Stern structure of ship

A stern and ship technology, applied in the direction of ship propulsion, hull, ship construction, etc., can solve the problems of increased load and decreased propeller efficiency, and achieve the effect of reducing supporting force and suppressing cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

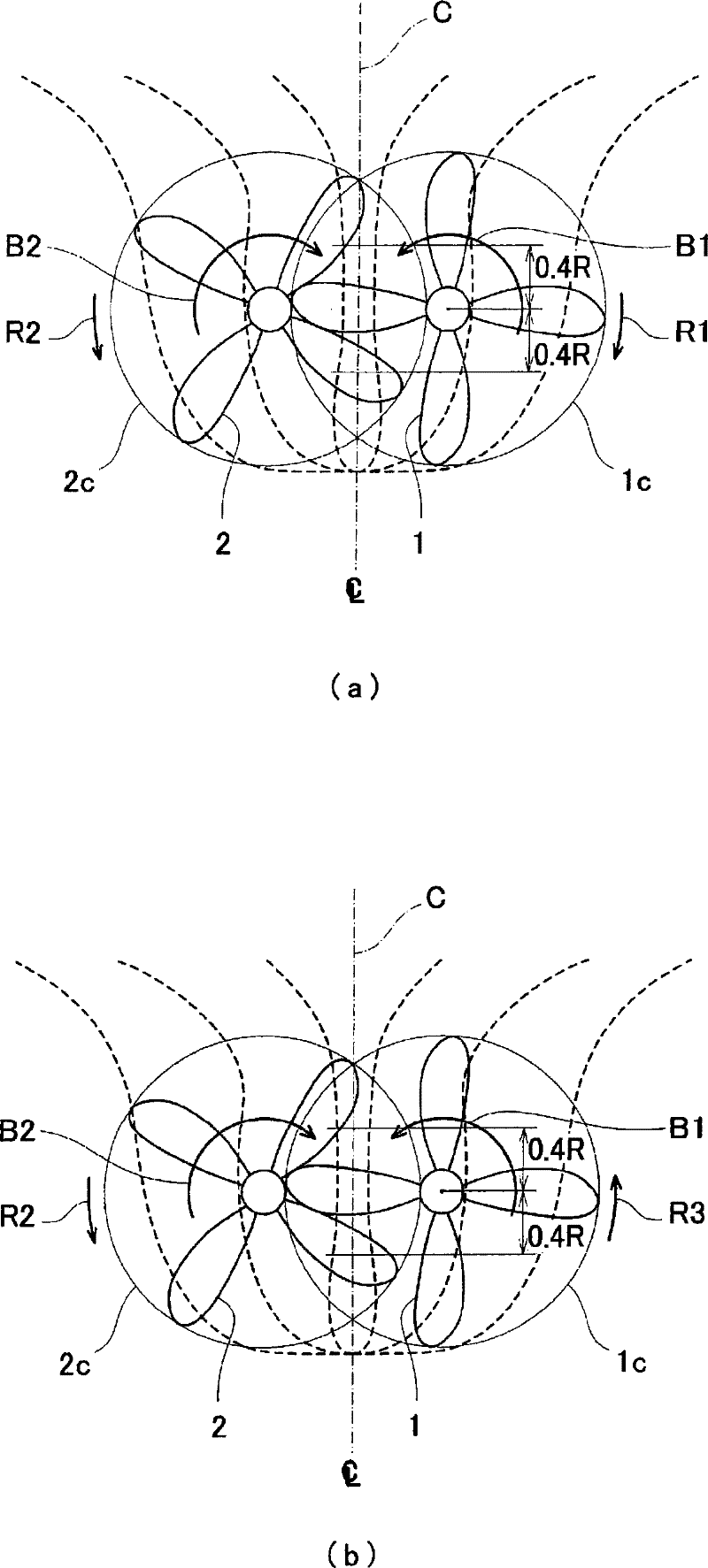

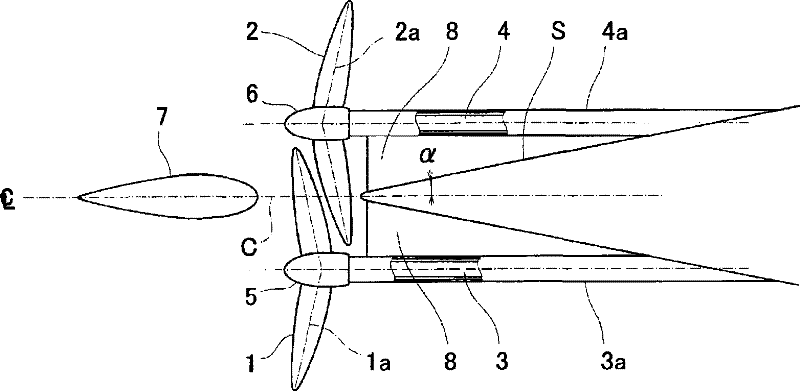

[0066] Embodiments of the present invention will be described below with reference to the drawings. figure 1 (a) and (b) are rear views of the stacked propeller viewed from the rear of the stern portion toward the front. figure 2 for its floor plan. In addition, the propellers on the left and right sides can be used no matter which one is in front. figure 2 is an example.

[0067] like figure 1 (a) and figure 2 As shown, two propellers 1 and 2 (starboard propeller 1 and port side propeller 2) that are a pair of left and right are arranged symmetrically with respect to the center line C of the hull.

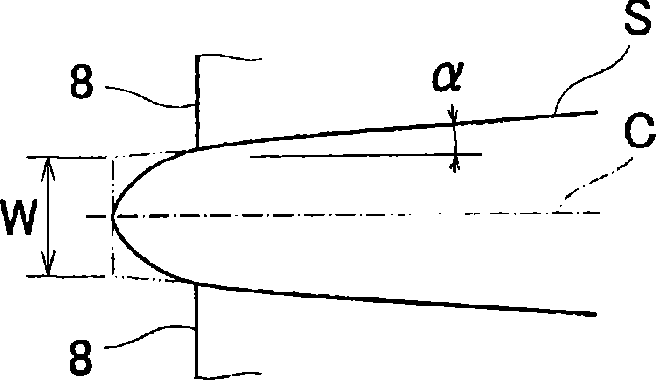

[0068] The positions in the height direction of the two propellers 1 and 2 and the positions in the width direction of the hull are set so that the propeller shafts 3 and 4 of the two propellers 1 and 2 are respectively located near the centers of the left and right bilge vortexes B1 and B2. The rotation directions R1 , R2 of the propellers 1 , 2 are set to be opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com