Water-based micro-nano flaky graphite radon radiation shielding coating and preparation method and construction method thereof

A radiation shielding, flake graphite technology, applied in coatings, buildings, building structures, etc., can solve the problems of time-consuming and labor-intensive, graphene is easy to agglomerate, and construction period is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of this water-based micro-nano flake graphite powder is as follows:

[0047] 1) Add water, dispersant, film-forming aid, and coupling agent to the disperser in sequence according to the proportion, add hydroxyethyl cellulose aqueous solution and defoamer under stirring, stir and disperse until uniformly mixed; then add expanded graphite powder , stirring and mixing to obtain a water-based expanded graphite powder slurry;

[0048] 2) The water-based expanded graphite powder slurry is put into a refiner to grind into a uniform slurry, and the water-based micro-nano flake graphite powder slurry is dried and dehydrated to obtain a water-based micro-nano flake graphite material.

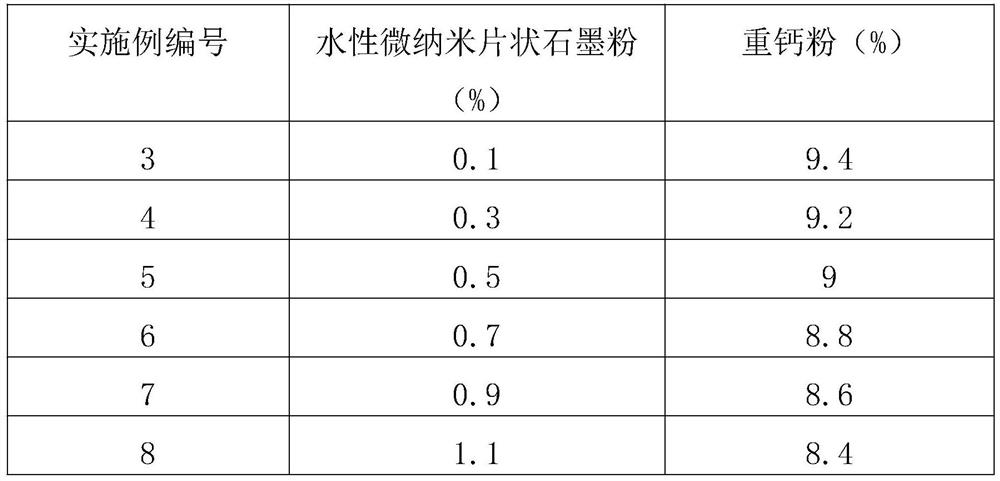

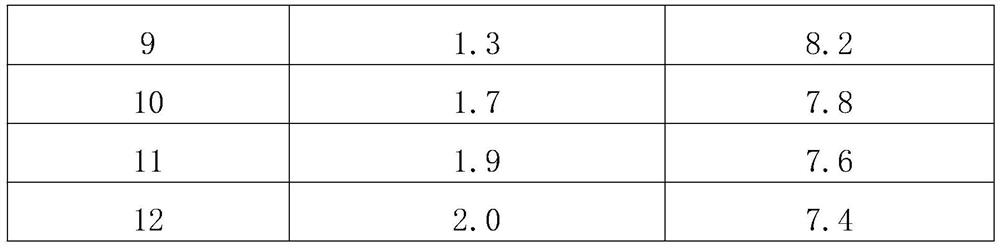

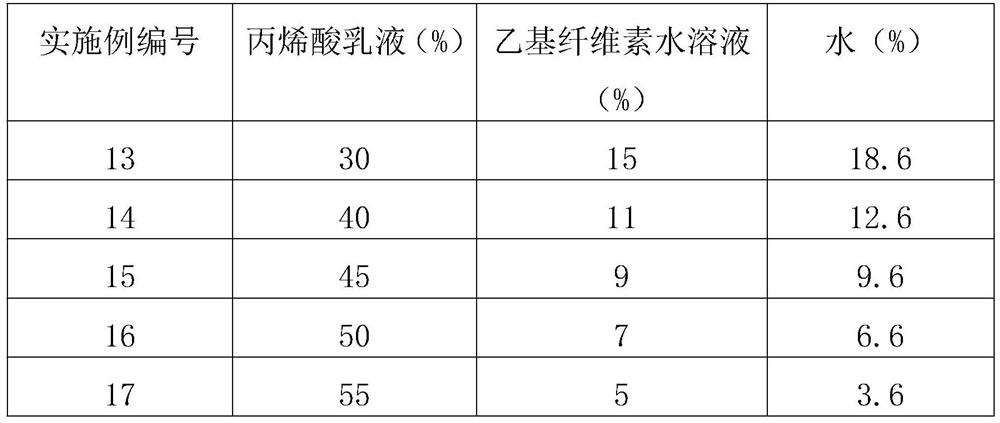

[0049] The method for preparing water-based micro-nano flake graphite radon radiation shielding coating comprises the following steps:

[0050] 1) Add water, dispersant, defoamer, and film-forming aid to the disperser sequentially according to the ratio and stir at high spee...

specific Embodiment 1

[0067] Embodiment 1 of the present invention comprises the following steps:

[0068] 1. Preparation method of water-based micro-nano flake graphite powder:

[0069] a, prepare expanded graphite powder:

[0070] Take the expandable graphite powder and heat it to 450°C for calcining until no water vapor emerges, and the expansion is completed, and the expanded graphite powder is obtained;

[0071] b. Preparation of water-based micro-nano flake graphite powder:

[0072] Ingredients: 8% expanded graphite powder, 15% hydroxyethyl cellulose aqueous solution, 1.5% coupling agent, 1% film-forming aid, 0.2% defoamer, 1% dispersant, and 73.3 The mass percentage of % water is composed of the raw materials of each component;

[0073] The hydroxyethyl cellulose aqueous solution is a hydroxyethyl cellulose aqueous solution with a mass percent content of hydroxyethyl cellulose of 2%; preparation method: add 1 weight part of hydroxyethyl cellulose to 49 parts by weight of water, add while ...

specific Embodiment 2

[0089] Embodiment 2 of the present invention comprises the following steps:

[0090] 1. Preparation method of water-based micro-nano flake graphite powder:

[0091] a, prepare expanded graphite powder:

[0092] Take the expandable graphite powder and heat it to 450°C for calcining until no water vapor emerges, and the expansion is completed, and the expanded graphite powder is obtained;

[0093] b. Preparation of water-based micro-nano flake graphite powder:

[0094] Ingredients: 8% expanded graphite powder, 15% hydroxyethyl cellulose aqueous solution, 1.5% coupling agent, 1% film-forming aid, 0.2% defoamer, 1% dispersant, and 73.3 The mass percentage of % water is composed of the raw materials of each component;

[0095] The hydroxyethyl cellulose aqueous solution is a hydroxyethyl cellulose aqueous solution with a mass percent content of hydroxyethyl cellulose of 2%; preparation method: add 1 weight part of hydroxyethyl cellulose to 49 parts by weight of water, add while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com