Portable cattle and sheep feeding stacker truck

A convenient, stacking technology, used in animal feeding devices, applications, animal husbandry, etc., can solve problems such as environmental pollution, environmental pollution, and diseases of dairy cows, and achieve good operation stability, strong operability, The effect of reducing the chance of getting sick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

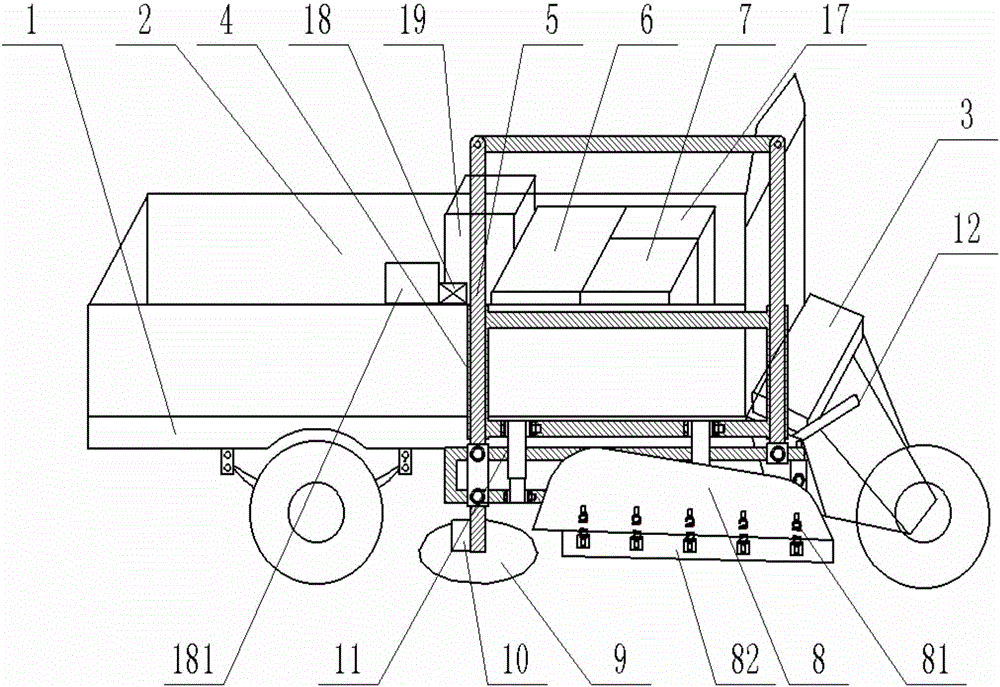

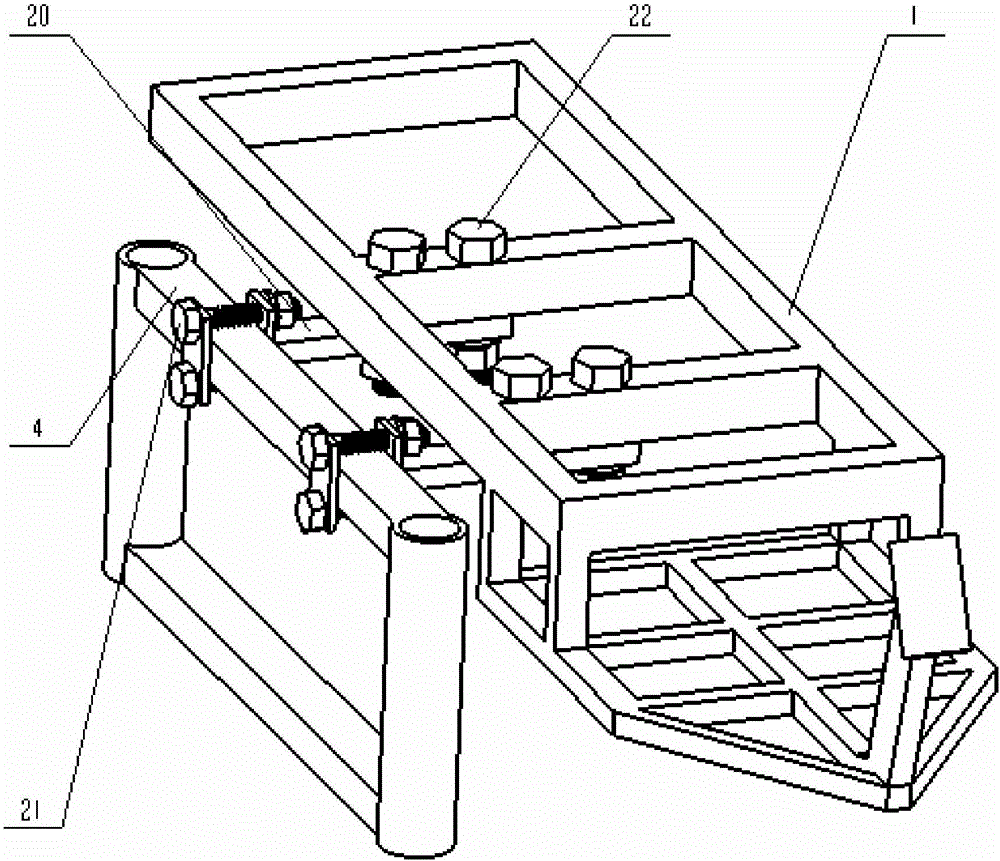

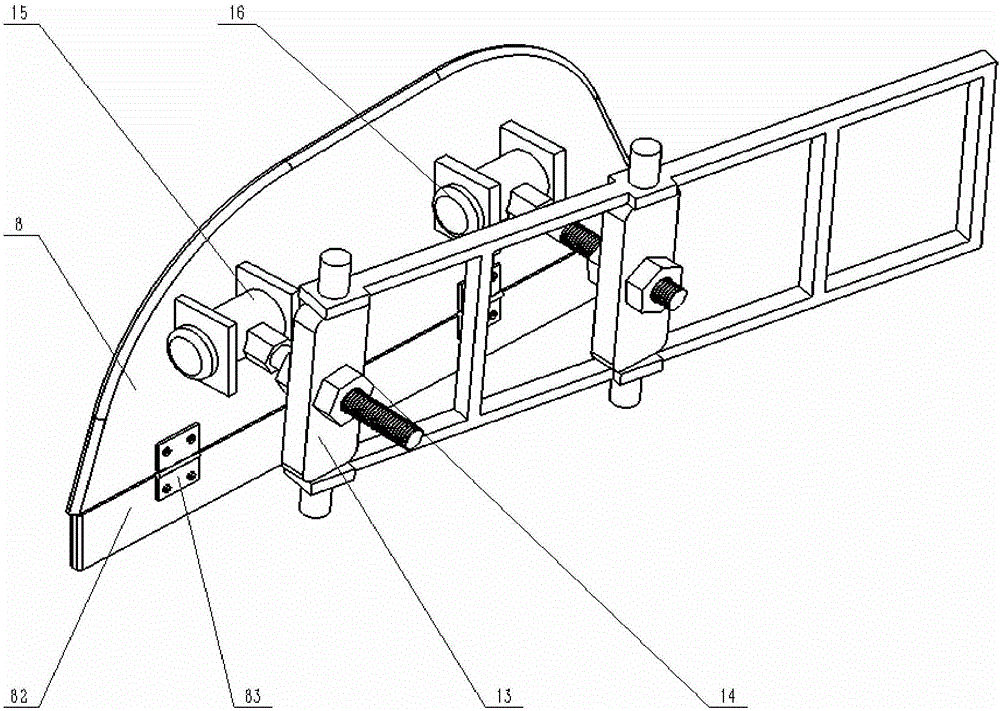

[0024] Such as Figure 1 to Figure 4 As shown, a portable cattle and sheep feeding stocker includes a chassis 1 and a stacker 8, the rear of the chassis 1 is a carriage 2, and the front of the carriage 2 is provided with a seat 3, and the interior of the carriage 2 is provided with There is a DC power supply 17, a circuit control structure 7, a hydraulic pump 18, an oil tank 19 and a hydraulic control structure 6. The hydraulic pump motor II 181 is connected to the DC power supply 17 through the circuit control structure 7, and the hydraulic pump 18 is connected to the hydraulic cylinder through a pipeline. 11. The oil tank 19 is connected, and a reversing valve and an overflow valve are provided on the pipeline. The chassis 1 is provided with a fixing frame 4 near the front right side,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com