Crack-proof GRC composite prefabricated member and manufacture method thereof

A prefabricated component and anti-cracking technology, which is applied to building components, structural elements, manufacturing tools, etc., can solve problems such as surface cracking of GRC composite prefabricated components, improve durability and decorative effect, reduce dry shrinkage rate, and reduce cracks The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

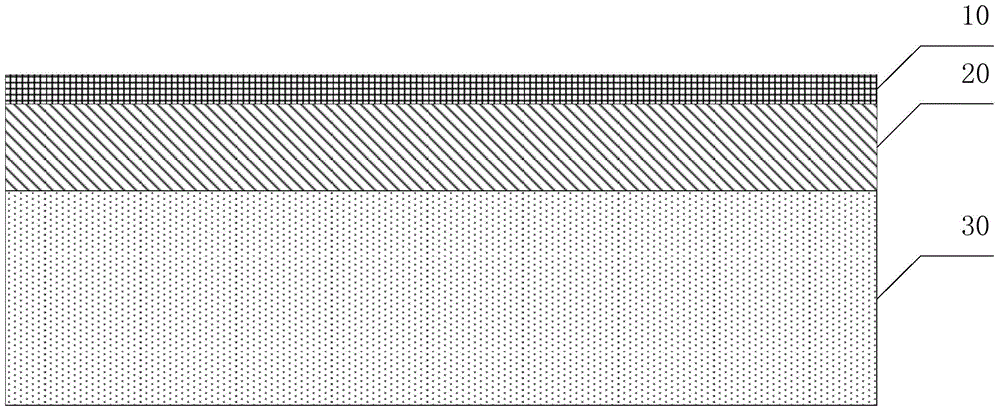

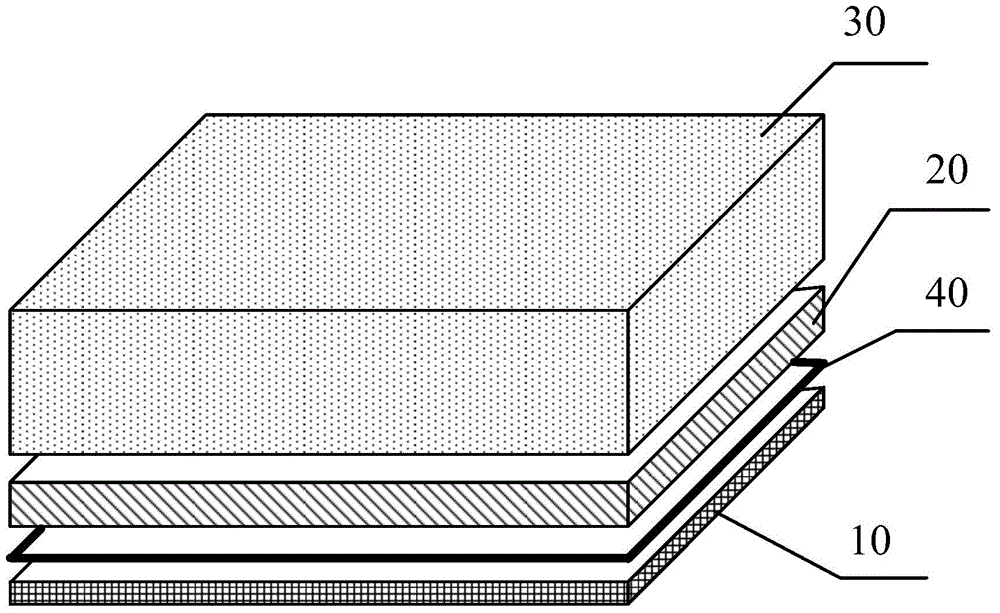

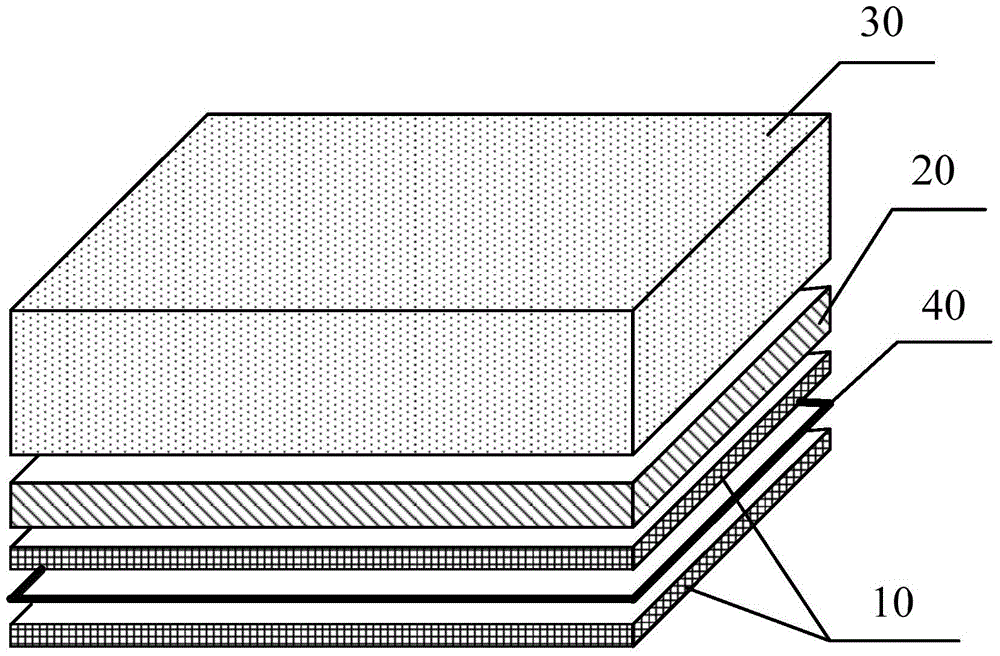

[0038] Those skilled in the art can understand that in the following embodiments of the anti-cracking GRC composite prefabricated component of the present invention (hereinafter referred to as component) and its preparation method, the three-layer structural formula of the anti-cracking GRC composite prefabricated component is used as a variety of different structures and different shapes. The basic structure of various components, anti-cracking GRC composite prefabricated components can be made into exterior wall panels, balconies, eaves, louvers, etc., as long as the building components that require exterior decoration and load-bearing at the same time can use the anti-cracking GRC composite prefabricated components of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com