Steel frame-reinforced masonry shear wall composite structure and construction method thereof

A technology of reinforced masonry and composite structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of reinforced masonry structure, such as unfavorable large space and large span, large seismic load, unfavorable earthquake resistance, etc., to achieve overall rigidity Moderate, small seismic force, low self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

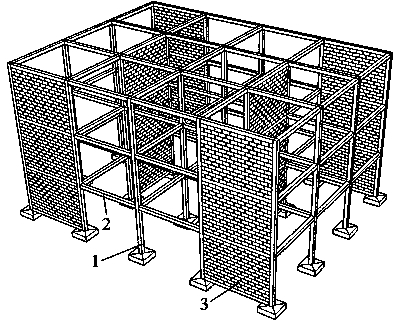

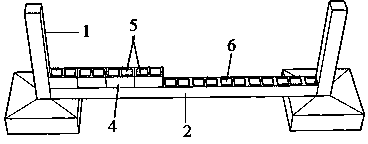

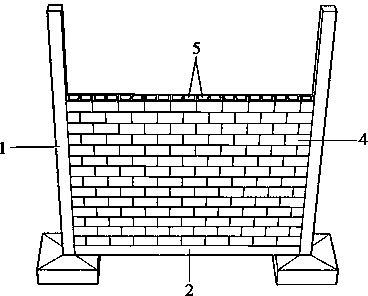

[0038] figure 1 The steel frame-reinforced masonry shear wall composite structure shown is composed of a steel frame, a reinforced masonry shear wall 3 and a floor slab. The steel frame is welded by steel frame columns 1 and steel frame beams 2 . The reinforced masonry shear wall is composed of blocks 4, mortar, steel bars and hole-filled concrete 8. The reinforced masonry shear wall 3 and the steel frame are connected as a whole through the vertical steel bars 7 arranged in the reinforced masonry shear wall 3. The specific structure is: the overall shape of the steel frame beam 2 is a cuboid cavity, There are holes on the upper and lower sides of the cavity 9 of the steel frame beam, and the position of the hole coincides with the hole 5 of the block of the adjacent reinforced masonry shear wall, and the vertical steel bar 7 passes through the hole of the steel frame beam 6 and the hole 5 of the block, the hole 5 of the block and the cavity 9 of the steel frame beam are fil...

Embodiment 2

[0056] figure 1 The steel frame-reinforced masonry shear wall composite structure shown is composed of a steel frame, a reinforced masonry shear wall 3 and a floor slab. The steel frame is formed by connecting steel frame columns 1 and steel frame beams 2 through bolts. The reinforced masonry shear wall is composed of blocks 4, mortar, steel bars and hole-filled concrete 8. The reinforced masonry shear wall 3 and the steel frame are connected as a whole through the vertical steel bars 7 arranged in the reinforced masonry shear wall 3. The specific structure is: the overall shape of the steel frame beam 2 is a cuboid cavity, There are holes on the upper and lower sides of the cavity 9 of the steel frame beam, and the position of the hole coincides with the hole 5 of the block of the adjacent reinforced masonry shear wall, and the vertical steel bar 7 passes through the hole of the steel frame beam 6 and the hole 5 of the block, the hole 5 of the block and the cavity 9 of the ...

Embodiment 3

[0074] figure 1 The steel frame-reinforced masonry shear wall composite structure shown is composed of a steel frame, a reinforced masonry shear wall 3 and a floor slab. The steel frame is welded by steel frame columns 1 and steel frame beams 2 . The reinforced masonry shear wall is composed of blocks 4, mortar, steel bars and hole-filled concrete 8. The reinforced masonry shear wall 3 and the steel frame are connected as a whole through the vertical steel bars 7 arranged in the reinforced masonry shear wall 3. The specific structure is: the overall shape of the steel frame beam 2 is a cuboid cavity, There are holes on the upper and lower sides of the cavity 9 of the steel frame beam, and the position of the hole coincides with the hole 5 of the block of the adjacent reinforced masonry shear wall, and the vertical steel bar 7 passes through the hole of the steel frame beam 6 and the hole 5 of the block, the hole 5 of the block and the cavity 9 of the steel frame beam are fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com