Liquid-sealed antivibration device

A technology of anti-vibration device and liquid seal, applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., to achieve the effect of inhibiting cavitation phenomenon, forming easy, and increasing the opening area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

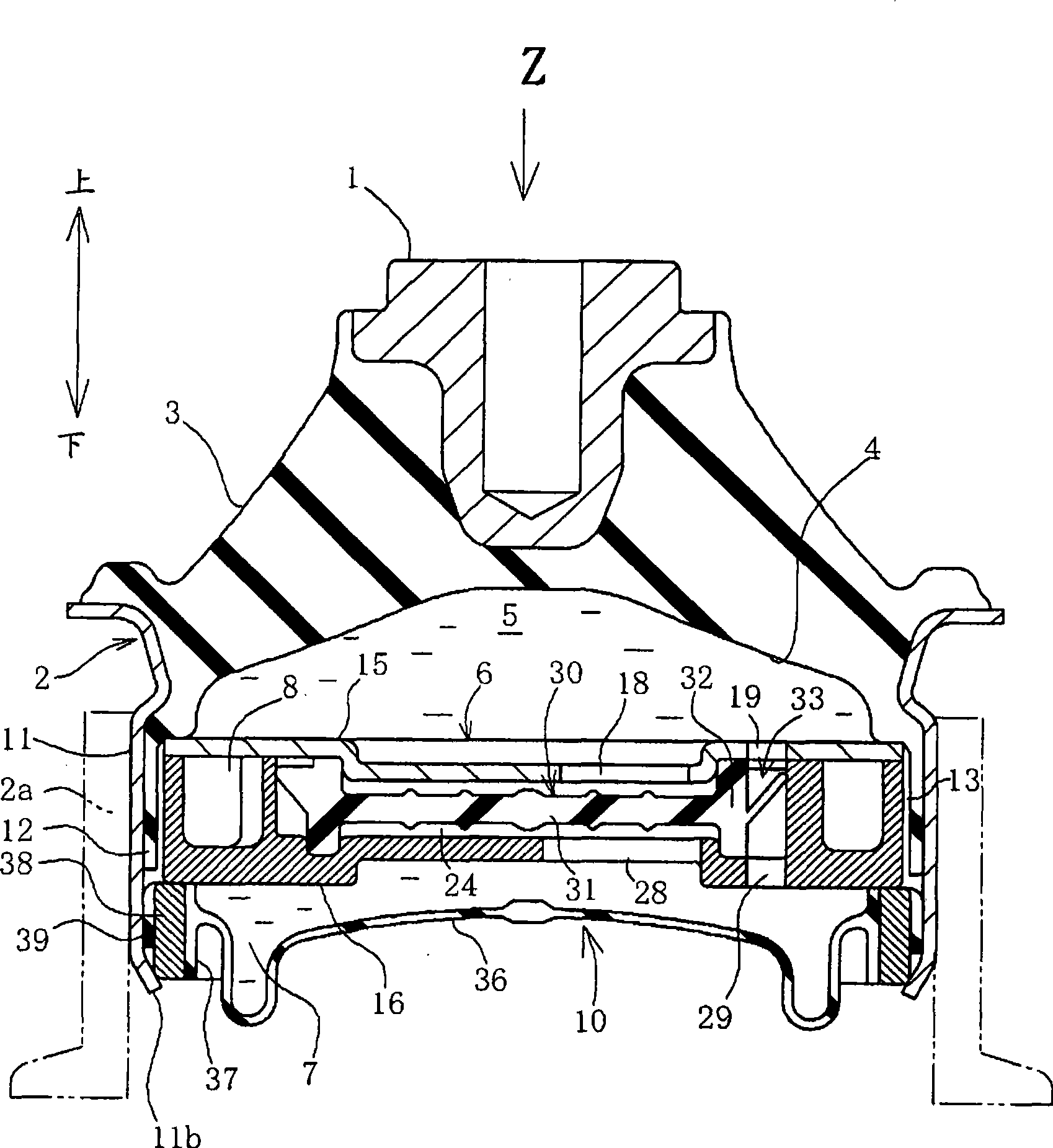

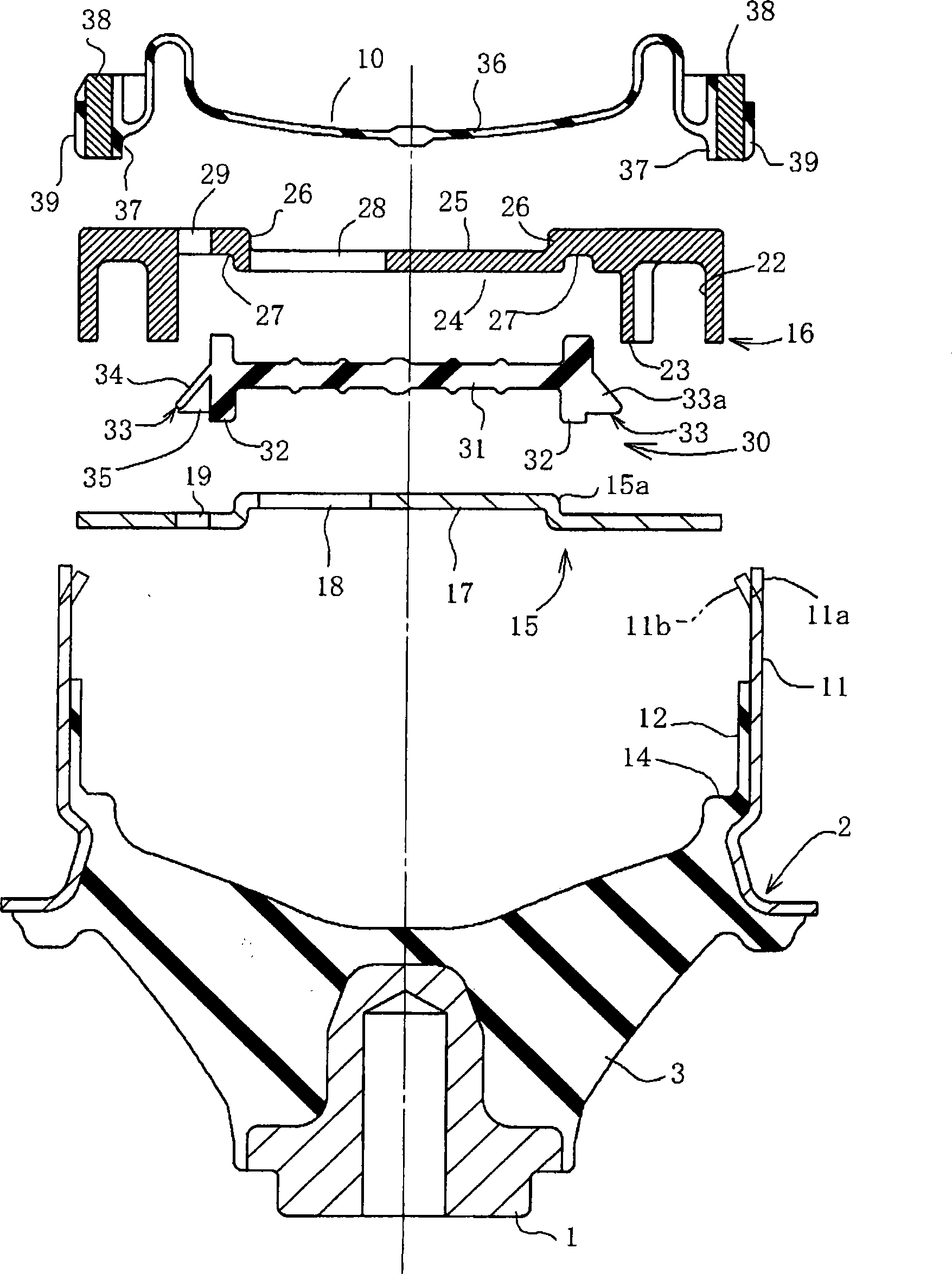

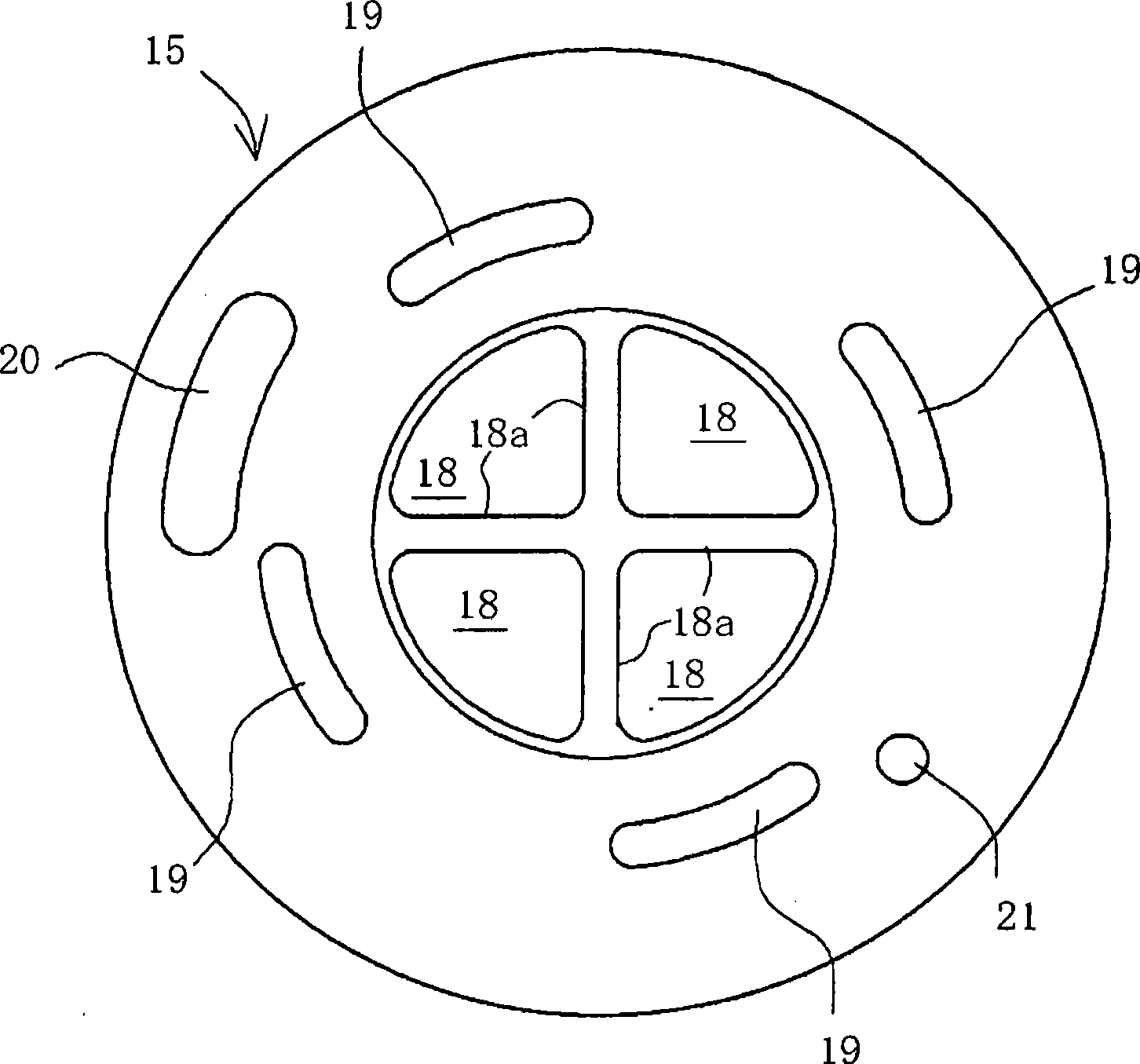

[0072] Next, an embodiment of an engine mount for an automobile will be described with reference to the drawings. figure 1 is the longitudinal sectional view of the engine bracket, figure 2 It is a figure which breaks down each constituent part. figure 1 It is also a section cut along the input direction Z of the main vibration. In addition, in the following description, each direction, such as up, down, left, and right, is based on the state shown in the figure which is the object of description.

[0073] In these figures, the engine mount includes a first mounting member 1 mounted on the side of the engine (not shown) as a vibration source, a second mounting member 2 mounted on the vehicle body (same as above) as a vibration receiving side, and a connection between them. Between the vibration isolator 3. The vibration isolator 3 is composed of a well-known elastic member for vibration isolation such as rubber, and is an elastic body serving as a vibration isolation main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com