Preparation method of modified polycarbonate material

A polycarbonate and water-based polyurethane technology, which is used in the preparation of modified polycarbonate materials, can solve the problems of people or objects being easily damaged by ultraviolet rays, easy to photoaging, and poor in ultraviolet shielding function, so as to improve the ultraviolet shielding ability. , Improve the effect of light aging resistance and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

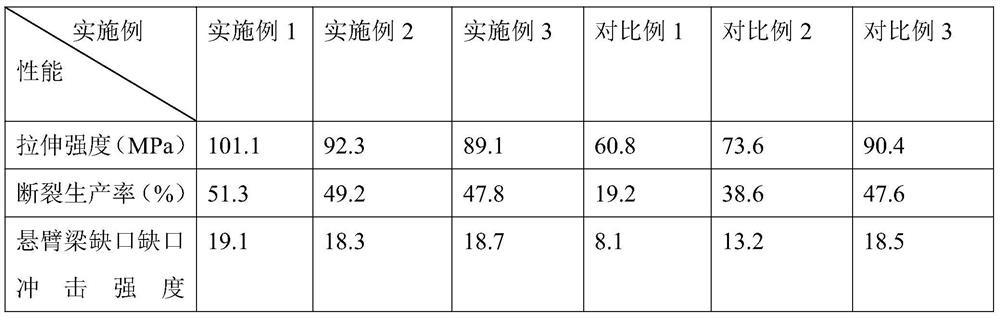

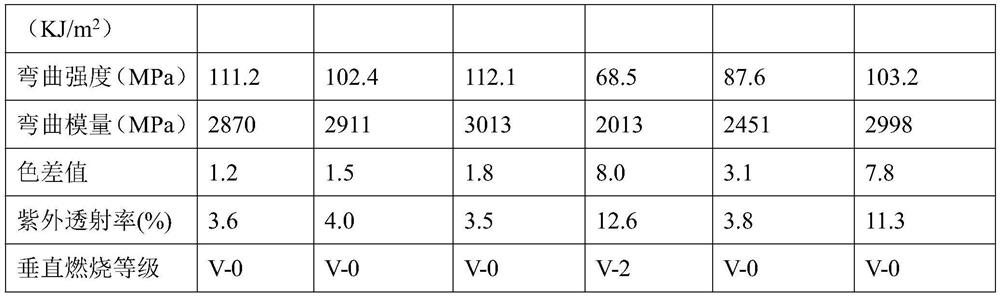

Examples

Embodiment 1

[0022] Embodiment 1: A kind of preparation method of modified polycarbonate material.

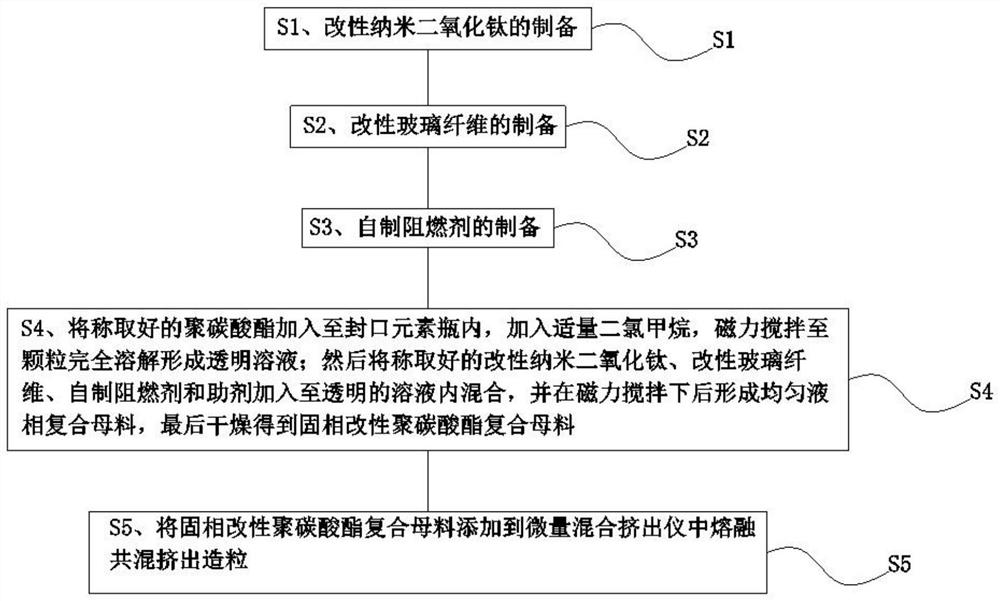

[0023] refer to figure 1 Shown, a kind of preparation method of modified polycarbonate material specifically comprises the steps:

[0024] S1, the preparation of modified nano titanium dioxide, the TiCL of 0.6kg 4 Dissolve in 6L of absolute methanol to obtain a zinc salt methanol solution with a concentration of 10%, then dissolve 0.3kg of KOH in 6L of absolute ethanol to obtain a concentration of 5% precipitant ethanol solution, wherein the control anhydrous The adding volume ratio of methyl alcohol and dehydrated alcohol is 1:1, and precipitating agent ethanol solution is added dropwise to zinc salt methanol solution, keeps stirring, and in the stirring process, add 0.3kg of the horsetail that grafting ratio is 0.8% in this reaction solution. Anhydride-grafted polyethylene is used as a modifier, and after 2 hours of heat preservation, a small amount of deionized water is added to termin...

Embodiment 2

[0031] A preparation method of a modified polycarbonate material, specifically comprising the steps of:

[0032] S1, the preparation of modified nano titanium dioxide, the TiCL of 0.5kg 4 Dissolve in 10L of absolute methanol to obtain a zinc salt methanol solution with a concentration of 5%, and then dissolve 0.2kg of KOH in 10L of absolute ethanol to obtain a 2% ethanol solution of the precipitant, in which the anhydrous The adding volume ratio of methyl alcohol and dehydrated alcohol is 1:1, and precipitating agent ethanol solution is added dropwise to zinc salt methanol solution, keeps stirring, and in the stirring process, the horsetail that the grafting rate of 0.8% of 0.2kg is added in this reaction solution Anhydride-grafted polyethylene is used as a modifier, and after 2 hours of heat preservation, a small amount of deionized water is added to terminate the reaction, and the solid product prepared is centrifuged and washed, dried by rotary evaporation, and then ground ...

Embodiment 3

[0035] A preparation method of a modified polycarbonate material, specifically comprising the steps of:

[0036] S1, the preparation of modified nano titanium dioxide, the TiCL of 1kg 4 Dissolve in 5L of absolute methanol to obtain a zinc salt methanol solution with a concentration of 20%, then dissolve 0.5kg of KOH in 5L of absolute ethanol to obtain a concentration of 10% precipitant ethanol solution, wherein the control anhydrous The adding volume ratio of methyl alcohol and absolute ethanol is 1:1, and precipitating agent ethanol solution is added dropwise to zinc salt methanol solution, keeps stirring, and in the stirring process, the horsetail that the grafting rate of 0.8% of 0.4kg is added in this reaction solution Anhydride-grafted polyethylene is used as a modifier, and after 2 hours of heat preservation, a small amount of deionized water is added to terminate the reaction, and the solid product prepared is centrifuged and washed, dried by rotary evaporation, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com