A kind of anti-ultraviolet, high barrier packaging film and preparation method

A high-barrier, anti-ultraviolet technology, applied in coatings and other directions, can solve the problems of dispersing and destroying material properties, poor anti-ultraviolet ability, etc., and achieve the effect of improving dispersibility, low cost, and excellent ultraviolet blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

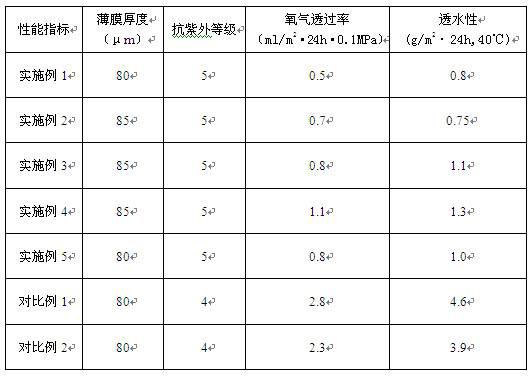

Examples

Embodiment 1

[0032] Mix 100kg sodium rectorite with 2kg quartz sand, and with the assistance of quartz sand, use a planetary ball mill to grind, so that the interlayer structure of rectorite is separated into mica-like nanoparticles; 28kg rectorite nanoparticles and Add 25kg of starch into 44kg of aqueous solution, and add 2kg of sodium lauryl sulfate, then stir at a speed of 40r / min for 15min to obtain a stable suspension; use a high-pressure spray dryer to dry the resulting suspension to solidify the starch , obtain the nano-rectorite of the layered structure of starch coating, then add in the polyvinylidene chloride emulsion to obtain composite emulsion, the mass fraction of the nano-rectorite of the layered structure of starch coating in the composite emulsion is 15%; Corona pretreatment is carried out on the polyethylene film, and then the prepared composite emulsion is evenly coated on the surface of the substrate film, and the infrared radiation with a frequency of 50 Hz is used to d...

Embodiment 2

[0035]Mix 100kg of calcium rectorite with 1kg of quartz sand, and with the assistance of quartz sand, use a stirring high-energy ball mill for grinding, so that the interlayer structure of rectorite is separated into mica-like nanoparticles; 28kg of rectorite nanoparticles And 30kg of starch was added to 41kg of aqueous solution, and 1kg of sodium lauryl sulfate was added, and then stirred at a speed of 45r / min for 12min to obtain a stable suspension; a high-pressure spray dryer was used to dry the resulting suspension to make the starch solidify to obtain the nano-rectorite of starch-coated layered structure, and then add polyvinylidene chloride emulsion to obtain a composite emulsion, and the mass fraction of the nano-rectorite of starch-coated layered structure in the composite emulsion is 20% Carry out coating acrylic resin pretreatment to polyethylene film, then the composite emulsion that will make is evenly coated on the surface of substrate film, adopts the infrared ray...

Embodiment 3

[0038] Mix 100kg potassium rectorite with 1.5kg quartz sand, and with the assistance of quartz sand, use a vibratory high-energy ball mill to grind the rectorite interlayer structure into mica-like nanoparticles; mix 26kg rectorite nano Microparticles and 25kg of starch were added to 47kg of aqueous solution, and 2kg of sodium lauryl sulfate was added, and then stirred at a speed of 42r / min for 12min to obtain a stable suspension; a high-pressure spray dryer was used to dry the resulting suspension to make The starch is solidified to obtain the nano-rectorite of the layered structure coated with the starch, and then added to polyvinylidene chloride emulsion to obtain a composite emulsion, and the mass fraction of the layered structure of the starch-coated nano-rectorite in the composite emulsion is 25 %; Carry out corona pretreatment to polyethylene film, then the composite emulsion that makes is evenly coated on the surface of substrate film, adopts the infrared ray radiation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com