Aerogel thermal insulation coating and preparation method thereof

A technology of thermal insulation and airgel, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of poor thermal insulation effect, low thermal insulation inhibition rate, large heat conduction of thermal insulation coatings, etc. It is suitable for popularization, Low drying shrinkage value, the effect of preventing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

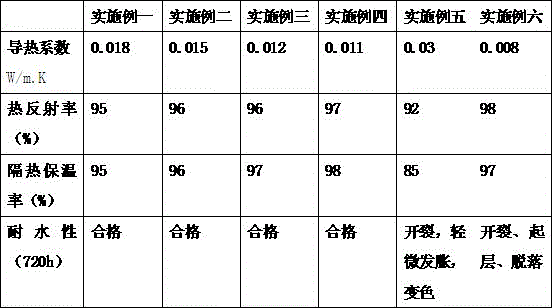

Examples

Embodiment 1

[0025] Embodiment 1. The formula of an airgel thermal insulation coating in this embodiment includes: 100 parts of film-forming agent, 3 parts of glass fiber, 2 parts of rock wool fiber, silica airgel 20 parts of glue, 5 parts of nano hollow silicon microspheres, 20 parts of porous powder quartz, additives including 3 parts of binder, 2 parts of penetrating agent, 1 part of thickener, 0.1 part of active agent and 2 parts of defoamer, The silica airgel content in the silica airgel mortar is 20%.

[0026] A preparation method of an airgel thermal insulation coating, comprising the following steps:

[0027] Step 1. Put 2 parts of wetting agent and 20 parts of deionized water into a container and stir in the ratio of parts by weight; mix 20 parts of silica airgel powder with 50 parts of deionized water, stir evenly, and mix the two The mixture is mixed, first stirred at a speed of 550r / min for 5 minutes, and then stirred at a speed of 1100r / min for 5 minutes to prepare silica air...

Embodiment 2

[0031] Embodiment 2: A kind of airgel thermal insulation coating of the present embodiment comprises: by weight ratio: 100 parts of film-forming agent, 3 parts of glass fiber, 2 parts of polypropylene fiber, silica airgel mucilage 26 parts, 6 parts of nano hollow silicon microspheres, 28 parts of porous powder quartz, 3 parts of binder, 2 parts of penetrant, 1 part of thickener, 0.1 part of active agent and 2 parts of defoamer, the silicon dioxide The silica airgel content in the airgel mucilage is 20%, and the silica airgel content in the silica airgel mucilage is 22%.

[0032] A preparation method of an airgel thermal insulation coating, comprising the following steps:

[0033] Step 1, put 2 parts of wetting agent and 15 parts of deionized water into a container and stir in the ratio of parts by weight; mix 22 parts of silica airgel powder with 60 parts of deionized water, stir evenly, and mix the two The mixture is mixed, first stirred at a speed of 550r / min for 6 minutes,...

Embodiment 3

[0037] Embodiment 3: A kind of airgel thermal insulation coating of this embodiment, comprises and comprises by weight ratio: 100 parts of film-forming agent, 3 parts of rock wool fibers, 3 parts of polypropylene fiber, silica airgel mucilage 28 parts, 7 parts of nano hollow silicon microspheres, 37 parts of porous quartz powder, 3 parts of binder, 3 parts of penetrating agent, 3 parts of thickening agent, 0.3 parts of active agent and 2 parts of defoamer, the silicon dioxide The silica airgel content in the airgel glue is 28%.

[0038] A preparation method of an airgel thermal insulation coating, comprising the following steps:

[0039] Step 1. Put 2 parts of wetting agent and 15 parts of deionized water into a container and stir in the ratio of parts by weight; mix 2:8 parts of silica airgel powder with 60 parts of deionized water, stir evenly, and The two mixtures were mixed, first stirred at a speed of 550r / min for 6 minutes, and then stirred at a speed of 1100r / min for 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com