Preparation method of exposing high-energy (001) crystal face ultrathin CdS nanobelt

A nanobelt and ultra-thin technology, applied in the field of photocatalysis, can solve the problems that are not conducive to large-scale industrial production, high equipment requirements, high reaction temperature, etc., and achieve the effect of inhibiting the probability of bulk phase recombination, low reaction temperature and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

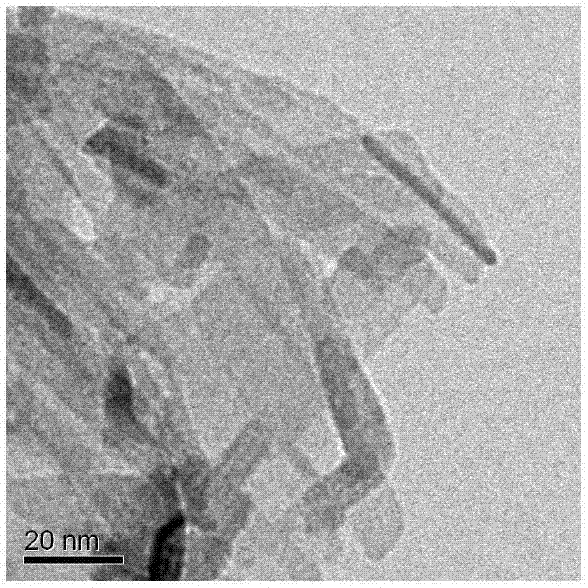

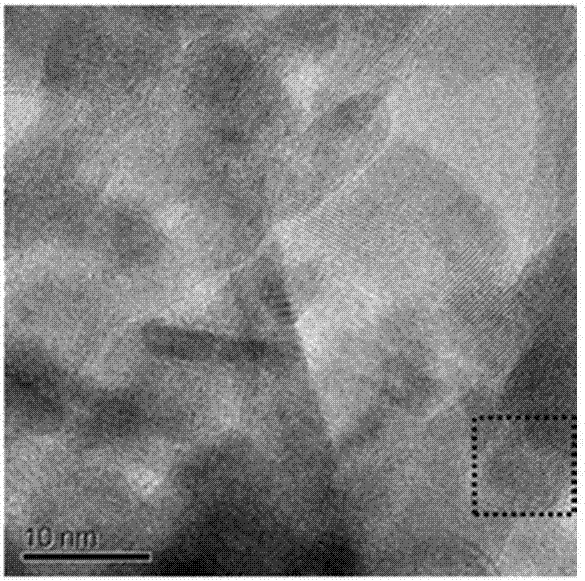

[0023] 10.0mmol Cd(NO 3 ) 2 , 33.4mmol S powder, 5.0mmol deionized, 1000.0mmol diethylenetriamine were fully stirred and dispersed evenly, and then placed in a 120ml polytetrafluoroethylene reactor, at a reaction temperature of 60°C and a stirring rate of 600 rpm Next, solvothermal reaction for 72h. After natural cooling to room temperature, the solvothermal product was collected by centrifugation. Then the product was dispersed in deionized water, the pH value of the solution was adjusted to 8, and ultrasonic stripping was performed for 10 h to obtain ultrathin CdS nanobelts with exposed high-energy (001) crystal planes. The thickness of the CdS nanobelt is about 1nm, the width is about 5nm, and the length is about 100nm as measured by an atomic force microscope.

Embodiment 2

[0025] 1.7mmol CdCl 2 2.5H 2 O, 15.0mmol S powder, 1.0mmol deionized, 1000.0mmol diethylenetriamine were fully stirred and dispersed evenly, and then placed in a 120ml polytetrafluoroethylene reactor, at a reaction temperature of 80°C and a stirring rate of 300 rpm Conditions, solvothermal reaction 48h. After natural cooling to room temperature, the solvothermal product was collected by centrifugation. Then the product was dispersed in deionized water, the pH value of the solution was adjusted to 9.0, and the ultrathin CdS nanoribbons with exposed high-energy (001) crystal planes were obtained by ultrasonic stripping for 2 h. The thickness of the CdS nanobelt is about 1nm, the width is about 10nm, and the length is about 100nm as measured by an atomic force microscope.

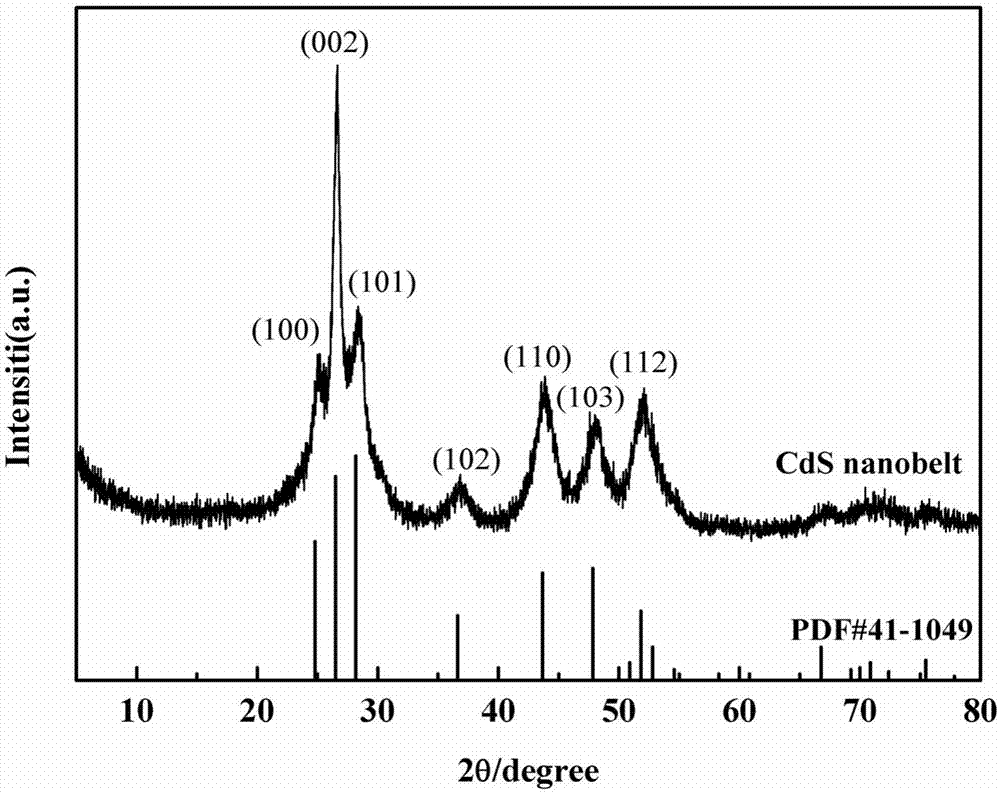

[0026] Such as figure 1 As shown, the (002) and (101) crystal plane diffraction peak intensity difference of CdS semiconductor standard PDF card is not big, and the (001) crystal plane diffraction peak int...

Embodiment 3

[0035] 3.0mmol CdCl 2 , 1.0mmol Cd(CH 3 COO) 2 , 5.0mmol S powder, 3.0mmol deionized, 1000.0mmol diethylenetriamine were fully stirred and dispersed evenly, and then placed in a 120ml polytetrafluoroethylene reactor, under the conditions of a reaction temperature of 100°C and a stirring rate of 30 rpm Next, solvothermal reaction for 72h. After natural cooling to room temperature, the solvothermal product was collected by centrifugation. Then the product was dispersed in deionized water, the pH value of the solution was adjusted to 10.5, and the ultrathin CdS nanoribbons with exposed high-energy (001) crystal planes were obtained by ultrasonic stripping for 6 h. The thickness of the nanobelt is about 3nm, the width is about 15nm, and the length is about 100nm as measured by an atomic force microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com