Masonry mortar produced by construction solid waste

A technology for solid waste and masonry mortar, which is applied in the field of masonry mortar, can solve the problems that blocks cannot be used for main works, lack of edges and corners, large monomers, etc., and achieves good workability and low drying shrinkage. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

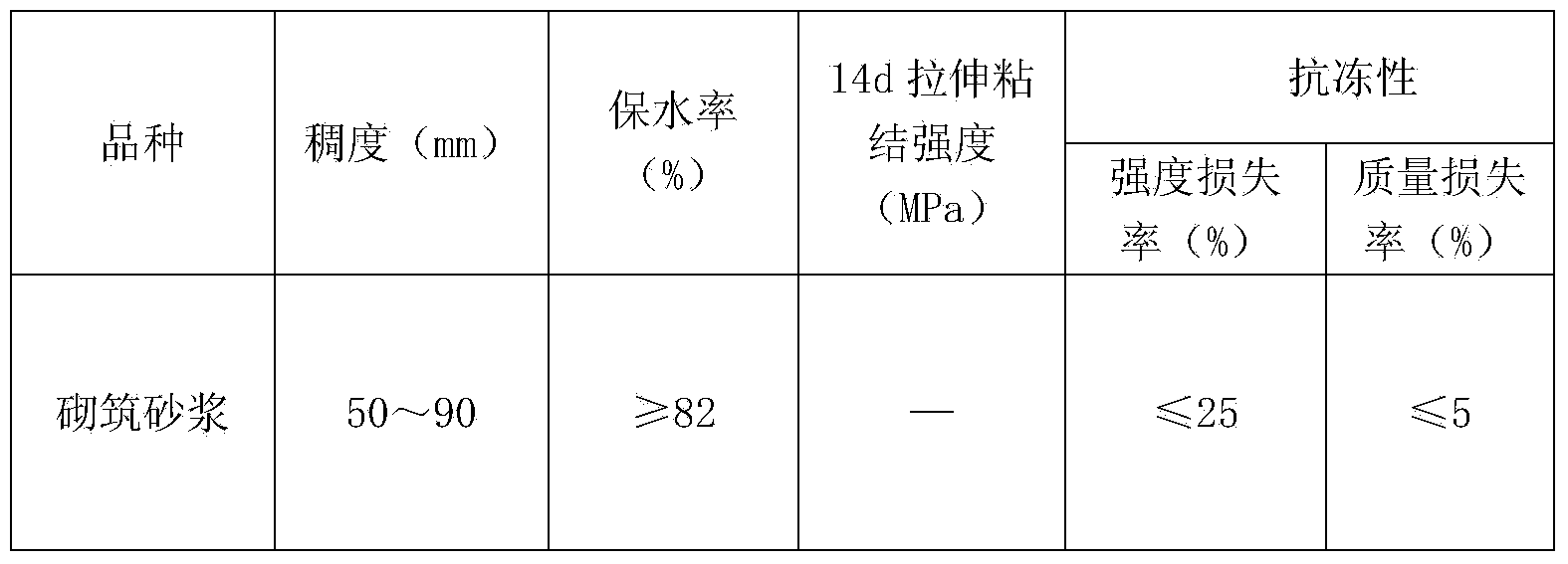

[0013] A masonry mortar produced from construction solid waste, which is composed of the following raw materials in parts by weight (kg):

[0014] Cement 170, construction solid waste 1,000, vitrified microbeads 30, limestone 40, shell powder 16, magnesium sulfate heptahydrate 3, redispersible latex powder 10, polytetrafluoroethylene fiber 3, butyltin trioctoate 0.8, calcium phosphate 2 , graphite powder 4, nano carbon powder 1, aluminum dihydrogen phosphate 2, triethanolamine oleic acid soap 0.8, aluminum nitride powder 2;

[0015] The construction solid wastes are waste concrete blocks, standard bricks and (hollow) aerated concrete blocks and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com