A kind of composite anti-ultraviolet finishing liquid and its preparation method and application

A technology of anti-ultraviolet and finishing liquid, applied in the field of textile fabrics, can solve problems such as poor ability to absorb ultraviolet rays, and achieve the effects of excellent anti-ultraviolet function and light resistance, excellent anti-ultraviolet performance, and strong absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0030] Nano ZnO, TiO2, SiO2 powder mixture 30g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80725g / L, polyoxyethylene ether 0.5g / L, polyethylene glycol (200) dimethacrylate 25g / L, azobisisobutyronitrile 0.5g / L, ethanol and methanol mixture 25g / L, of which ethanol 15g / L, methanol 10g / L, urea 12g / L, glycerin 2g / L, leveling agent BYK246 0.5g / L, defoamer 902W 0.2g / L, curing agent KH560 1.5g / L.

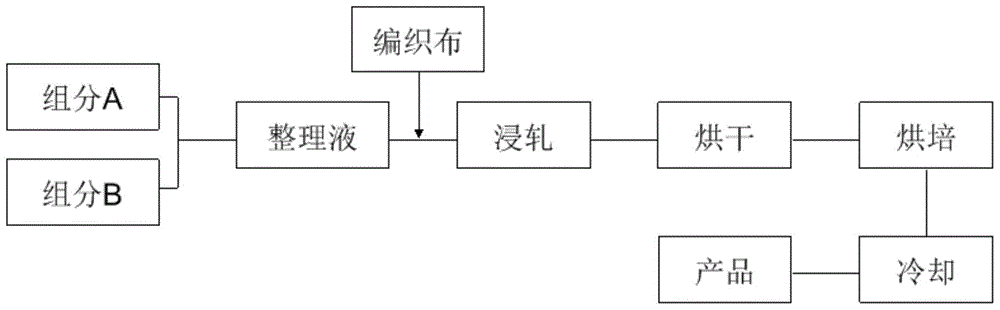

[0031] 1.2 The preparation method of the finishing solution is as follows: figure 1 As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve polyethylene glycol (200) dimethacrylate and a small amount of azobisisobutyronitrile in a mixture of ethanol and methanol to form a solution ...

Embodiment 2

[0034] 2.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0035] Nano ZnO, TiO2, SiO2 powder mixture 25g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80720g / L, polyoxyethylene ether 0.7g / L, aryl β-diketone ligand 15g / L, azobisisobutyronitrile 1g / L , ethanol and methanol mixture 29g / L, of which ethanol 17g / L, methanol 12g / L, urea 10g / L, glycerin 3g / L, leveling agent BYK2460.3g / L, defoamer 902W 0.6g / L, solidified Agent KH560 1g / L.

[0036] 2.2 The preparation method of the finishing solution is as follows: figure 1As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve aryl β-diketone ligands and a small amount of azobisisobutyronitrile in a mixture of ethanol and methanol to form a solution to obtain component B. After mixing c...

Embodiment 3

[0039] 3.1 The composition and content of the composite UV-resistant finishing solution in this embodiment are as follows:

[0040] Nano ZnO, TiO2, SiO2 powder mixture 27g / L, of which ZnO, TiO 2 and SiO 2 The mass ratio is 1:1:1, synergist FK-80730g / L, polyoxyethylene ether 1g / L, amino acid schiff base 30g / L, azobisisobutyronitrile 0.7g / L, ethanol and methanol mixture 35g / L, including ethanol 20g / L, methanol 10g / L, urea 15g / L, glycerin 4g / L, leveling agent BYK246 1g / L, defoamer 902W 1g / L, curing agent KH560 2g / L.

[0041] 3.2 The preparation method of the finishing solution is as follows: figure 1 As shown, put the nano-ZnO, TiO2, SiO2 powder mixture into water, stir rapidly to dissolve it in water, then add polyoxyethylene ether and synergist FK-807 to obtain component A after uniform miscibility. Dissolve amino acid schiff base and a small amount of azobisisobutyronitrile in the mixture of ethanol and methanol to form a solution to obtain component B. After mixing compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com