Nano transparent thermal insulation coating

A heat-insulating coating, nano-technology, applied in the direction of coatings, etc., can solve the problems of nano-transparent heat-insulating coatings research started late, and transparent heat-insulating glass coatings are rarely reported, and achieve high absorption rate and high shielding rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

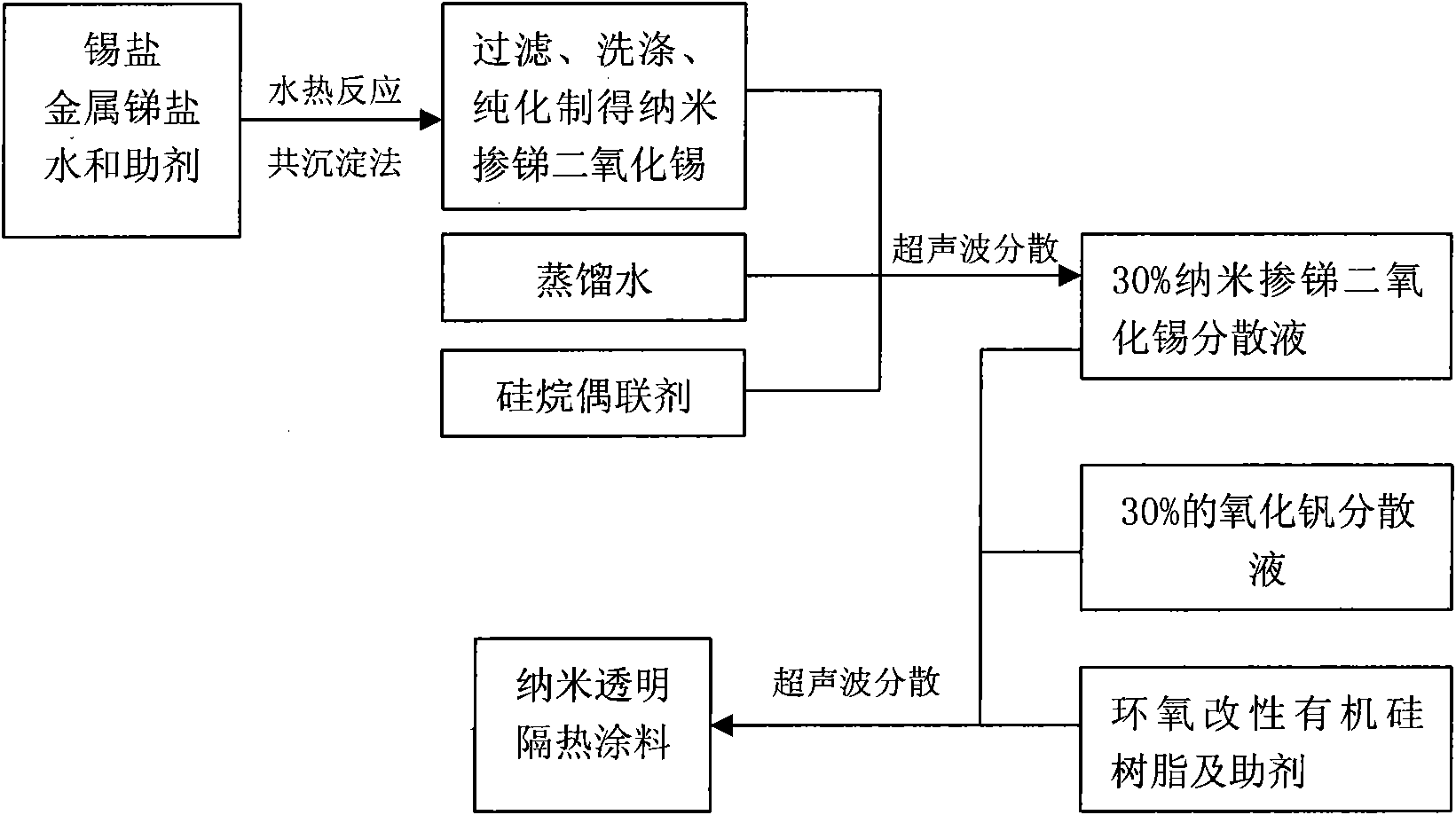

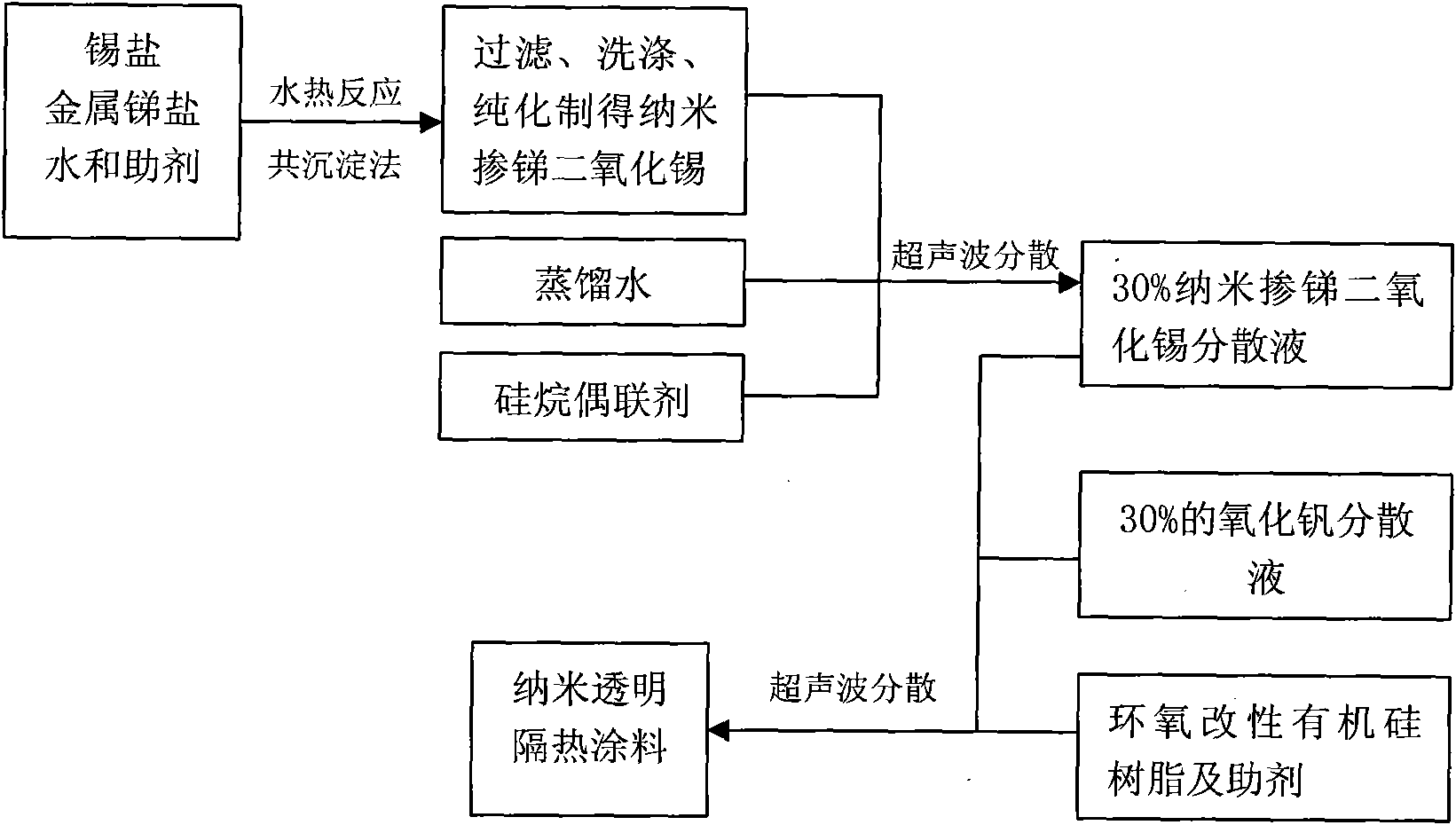

[0035] The preparation of nano-antimony-doped tin dioxide in the present invention adopts the method of chemical dispersion to ensure the effective and stable dispersion of nanoparticles in the coating, and this method also avoids the escape of moisture on the surface of the particles during the drying and calcination of nano-powders The phenomenon of agglomeration of secondary particles is caused.

[0036] On the other hand, prepare a 30% nano-vanadium oxide dispersion: select nano-scale vanadium dioxide with a particle size of 10nm to 25nm and a phase transition temperature of 26°C, add glycidyl etheroxypropylmethyldiethoxy It is prepared by dispersing silane dispersant in water by ultrasonic dispersing machine.

[0037] In addition: epoxy modified silicone resin as film-forming resin, polysiloxane-polyether copolymer emulsion type defoamer, organic fluorine water-based leveling agent and water.

[0038] Mix the prepared 30% nano-antimony-doped tin dioxide dispersion and 30...

Embodiment 1

[0040] Embodiment one: take the following preparations by weight ratio:

[0041] 30% nano antimony-doped tin dioxide dispersion 10%

[0042] 30% nano vanadium oxide dispersion 3%

[0043] Waterborne epoxy modified silicone resin film former 70%

[0044] Polysiloxane-polyether copolymer emulsion defoamer 0.3%

[0045] Organic fluorine water-based leveling agent 0.05%

[0046]water balance

[0047] Add the ingredients into the high-energy stirring mill according to the above formula and stir for 3 hours to disperse.

Embodiment 2

[0048] Embodiment two: take the following preparations by weight ratio:

[0049] 30% nano antimony-doped tin dioxide dispersion 15%

[0050] 30% nano vanadium oxide dispersion 5%

[0051] Waterborne epoxy modified silicone resin film former 60%

[0052] Polysiloxane-polyether copolymer emulsion defoamer 0.5%

[0053] Organic fluorine water-based leveling agent 0.5%

[0054] water balance

[0055] Add the ingredients into a high-energy grinder according to the above formula amount, grind and disperse for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com