Patents

Literature

32results about How to "High shielding rate" patented technology

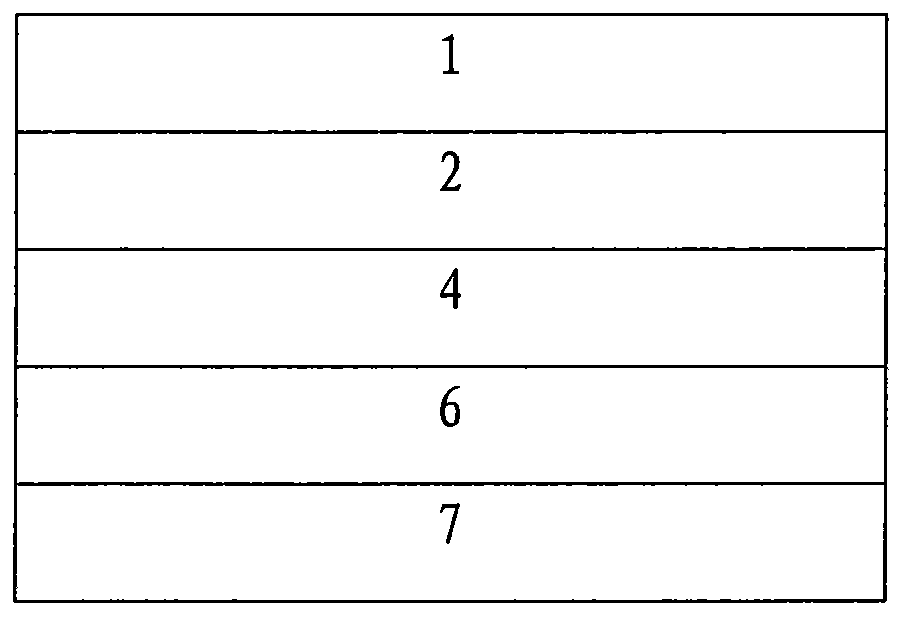

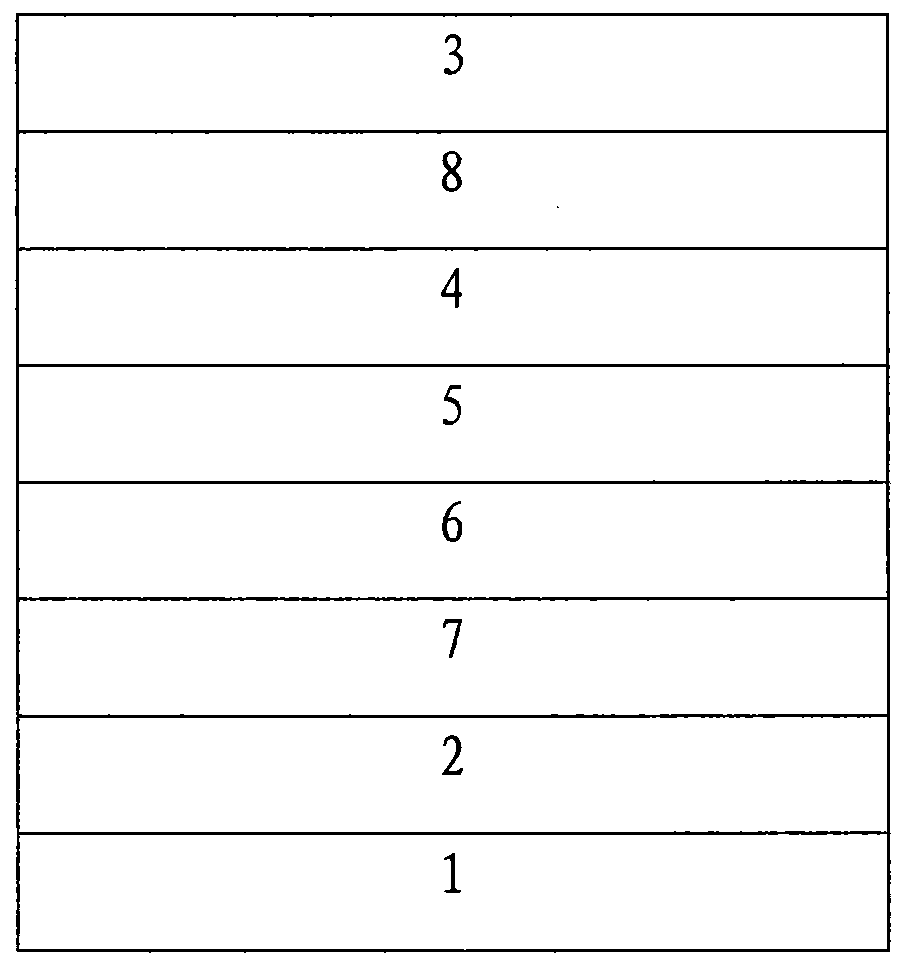

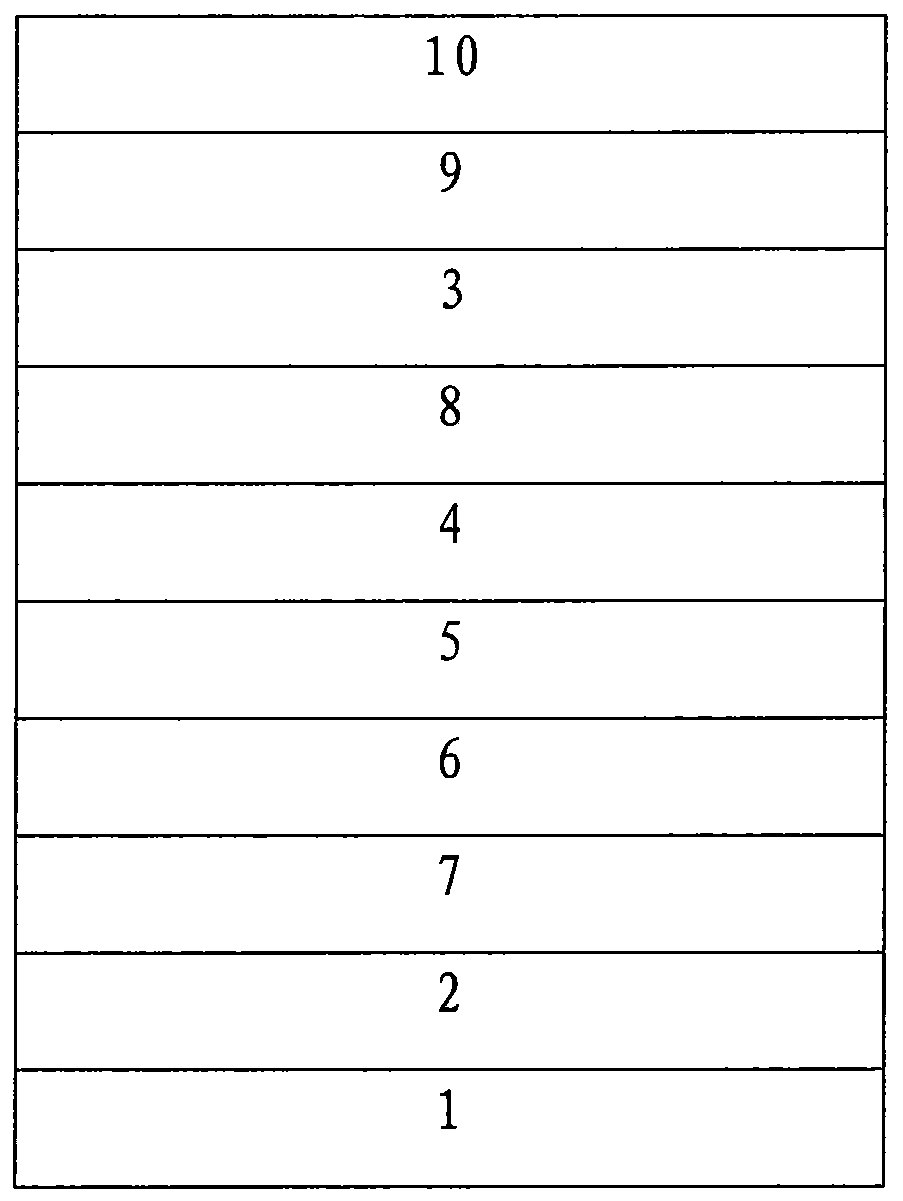

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

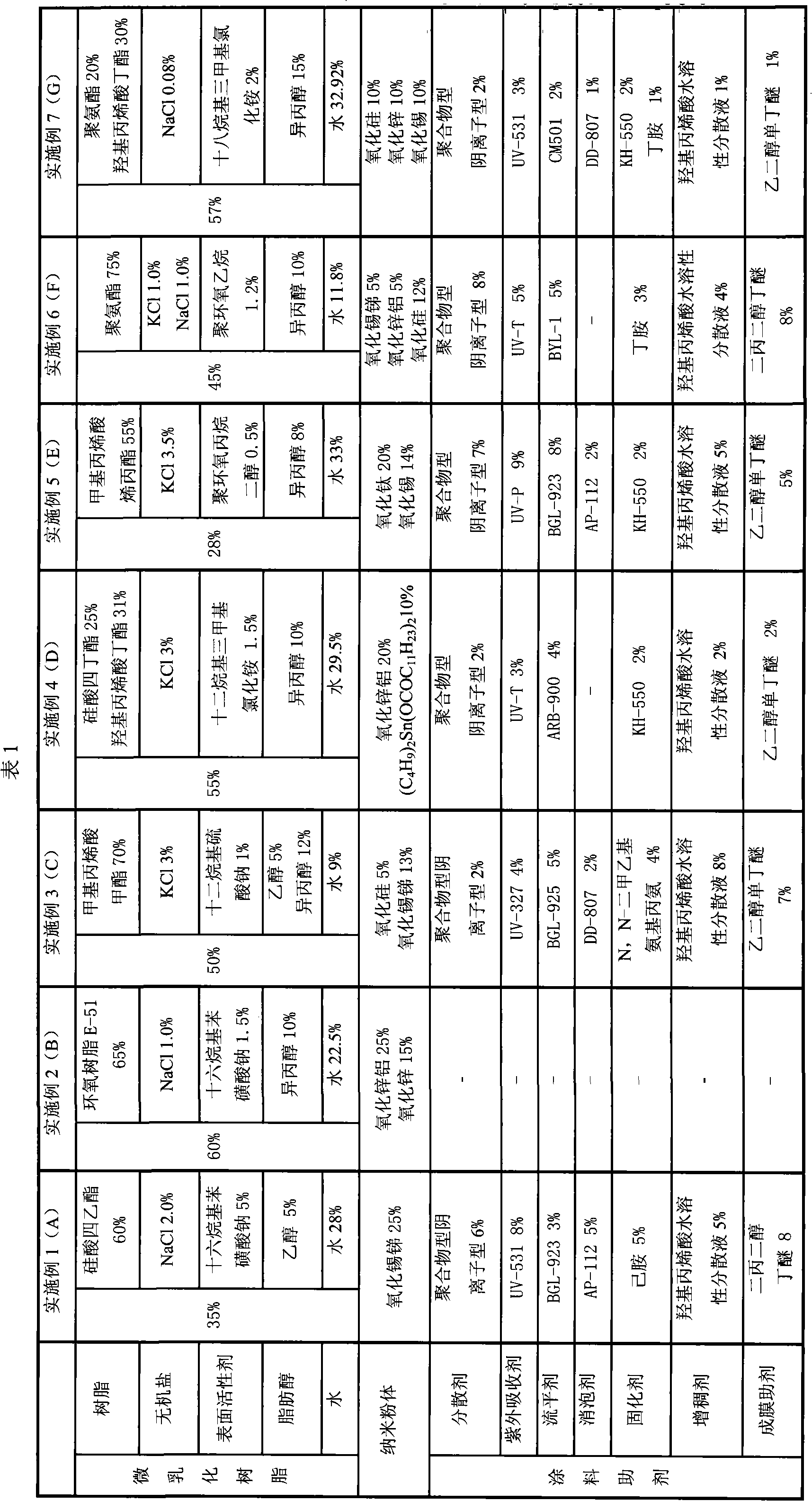

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

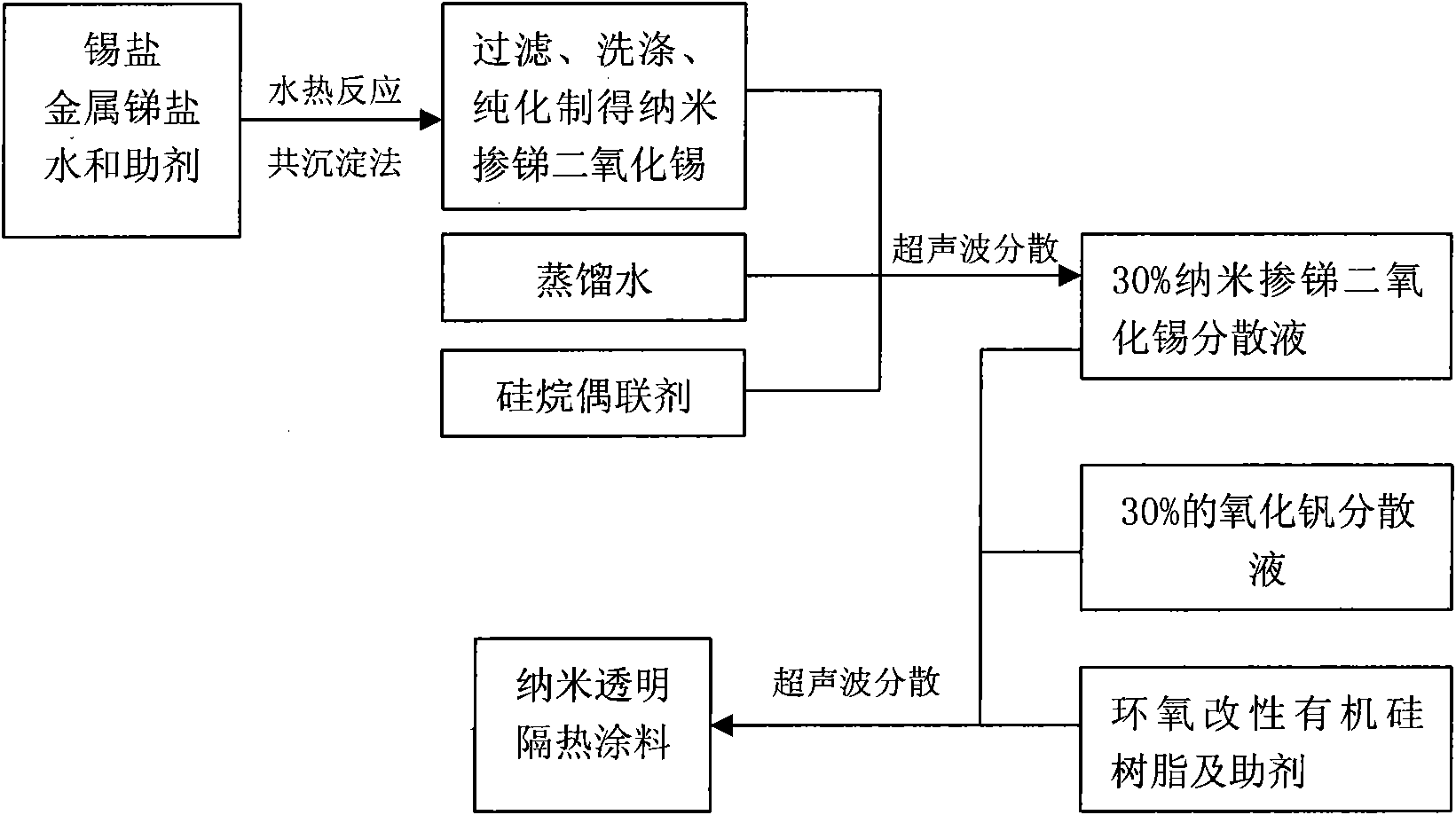

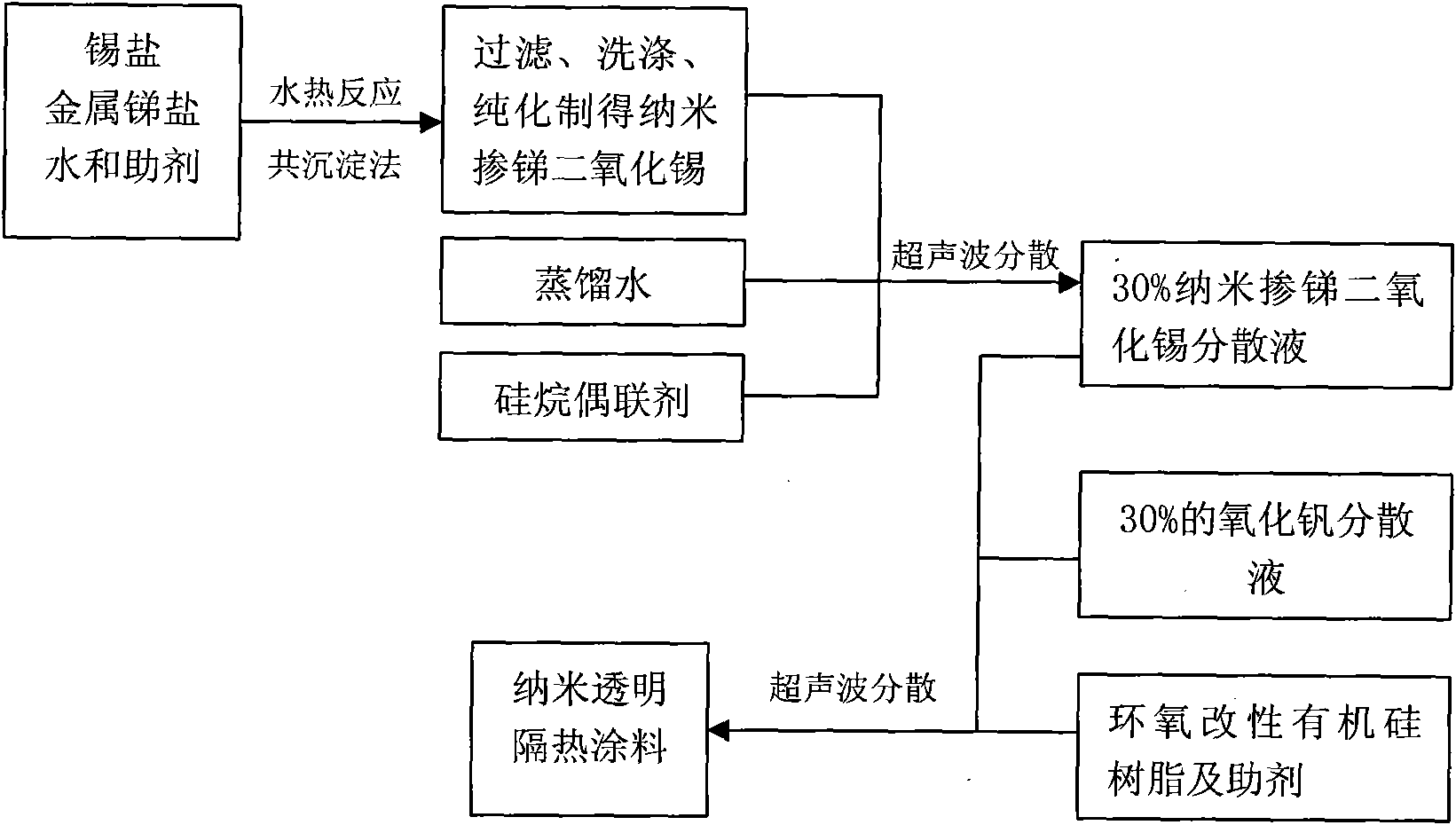

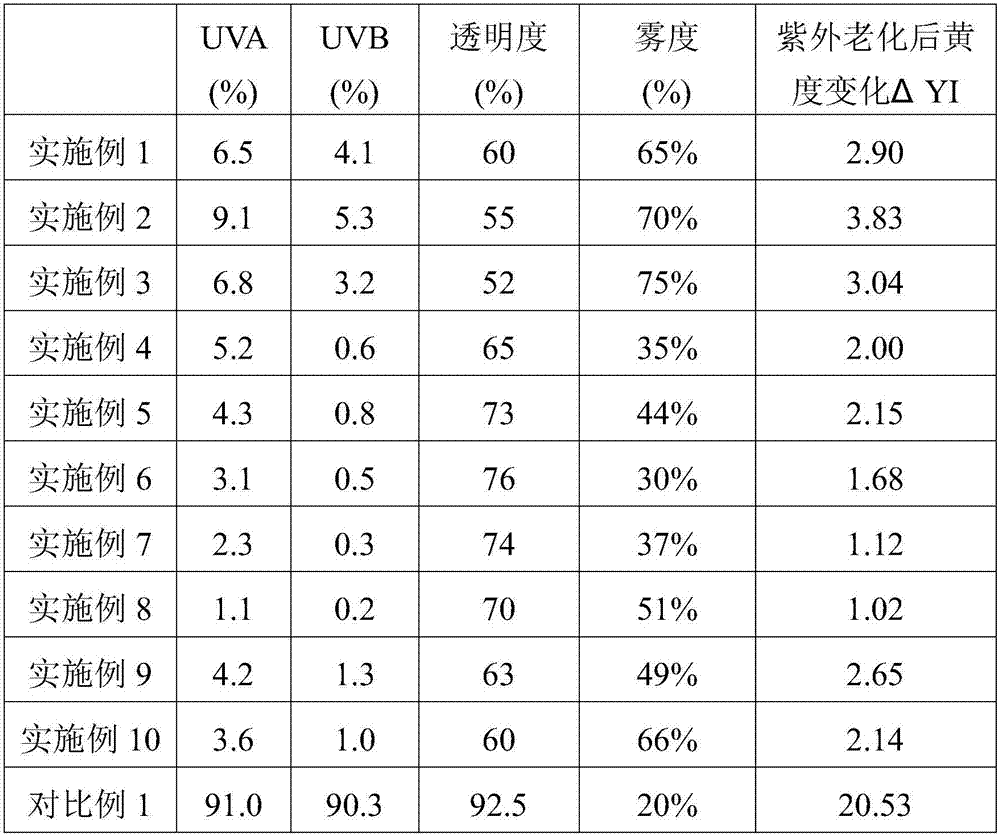

Nano transparent thermal insulation coating

ActiveCN101982514ASpecial optical propertiesHigh shielding rateCoatingsSide effectThermal insulation

The invention relates to the technical field of thermal insulation coatings, in particular to a nano transparent thermal insulation coating with a switch function, which comprises the following components in percentage by weight: 10-30% of nano-sized antimony doped stannic oxide dispersion the concentration of which is 30%, 2-10% of nano-sized vanadium oxide dispersion the concentration of which is 30%, 30-70% of film-forming agent, 0.3-0.8% of antifoaming agents, 0.05-0.8% of flatting agent and the balance water. The nano transparent thermal insulation coating is prepared by adding the components to a high-energy stirring mill to stir in accordance with the formula. The coating in the invention has the advantages of safety, non-toxic side effects, non-pollution on the environment, high bonding strength, short drying time, high transparence, non-influence on visual effect, corrosion prevention, acid-base resistance and the like, and is convenient to use.

Owner:江苏引潮蕴飞新材料有限公司

Polycarbonate composition and preparation method

The invention discloses a polycarbonate composition and a preparation method. The composition comprises polycarbonate and melanin, or polycarbonate, melanin and an antioxidant, wherein based on 100 parts by weight of the polycarbonate, the melanin is 0.05-10 parts by weight and the antioxidant is 0.01-1 part by weight, and the melanin is selected from a group which consists of naturally extracted melanin, and melanoid prepared by chemical synthesis and a biological fermentation method. The preparation method comprises one of the following steps: (a) melting and blending polycarbonate, melanin and the antioxidant according to the usage amounts to prepare the polycarbonate composition; and (b) dissolving polycarbonate into an organic solvent, adding melanin of the usage amount, performing uniform stirring and mixing; and performing drying to obtain the polycarbonate composition. The polycarbonate composition provided by the invention can enhance the ultraviolet light blocking ability and light stability of polycarbonate at the same time and increases the service life of the polycarbonate.

Owner:JIANGNAN UNIV

Neutron shield material with flame-retardant neutron shield heat-shielding performance and preparation method thereof

The invention discloses a neutron shield material with flame-retardant neutron shield heat-shielding performance and a preparation method thereof. The material is prepared from dimethylvinyl silica gel, a neutron absorber material, a flame-retardant functional filler, a heat-shielding functional filler, vulcanizing agent 2,5-dimethyl-2,5-dihexane and a powder surface modifier. The method comprises the steps of adding the dimethylvinyl silica gel and vulcanizing agent 2,5-dimethyl-2,5-dihexane in an open mill for plastication, then mixing the mixture and the neutron absorber material, the flame-retardant functional filler, the heat-shielding functional filler as well as the powder surface modifier, adding the mixed solution in a vacuum internal mixer for banburying, and finally adding a product obtained after the banburying into a press vulcanizer to obtain the neutron shield material with the flame-retardant neutron shield heat-shielding performance. The material has the thermal neutron shielding performance, and has good tenacity, flame-retardance, heat-shielding performance and mechanical strength, peripheral protection of nuclear instruments with complicated shaped can be met, and the material is also a good core material for neutron protection clothing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

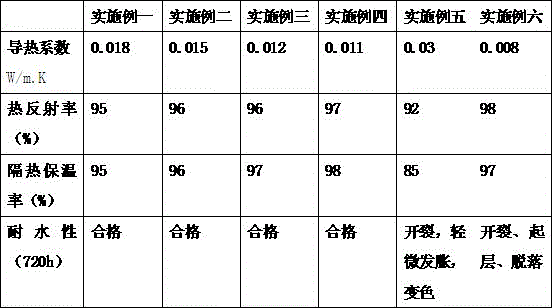

Aerogel thermal insulation coating and preparation method thereof

The invention discloses an aerogel thermal insulation coating and a preparation method thereof, belongs to the field of thermal insulation coatings and aims at solving the problems that the thermal insulation coating in the prior art has large heat conduction, low thermal insulation inhibition ratio and a poor thermal insulation effect. The aerogel thermal insulation coasting is prepared from materials in parts by weight: 100 to 110 parts of film forming agent, 40 to 100 parts of filler and 2 to 8 parts of fire resistant fiber, wherein the filler is prepared from 20 to 40 parts of silicon dioxide aerogel cement and 5 to 10 parts of nanometer hollow silicon microsphere, and an aid is prepared from 3 to 6 parts of binder, 1 to 4 parts of penetrant, 0.5 to 5 parts of thickener, 0.1 to 0.4 part of active agent and 2 to 3 parts of defoamer. The coating disclosed by the invention can form a three-dimensional network hollow structure on the surface of a building wall body, the three-dimensional network hollow structure is formed by sealed microspheres which are connected together, and a fine nano-porous network structure of aerogel and the nanometer hollow silicon microspheres can form a stacked static-state air set; thus, heat conductivity coefficient of a coating is smaller than 0.015W / m.K, and heat conductivity can be effectively prevented.

Owner:XINHUASHENG ENERGY SAVING TECH CO LTD

Heat ray shielding material

InactiveCN103221850AGood light fastnessImprove permeabilityOther chemical processesCoatingsSilver plateIndium

Provided is a heat ray shielding material that has superior visible light transmittance, radio wave transmittance, and light resistance, can shield infrared rays across a wide band, and has a high infrared ray shielding rate. The heat ray shielding material has a heat ray shielding layer that contains silver plate particles and metal oxide particles. Preferable are: an embodiment wherein the metal oxide particles are tin-doped indium oxide particles; an embodiment wherein the silver plate particles and the metal oxide particles are mixed and dispersed in a binder in the heat ray shielding layer; and an embodiment wherein a silver-plate-particle-containing layer that contains the silver plate particles and a metal-oxide-containing layer that contains the metal oxide are laminated in the heat ray shielding layer.

Owner:FUJIFILM CORP

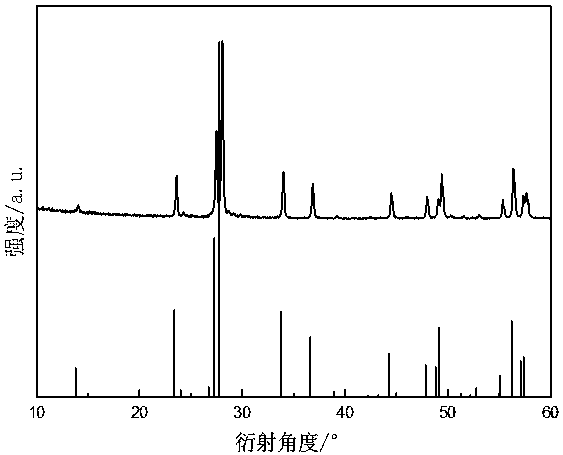

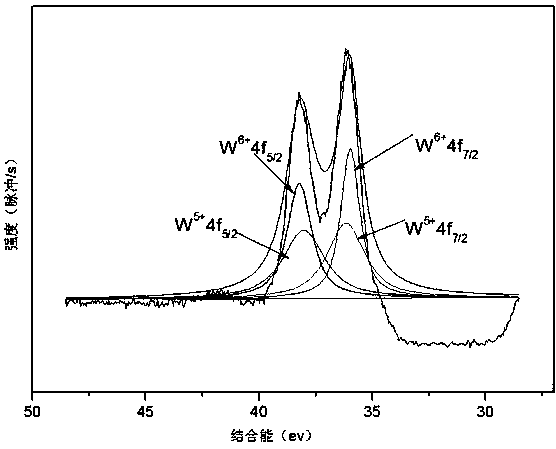

Tantalum-doped cesium tungsten bronze and preparation method and application thereof

InactiveCN109678211ASimple processHigh shielding rateMaterial nanotechnologyCoatingsTransmittanceNear infrared light

The invention discloses tantalum-doped cesium tungsten bronze and a preparation method and application thereof. The tantalum-doped cesium tungsten bronze adopts a molecular formula of CsxTayW1-yO3, wherein y is greater than or equal to 0.01 and smaller than or equal to 0.30, and x is greater than or equal to 0.20 and smaller than or equal to 0.33. The tantalum-doped cesium tungsten bronze is applied to preparation of heat-insulating coating or a heat-insulating film, so that the heat-insulating coating or the heat-insulating film has the advantages of high near-infrared light shielding rate toand high visible light transmittance.

Owner:SHENZHEN UNIV

Uvioresistant laminated plastic film

The invention discloses an uvioresistant laminated plastic film. The uvioresistant laminated plastic film is prepared from, by weight, 65-75 parts of polypropylene, 45-55 parts of corn starch, 4-5 parts of montmorillonite, 10-16 parts of bamboo charcoal powder, 4-8 parts of plasticizer, 5-7 parts of fish glue from scale, 8-15 parts of collagenous fibers, 2-5 parts of elastomer, 5-8 parts of polylactic acid, 3-8 parts of plant fibers, 5-10 parts of nano titanium dioxide, 5-10 parts of waterproof agent, 3-6 parts of tea polyphenols, 6-12 parts of peroxide and 2-7 parts of antistatic agent. The adopted corn starch is rich in sources, low in cost and environment friendly, the prepared plastic film is high in strength, low in production cost, biodegradable and antistatic, and white pollution can be mitigated. By the aid of the characteristics of ultraviolet shielding of montmorillonite and oxidation resistance of tea polyphenols, the film is good in ultraviolet resistance and oxidation resistance, and rate of ultraviolet shielding is over 96%; as bamboo charcoal powder is added in the formula, a lot of negative ions can be released, and the plastic film is strong in odor adsorbability, antibacterial property and deodorization capability.

Owner:桐城市弘业塑胶有限公司

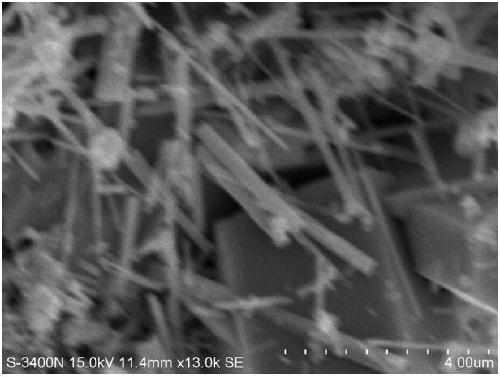

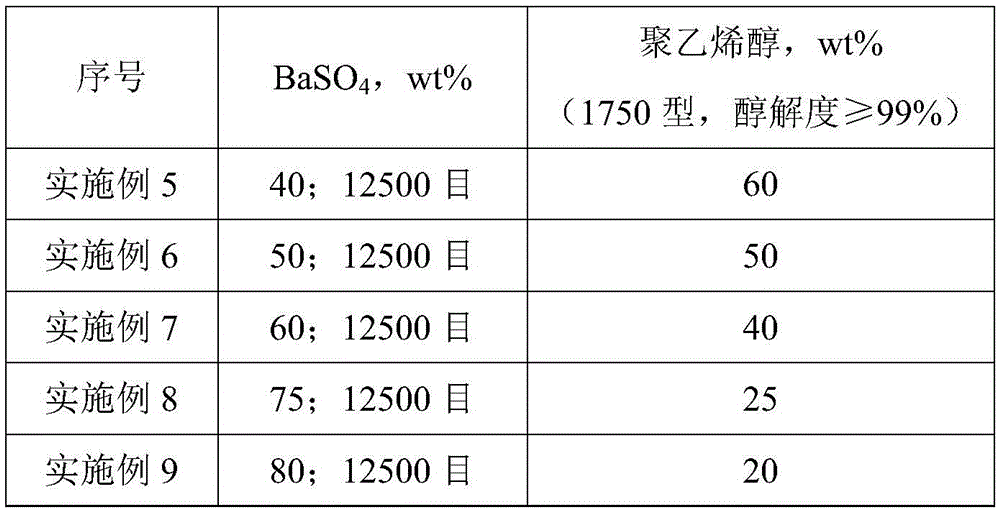

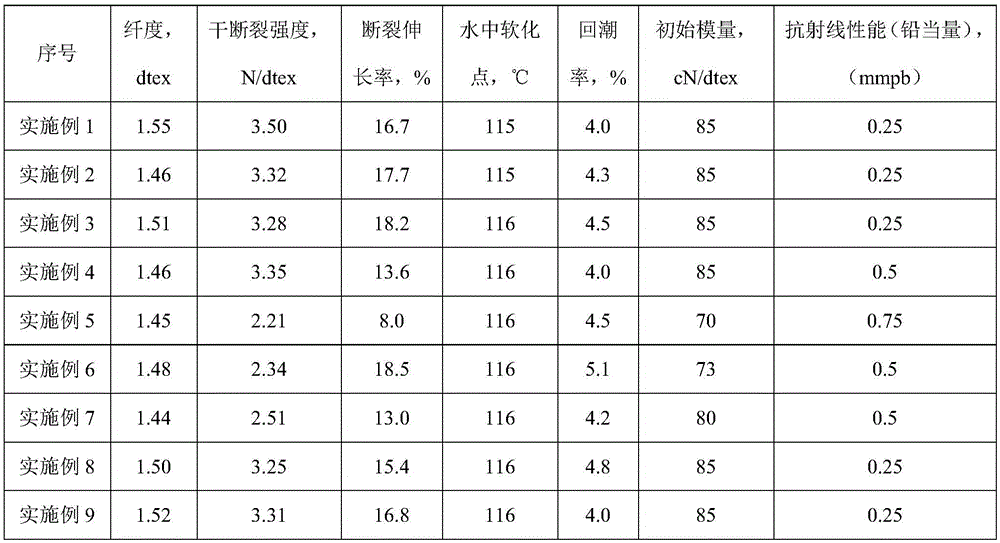

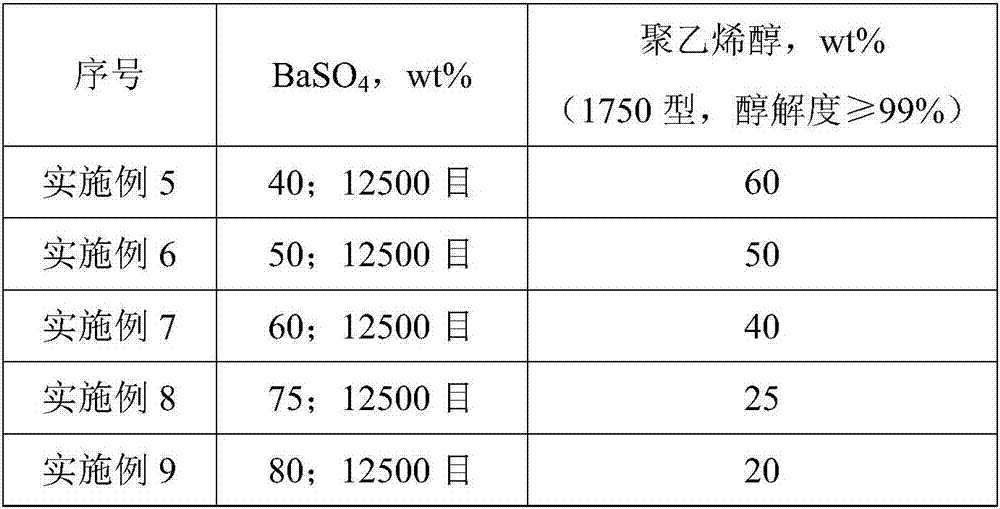

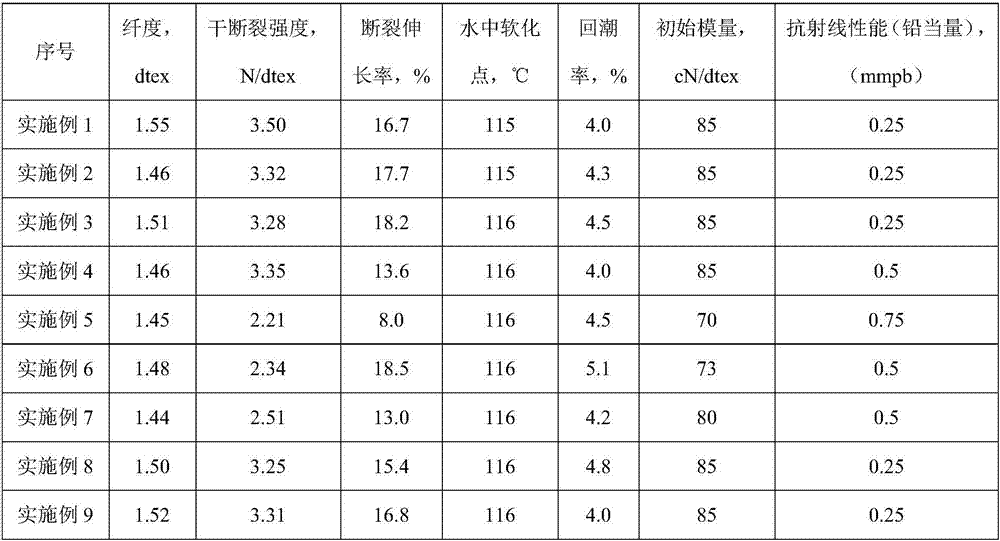

Barium sulfate/polyvinyl alcohol composite fiber and preparation method thereof and non-woven fabric

ActiveCN105624821AImprove radiation resistanceImprove breathabilityMonocomponent synthetic polymer artificial filamentWet spinning methodsBreaking strengthPolyvinyl alcohol

The invention discloses barium sulfate / polyvinyl alcohol composite fiber and a preparation method thereof and non-woven fabric. The composite fiber consists of the following components in percentage by mass: 20-80% of barium sulfate and 80-20% of polyvinyl alcohol. The composite fiber is prepared by blending superfine barium sulfate and polyvinyl alcohol and performing a wet spinning technology; and the prepared non-woven fabric has the characteristics of good resistance to ray radiation, good air permeability, smooth hand feeling, gentle gloss and wearing comfort and softness. The fineness of the composite fiber is 1.5-5dtex, the dry breaking strength is 2.0-8.0cN / dtex, the dry elongation at break is 15-40%, and the initial modulus reaches 60-100cN / dtex. The shielding rate of the non-woven fabric with fixed weight of 500g / m<2> and prepared from the composite fiber against medium- and low-energy X rays can exceed 70%, and the shielding rate of protective clothing can be further improved by adjusting the thickness or layer number of the fabric.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

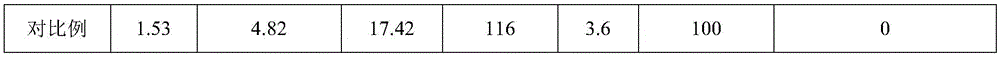

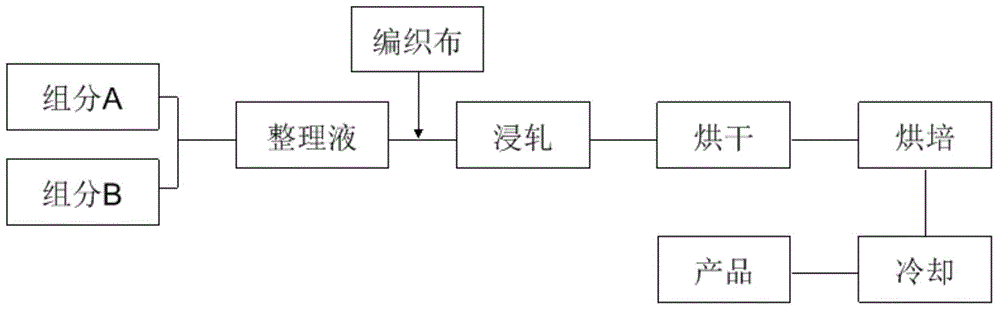

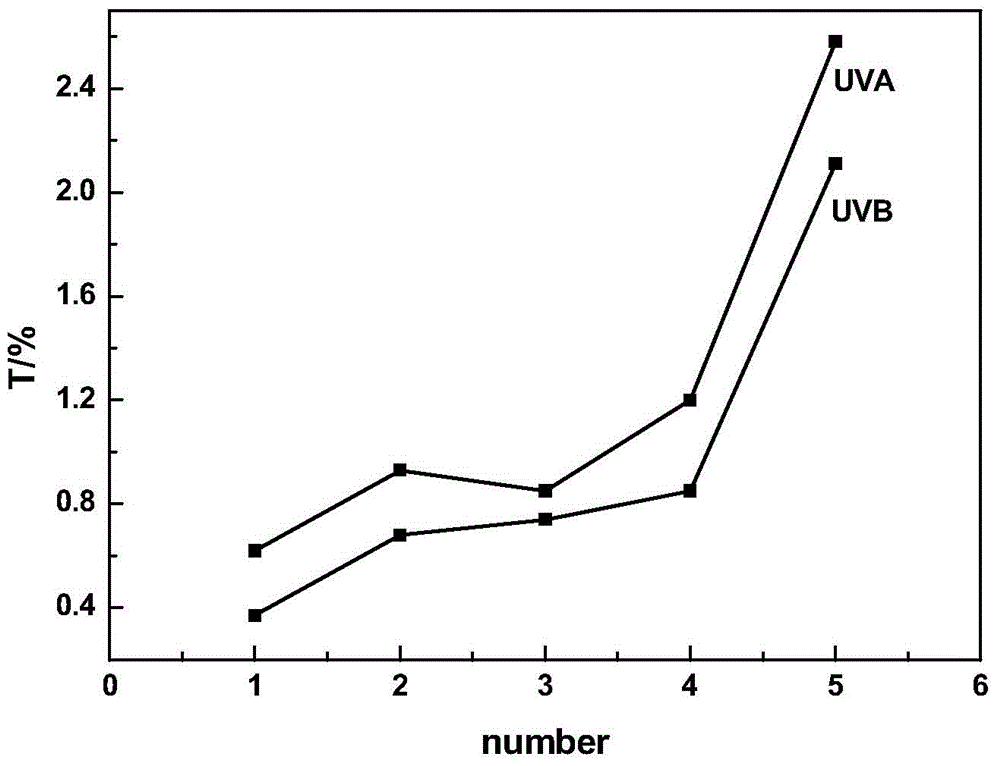

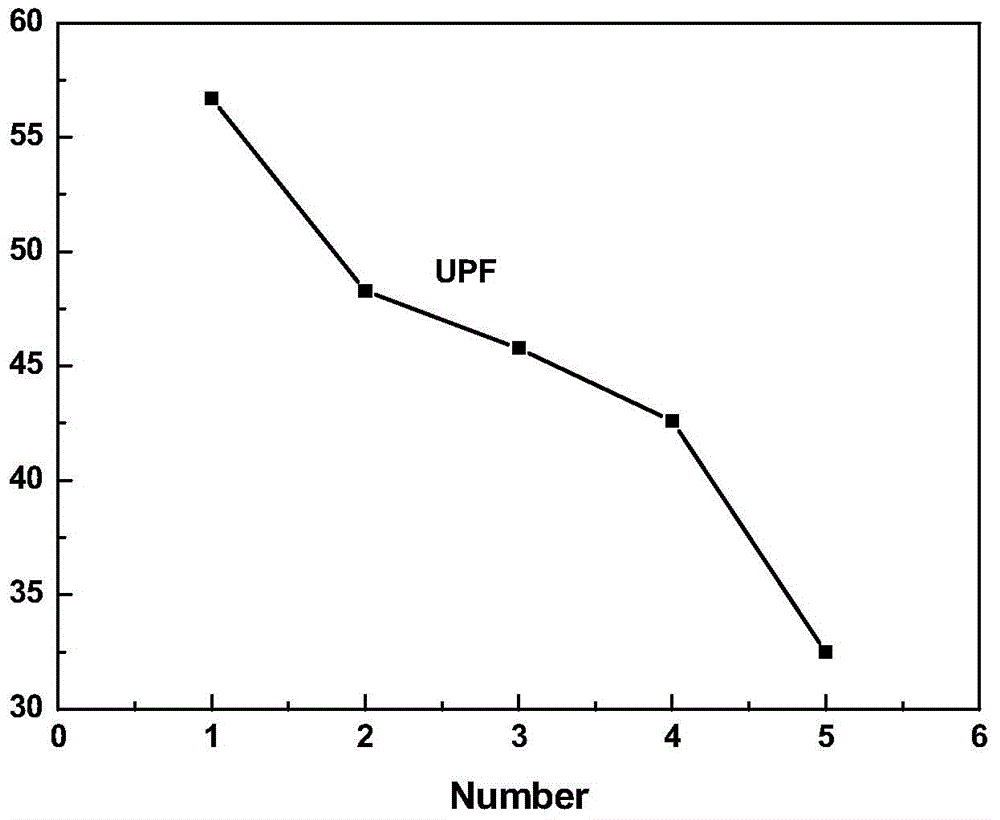

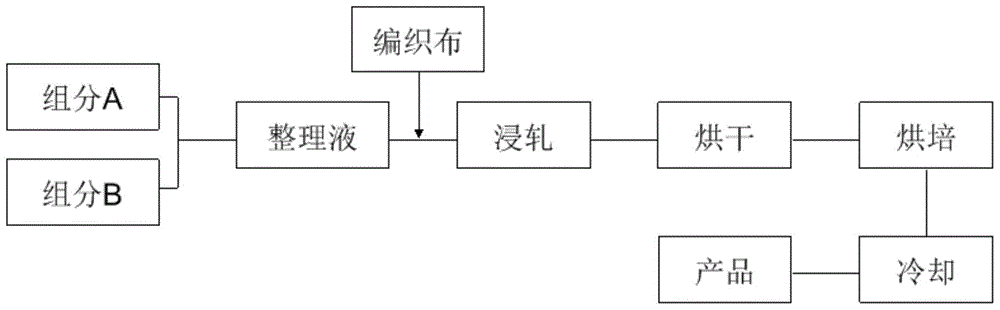

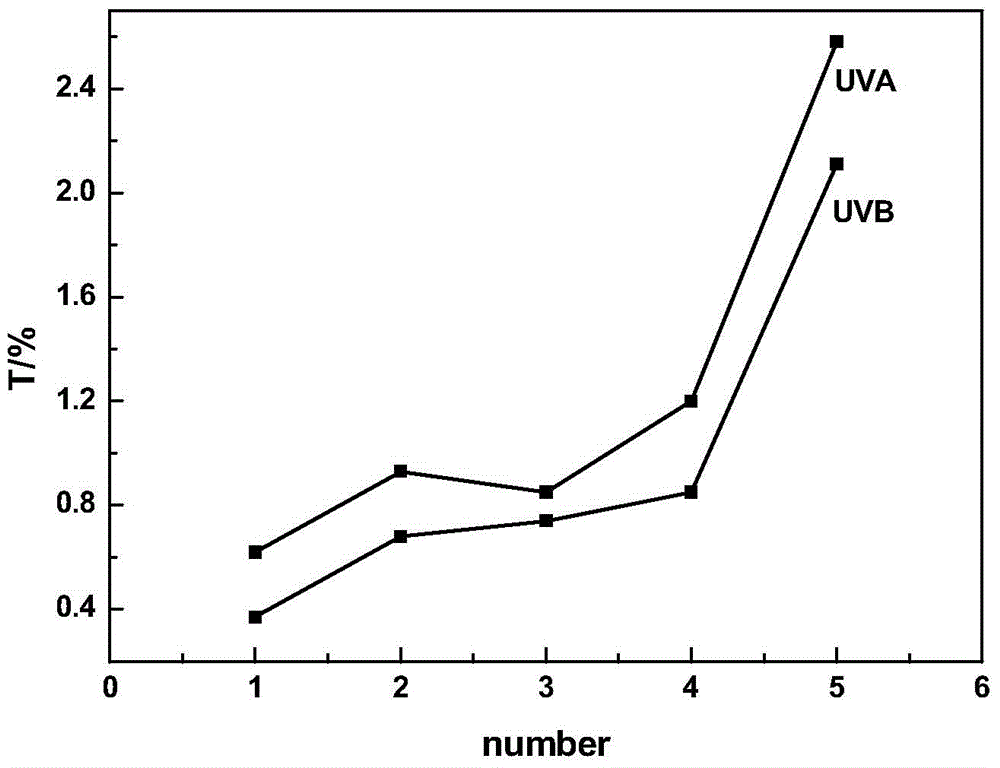

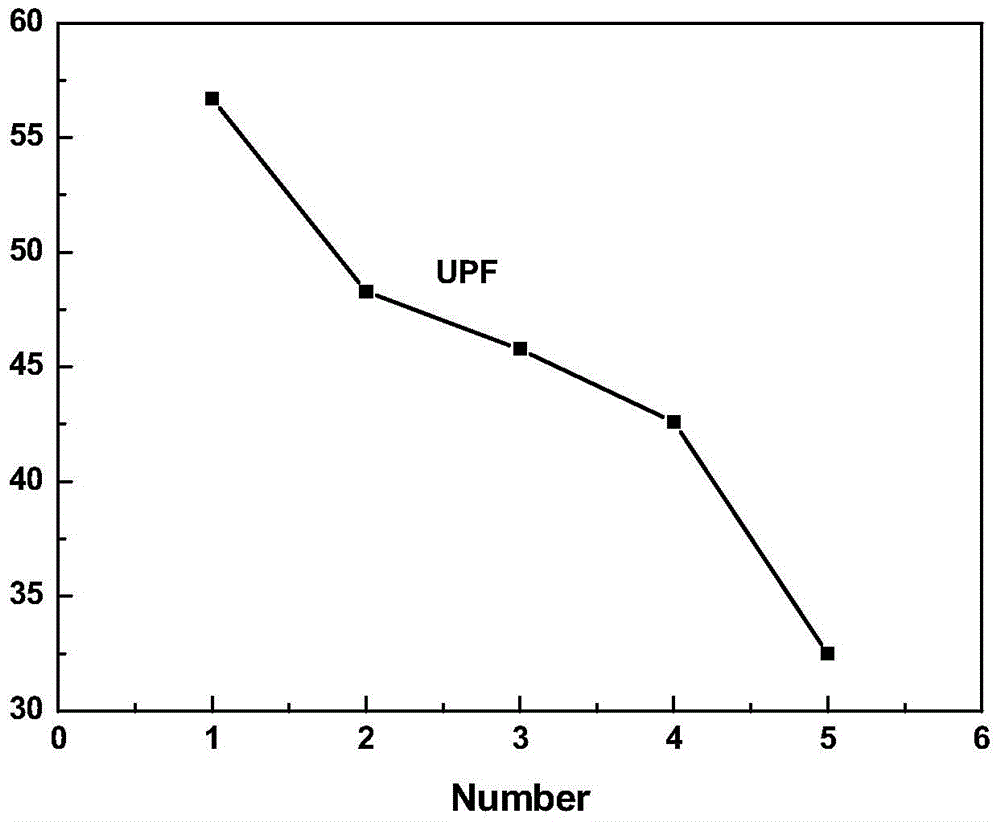

Composite ultraviolet-proof finishing liquid and preparation method and application thereof

The invention relates to composite ultraviolet-proof finishing liquid. The composite ultraviolet-proof finishing liquid comprises 25-30 g / L of nanometer oxide, 15-30 g / L of metallo chelate, 20-30 g / L of synergist, 15-20 g / L of ethyl alcohol, 10-15 g / L of methyl alcohol, 10-15 g / L of urea, 2-4 g / L of glycerinum, 0.5-1 g / L of polyoxyethylene ether, 0.5-1 g / L of azodiisobutyronitrile, 0.3-1 g / L of flatting agent, 0.2-1 g / L of antifoaming agent, and 1-2 g / L of curing agent, water serves as the solvent, the nanometer oxide is the powder mixture of ZnO, TiO2 and SiO2. Woven cloth treated through the finishing liquid has the excellent ultraviolet-proof function, the shading coefficient reaches to over 70%, the ultraviolet light shielding rate reaches to over 98%, and the ultraviolet protection factor (UPF) is higher than 40.

Owner:NINGBO SANDO KNITTING

Preparation method of anti-ultraviolet microcapsule finishing agent

PendingCN110387748AStrong absorption capacityMild performanceLight resistant fibresMicroballoon preparationHydrogenUltraviolet

The invention relates to a preparation method of an anti-ultraviolet microcapsule finishing agent and belongs to the technical field of sunscreen. The anti-ultraviolet microcapsule finishing agent isprepared from gelatin composite polyvinyl alcohol as a microcapsule wall material, gelatin is a polypeptide molecular mixture with molecular weight reaching tens of thousands to hundreds of thousandsand mainly contains amino acid, gelatin micelle has positive charges below an isoelectric point, the gelatin has excellent hydrophilicity due to a large quantity of hydroxyl on the molecular structure, the gelatin cannot be dissolved in cold water easily, after the gelatin and polyvinyl alcohol are mixed, molecular chains of the polyvinyl alcohol and polypeptide molecules of the gelatin can form astable 3D network structure, the finishing agent has chemical stability and cannot react due to adoption of the gelatin and the polyvinyl alcohol as the wall material and the core material, microcapsules can form a compact film on the surface of fabric, hydrophilic groups of the gelatin can form hydrogen bonds with groups of the fabric, and the washing fastness of the finishing agent can be effectively improved.

Owner:李新根

Plastic film

The invention discloses a plastic film. The plastic film is characterized by being prepared from the following raw materials in parts by weight: 80-100 parts of polypropylene, 25-30 parts of corn starch, 5-10 parts of montmorillonite, 0.5-2 parts of antimonous oxide, 0.5-1 part of aluminum hydroxide, 0.1-0.5 part of phosphite ester, 1-5 parts of tourmaline, 3-8 parts of nano-titanium dioxide, 4-8parts of plasticizer, 5-8 parts of fish scale gelatin, 6-10 parts of collagenous fibers, 2-5 parts of elastomer, 1-4 parts of silver-loaded zeolite, 0.2-0.5 part of tea tree essential oil, 5-10 partsof bamboo charcoal powder, 3-5 parts of polylactic acid, 0.2-0.5 part of nano- bentonite, 2-5 parts of bamboo fibers and 1-4 parts of calcium carbonate. The plastic film has good ultraviolet and oxidation resistance, has an ultraviolet screening factor reaching over 96 percent, can release massive anions by adding bamboo coal powder, and has strong performance for adsorbing foreign odor, resistingbacteria and removing smell.

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

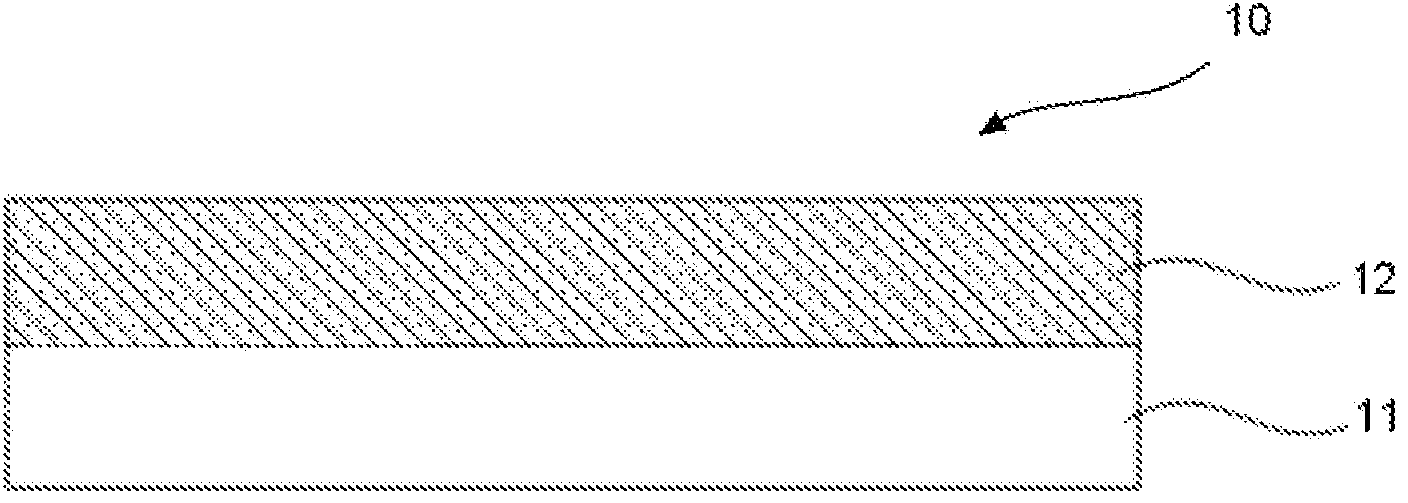

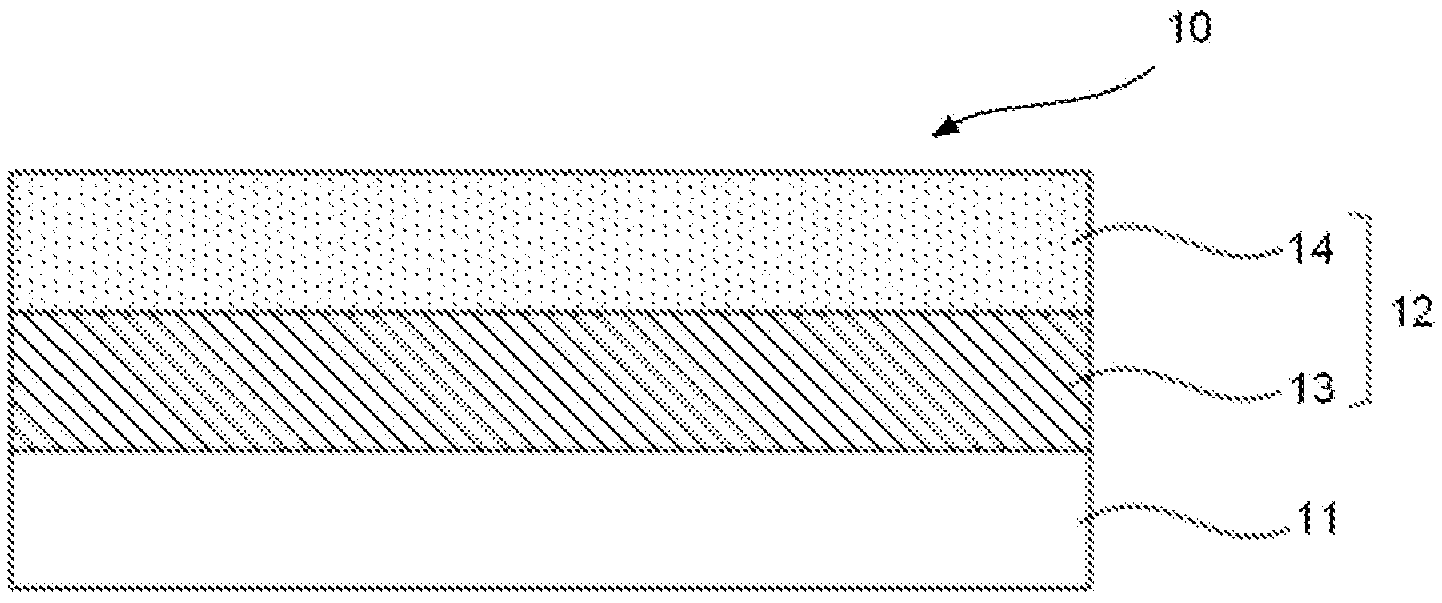

Electrostatic-adhered heat-insulating film and manufacturing method thereof

InactiveCN103481565AImprove compactnessImprove directionalitySynthetic resin layered productsLight transmissionReflectivity

The invention provides a manufacturing method of an electrostatic-adhered heat-insulating film having the characteristics of excellent light transmission property, high infrared and ultraviolet reflection rates, simple manufacturing process and durability. The manufacturing method of the electrostatic-adhered heat-insulating film comprises the step of overlapping functional layers on a provided substrate layer.

Owner:HANGZHOU ZEAL SCI & TECH

High-efficiency anti-ultraviolet clothing fabric and preparation method thereof

InactiveCN107164968AExtended service lifeNon-irritatingTextiles and paperPolyesterUltraviolet lights

The invention discloses a high-efficiency anti-ultraviolet clothing fabric and a preparation method thereof. The high-efficiency anti-ultraviolet clothing fabric is prepared from the following ingredients in parts by weight: 30-40 parts of long staple, 15-25 parts of polyester fiber, 10-15 parts of fibrilia, 5-10 parts of silk fiber, 1-5 parts of an ultraviolet screening agent, 1-5 parts of a thickener, 1-5 parts of polyethylene glycol and 5-10 parts of a coating agent. The clothing fabric is reasonable in proportion of various ingredients, has good moisture-absorbing, moisture-dispersing and ventilating functions, and is smooth and full in hand feeling, free of thrill to skin and more comfortable to skin; the high-efficiency anti-ultraviolet clothing fabric is nontoxic in fabric, free of thrill, harmless to a human body and stable in ultraviolet shielding property, is not affected by heat, light or other substances; and the high-efficiency anti-ultraviolet clothing fabric is high in ultraviolet shielding rate, high in persistence and long in effective action time, is capable of shielding ultraviolet light on a full-wave band, still has relatively high capability of absorbing the ultraviolet light under the condition that clothing is relatively thin and light in color, and is easy to popularize and apply.

Owner:海盐派特普科技有限公司

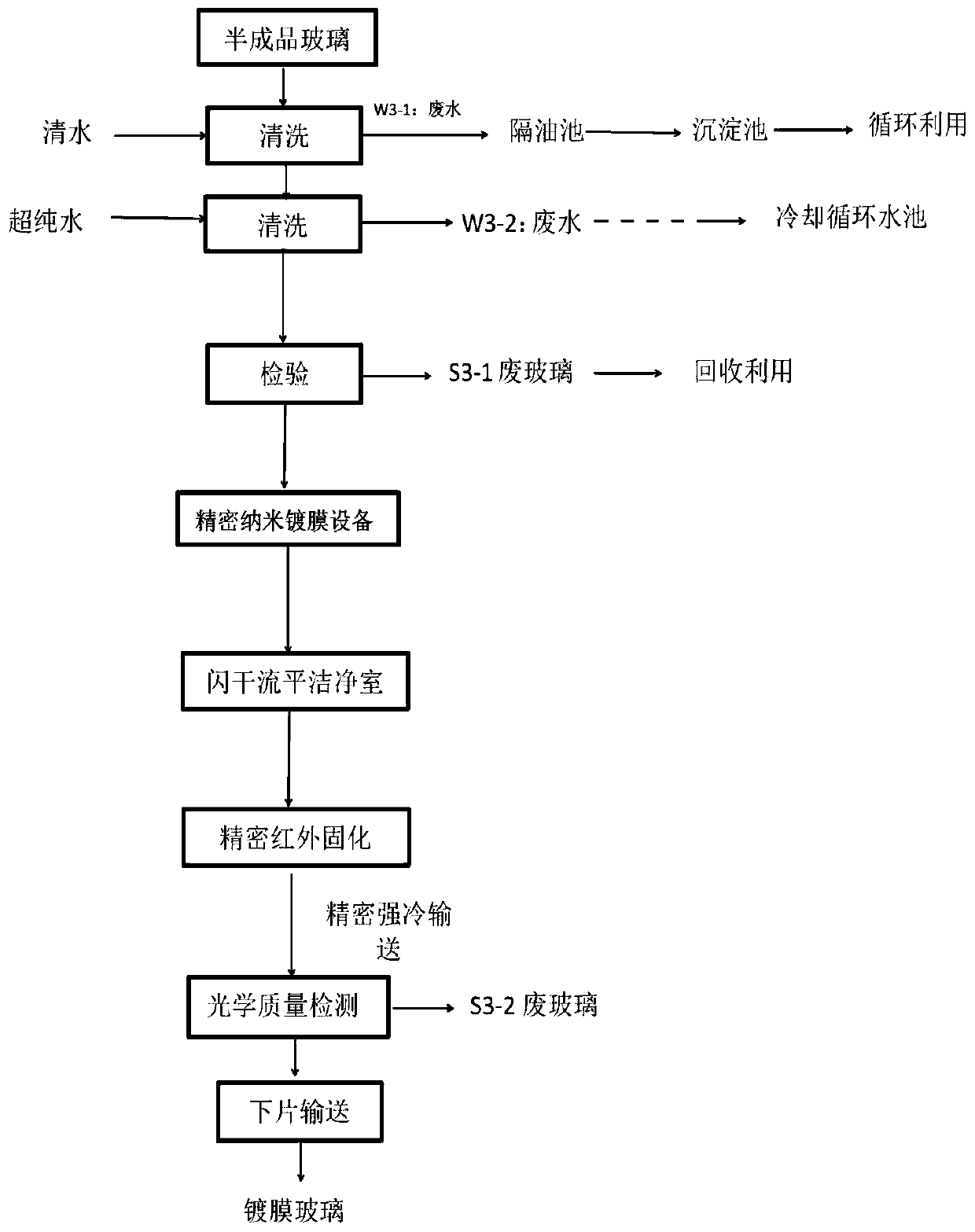

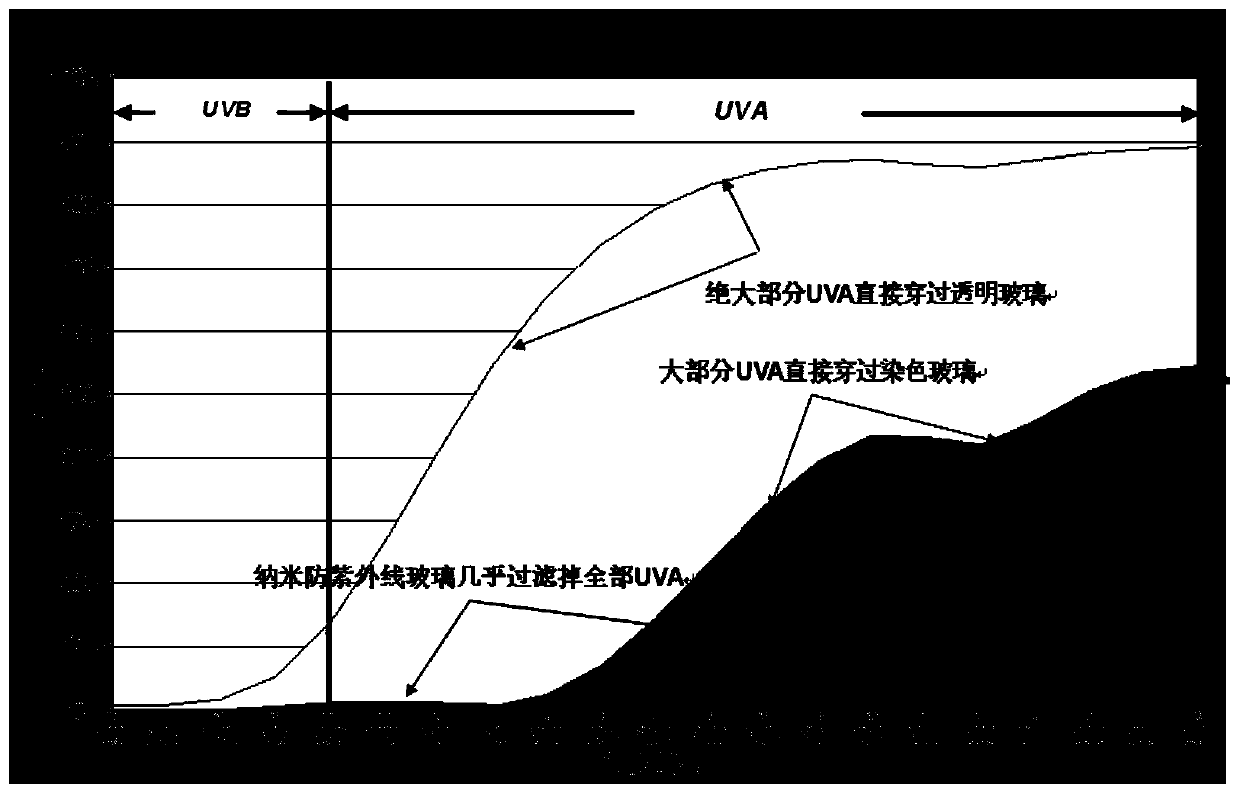

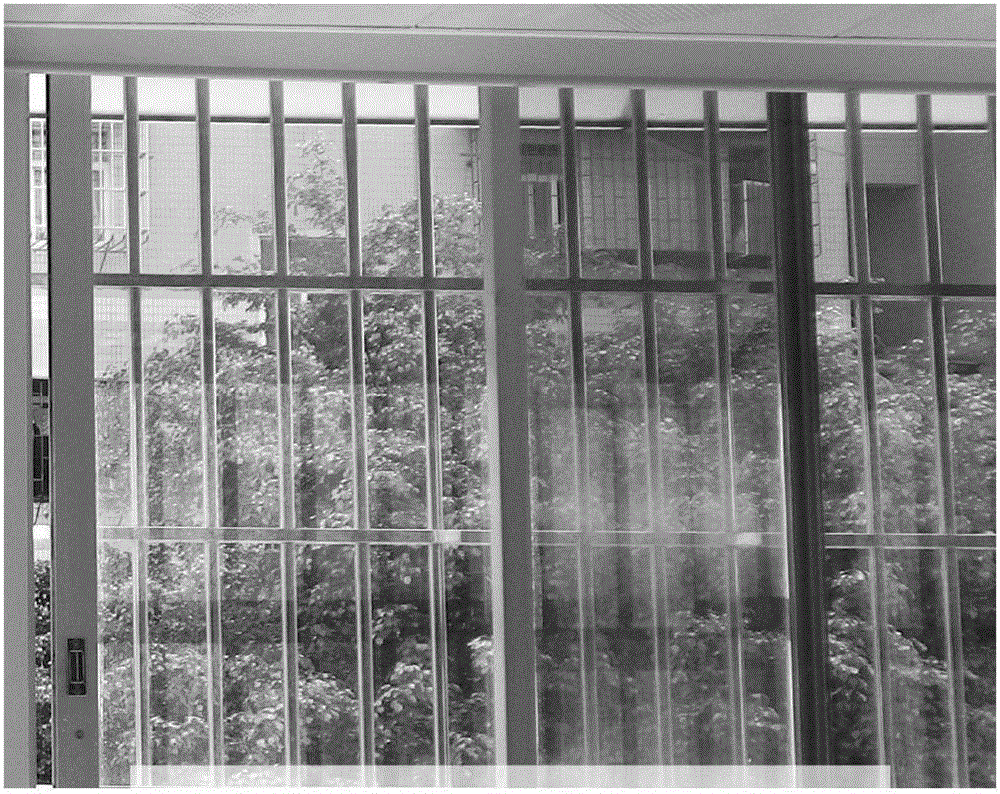

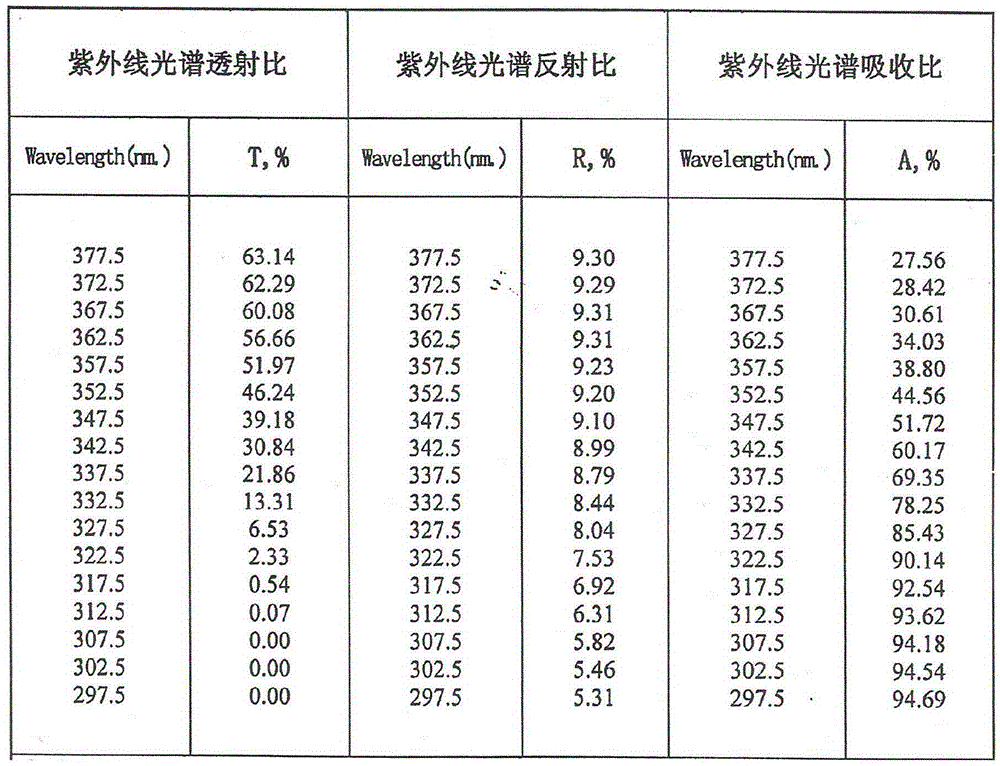

Processing method of nano-coated anti-ultraviolet glass

The invention discloses a processing method of a nano-coated anti-ultraviolet glass. The processing method comprises at least: cleaning->coating preparation->precision coating equipment->precision flash drying leveling->precision infrared curing->precision strong cooling conveying. The nano-coated anti-ultraviolet glass has obvious advantages of ultraviolet-shielding compared with the ordinary glass. The nano-coated anti-ultraviolet glass is prepared by coating a layer uniform nano material on the glass surface by using the nano-coating process, the ultraviolet-shielding ability of the nano anti-ultraviolet glass can be greatly improved, and the original visible light transmittance and color of the float glass are not significantly changed. Modified nano titanium dioxide is added in the nano-coated anti-ultraviolet glass, the nano titanium dioxide is wetted with a surfactant, the clustered nano-titanium dioxide is dispersed by using the ultrasonic wave high frequency, and a film of thesurfactant is formed on the surface of the nano titanium dioxide particles, so that the dispersivity of the nano titanium dioxide in the coating is improved, the coating powdering resistance is improved, and the visible light transmittance and ultraviolet shielding rate are increased.

Owner:SICHUAN YUGUANG OPTICAL GLASS CO LTD

A kind of barium sulfate/polyvinyl alcohol composite fiber and its preparation method, nonwoven fabric

ActiveCN105624821BImprove radiation resistanceImprove breathabilityMonocomponent synthetic polymer artificial filamentWet spinning methodsBreaking strengthPolyvinyl alcohol

The invention discloses barium sulfate / polyvinyl alcohol composite fiber and a preparation method thereof and non-woven fabric. The composite fiber consists of the following components in percentage by mass: 20-80% of barium sulfate and 80-20% of polyvinyl alcohol. The composite fiber is prepared by blending superfine barium sulfate and polyvinyl alcohol and performing a wet spinning technology; and the prepared non-woven fabric has the characteristics of good resistance to ray radiation, good air permeability, smooth hand feeling, gentle gloss and wearing comfort and softness. The fineness of the composite fiber is 1.5-5dtex, the dry breaking strength is 2.0-8.0cN / dtex, the dry elongation at break is 15-40%, and the initial modulus reaches 60-100cN / dtex. The shielding rate of the non-woven fabric with fixed weight of 500g / m<2> and prepared from the composite fiber against medium- and low-energy X rays can exceed 70%, and the shielding rate of protective clothing can be further improved by adjusting the thickness or layer number of the fabric.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Lead-free radiation shielding sheet and manufacturing method therefor

The present invention relates to a method of preparing a lead-free radiation shielding sheet with excellent shielding performance not only in a high energy (100 kVp) band but also in a low energy (50 to 80 kVp) band and improved durability of the sheet. bands without containing lead. The radiation shielding sheet of the present invention uses antimony (Sb), which has a high shielding rate even in the low energy band instead of lowering the content of tungsten having a relatively lower shielding rate in the low energy band than in the high energy band, thereby increasing the shielding performance in both high energy (100 kVp) and low energy bands. Further, the radiation shielding sheet of the present invention may increase not only durability, but also elasticity, tearing strength, and tensile strength by mixing additives such as zinc oxide with the rubber.

Owner:RASGO CO LTD +1

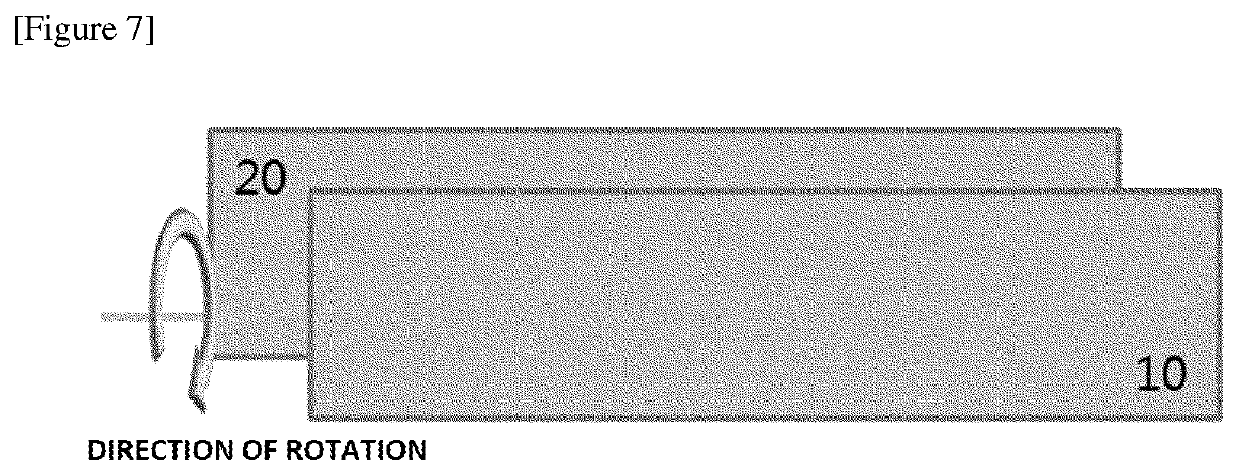

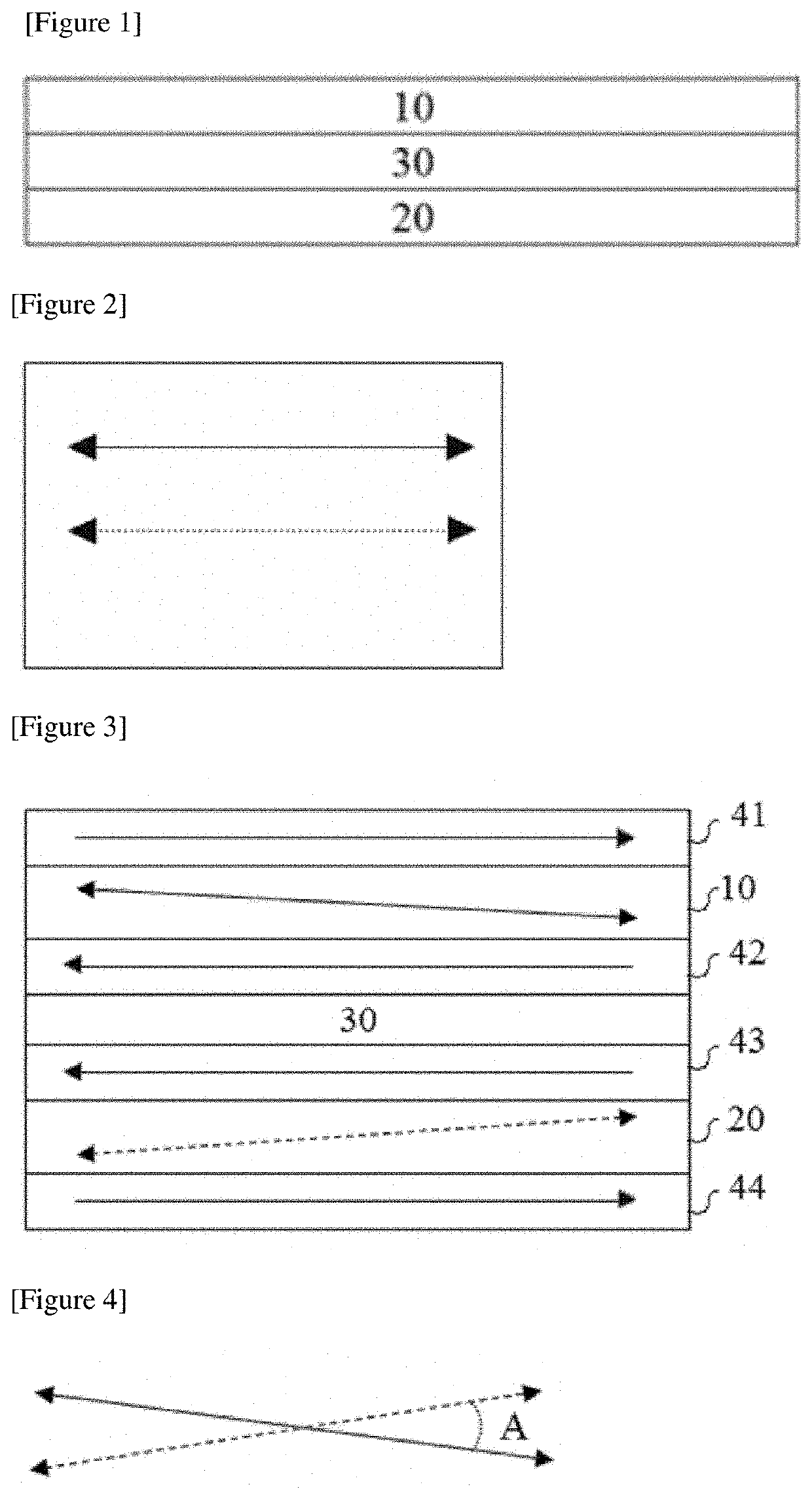

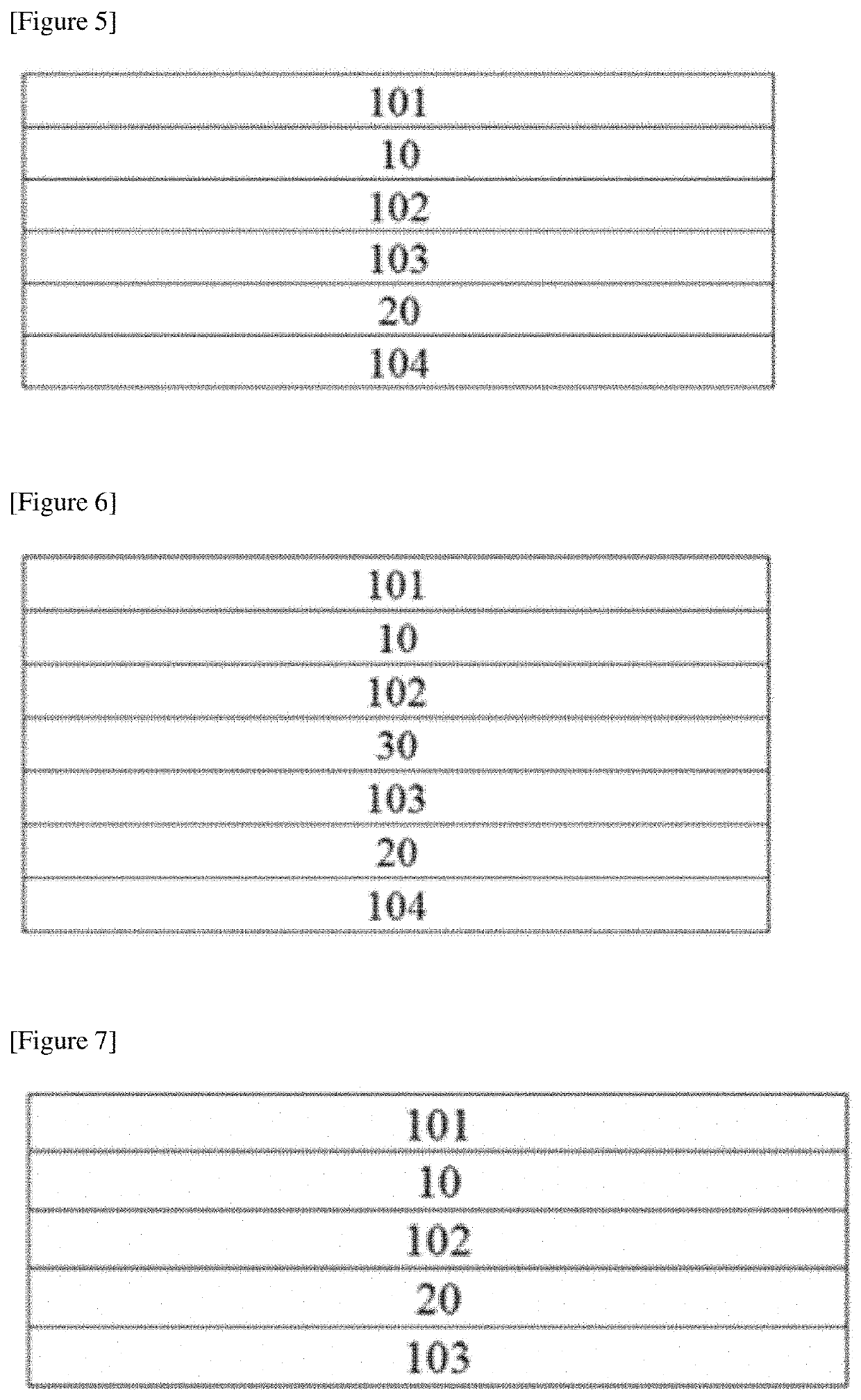

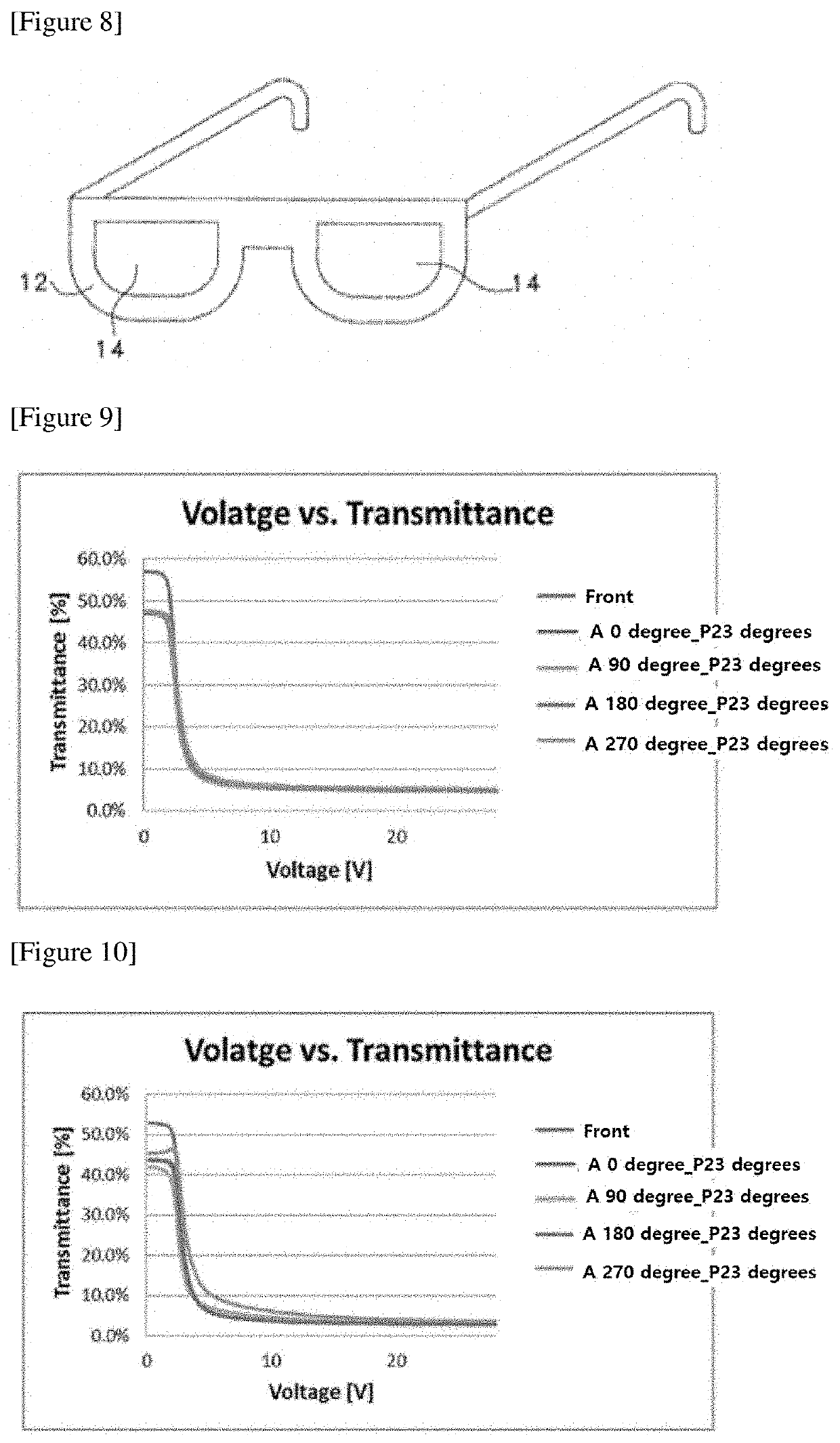

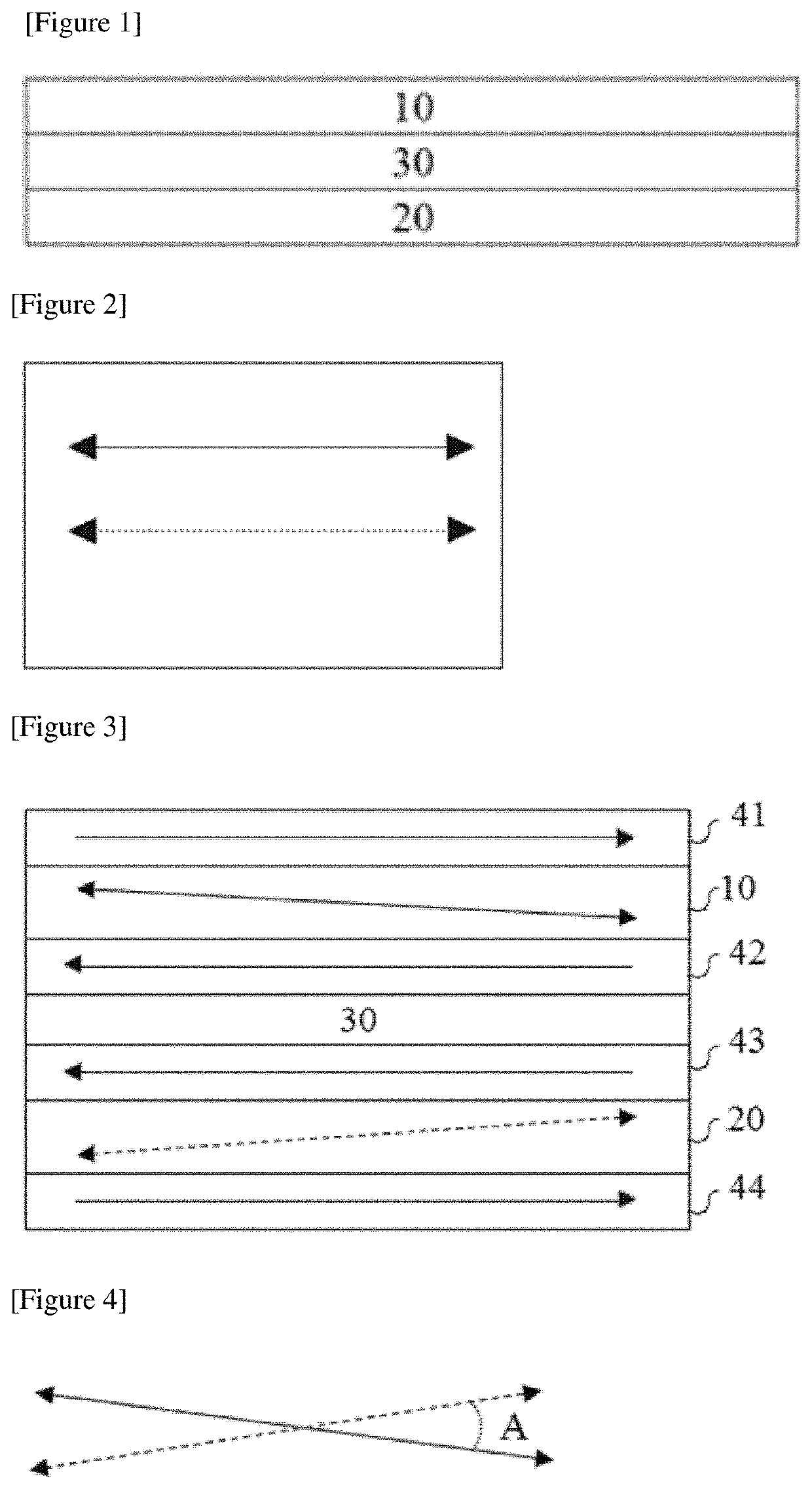

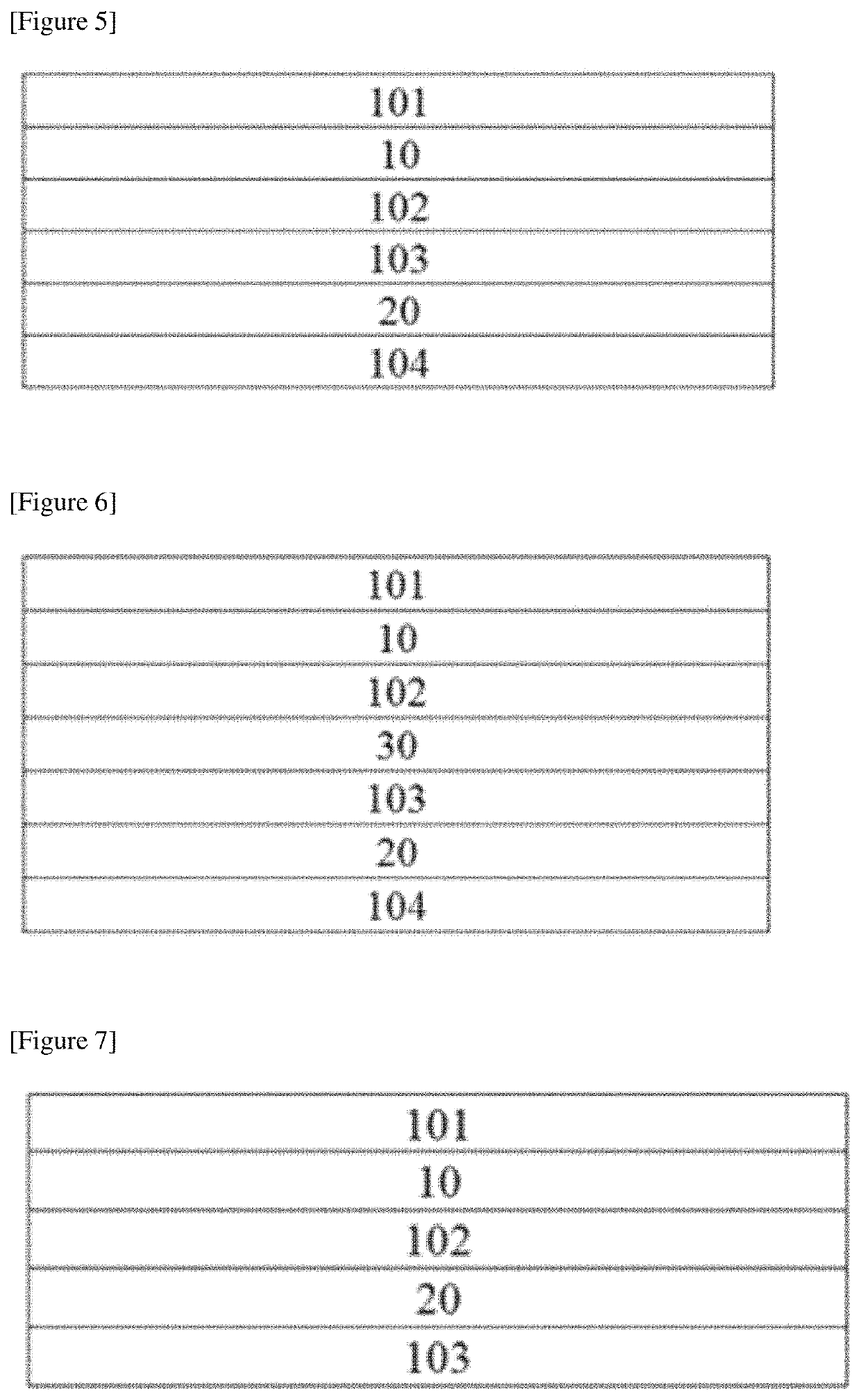

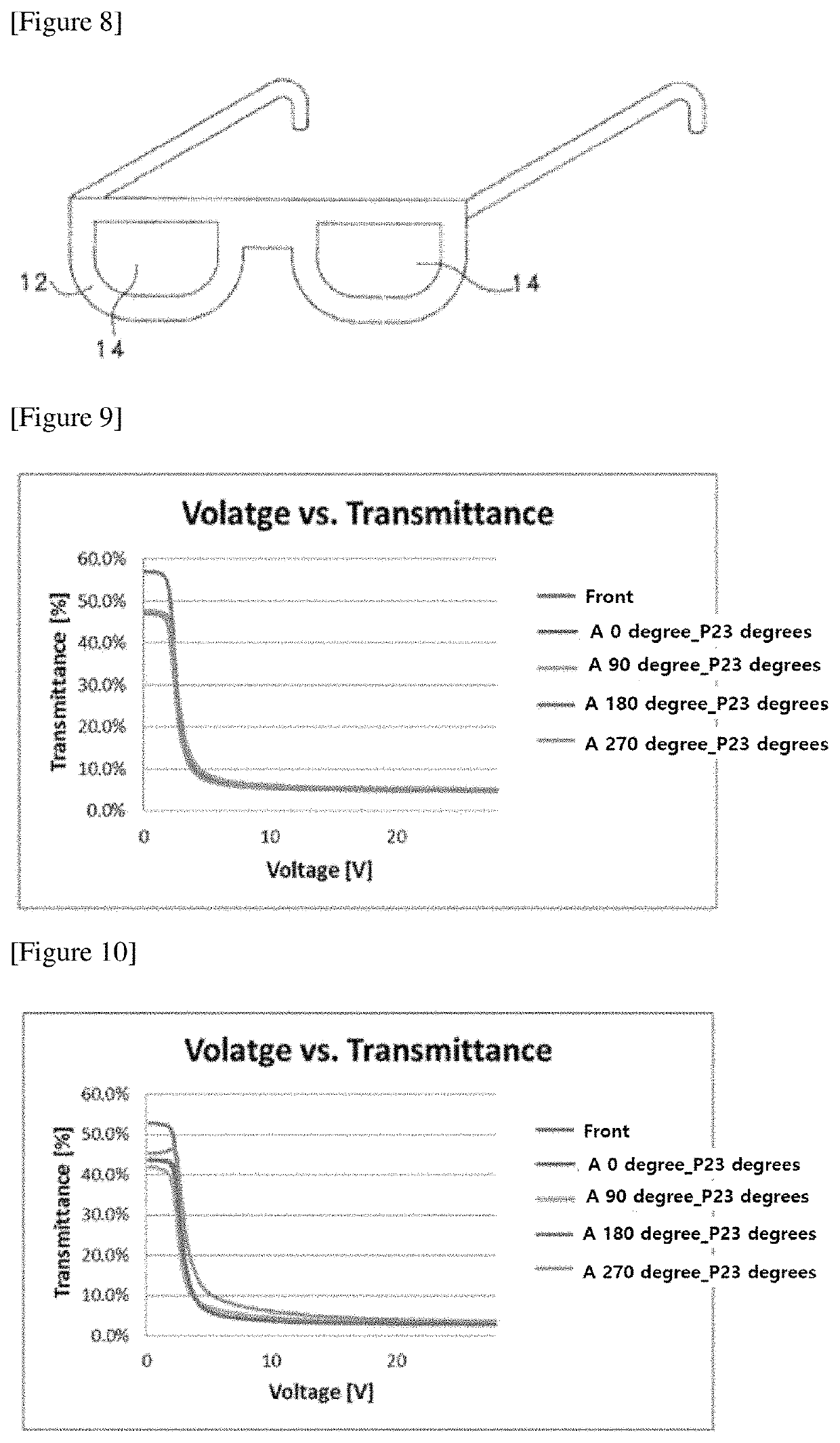

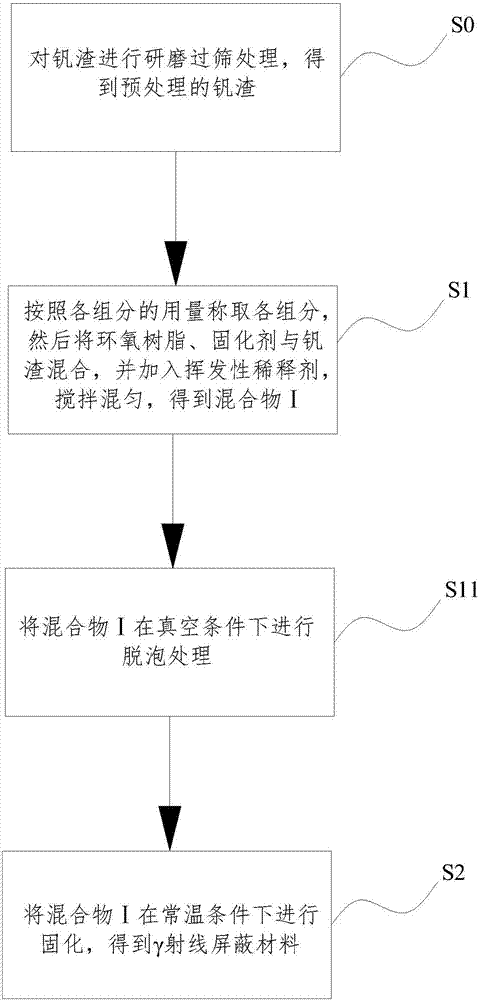

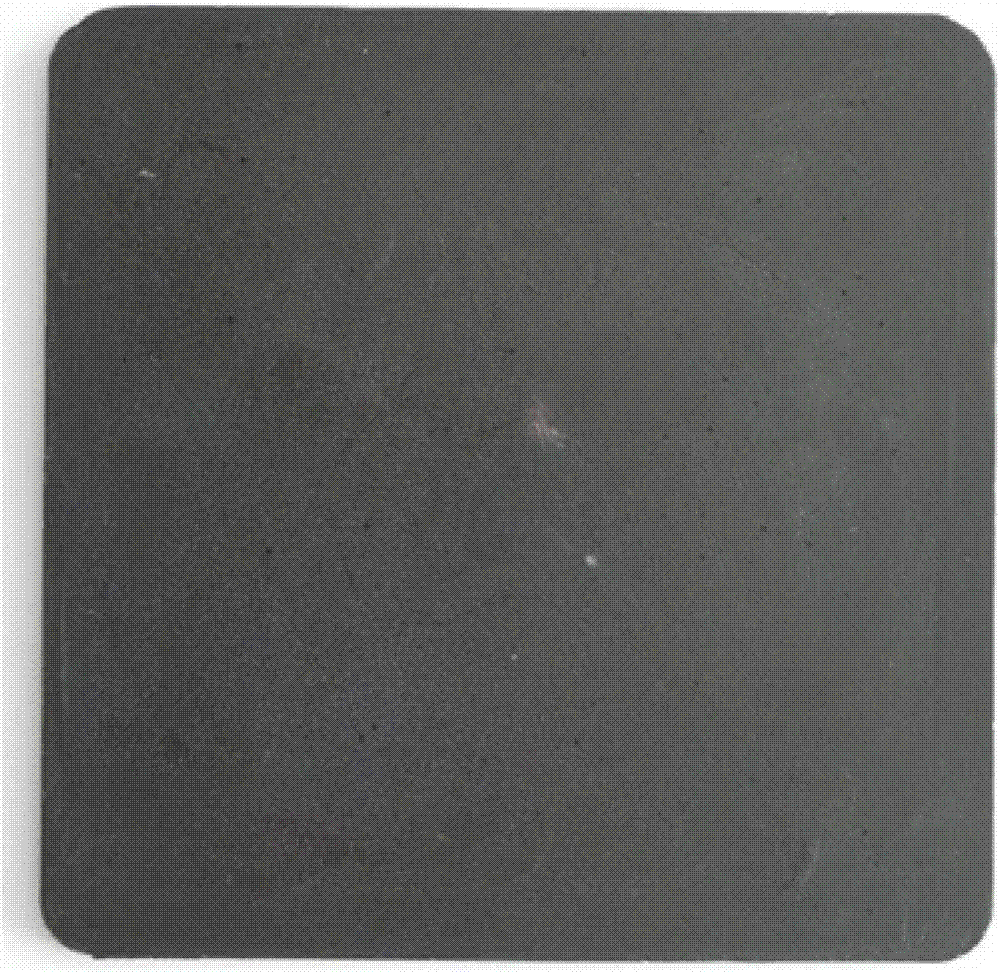

Transmittance-variable device

ActiveUS11003032B2High light transmittanceHigh shielding rateLiquid crystal compositionsSpectales/gogglesOptical axisEyewear

A transmittance-variable device is disclosed herein. In some embodiments, the transmittance-variable device includes a first guest host layer, a second guest host layer, and a phase difference element disposed between the first and second guest host layers, wherein each of the first and second guest host layers comprise a liquid crystal host and a dichroic dye guest, and the liquid crystal hosts are capable of being horizontally oriented such that their optical axes are horizontal to each other. The transmittance-variable device can switch between a clear state and a black state, can exhibit high transmittance in the clear state and a high shielding rate in the black state, and can exhibit a high contrast ratio even at the inclination angle. Such a transmittance-variable device can be used in architectural or automotive materials, or eyewear such as goggles for augmented reality experience or sports, sunglasses or helmets.

Owner:LG CHEM LTD

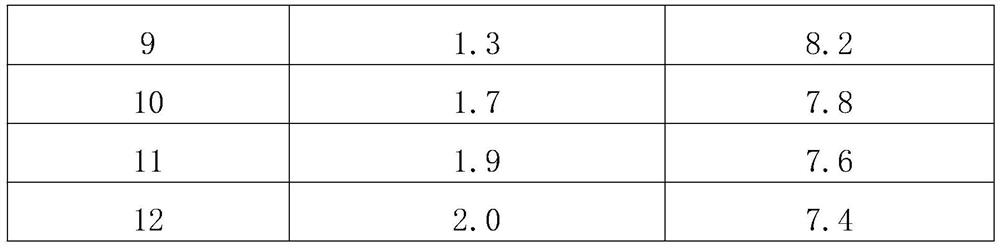

Water-based micro-nano flaky graphite radon radiation shielding coating and preparation method and construction method thereof

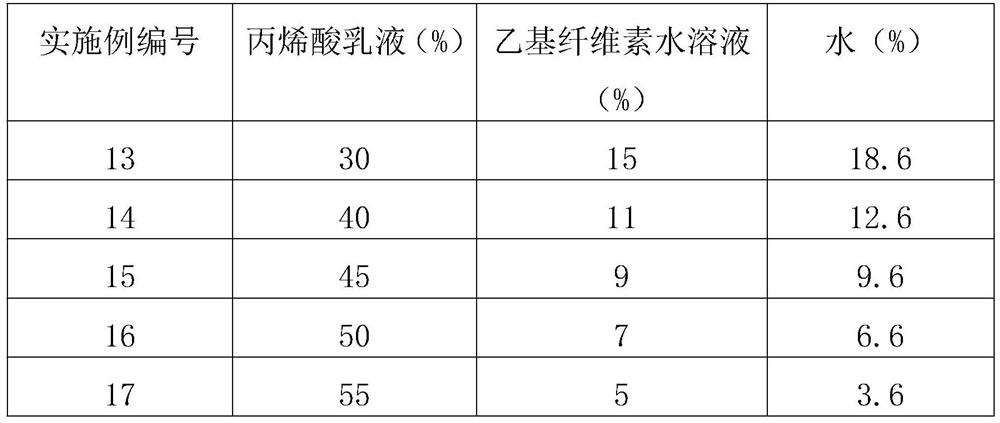

InactiveCN111826041ANot easy to drySlow dryingCovering/liningsCoatingsMicro nanoHydroxyethyl cellulose

The invention relates to a water-based micro-nano flaky graphite radon radiation shielding coating and a preparation method and a construction method thereof. The water-based micro-nano flaky graphiteradon radiation shielding coating is prepared from the following components in percentage by mass: 0.1-2% of water-based micro-nano flake graphite powder; 10-30% of quartz powder; 0-30% of ground calcium carbonate powder, 30-60% of acrylic emulsion, 5-15% of hydroxyethyl cellulose aqueous solution, 10-20% of water, 0.3-1% of dispersing agent, 0.1-0.5% of defoaming agent, 0.3-1.5% of coalescing agent, 0.1-0.5% of thickening agent and 0.1-0.3% of preservative. According to the invention, the defects of long drying time and low speed caused by a plurality of processes in on-site radon radiationshielding coating construction engineering are avoided; the coating can be used for various building structure base surfaces, particularly can be used for special-shaped structures such as cylinders,arc tops and bent corners, has the advantages of waste collection, emission reduction, water-based environmental protection and long service life, and has important application value for radon radiation treatment of constructional engineering.

Owner:核工业二0三研究所

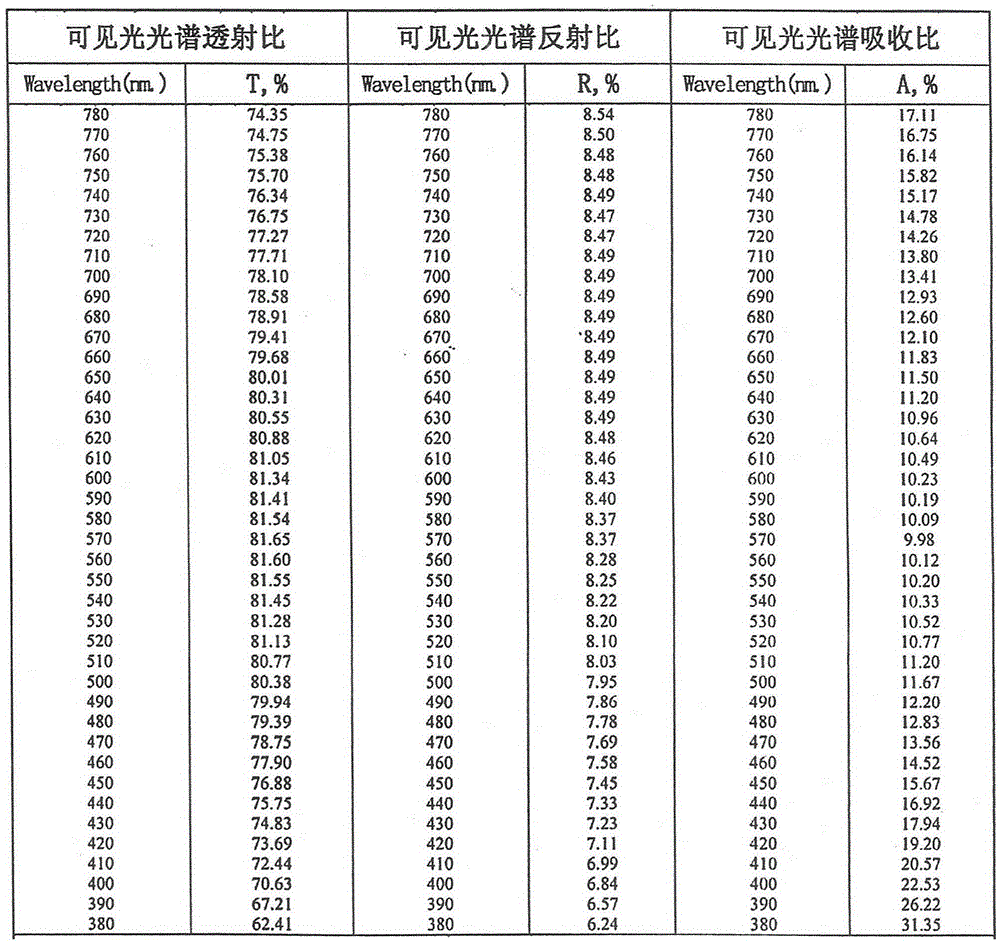

A kind of transparent glass thermal insulation coating

The invention discloses a transparent glass thermal insulating coating which comprises the following components in parts by weight: 30-50 parts of crylic acid modified organic silicon resin, 15-20 parts of low viscosity high chlorinated polyethylene resin, 5-10 parts of nanometer titania, 2-3 parts of nano-zinc oxide, 20-30 parts of n-butyl acetate, 2-5 parts of n-butyl alcohol and 2-5 parts of cyclohexanone. The coating disclosed by the invention is relatively high in shielding rate in an infrared area, good in transmissivity in a visible light area, and remarkable in absorption effect in an ultraviolet area, the transmissivity of visible light is greater than 80%, the shielding rate of infrared light is greater than or equal to 61%, the energy-saving effect is remarkable, the temperature can be reduced by 5-10 DEG C, and the energy can be saved by 20-30%. The coating is good in adhesion to surfaces of glass products, has a self-cleaning function, is free of charge, water or dust on the surface, and can be applied to coating on surfaces such as door and window glass, automobile glass and glass curtain walls of high-rise buildings.

Owner:开平市日固力涂料有限公司

Transmittance-Variable Device

ActiveUS20200233246A1High light transmittanceHigh shielding rateNon-linear opticsOptical partsEyewearOptical transmittance

A transmittance-variable device is disclosed herein. In some embodiments, a transmittance-variable device includes first and second guest host layers, the first and second guest host layers are superposed, wherein each of the first and second guest host layers comprise a liquid crystal host and a dichroic dye guest, and wherein the device is capable of switching between a transparent mode and a black mode. The transmittance-variable device can exhibit high transmittance in the transparent state and a high shielding rate in the black state, and can exhibit a high contrast ratio even at the inclination angle, and exhibit excellent viewing angle symmetry in all directions. Such a transmittance-variable device can be applied to various applications including various architectural or automotive materials which need to adjust the transmittance, or eyewear such as goggles for augmented reality experience or sports, sunglasses or helmets.

Owner:LG CHEM LTD

Coating Composition of insulating heat for glass, and preparation method

InactiveCN101050065BCurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyInorganic salts

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

Neutron shielding material with flame-retardant and heat-insulating properties and preparation method thereof

ActiveCN104744945BHigh mechanical strengthImprove insulation performanceShieldingPowder mixtureThermal insulation

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

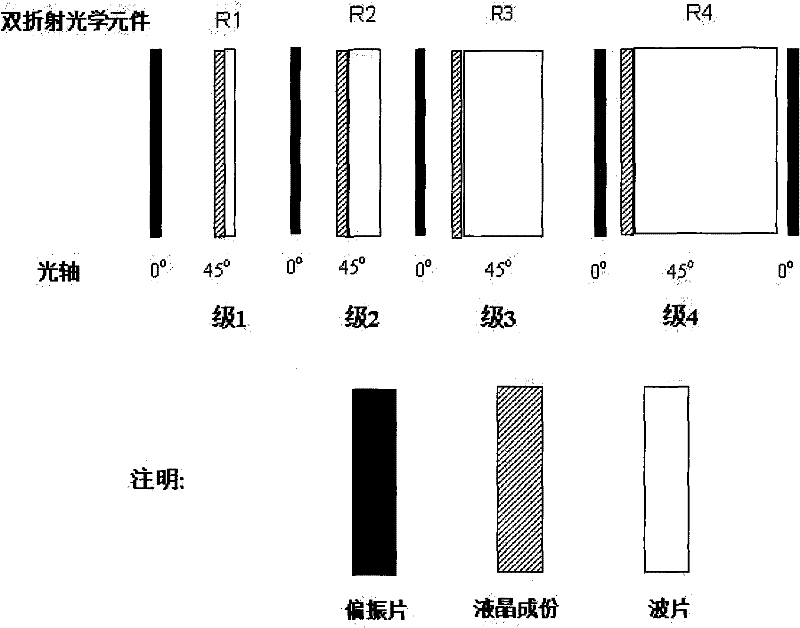

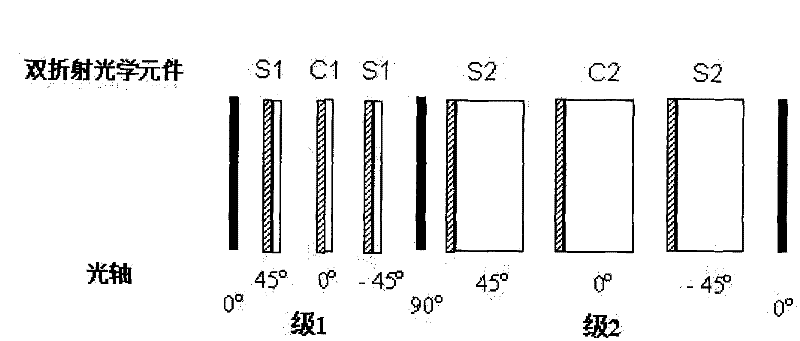

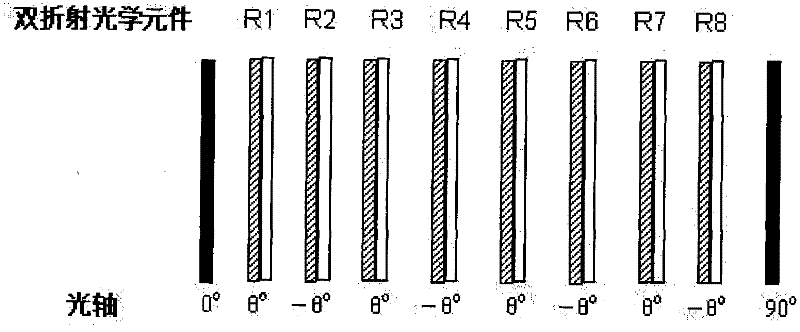

A liquid crystal tunable filter and its configuration method

InactiveCN101799596BImprove transmittanceHigh resolutionStatic indicating devicesCombined methodPolarizer

The invention discloses a liquid crystal tunable filter and a configuration method thereof. The filter includes several cascaded Leo configuration filter units, and the Leo configuration filter unit consists of polarizers on both sides and a middle A birefringent optical element is formed, wherein part or all of the Leo configuration filter units are combined in two consecutive cascades or three consecutive cascades to form a combined unit. The merge method is stacked or fan merged. The birefringent optical element is a liquid crystal tunable wave plate, a fixed wave plate or a combination of a liquid crystal tunable wave plate and a fixed wave plate. The liquid crystal tunable filter of the present invention has the advantages of high pass rate, narrow half-width, high shielding rate, adjustable spectral range, strong stability, no need for mechanical rotation, and real-time controllable advantages. It can be widely used in Imaging, biology, medicine, materials, optics, optoelectronics, astronomy and other fields.

Owner:SHENZHEN KINGWAY OPTOELECTRONICS

A kind of composite anti-ultraviolet finishing liquid and its preparation method and application

The invention relates to composite ultraviolet-proof finishing liquid. The composite ultraviolet-proof finishing liquid comprises 25-30 g / L of nanometer oxide, 15-30 g / L of metallo chelate, 20-30 g / L of synergist, 15-20 g / L of ethyl alcohol, 10-15 g / L of methyl alcohol, 10-15 g / L of urea, 2-4 g / L of glycerinum, 0.5-1 g / L of polyoxyethylene ether, 0.5-1 g / L of azodiisobutyronitrile, 0.3-1 g / L of flatting agent, 0.2-1 g / L of antifoaming agent, and 1-2 g / L of curing agent, water serves as the solvent, the nanometer oxide is the powder mixture of ZnO, TiO2 and SiO2. Woven cloth treated through the finishing liquid has the excellent ultraviolet-proof function, the shading coefficient reaches to over 70%, the ultraviolet light shielding rate reaches to over 98%, and the ultraviolet protection factor (UPF) is higher than 40.

Owner:NINGBO SANDO KNITTING

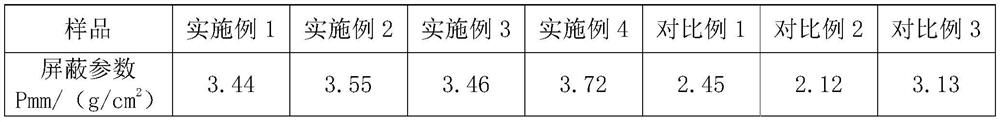

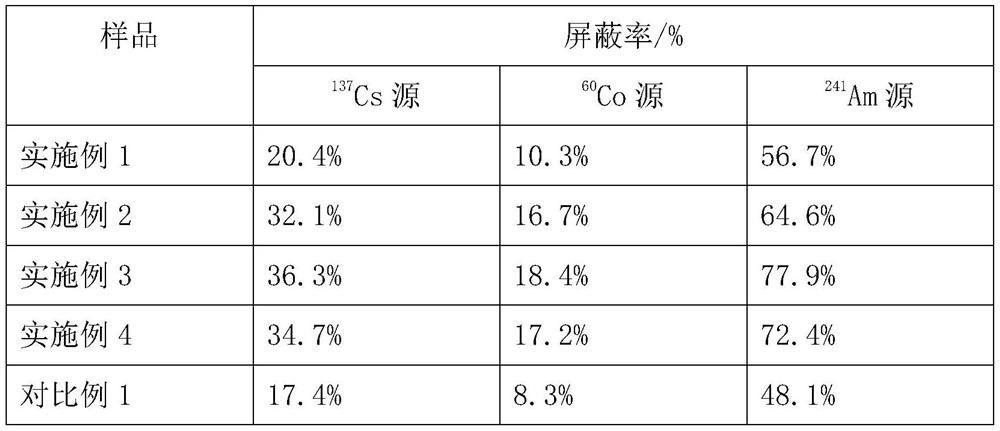

An ionizing radiation protective suit

ActiveCN110838379BExcellent performance against ionizing radiationHigh shielding ratePolyurea/polyurethane coatingsShieldingPolyethylene glycolEngineering

The invention belongs to the technical field of radiation protection clothing, in particular to an ionizing radiation protection clothing. The protective clothing includes an inner layer structure, an outer layer structure and an intermediate layer structure; the intermediate layer structure is a coating structure, and the coating used is composed of the following components and parts by weight: 40-50 parts of erbium oxide, 10-20 parts of bismuth oxide 5-15 parts of nano titanium dioxide, 10-20 parts of water-soluble polyurethane, 20-30 parts of silicone gel, 1-5 parts of polyethylene glycol. The protective clothing of the invention has excellent performance in preventing ionizing radiation, especially the performance in preventing gamma rays.

Owner:王震

A radiation-proof rubber product with element gradient combination and its preparation method

ActiveCN106009944BAchieve uniform shielding effectHigh shielding rateNatural rubber coatingsChloropene polymer coatingsPolymer scienceHigh energy

The invention discloses an element gradient combined anti-radiation rubber product and a preparation method thereof, and aims to solve the problems that generally, all fillers of a conventional anti-radiation protection rubber product are mixed together and filled, the contents of different filling components are not high, the overall shielding effect can be degraded, if a shielding material is added, filler sedimentation or layering of different degrees can be caused in the product preparation process, and furthermore the physical and mechanical properties of a finished product can be also greatly degraded. The element gradient combined anti-radiation rubber product comprises N layers of single shielding layers compounded in a gradient manner, wherein N is a natural number; N is greater than or equal to 2. By adopting the element gradient combined anti-radiation rubber product disclosed by the invention, a uniform shielding effect on a wide-energy spectrum high-energy ray can be achieved, the shielding rate of gamma and X-rays is higher than 30%, and the product is friendly to human bodies and the environment. The element gradient combined anti-radiation rubber product is reasonable to design, convenient to use, good in anti-radiation effect, high in production efficiency and filler utilization rate, good in comprehensive shielding property, capable of meeting requirements on industrial, large-scale and on-batch production, relatively high in application value, and relatively good in application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Transmittance-variable device

ActiveUS11099435B2High light transmittanceHigh shielding rateNon-linear opticsOptical partsEyewearEngineering

A transmittance-variable device is disclosed herein. In some embodiments, a transmittance-variable device includes first and second guest host layers, the first and second guest host layers are superposed, wherein each of the first and second guest host layers comprise a liquid crystal host and a dichroic dye guest, and wherein the device is capable of switching between a transparent mode and a black mode. The transmittance-variable device can exhibit high transmittance in the transparent state and a high shielding rate in the black state, and can exhibit a high contrast ratio even at the inclination angle, and exhibit excellent viewing angle symmetry in all directions. Such a transmittance-variable device can be applied to various applications including various architectural or automotive materials which need to adjust the transmittance, or eyewear such as goggles for augmented reality experience or sports, sunglasses or helmets.

Owner:LG CHEM LTD

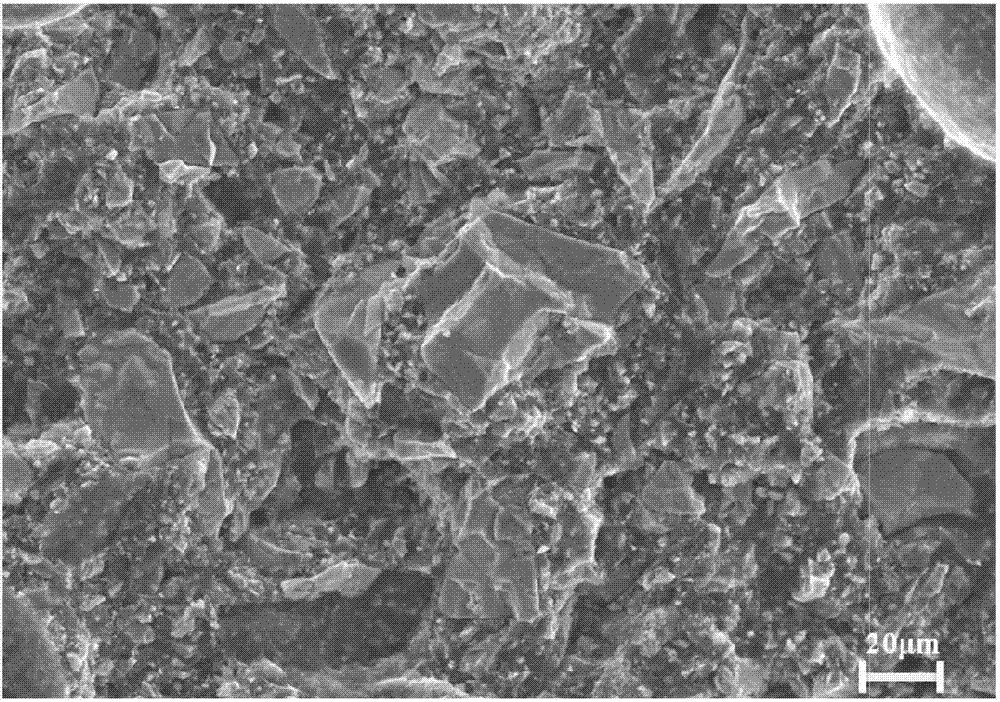

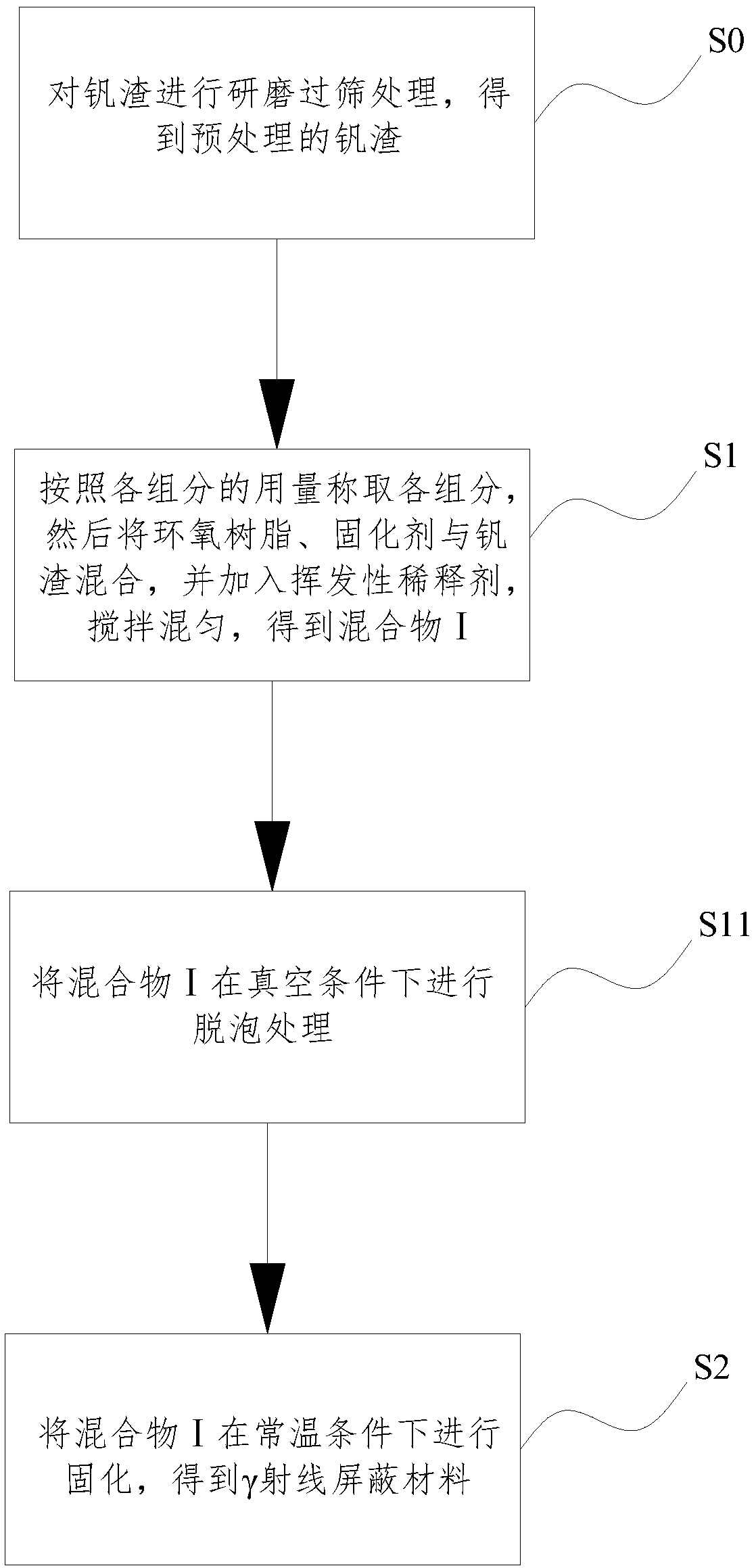

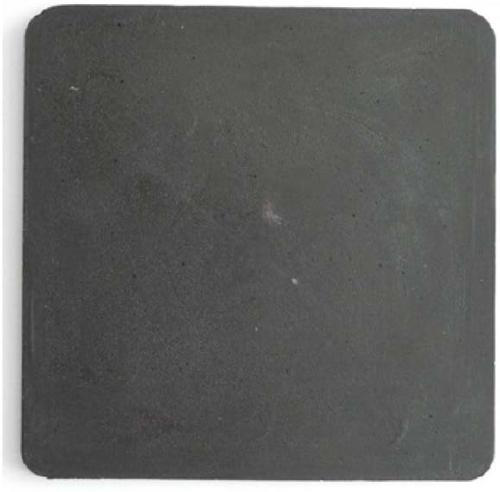

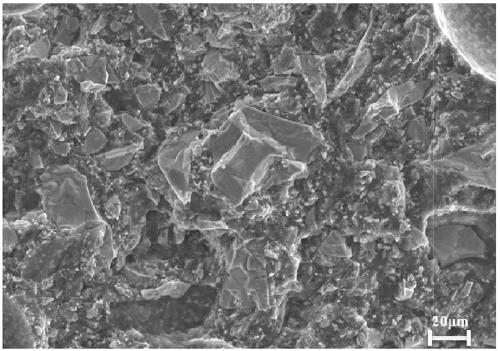

Gamma-ray shielding material and preparation method thereof

The invention discloses a gamma-ray shielding material, belonging to the technical field of shielding materials. The gamma-ray shielding material is prepared from the following components in parts by weight: 5-90 parts of vanadium slag, 5-8 parts of epoxy resin, 3-5 parts of a curing agent and 30-240 parts of a volatile diluent, wherein the epoxy resin is bisphenol A type epoxy resin, the curing agent is synthetic resin, and the volatile diluent is one or more of alcohol compounds, ketone compounds and aromatic compounds. According to the gamma-ray shielding material, the problem that vanadium slag is difficult to be comprehensively utilized in the past is solved, a new way is opened for the utilization of the vanadium slag, and a very cheap raw material is found for the production of a gamma-ray protecting material; and the gamma-ray shielding material has the characteristics of low cost, simplicity in production and operation, no secondary pollution and the like.

Owner:NORTHEASTERN UNIV

A kind of γ-ray shielding material and preparation method thereof

The invention discloses a gamma ray shielding material, which belongs to the technical field of shielding materials. The shielding material is prepared from the following components: 5-90 parts of vanadium slag; 5-8 parts of epoxy resin; 3-5 parts of curing agent; 30-240 parts of volatile diluent; the epoxy resin is bisphenol A type epoxy Resin; the curing agent is a synthetic resin; the volatile diluent is one or more of alcohol compounds, ketone compounds, and aromatic compounds. The invention solves the problem of difficulty in comprehensive utilization of vanadium slag in the past. It not only opens up a new way for the utilization of vanadium slag, but also finds very cheap raw materials for the production of γ-ray protection materials. It has the advantages of low cost, simple production operation and no secondary use. pollution and other characteristics.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com