A radiation-proof rubber product with element gradient combination and its preparation method

A rubber product and anti-radiation technology, which is applied in the field of radiation protection rubber materials and radiation protection, can solve the problems of reducing the physical and mechanical properties of the finished product, reducing the overall shielding effect, and the content of filling components is not high, so as to achieve good comprehensive protection effect and good physical and chemical properties. Effects of mechanical properties and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

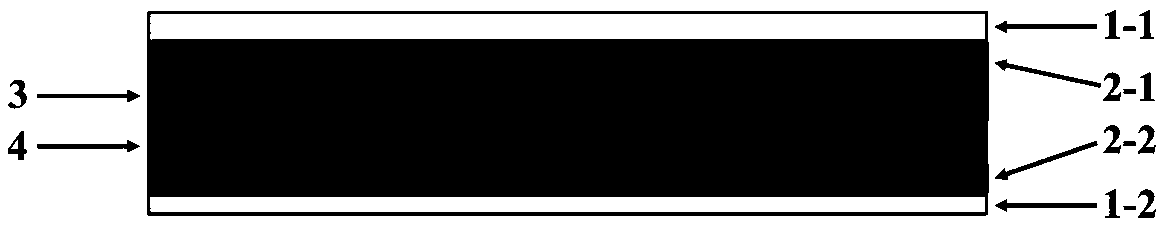

Image

Examples

Embodiment 1

[0084] (1) Preparation of compound latex for impregnation

[0085] ① At room temperature, mix 100 parts of TVR LATEX rubber latex (by dry weight), 1.5 parts of sulfur, 0.8 parts of zinc oxide, 1.5 parts of accelerator ZDC, 2.0 parts of antioxidant D, 0.3 parts of sodium hydroxide and 5.0 parts of formazan Mix base cellulose evenly, keep warm at 60°C for 30 minutes, and then cool to obtain natural rubber compound latex.

[0086] ② Prepare 150 parts of gadolinium oxide, 185 parts of bismuth iodate and 185 parts of tungsten oxide powder with an average particle size of not more than 30 microns to prepare ammonia aqueous dispersions with a mass fraction of 40%, and the concentration of ammonia gas is 5%.

[0087]③ Under continuous stirring, slowly add the three shielding filler dispersions in step ② into the compound latex in step ① to obtain impregnated composite latexes containing gadolinium oxide, bismuth iodate and tungsten oxide respectively, that is, to obtain gadolinium oxi...

Embodiment 2

[0097] (1) Preparation of composite latex for impregnation

[0098] ① At 25°C, mix 100 parts of anionic water-soluble neoprene latex (model 41F, by dry weight), 5.0 parts of zinc oxide, 1.0 parts of sulfur, 1.0 parts of accelerator TT, 1.5 parts of accelerator NA-22, 2.0 parts 1 part of antioxidant A, 0.2 part of sodium hydroxide, 0.1 part of potassium hydroxide and 5.0 parts of N330 carbon black were uniformly mixed to obtain neoprene compound latex.

[0099] ② Mix 100 parts of TVR LATEX rubber latex (by dry weight), 1.5 parts of sulfur, 2.0 parts of zinc oxide, 3.0 parts of accelerator ZDC+TT (1:1 mixing), 1.5 parts of antioxidant D and 0.1 parts of hydrogen at room temperature Mix sodium oxide evenly, keep warm at 60°C for 30 minutes, and then cool to obtain natural rubber compound latex.

[0100] ③ Uniformly mix 150 parts of bismuth iodate powder, 3 parts of sodium lauryl sulfate and 225 parts of soft water with an average particle size not exceeding 30 microns, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com