Limestone micro powder-steel slag powder-slag powder composite admixture and preparation process thereof

A composite admixture and preparation process technology, which is applied in the field of limestone micropowder-steel slag powder-slag powder composite admixture and its preparation process, can solve the problems of low activity, large particle size of raw materials, and poor concrete compressive strength. Achieve the effects of improving compatibility, reducing drying shrinkage, and improving concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

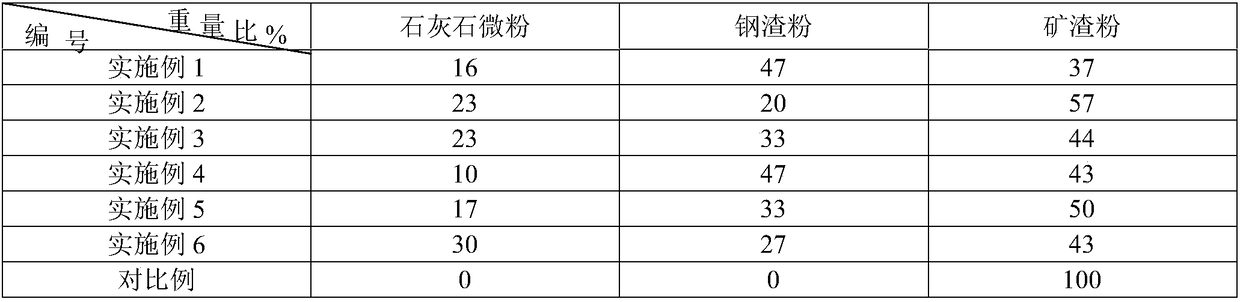

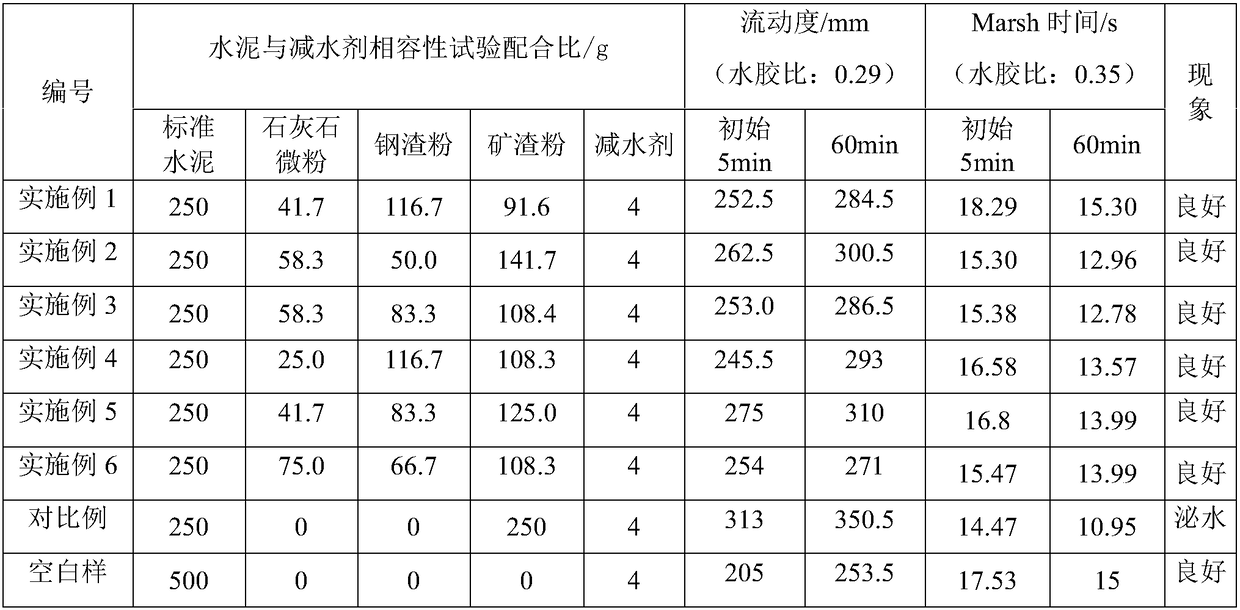

[0022] The present invention mixes S95 grade slag powder with limestone micropowder and steel slag powder, and utilizes the mutual excitation and synergistic effect between the three to prepare a composite admixture with high early strength, sustained growth in later strength, and compensating shrinkage effect. Improve the compatibility of cement and water reducer, improve the strength of concrete. The technical solutions of the present invention are described in detail below through specific examples.

[0023] The limestone micropowder-steel slag powder-slag powder composite admixture of the present invention is prepared through the following process:

[0024] 1) drying, crushing, grinding, grading or sieving limestone and steel slag respectively to obtain limestone fine powder and steel slag powder;

[0025] Specifically, the limestone is dried to a moisture content of less than 1%, and then crushed to a particle size of less than 4.75mm using a jaw crusher, followed by gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com