Borehole ground potential measuring electrode

A technology for measuring electrodes and ground potential, which is applied in measurement, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as management confusion, short steel cages, and piling depths that do not meet the requirements, so as to increase the signal-to-noise ratio, Effect of suppressing interference and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

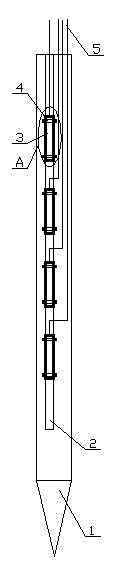

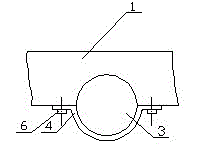

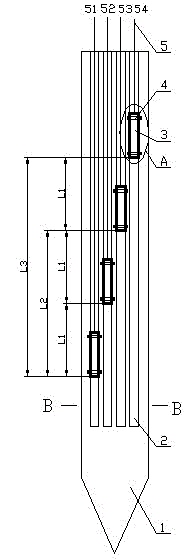

[0020] control figure 1 , The ground potential measuring electrode of the present invention is mainly composed of an insulating rod 1, an electrode bottle 3 with a copper sulfate solution built in it, and a wire 5. The insulating rod 1 of the present embodiment is made of Bakelite (also can be made of insulating plastic), and the cross section of the insulating rod 1 along the width direction is rectangular, see figure 2 , the front end of which is a tip that facilitates sinking. Four semicircular grooves 2 are arranged on one side of the insulating rod 1, and the four semicircular grooves 2 are arranged parallel and side by side along the width direction of the insulating rod. The radius of the semicircular channel is equivalent to the radius of the electrode bottle 3, and an electrode bottle 3 is placed in the channel according to the length direction and the direction of the channel in each channel. The electrode bottles 3 placed in the four semicircular channels 2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com