Silicate skin glass, micro-pore optics and preparation method thereof

A skin glass and silicate technology, which is applied in the field of curved square-hole microchannel plates, can solve the problems of excessive thermal expansion coefficient difference, large internal stress, and cannot serve as the skin glass of curved square-hole microchannel plates, etc., and achieves thermal expansion. The effect of small coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

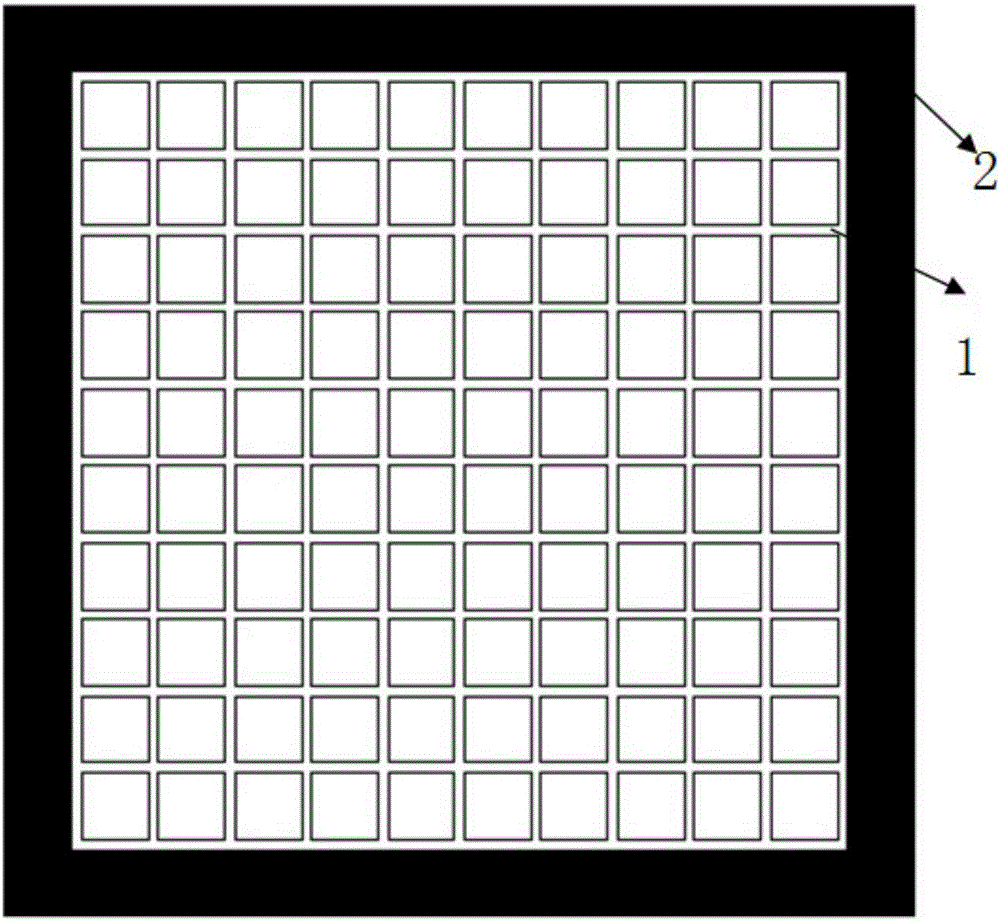

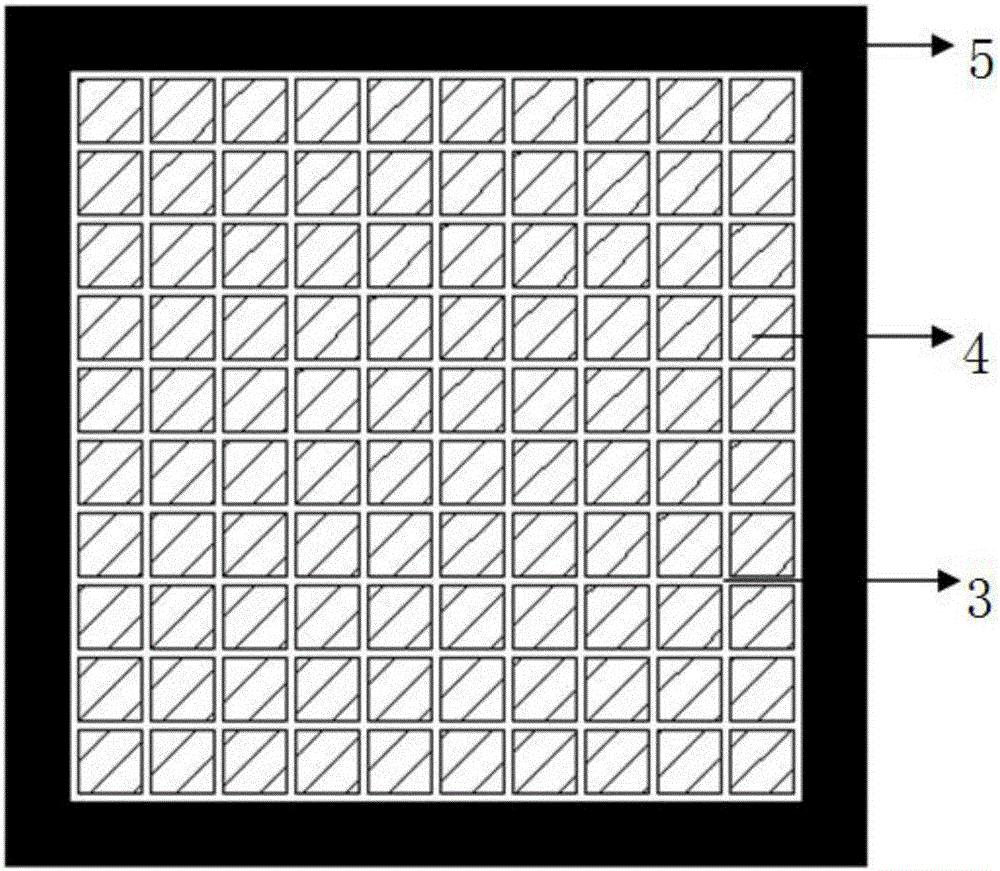

[0042] Another embodiment of the present invention proposes a method for preparing a curved square hole microchannel plate, comprising the following steps:

[0043] (1) Mix silicic acid, barium nitrate or barium carbonate, sodium carbonate, potassium carbonate or potassium nitrate, basic magnesium carbonate, calcium carbonate, aluminum hydroxide to obtain a mixed raw material, add clarifier to the mixed raw material, and heat High-temperature melting and clarification, and then drawn into a molded skin glass tube at 1200-1350 ° C, the temperature of high-temperature melting and clarification and drawing molding of specific examples are shown in Table 3; wherein the weight ratio of clarifier and mixed raw materials is 0.1- 0.8: 0.92-0.99; the composition of the described skin glass tube is (in molar percentage): SiO 2 , 60-80%; 2 o 3 , 5-20%; Al 2 o 3 , 0.1-3.5%; Na 2 O, K 2 O and Cs 2 The total content of O is 0.1-10%; the total content of MgO, BaO and CaO is 3-15%; Na ...

Embodiment 5

[0054] The composition of the skin glass tube of embodiment 5 is identical with embodiment 1 silicate skin glass components, and the composition of embodiment 6 skin glass tube is identical with embodiment 2 silicate skin glass components, and the skin glass component of embodiment 7 The composition of the tube is the same as that of the silicate skinned glass of Example 3, the composition of the skinned glass tube of Example 8 is the same as that of the silicate skinned glass of Example 4, and the composition of the skinned glass tube of Comparative Example 3 is the same as that of the comparative example 1 The composition of the silicate skin glass is the same, and the composition of the skin glass tube of Comparative Example 4 is the same as that of Comparative Example 2. See Table 4 for the weight ratios of mixed raw materials and clarifiers in Examples 6-8 and Comparative Examples 3-4. The tensile strength of the curved square-hole microchannel plates of Examples 5-8 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com