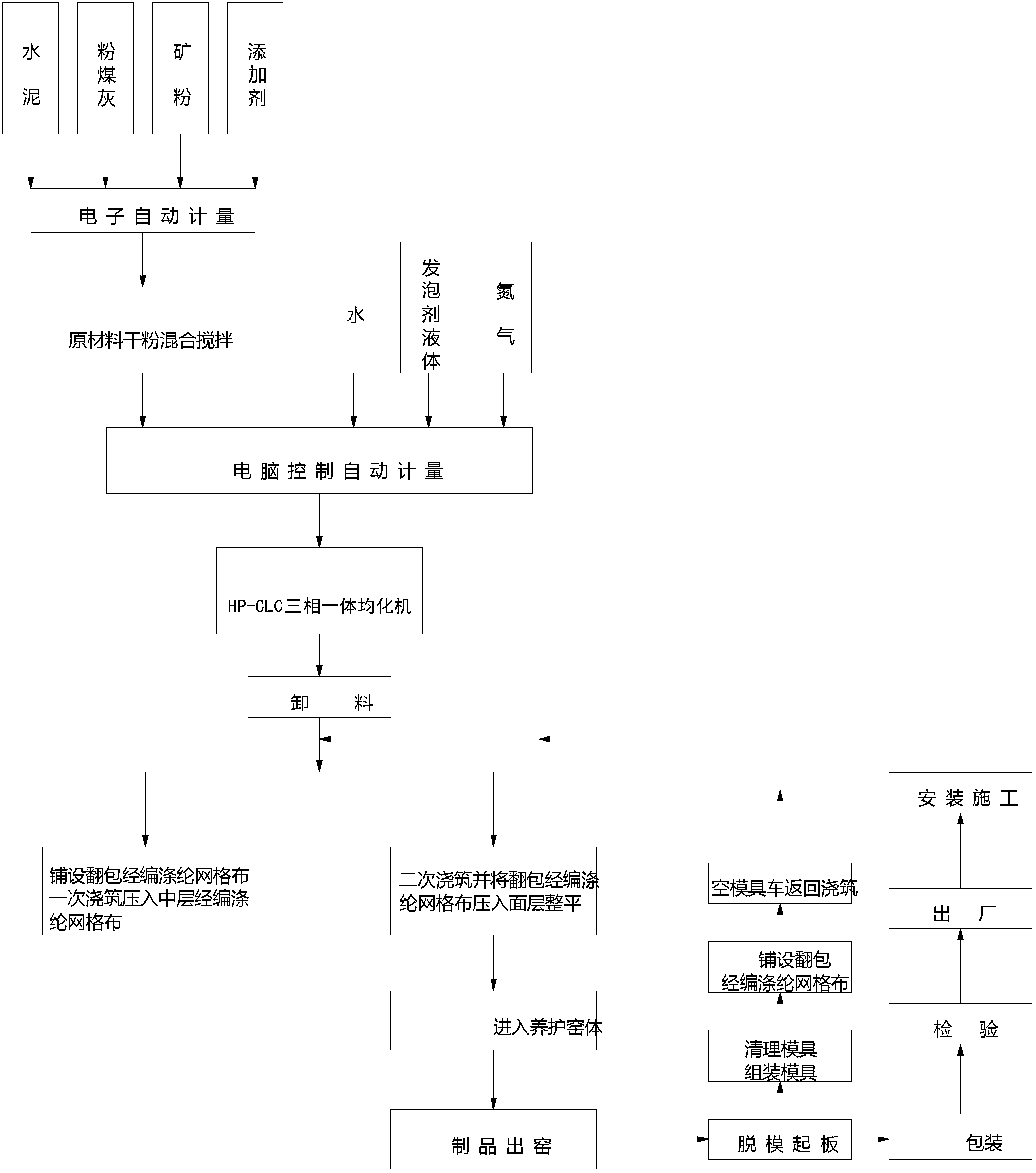

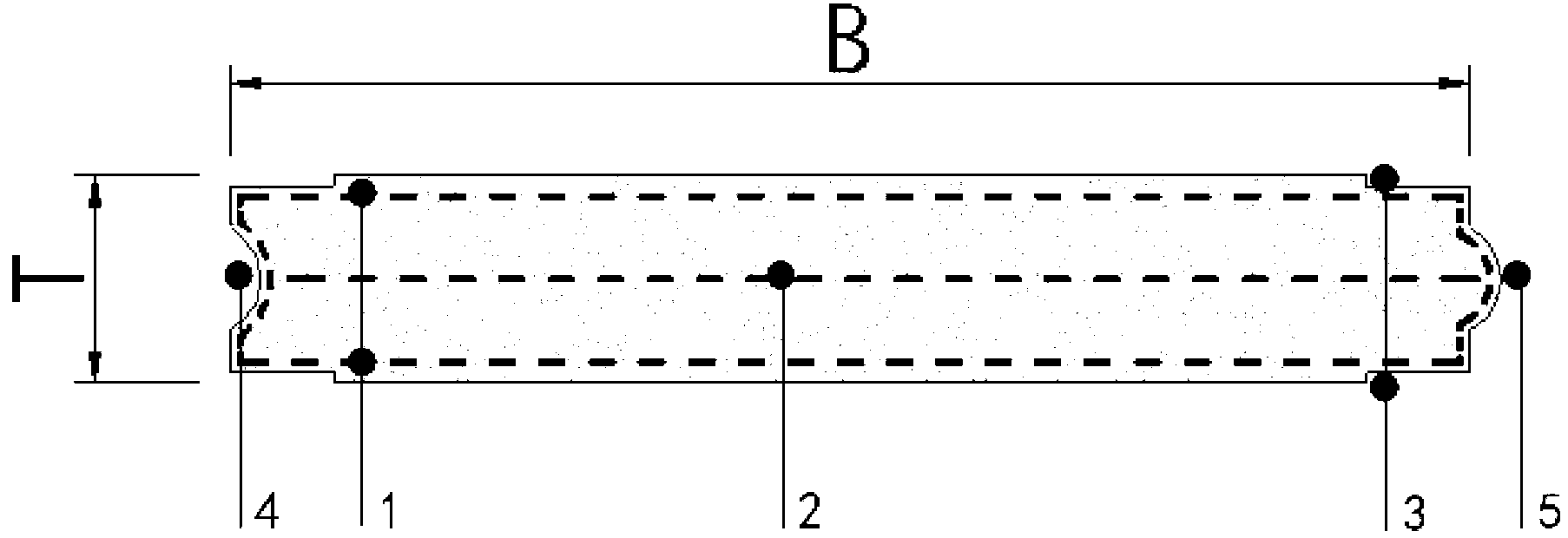

[0061] Example 1: HP-CLC wallboard for exterior walls

[0062] The first step of raw materials and pre-production preparation: 1. Mix 600 kg of cement, 400 kg of fly ash, 350 kg of inorganic heavy skeleton material, 4 kg of toughening fiber, and 13 kg of high-performance activator. The above materials are required according to the weight data Input the raw material into the metering hopper, the raw material screw feeder will automatically measure and transport it to the dry powder mixing equipment, the dry powder will be mixed and homogenized for 8-10 minutes, and the mixing homogenization degree will reach 99%, and then the mixed and homogenized finished dry powder will be put into the finished product storage 2. The polymer initiator is dissolved in 1:40 water (mass ratio) for 30 minutes, and transported to the foaming liquid storage tank for use; 3. The nitrogen working machine is started to make the nitrogen concentration to 99% for use; 4. 1. Fill the mixing water tank fo...

Embodiment 2

[0066] Example 2: HP-CLC wall panels for interior walls

[0067] The first step of raw materials and pre-production preparation: 1. Mix 400 kg of cement, 600 kg of fly ash, 250 kg of inorganic heavy skeleton material, 4 kg of toughening fiber, and 15 kg of high-performance activator. The above materials are required according to the weight data Input the raw material into the metering hopper, the raw material screw feeder will automatically measure and transport it to the dry powder mixing equipment, the dry powder will be mixed and homogenized for 8-10 minutes, and the mixing homogenization degree will reach 99%, and then the mixed and homogenized finished dry powder will be put into the finished product storage 2. The polymer initiator is dissolved in 1:35 water (mass ratio) for 30 minutes, and transported to the foaming liquid storage tank for use; 3. The nitrogen working machine is started to make the nitrogen concentration to 99% for use; 4. 1. Fill the mixing water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com