Food preservative film based on titanium-based composite material as well as preparation method and application of food preservative film

A titanium-based composite material and food preservation technology, which is applied in the field of food preservation film and its preparation based on titanium-based composite materials, can solve the problems of low oxygen permeability, uneven film shedding, and high water permeability of soybean protein isolate film. Achieve excellent thermally reversible gel properties, good stability and dispersion, and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

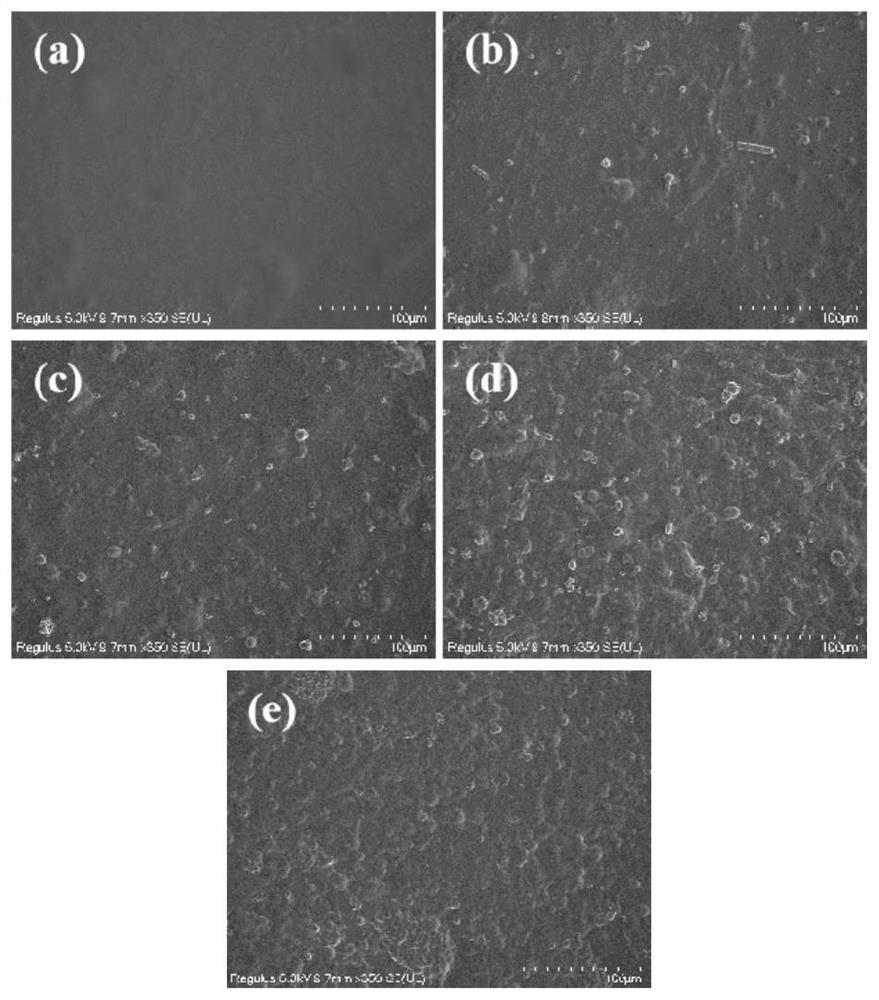

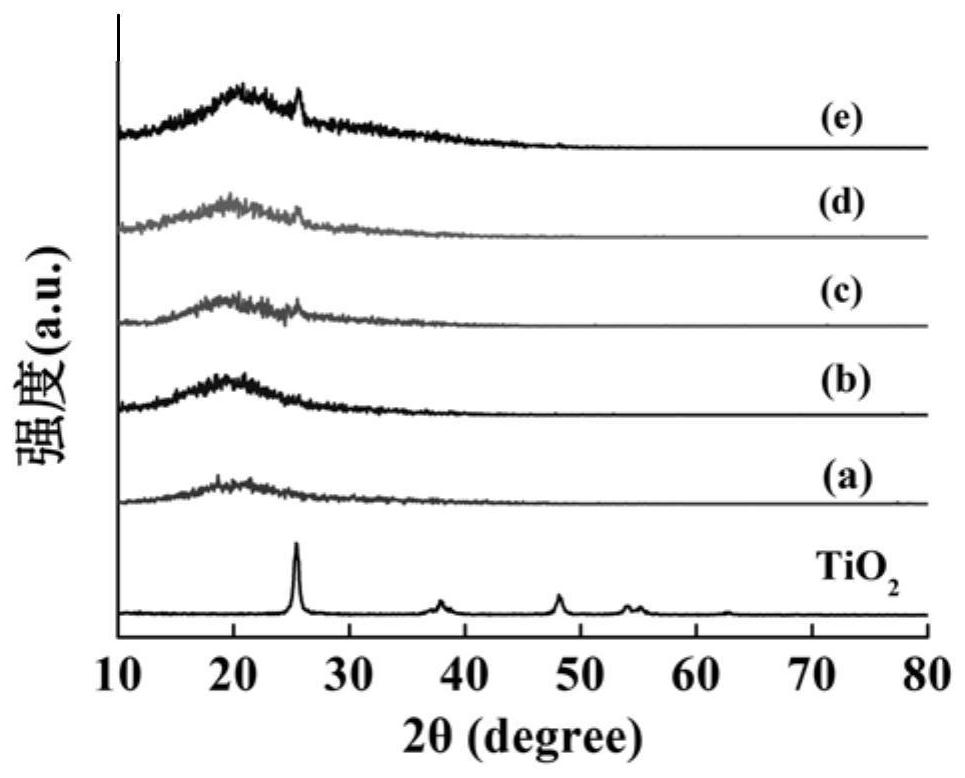

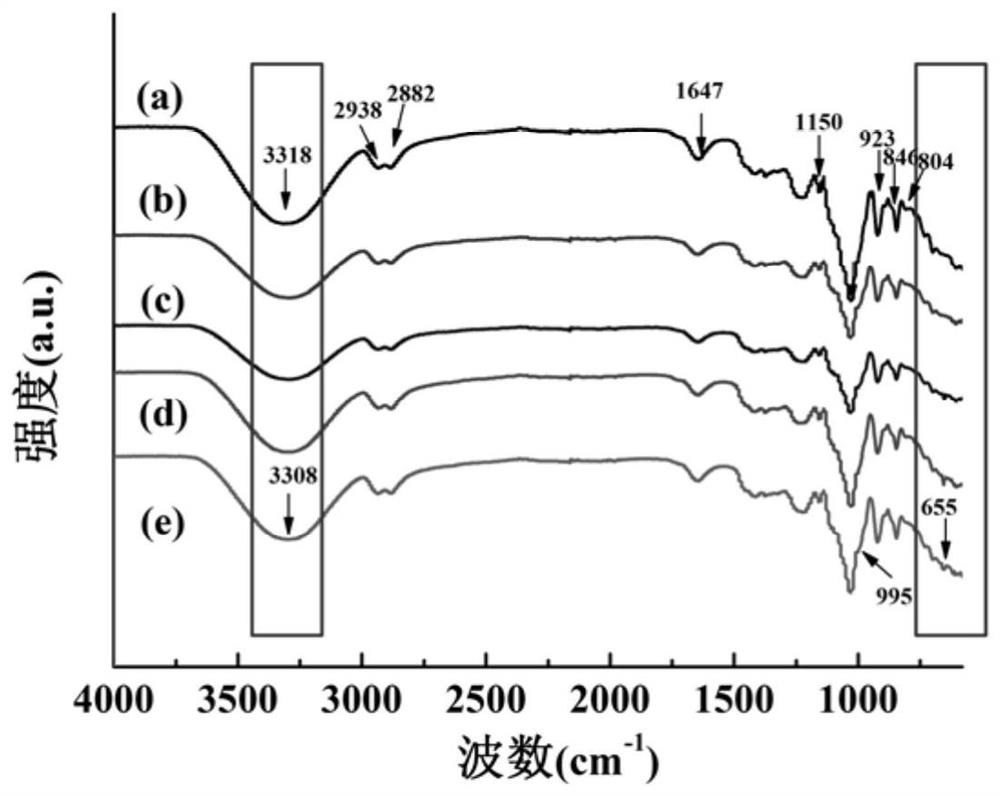

[0029] Material preparation: Weigh 1 g of κ-carrageenan and 1 g of konjac glucomannan into 200 mL of distilled water at a room temperature of 25°C. Subsequently, 0.6 g of glycerol was added, heated and stirred in a water bath at 80° C. for 30 min. Adding hydrothermally treated nano-TiO to the above bio-based film-forming solution 2 (0%, 1%, 3%, 5% and 7%, w / w, Nano TiO 2 / biopolymer matrix), sonicate for 30min to disperse in the solution, then continue to stir for 30min. Stand at room temperature for 2-4h to remove air bubbles in the solution. Pour 40 g of the film-forming solution into a polystyrene petri dish, and dry it in an oven at 60° C. for 10-15 hours to obtain a composite film. The composite film was peeled off from the petri dish, and stored at 25° C. and 50% RH. Will contain 0%, 1%, 3%, 5%, 7% nano TiO 2 The composite membranes are named KC / KGM, KC / KGM / 1%TiO 2 、KC / KGM / 3%TiO 2 、KC / KGM / 5%TiO 2、KC / KGM / 7%TiO 2 , that is, KC / KGM, KC / KGM / 1%TiO described in the pr...

Embodiment 2

[0039] Antibacterial Effect Analysis of Composite Membrane

[0040] Transfer Penicillium viridans to 100mL of normal saline, adjust the concentration to 105CFU / mL, add 10x10cm 2 KC / KGM, KC / KGM / 1%TiO prepared in Example 1 2 、KC / KGM / 3%TiO 2 、KC / KGM / 5%TiO 2 、KC / KGM / 7%TiO 2 membrane. After 6 hours of xenon lamp irradiation, the bacterial solution was diluted, and 1.0 mL of the sample solution was inoculated into PDA medium. The plate was placed in a constant temperature incubator at 26°C for 5 days, and the antibacterial effect of the film was observed. See the experimental results Figure 7 , as shown, the KC / KGM composite film did not show any growth inhibition of P. aeruginosa. KC / KGM / 3%TiO 2 The antibacterial rate of the nanocomposite film was 53.6% after being illuminated for 6 hours. When the nano-TiO was further increased 2 When the concentration value is 5%, the antibacterial effect is significantly enhanced, and the antibacterial rate reaches 72.5%. Nano-TiO 2 Wh...

Embodiment 3

[0042] Analysis of the Fresh-keeping Effect of Composite Film on Sliced Bread

[0043] The KC / KGM film prepared in Example 1, the composite film KC / KGM / 5%TiO 2 And the fresh-keeping experiment of packaging bags sold on the market and PET film when packaging bread slices: irradiate bread slices (7.00±0.05g) with ultraviolet light for at least 20 minutes to sterilize before the experiment begins. Then, inoculate 9 µL of the prepared Penicillium aeruginosa spore suspension on the sliced bread. The inoculated bread slices were sealed in PET bags, bags made of KC / KGM composite film, KC / KGM / 5%TiO 2 In bags made of composite film, and stored at 25°C for 14 days. Assess the freshness of the package by visually inspecting for mold growth. See the experimental results Figure 8 .

[0044] Experimental results: After being stored at 25°C for 14 days, compared with other groups with large areas of mold colonies, the bread slices using the packaging film of the present invention m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com