Self-current-stabilizing micropulse electronic gun based on secondary electron multiplying

A secondary electron multiplication and micro-pulse technology, which is applied in the direction of electron multiplier tubes, electron multiplier details, dynodes, etc., can solve the problems that the instability of micro-pulse electron guns hinders the practical application of micro-pulse electron guns, and the output current is unstable. , achieving high average flow intensity and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

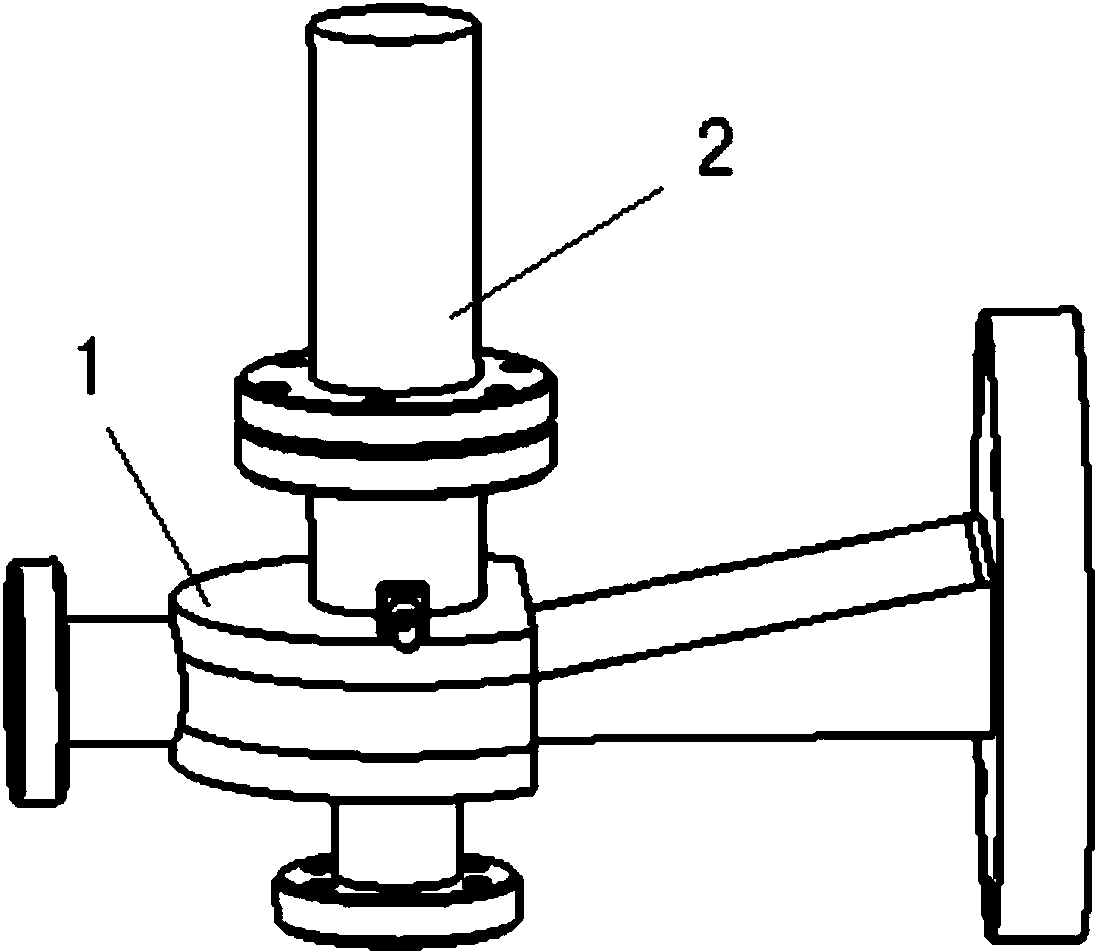

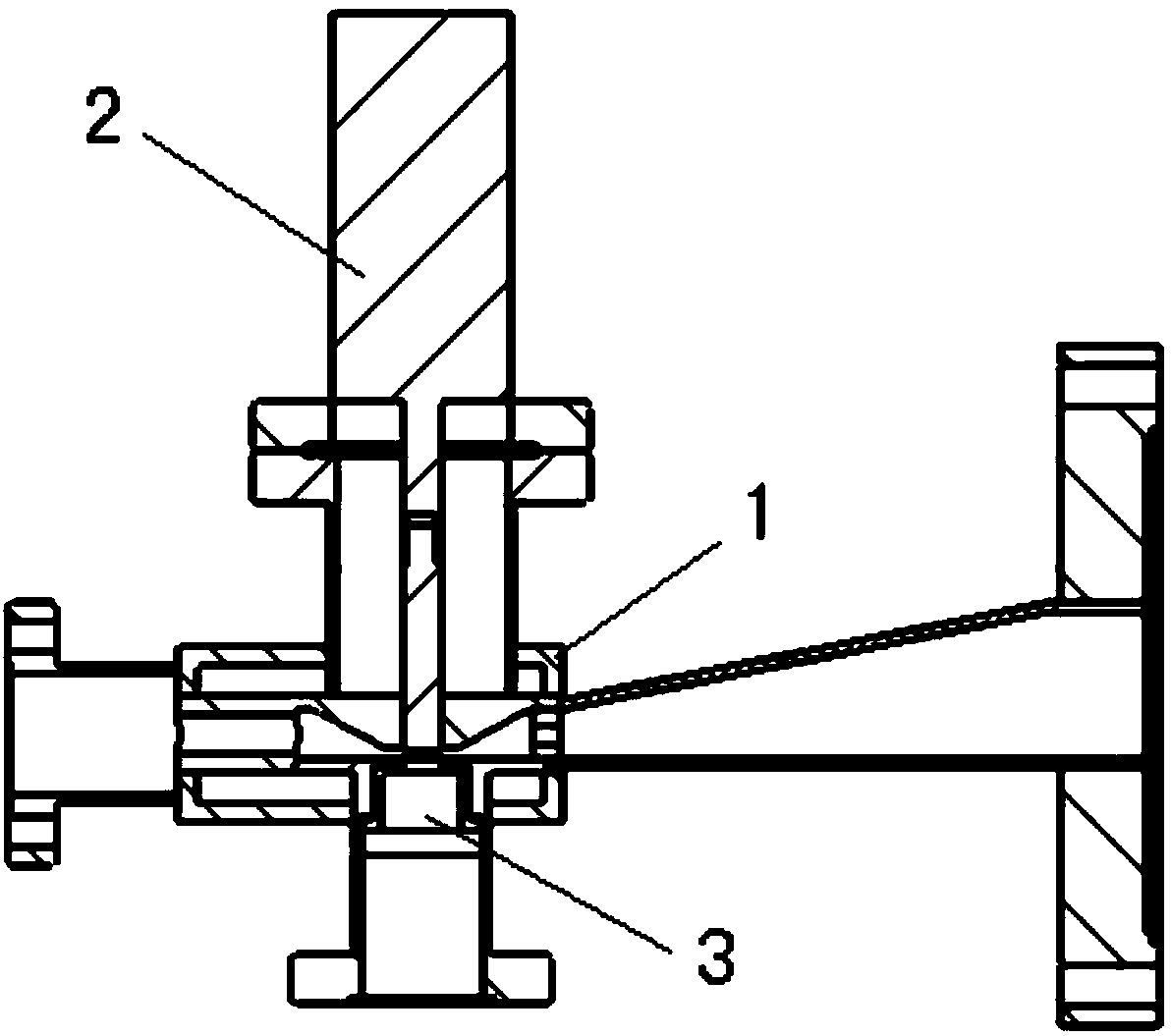

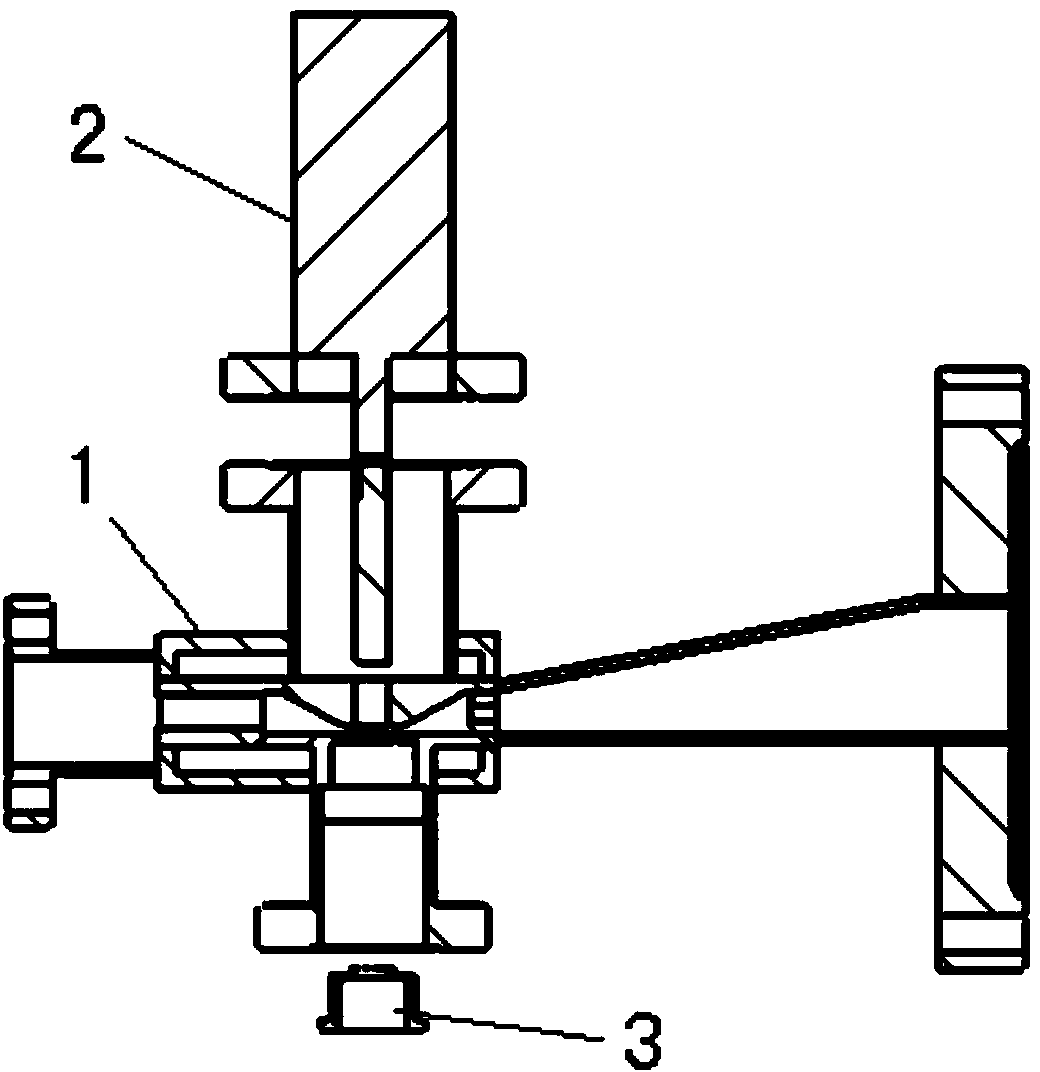

[0032] Example: such as Figure 8 As shown, in this embodiment, the self-stabilizing flow micro-pulse electron gun based on secondary electron multiplication is installed on the existing experimental platform, and the tapered waveguide 8 is connected to the T-shaped waveguide of the three-way through the tapered waveguide flange 9. The T One end of the type waveguide is connected to the microwave power source, one end is connected to the main cavity, and the other end is connected to the vacuum pump; on the existing experimental platform, the signal source and the pulse modulator are respectively connected to the input end of the power amplifier, and the output end of the power amplifier is sequentially passed through the directional coupler, the waveguide and the vacuum pump. The shaft converter, the ceramic window and the T-shaped waveguide are connected to the tapered waveguide flange 9; the two output ends of the directional coupler are respectively connected to the peak po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com