Low-delay-pulse, low-crosstalk and high-collection-efficiency micro-channel plate

A micro-channel plate, collection efficiency technology, applied in electron multiplier details, dynodes, etc., can solve the problems of high probability of bounce, large crosstalk and delayed pulse of micro-channel plate, crosstalk and delayed pulse, etc., to reduce bounce The probability of reducing crosstalk and delayed pulses, and the effect of increasing the opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the invention will be further clearly and completely described below in conjunction with the accompanying drawings.

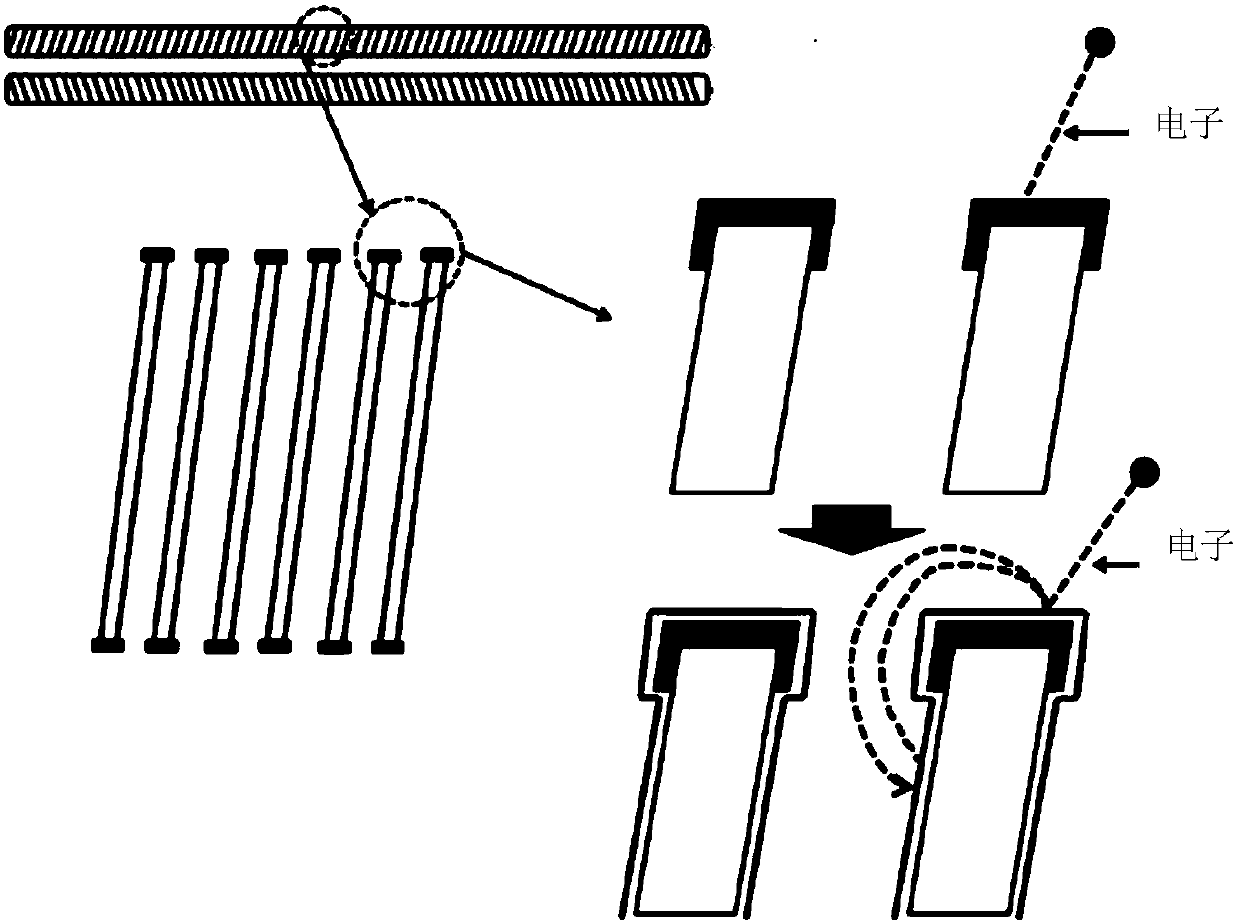

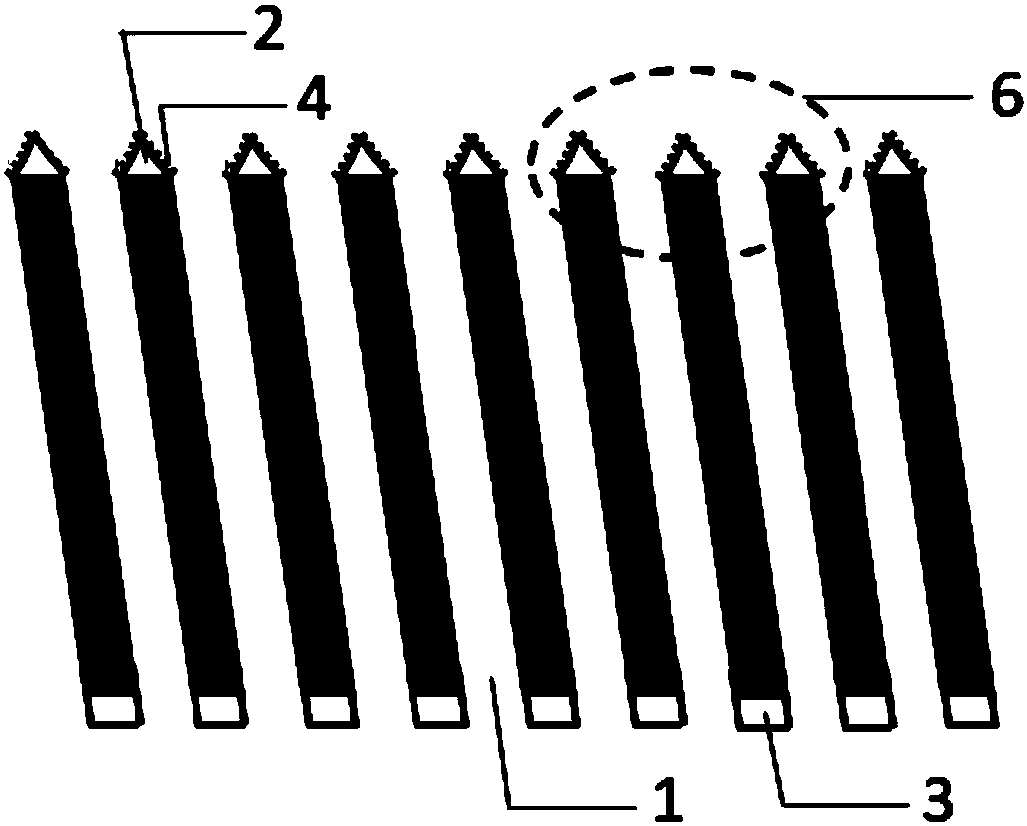

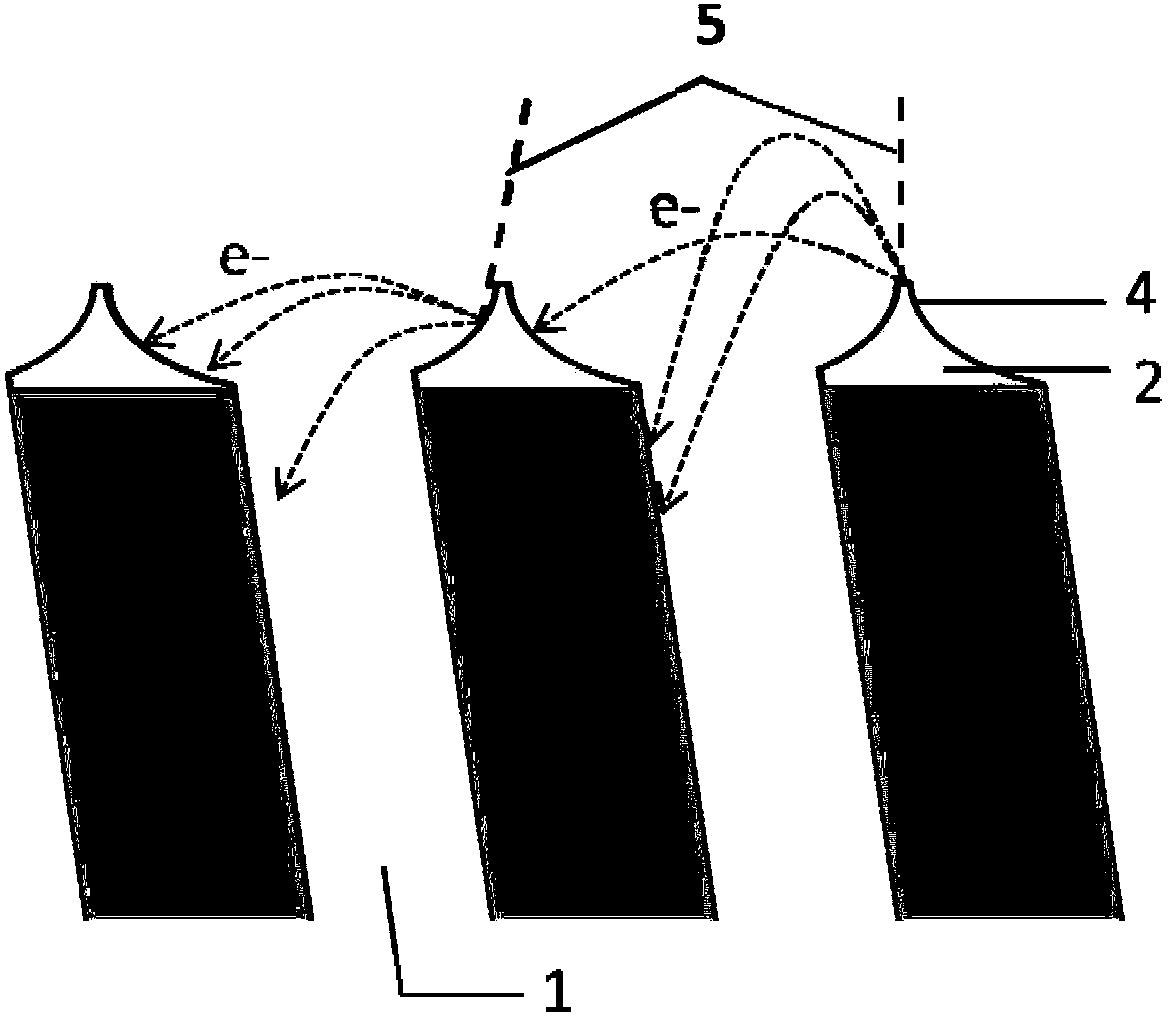

[0029] see Figure 2 to Figure 4 The low-delay pulse, low crosstalk and high collection efficiency microchannel plate of the present invention includes a two-dimensional array composed of several parallel channels 1, and the two end faces of the two-dimensional array are plated with metal conductive materials as the input electrode layer 2 and Output electrode layer 3. The input electrode layer 2 is provided with the input port 6 of the channel, and the output electrode layer 3 is provided with the output port of the channel; the input port decreases gradually from top to bottom, and the channel opening area ratio of the microchannel plate can be increased to 90%. above. The opening area ratio of traditional microchannel plates is about 60%, and the input electrodes are NiCr alloys. The probability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com