Moth compound eye bionic optical device based on super-resolution laser radiation and 3D printing method and application thereof

A technology of bionic optics and laser radiation, applied in the direction of photosensitive materials, optics, 3D object support structures, etc. used in optomechanical equipment, to achieve high response threshold and improve responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

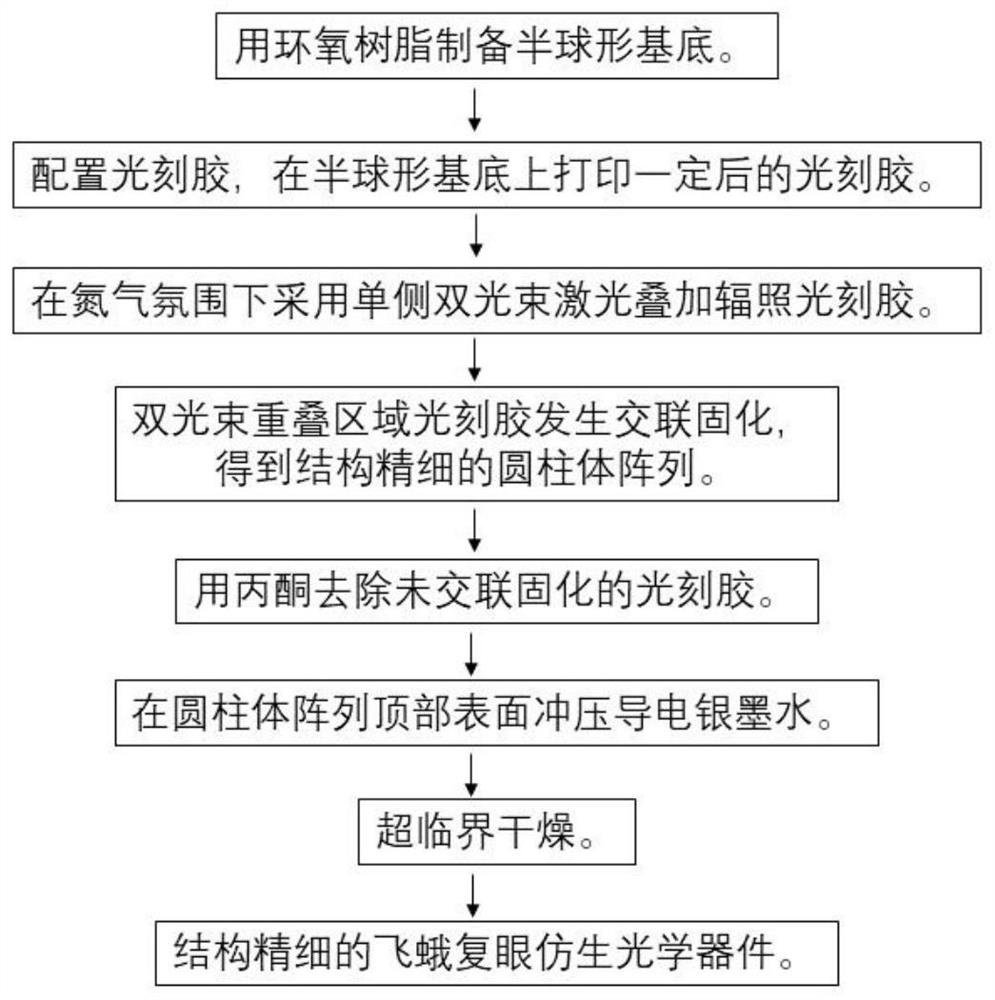

[0036] figure 1 It is a schematic flow chart of the 3D printing method of the moth compound eye bionic device based on super-resolution laser radiation in Example 1. like figure 1 As shown, the 3D printing method of the moth compound eye bionic device is as follows:

[0037] 1. With 50wt% pentaerythritol triacrylate (PETA), 3%wt% photoinitiator 819, 1wt% 2,2,6,6-tetramethylpiperidinyloxy (TEMPO), 23wt% After mixing dodecyl acetate and 23wt% octadecyl acetate, treat it in an ultrasonic bath at 50°C for 40 minutes to obtain a homogeneous mixture, and then fill it with nitrogen to remove the oxygen in it to prepare a photoresist;

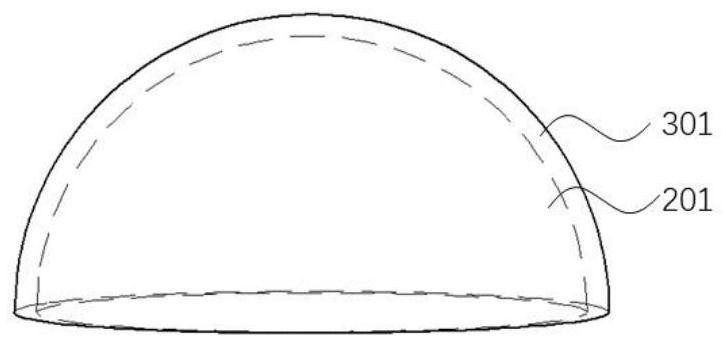

[0038] 2. The photoresist was used as the printing material by two-photon microprinting method, and 201( figure 2 ) print photoresist 301 (thickness is 1μm), such as image 3 shown.

[0039]3. Under a nitrogen atmosphere, a six-axis precision manipulator is used to manipulate the double-beam laser (laser irradiation power is 100W, wavelength is 1...

Embodiment 2

[0045] The difference from Example 1 is that the photoresist described in step 1 is 53wt% of pentaerythritol triacrylate (PETA), 2%wt% of photoinitiator 907, 1wt% of 2,2,6,6- Tetramethylpiperidinyloxy (TEMPO), 22 wt% dodecyl acetate and 22 wt% octadecyl acetate. The hemispherical base material in step 2 is polymethyl methacrylate (PMMA). The diameter of the hemispherical substrate is 25 mm, and the thickness of the photoresist printed on the substrate is 2 μm. The irradiation power of the double-beam laser described in step 3 is 120mW, the wavelength is 353nm, and the cylinder array of the compound eyes of the bionic moth is printed on the hemispherical substrate with a diameter of 500nm and a height of 2μm, and the distance between the centers of adjacent cylinders is 1000nm. The acetone described in step 4 was ultrasonically cleaned at 60° C. for 20 minutes, and then cleaned with isopropanol and deionized water for 5 minutes. Conductive silver ink described in step 5 (sil...

Embodiment 3

[0047] The difference from Example 1 is that the photoresist described in step 1 is 51wt% of pentaerythritol triacrylate (PETA), 2wt% of photoinitiator 369, 2wt% of 2,2,6,6-tetramethyl piperidinyloxy (TEMPO), 22 wt% dodecyl acetate and 23 wt% octadecyl acetate. The hemispherical base material in step 2 is polyimide (PI). The diameter of the hemispherical substrate is 23 mm, and the thickness of the photoresist printed on the substrate is 1.5 μm. The irradiation power of the double-beam laser described in step 3 is 110mW, the wavelength is 253nm, and the cylinder array of the bionic moth compound eyes is printed on the hemispherical substrate with a diameter of 480nm and a height of 1.5μm. The distance between the centers of adjacent cylinders is 900nm. The acetone described in step 4 was ultrasonically cleaned at 55° C. for 15 minutes, and then cleaned with isopropanol and deionized water for 4 minutes. Conductive silver ink described in step 5 (silver content is 25wt%, ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com