Electrode lead unit, vacuum optoelectronic device and manufacturing method thereof

An electrode lead and manufacturing method technology, applied in the field of optoelectronic devices, can solve problems such as the inability to meet the needs of multi-electrode leads, and achieve the effects of avoiding device explosion or slow gas leakage, reliable performance, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

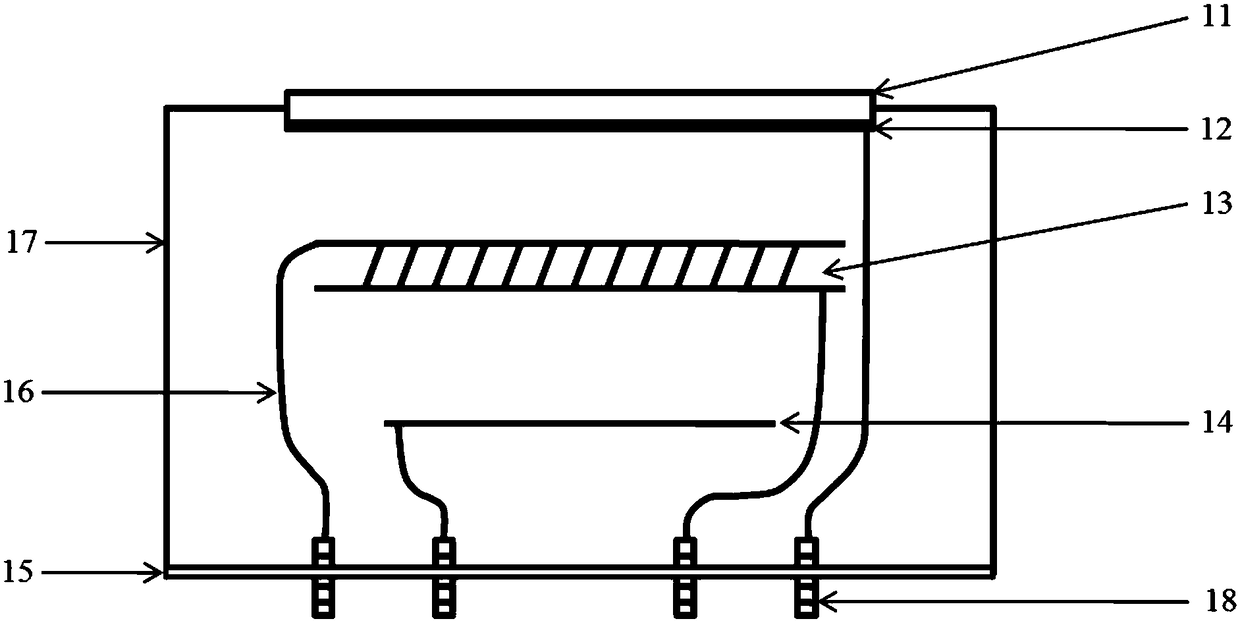

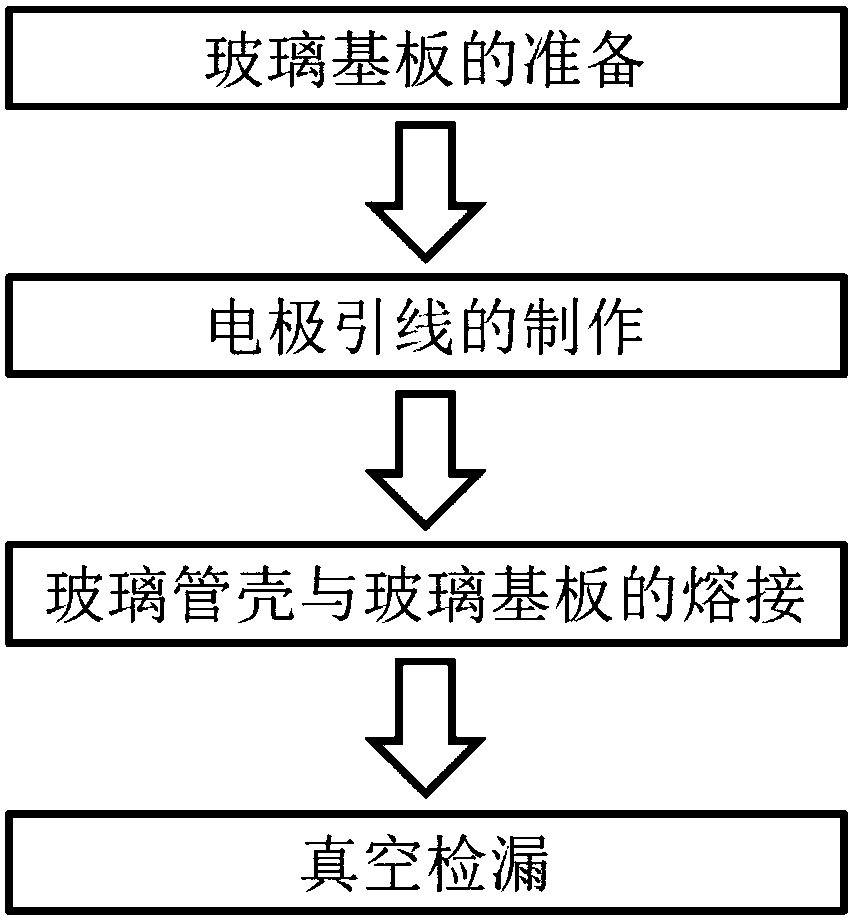

[0052] see figure 2 , the preferred implementation method of the present invention to make the electrode lead unit mainly includes the following steps:

[0053] First, the preparation of the glass substrate. Usually the glass substrate is made of borosilicate glass with a thickness of 2 mm and a flat surface. The size of the glass substrate is larger than 20 mm × 20 mm. It is ultrasonically cleaned with a glass cleaner and dried at high temperature.

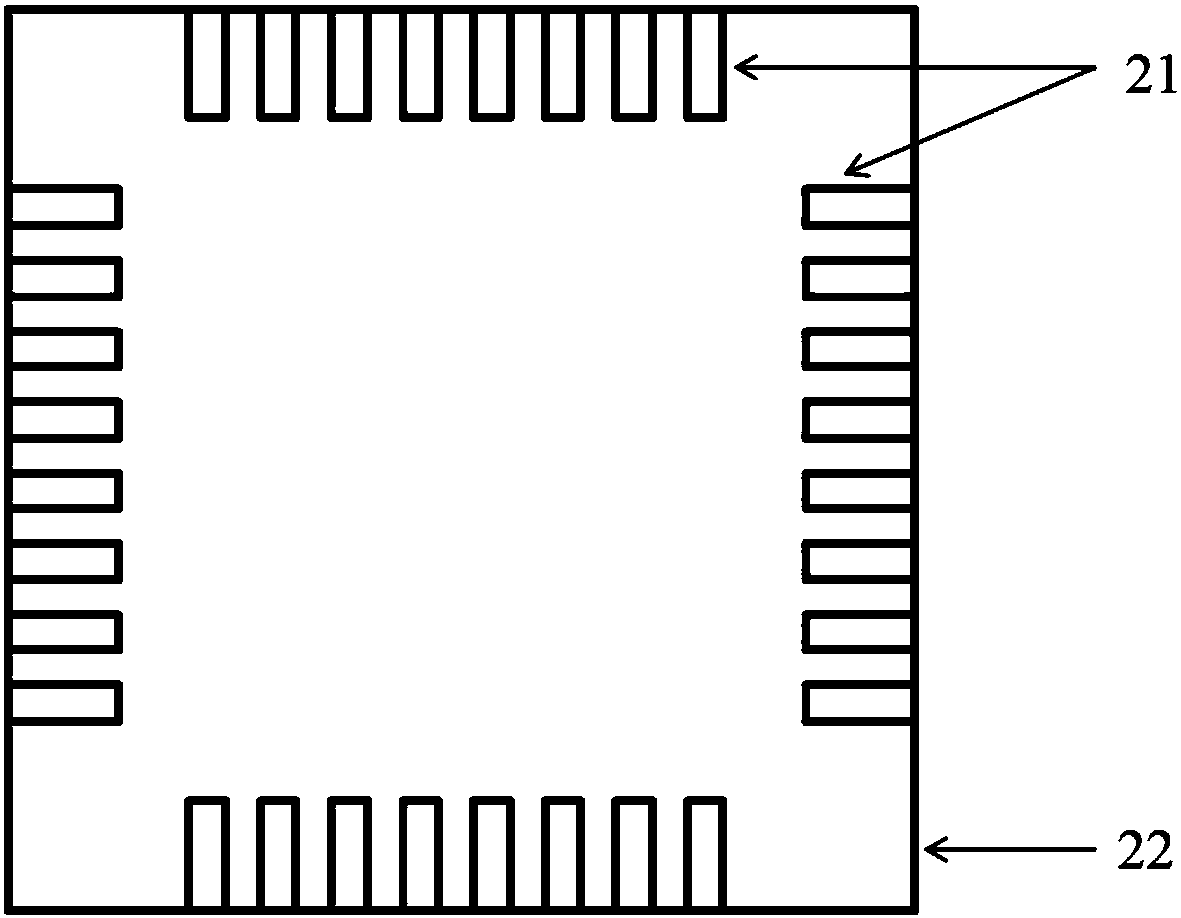

[0054] Second, the fabrication of electrode leads. Electrode leads are fabricated on glass substrates using standard semiconductor processes. The standard semiconductor process includes metal film deposition, photolithography, etching or corrosion or peeling, etc. The metal film can choose a single metal such as gold, silver or a stacked structure of multiple metal films such as titanium and platinum. The thickness of the metal film is greater than 500 nanometers. image 3 It is a typical electrode lead distribution state for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com