Novel micro-channel plate electrode with ion blocking function and manufacturing method thereof

A microchannel plate and electrode technology, which is applied in the manufacture of electrode systems, dynodes, cold cathodes, etc., can solve the problem of weakening the advantages of high quantum efficiency of GaAs photocathodes, limiting the performance improvement and improvement of third-generation tubes, and manufacturing ion barrier films. Complex process and other problems, to achieve good low electron scattering rate, improve device detection efficiency, reduce false secondary electron noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

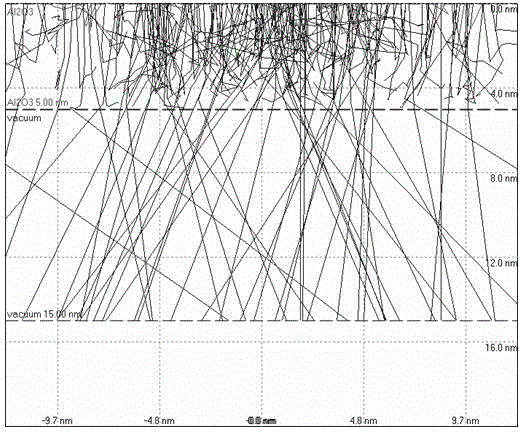

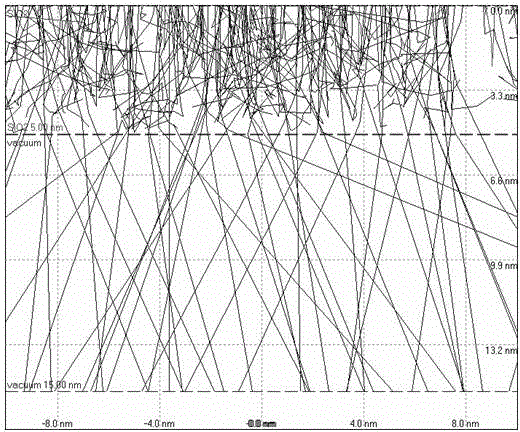

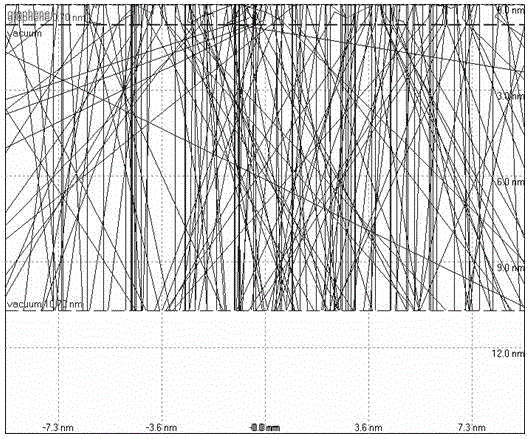

[0017] A microchannel plate electrode with an ion blocking function, the electrode is made on the input or output surface of the microchannel plate 4 in the negative electron affinity photocathode type vacuum photodetection device, and is used to apply pressure to the normal operation of the microchannel plate 4. Working voltage, during production: transfer and manufacture a high-strength, uniform and high-coverage single-layer or multi-layer graphene film on the input or output surface of the micro-channel plate 4, so that the film layer has both conventional micro-channel plate electrodes function, and also has the function of ion barrier film to replace the traditional nickel-cadmium metal electrode and then make Al 2 o 3 or SiO 2 The structural scheme of the ion barrier film, the negative electron affinity photocathode type vacuum photodetector device is mainly composed of the light window 2 at the front, the photocathode 3 on the light window, the microchannel plate 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com