Flexible steel strand cage of underground diaphragm wall self-adaptive to trough deflection and construction method thereof

An underground diaphragm wall and steel strand technology, which is applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of uneven center of gravity, large impact on the surrounding environment, poor stability of the tank wall, etc., and achieves strong applicability, The effect of economical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] The invention provides a flexible steel strand cage for an underground continuous wall that can adapt to the deflection of the groove and its implementation method. The flexible steel strand cage is used to replace the traditional steel cage with high rigidity, so that when the reinforcement is lowered, it can Freely adapts to the deflection of the tank walls.

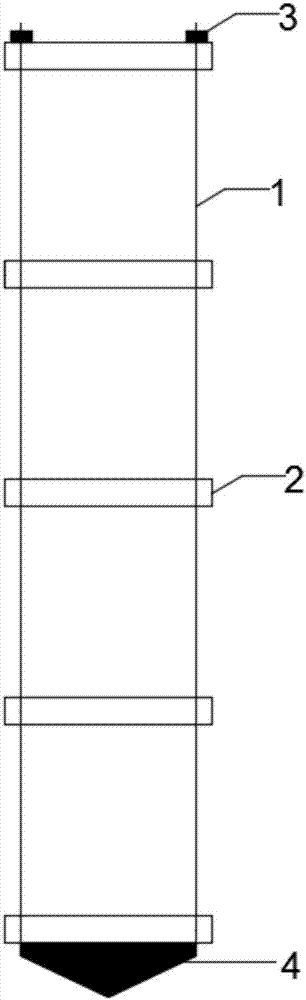

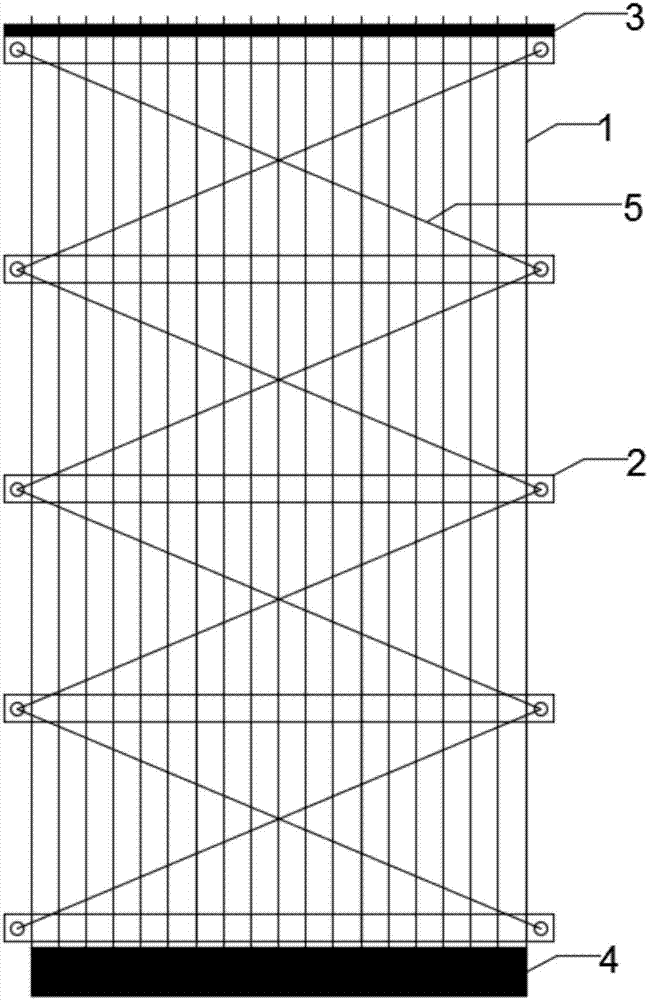

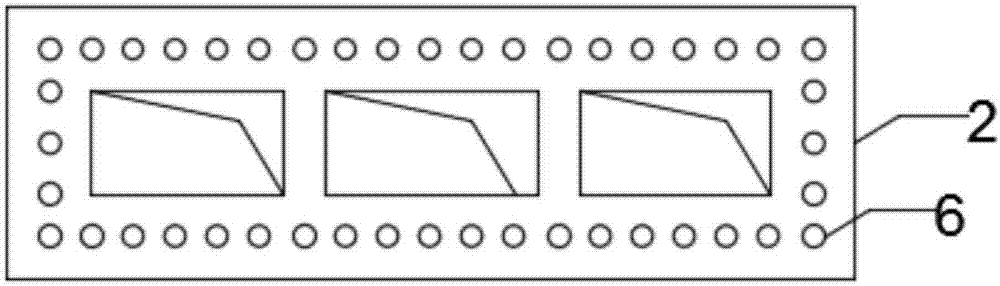

[0026] For details, please refer to Figure 1-3 , a flexible steel strand cage for an underground diaphragm wall that can be self-adaptive to trough deflection, including a steel strand 1, a steel strand positioning plate 2, and an X-shaped diagonal tie bar 5; the steel strand positioning plate 2 is laid Steel strand perforation 6, a group of steel strands 1 vertically pass through a plurality of steel strand positioning plates 2 arranged at intervals; the steel strand positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com