Ultraviolet blocking master batch of polyolefin high-transmittance film and preparation method of ultraviolet barrier master batch

A technology of UV blocking and polyolefin, which is applied in the field of UV blocking masterbatch and preparation of polyolefin high-transparency films, can solve the problems of increased haze and decreased light transmittance of the film, and achieves low cost, simple preparation process, and good mechanical properties. The effect of the performance protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

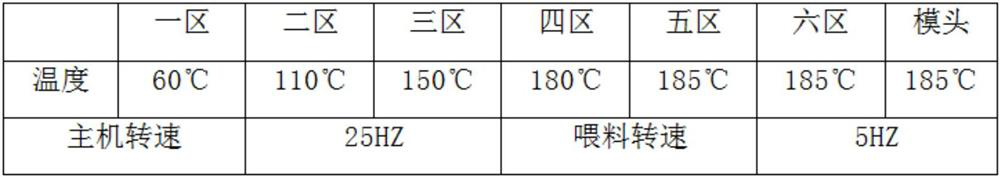

[0025] The steps of this embodiment are as follows:

[0026] (1) The raw material formula of UV blocking masterbatch for Group 1-4 polyethylene high-transparency film is shown in Table 1.

[0027] Table 1 Group 1-4 polyethylene high-transparency film UV barrier masterbatch raw material formula (unit: parts by weight)

[0028] raw material group 1 group 2 group 3 group 4 polyethylene resin 82 77 72 67 Triazine UV Absorbers 6 9 9 12 Benzotriazole UV Absorbers 4 6 6 8 Inorganic Nanoparticles 5 5 10 10 Processing aids 3 3 3 3

[0029] The melt index of the polyethylene resin used is 10-20g / 10min, and the density is 0.9-0.93g / cm3.

[0030] The triazine ultraviolet absorber used is ultraviolet absorber UV-1164.

[0031] The benzotriazole ultraviolet absorber used is ultraviolet absorber UV-328.

[0032] The inorganic nanoparticles used are nanometer zinc oxide coated with a silane coupling agent. The particle siz...

Embodiment 2

[0040] Embodiment 2: comparative examples 1~3

[0041] The preparation method of the barrier masterbatches of Comparative Examples 1-3 is the same as that of Group 2 in Example 1, and the differences are shown in Table 3.

[0042] Table 3 Raw material formulations of barrier masterbatches in comparative examples 1 to 3 (unit: parts by weight)

[0043] raw material Comparative example 1 Comparative example 2 Comparative example 3 polyethylene resin 77 77 82 Triazine UV Absorbers 15 9 Benzotriazole UV Absorbers 15 6 Inorganic Nanoparticles 5 5 Processing aids 3 3 3

[0044] Performance test results of groups 1-4 and comparative examples 1-3

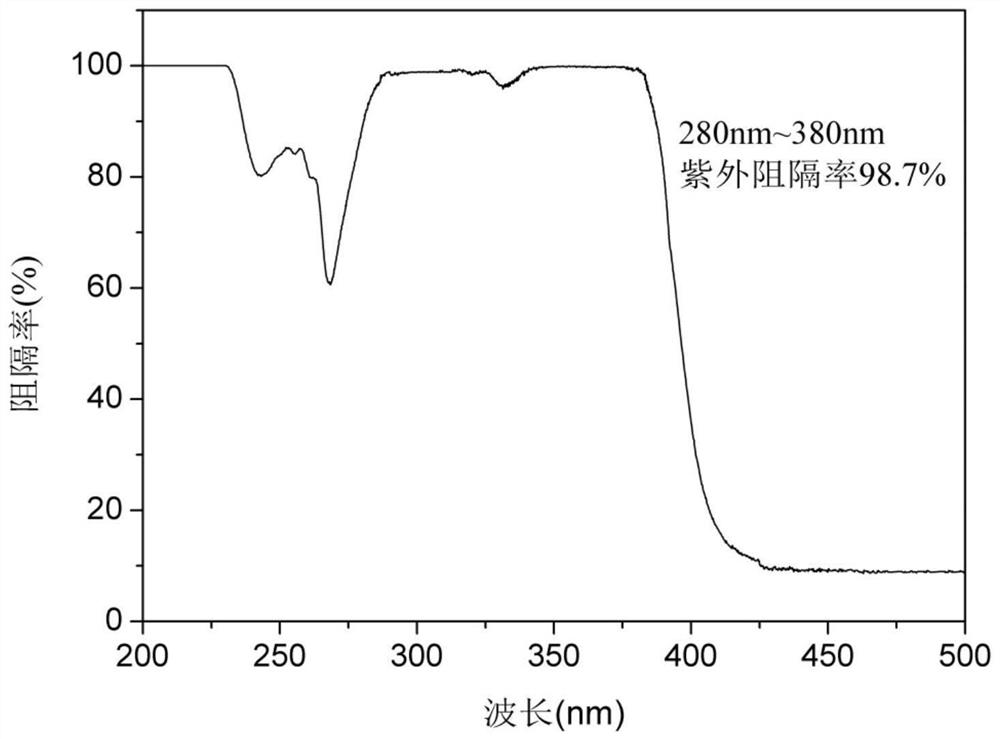

[0045] Groups 1-4 and Comparative Examples 1-3 were prepared with 80 μm thick PE films according to the addition amount of 1.5% by weight, and the film properties were tested at the initial stage and after 3000 hours of UV aging with reference to GB / T 2410-2008 and ASTM G154. ...

Embodiment 3

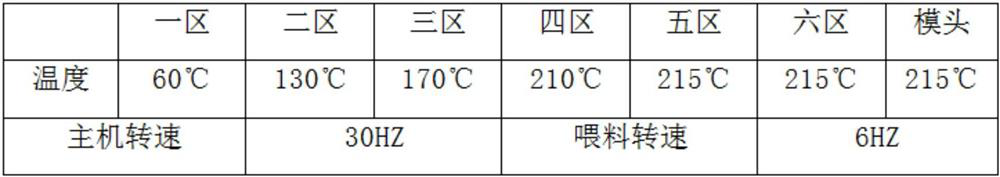

[0051] The steps of this embodiment are as follows:

[0052] (1) The raw material formula of the ultraviolet blocking masterbatch of group 5-8 polypropylene high-transparency film is shown in Table 6.

[0053] Table 6 Group 5-8 Polypropylene high-transparency film UV barrier masterbatch raw material formula (unit: parts by weight)

[0054] raw material Group 5 Group 6 Group 7 Group 8 polypropylene resin 82 77 72 67 Triazine UV Absorbers 6 9 9 12 Benzotriazole UV Absorbers 4 6 6 8 Inorganic Nanoparticles 5 5 10 10 Processing aids 3 3 3 3

[0055] The melt index of the polypropylene resin used is 8-15g / 10min, and the density is 0.9-0.95g / cm 3 .

[0056] The triazine ultraviolet absorber used is ultraviolet absorber UV-1577.

[0057] The benzotriazole ultraviolet absorber used is ultraviolet absorber UV-326.

[0058] The inorganic nanoparticles used are nano cerium oxide coated with stearic acid. The particle d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com