Method and device for drying wood

A wood drying and drying device technology, applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., can solve the problems of reducing the partial pressure gradient, unevenness and bursting of wood moisture content, and achieve the elimination of unevenness. The effect of distribution, small reduction rate of wood and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

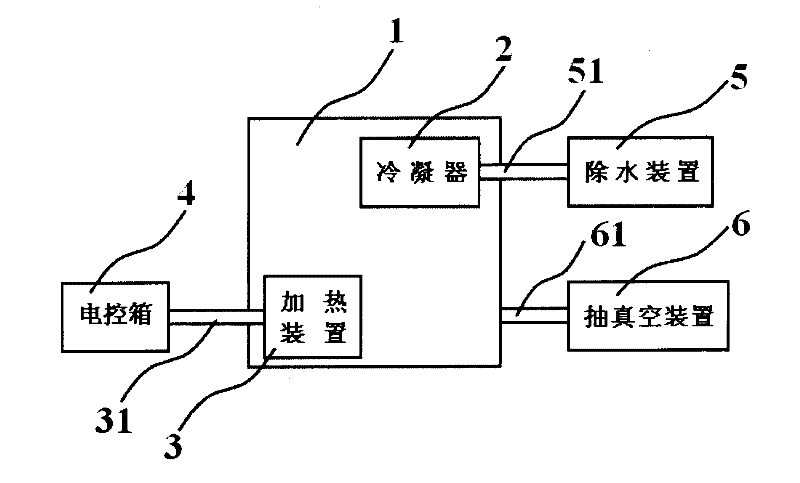

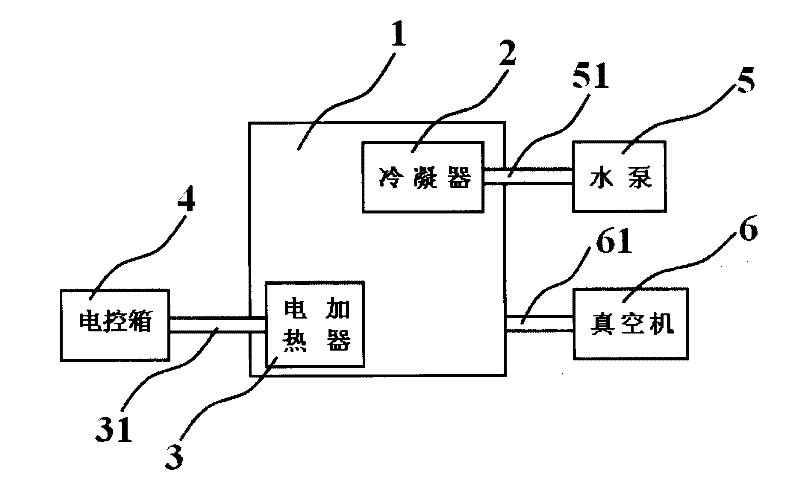

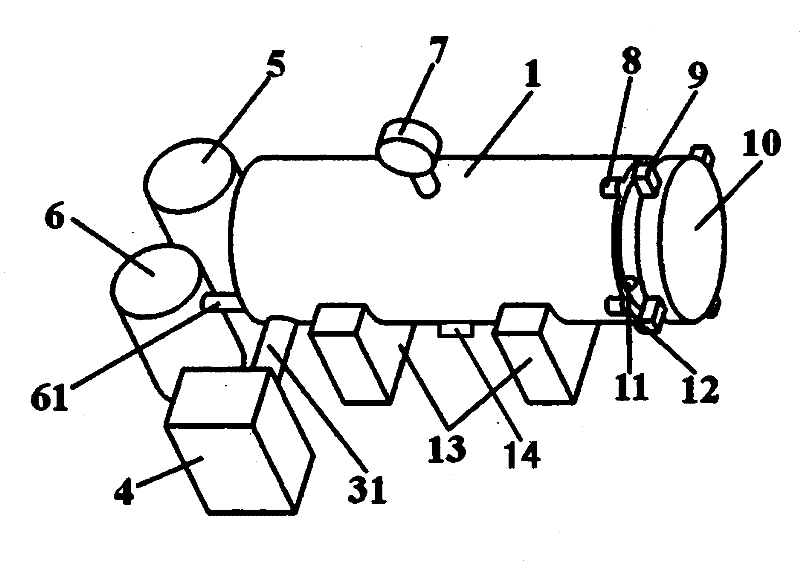

Method used

Image

Examples

Embodiment 1

[0037] Wood drying method is characterized in that comprising the following steps carried out in sequence:

[0038] The first step: process the wood into a wood section of the required size, the length of the wood section is 200mm, and the cross-sectional area of the wood section is 20 square centimeters;

[0039] The second step: put the wood section in the drying device and seal the drying device;

[0040] Step 3: Start the heating device with a fan to heat the drying device to make the temperature reach 65°C and keep it for 20 minutes to 2 hours;

[0041] Step 4: Start the vacuum device, vacuum the drying device, make the absolute pressure negative 0.098 MPa, and keep it for 20 minutes to 2 hours;

[0042] Step 5: Start the water discharge device;

[0043] Step 6: Turn off the water drain and remove the wood section.

Embodiment 2

[0045] Wood drying method is characterized in that comprising the following steps carried out in sequence:

[0046] The first step: process the wood into a wood section of the required size, the length of the wood section is 2000mm, and the cross-sectional area of the wood section is 1 square meter;

[0047] The second step: put the wood section in the drying device and seal the drying device;

[0048] Step 3: Start the heating device with a fan, heat the drying device, make the temperature reach 80°C, and keep it for 20 minutes to 2 hours;

[0049] Step 4: Start the vacuuming device, vacuumize the drying device, make the absolute pressure negative 0.05 MPa, and keep it for 20 minutes to 2 hours;

[0050] Step 5: Start the water discharge device;

[0051] Step 6: Turn off the water drain and remove the wood section.

Embodiment 3

[0053] Wood drying method is characterized in that comprising the following steps carried out in sequence:

[0054] The first step: process the wood into a wood section of the required size, the length of the wood section is 5000mm, and the cross-sectional area of the wood section is 2 square meters;

[0055] The second step: put the wood section in the drying device and seal the drying device;

[0056] Step 3: Start the heating device with a fan, heat the drying device, make the temperature reach 70°C, and keep it for 20 minutes to 2 hours;

[0057] Step 4: Start the vacuum device, vacuum the drying device, make the absolute pressure negative 0.095 MPa, and keep it for 20 minutes to 2 hours;

[0058] Step 5: Start the water discharge device;

[0059] Step 6: Turn off the water drain and remove the wood section.

[0060] The wood drying method described in any of the above embodiments is characterized in that the length of the wood segment in the first step is 200mm-5000m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com