Processing method of nano-coated anti-ultraviolet glass

A processing method and anti-ultraviolet technology, applied in coating and other directions, can solve the problems of high-altitude cleaning glass curtain wall, inability to isolate ultraviolet rays, easy glass pollution, etc., to increase visible light transmittance, improve ultraviolet blocking ability, and improve coating resistance The effect of powdering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

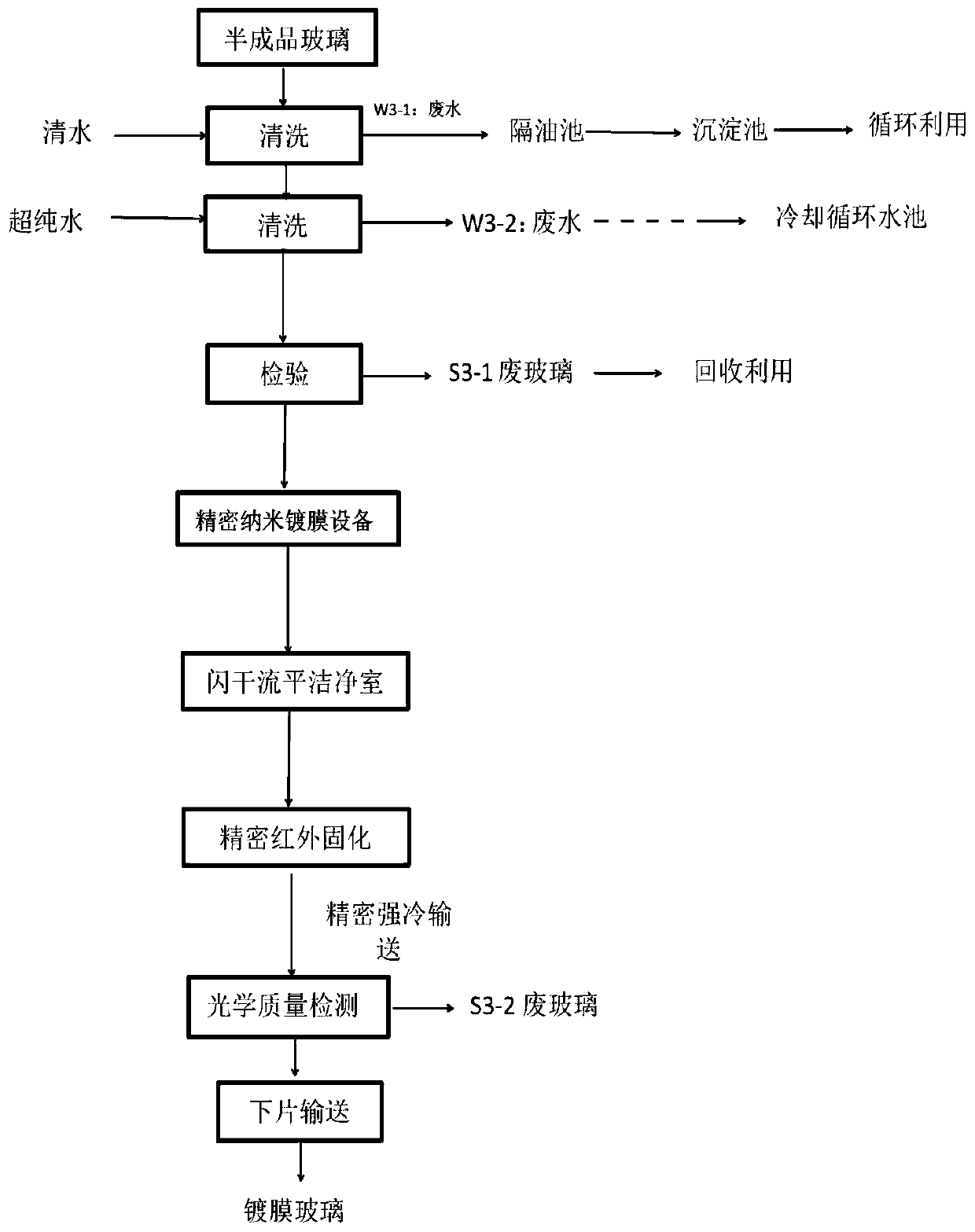

[0021] like figure 1 As shown, the invention discloses a processing method of nano-coated anti-ultraviolet glass. The processing method at least includes: cleaning→coating preparation→precision coating equipment→precise flash dry leveling→precise infrared curing→precise forced cooling transportation.

[0022] Preferably, the cleaning step is: cleaning with ultra-pure water cleaning equipment, first cleaning with clean water, and then recycling the discharged waste water through a grease trap and a sedimentation tank, and then cleaning with ultra-pure water, and the cleaned waste water enters the cooling Circulating pool. Further, reverse osmosis water treatment equipment and ion exchange equipment are combined to prepare ultra-pure water for the electronics industry with a purity of 106Ω. Industrial water passes through reverse osmosis equipment and deionization equipment to remove impurity ions in the water and become deionized water. The water output meets the needs of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com