Foundation reinforcing method by using pre-added aggregate stirred pile

A technology for foundation reinforcement and mixing piles, applied in sheet pile wall, soil protection, infrastructure engineering and other directions, can solve problems such as hidden dangers of engineering safety, poor pile formation, low pile strength and rigidity, etc., and achieve technical economy. Good, easy to adjust controls, solve technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

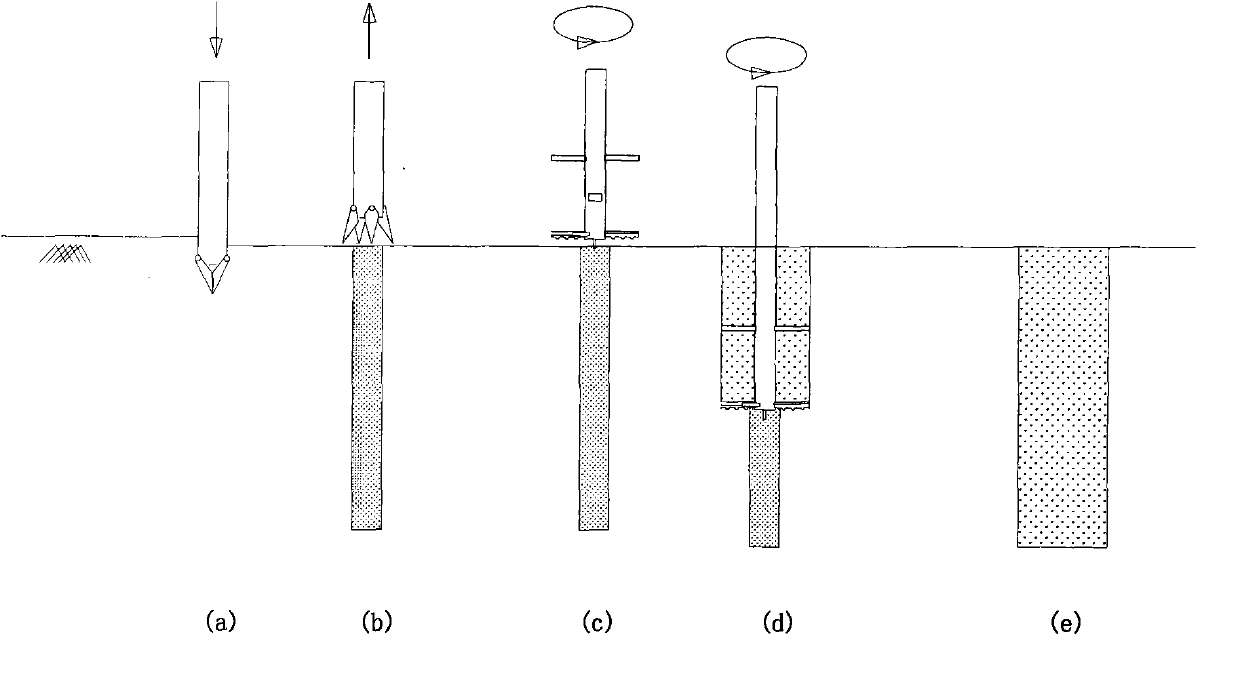

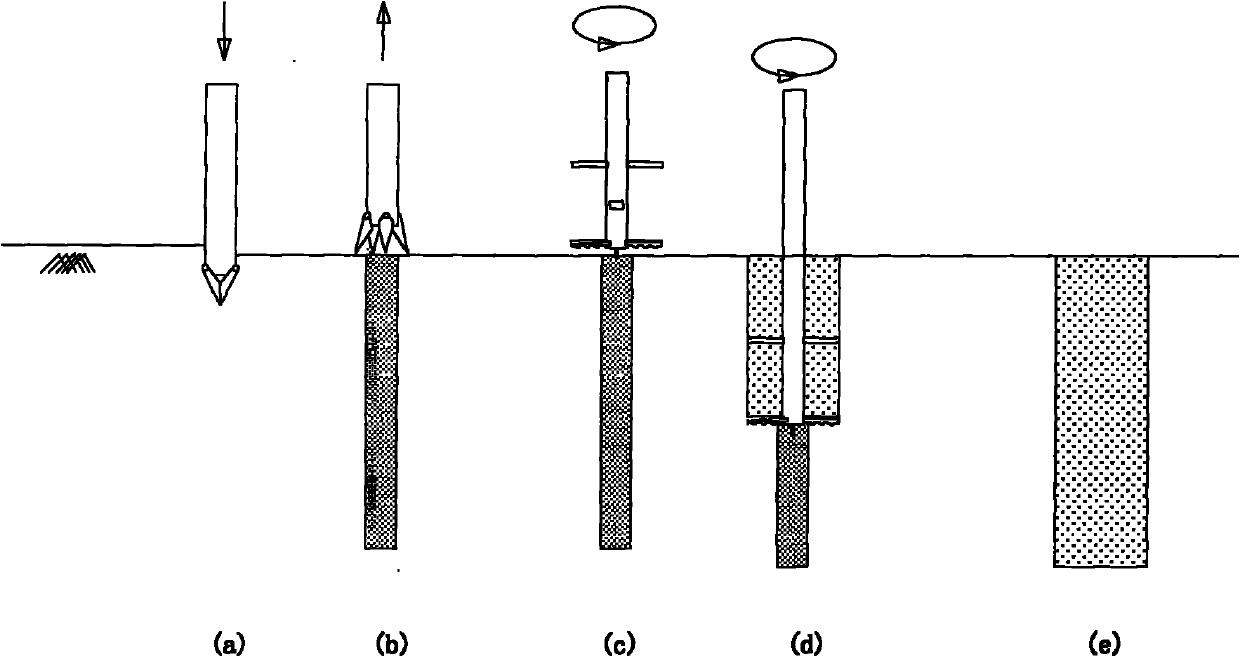

Method used

Image

Examples

Embodiment 1

[0024] The lithology of the stratum lithology in a station of a passenger dedicated line engineering station to the departure line pre-adding aggregate mixing pile is: miscellaneous fill, brownish yellow, slightly dense, slightly wet. Silty clay, brownish-yellow, flow plastic. Clay, brown-yellow, soft plastic. Silt, brown-gray, dense, slightly wet. Silty silty clay, brown-gray, flow plastic. Silty clay, brownish-gray, flow plastic. Silty clay, brownish gray, hard plastic.

[0025] Due to the strict standards for post-construction settlement of the passenger dedicated line, CFG pile reinforcement, mixing pile reinforcement, and rotary grouting piles were compared when selecting a foundation treatment plan: CFG pile reinforcement has higher stratum adaptability and stronger pile body strength and stiffness. However, compared with the mixing pile, the deformation coordination ability and economy of the ground are poor; the cost of the mixing pile reinforcement is lower becaus...

Embodiment 2

[0029] The landform of a certain line is dominated by coastal plains, and the strata are mainly composed of cohesive soil and silt soil of Quaternary coastal facies and marine-terrestrial interfacial facies. Silty clay: yellowish brown, in soft plastic state, partly in flow plastic state; silty silty clay: gray and silty clay, in flow plastic state; silty clay: grayish yellow, in plastic to hard plastic state.

[0030] The length of the designed pre-added aggregate mixing pile is 12 meters, and the diameter is 0.5m. According to the indoor ratio test, when the strength of the pile body required by the design is reached, the sand content is 20% of the soil weight, and the cement content is 20% of the soil weight. 22%.

[0031] During the construction, the sand pile construction adopts the pile forming equipment and technology of the impact method, the pipe diameter is 200mm, and the sand is fine and medium sand. After the construction of the sand pile, the cement mixing pile ma...

Embodiment 3

[0033] The foundation of a certain project is: silty clay: gray, brown-gray, strong viscosity; silty silty clay, sandwiched with thin layer of silt, silty clay; silty clay, gray, brown-gray, soft plastic ~ flow plastic, smelly .

[0034] The length of the designed pre-added aggregate mixing pile is 15 meters, the diameter is 0.5m, the designed sand content is 18% of the soil weight, and the cement content is 20% of the soil weight.

[0035] During construction, the sand pile construction adopts the hammering pile forming equipment and technology, the pipe diameter is 200mm, the sand is fine and medium sand, the curing agent is No. The unconfined compressive strength of the sky pile body is 5.2MPa.

[0036]Of course, the present invention can pour sand aggregates into the foundation to form sand piles by means of vibration, hammering, impact, static pressure or a combination of several methods in screw conveying. The amount of sand mixed can be added arbitrarily according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com