Ultra-thin layer repairing agent and construction technology thereof

A repairing agent and ultra-thin technology, which is applied in the field of ultra-thin layer repairing agent and its construction technology, can solve the problems of hollowing, low wear resistance, and low strength in the later stage, and achieve noise reduction, good wear resistance, and dry shrinkage low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

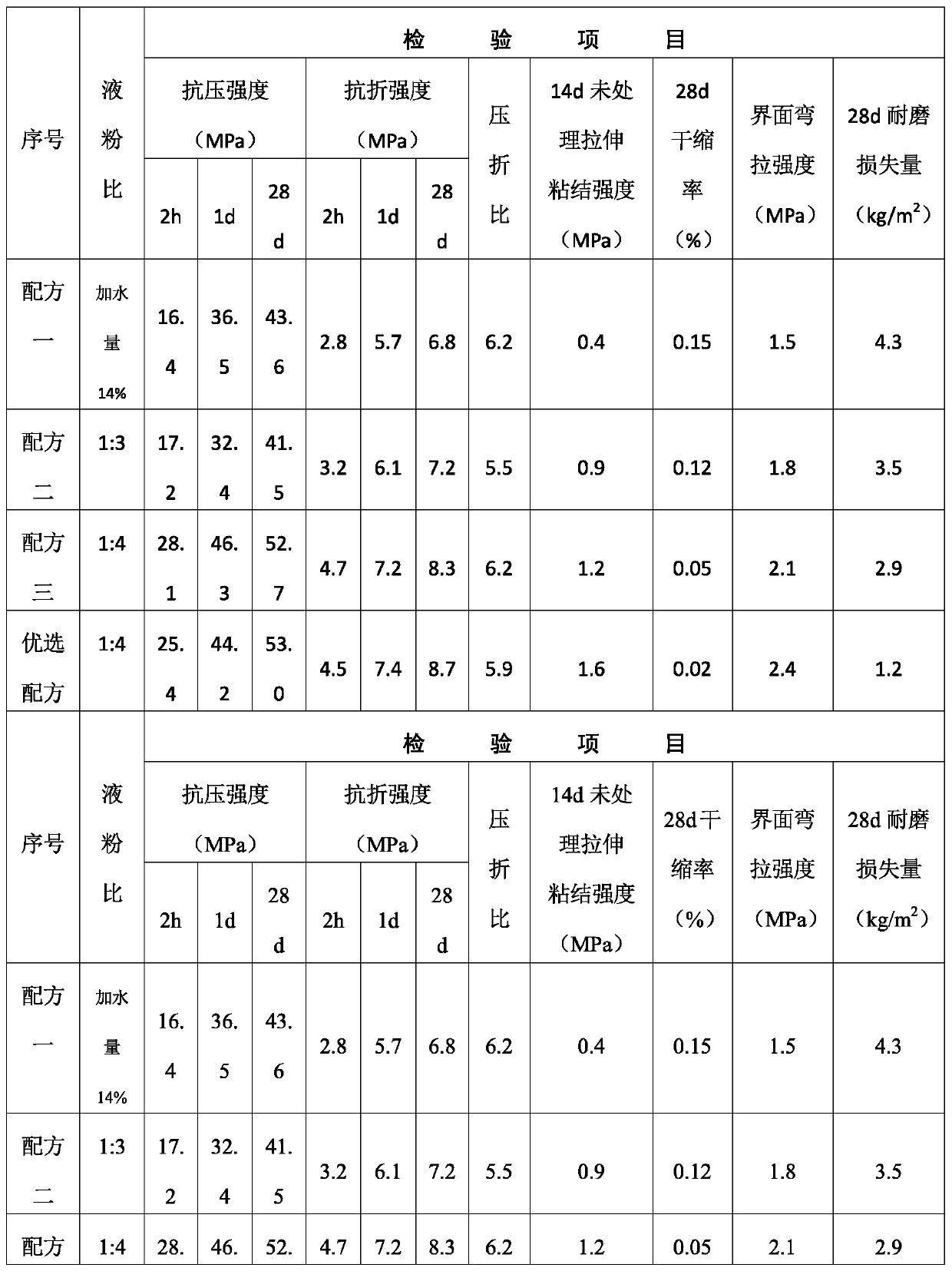

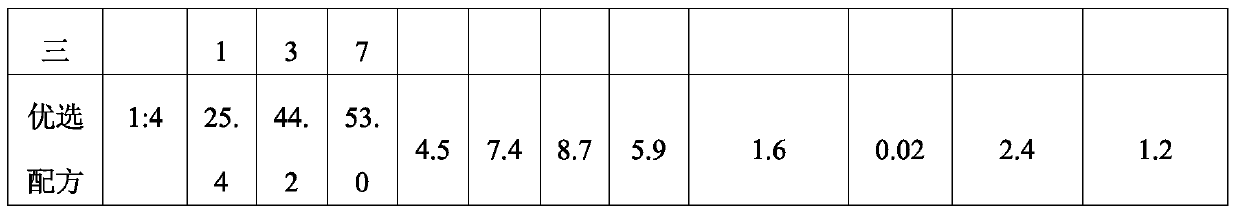

[0023] Table I:

[0024] Main technical performance indicators of ultra-thin layer repair mortar

[0025]

[0026] Recipe one:

[0027] No liquid material (powder directly add water and mix)

[0028] Powder: 45% sulfoaluminate cement, 50% refined graded quartz sand, 5% fly ash, 0.2% retarder, 0.3% cellulose

[0029] Water content of powder: 14%

[0030] [Test conclusion]: When the amount of water added is large, the mixture has poor encapsulation, many pores, and fine cracks appear on the surface after hardening; when the amount of water added is small, the mixture is dry, no flow, and difficult to construct.

[0031] Recipe 2:

[0032] Liquid material part: polymer emulsion 40%, clean water 60%, hydroxymethyl propyl cellulose 0.5%, bactericidal preservative 0.2%, dispersant 0.6%

[0033] Powder part: 30% sulfoaluminate cement, 10% slag, 20% ordinary Portland cement, 40% quartz powder, 2% naphthalene-based water reducer, 0.2% coagulant, 0.05% powder defoamer, Toner 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com