Ultraviolet barrier plastic and preparation method thereof

A UV blocking and plastic technology, applied in the field of plastic materials, can solve the problems of shortened UV blocking timeliness, narrow effective wave band, limited blocking effect, etc., and achieve excellent UV blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

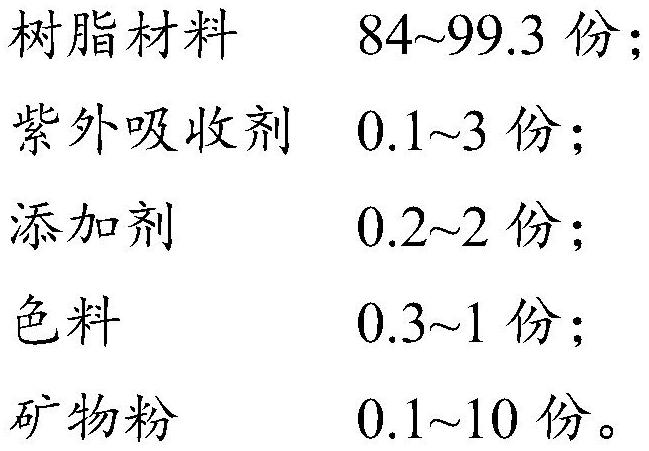

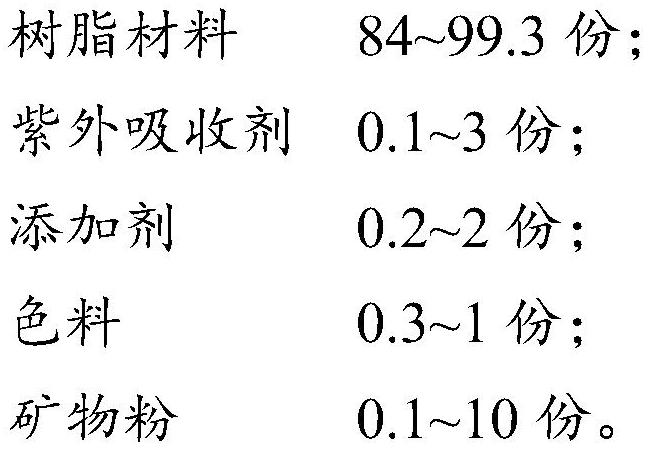

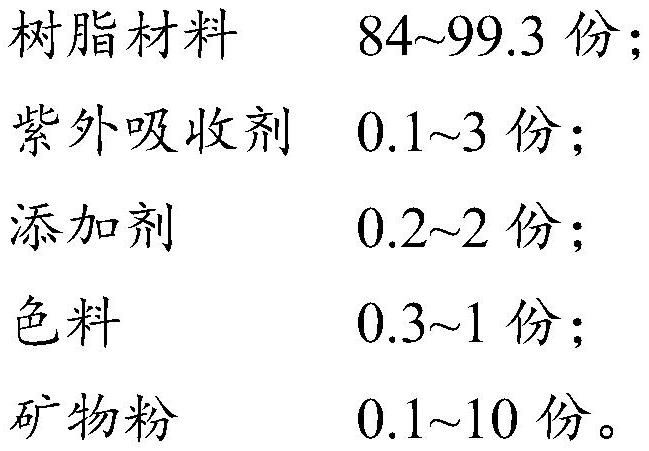

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method for the ultraviolet blocking plastic described in the above technical solution, comprising the following steps:

[0029] Mix resin materials, UV absorbers, additives, colorants and mineral powders to obtain premixed materials;

[0030] The premixed material is extruded through an extruder to obtain a UV-blocking plastic.

[0031] The invention mixes the resin material, the ultraviolet absorber, the additive, the colorant and the mineral powder to obtain the premixed material. In the present invention, the mixing is preferably carried out in a high-speed mixer; the mixing speed is preferably 100-200r / min, more preferably 120-170r / min; the mixing time is preferably 2-10min, more preferably 4-6 minutes; the mixing temperature is preferably 30-80°C.

[0032] After the premix is obtained, the present invention extrudes the premix through an extruder to obtain an ultraviolet blocking plastic. In the present inventi...

Embodiment 1

[0035] In parts by weight, 98 parts of HDPE resin, 0.3 part of ultraviolet absorber BASF TinUvin1130, 0.8 part of additive (the specific composition is 10100.1 part of antioxidant, 0.3 part of silane coupling agent, 0.4 part of erucamide), 0.4 part Pigment titanium yellow and 0.5 parts of 600 mesh TiO 2 Mixed, all added to a high-speed mixer, stirred at 150r / min for 5 minutes to obtain a premix; the premix was added to a twin-screw extruder through the main feed port for co-extrusion, and the twin-screw extruder barrel The temperature is 110-150° C., the rotational speed of the screw is 300-400 r / min, and the vacuum degree is 0.5-0.8 MPa to obtain an ultraviolet-blocking plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com